Professional Documents

Culture Documents

Cems A 10 Part II Appx

Uploaded by

aldairlopesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cems A 10 Part II Appx

Uploaded by

aldairlopesCopyright:

Available Formats

INTERNATIONAL TRUCK AND ENGINE CORPORATION

CEMS NUMBER:

(CORPORATE ENGINEERING MATERIAL SPECIFICATION) CEMS A-10, PART II APPX

TITLE: CURRENT ISSUE DATE:

Mechanical Steel Tubing Part II - Cold Drawn Butt Welded October 2001

Mechanical Steel Tubing - Appendix

WRITTEN/REVIEWED BY: APPROVED BY: SUPERSEDES ISSUE OF:

Materials Engineering Materials Engineering July 1999

PRINTED COPIES OF THIS DOCUMENT MUST BE VERIFIED FOR CURRENT REVISION

This specification may involve hazardous materials, equipment, and procedures. This specification does not purport to address all of

the safety issues associated with its use. The user is responsible to consult appropriate safety and health practices and to determine

the applicability of regulatory limits prior to use.

Change Notice: Editorial Changes

Appendix

General Information (Not a Requirement)

A.1 CONTENTS

PAGE

DESCRIPTION OF GRADES .………………………….…………………….……………. 1

COMPARISON OF GRADES SDE & MDE VS DOM (A-10, Part I) TOLERANCES …… 1

HEAT TREATMENT …………………. …………………………………………………… 2

SPECIAL SHAPE TUBING ……………………. ………………………………………….. 2

MACHINABILITY RATINGS ……………………………………………………………... 2

PRICING – ANALYSIS & RESTRICTED TOLERANCES EXTRAS ….……………….... 2

AVAILABILITY AND COMPARATIVE PRICES ………………………………………… 3

A.2 Description of Grades

A.2.1 Grades SD and MD are produced by furnace butt welding of preheated steel strip which has been bent into a circular

shape by a series of rolls. The continuous tube is cut into length, cooled, and prepared for cold drawing. Grades SDE and

MDE are produced by electric resistance welding of steel strip which has been rolled to a circular shape. After removal of

the weld flash the tube is cut into lengths and prepared for drawing. These grades are available in rounds only.

A.2.2 Sink drawn tubing, Grades SE and SDE, are drawn through a die only. Grades MD and MDE mandrel drawn tubing

are drawn simultaneously over a mandrel and through a die. Mandrel drawn tubing has the advantage of better inside

diameter tolerances, wall tolerances, and inside surface finish.

A.2.3 Because of the higher weld efficiency of the electric resistance welding process. Grades SDE and MDE have better

properties for torsional applications than Grades SD and MD. Grade MDE is not recommended for hydraulic cylinder

applications because the surface quality and inspection criteria are lower than those required for Grade DOM (A-10, Part I,

mandrel drawn tubing), but it may be considered as a lower price alternate to Grade DOM for most mechanical applications.

Also, Grades SDE and MDE can be ordered to special close tolerances. By careful ordering, tubing meeting Grade DOM

tolerances can be obtained in many sizes at substantial cost savings.

A.3 Comparison of Grades SDE & MDE vs. DOM (A-10, Part I) Tolerances

Tolerances shown in Table I for Grades SDE, MDE, and DOM are allowable deviations as increase in OD or decrease in ID;

increases in ID and decreases in OD are not allowed. See “Pricing – Restricted Tolerances Extras.”

This document is restricted and may not be sent outside International Truck and Engine Corporation or reproduced without permission from

Corporate Technical Standards. Suppliers are required to assume all patent liability. ã2001 by International Truck and Engine Corporation.

OCTOBER 2001 Page 1 of 3

NUMBER: TITLE CURRENT ISSUE DATE:

CEMS A-10, PART II, APPX Mechanical Steel Tubing Part II - Cold Drawn Butt October 2001

Welded Mechanical Steel Tubing - Appendix

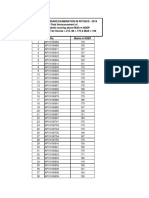

TABLE I

OD PLUS OR ID MINUS TOLERANCES*

Grades SDE & MDE

Outside Grade

Diameter DOM Restricted

Standard

80% 50% 30%

Inches

0.500 thru 1.499 0.005 0.005 0.004 0.0025 0.0015

1.500 thru 1.699 0.005 0.010 0.008 0.0050 0.0030

1.700 thru 2.099 0.006 0.010 0.008 0.0050 0.0030

2.100 thru 2.499 0.007 0.010 0.008 0.0050 0.0030

2.500 thru 2.899 0.008 0.010 0.008 0.0050 0.0030

2.900 thru 3.299 0.009 0.010 0.008 0.0050 0.0030

Millimeters

12.70 thru 38.07 0.13 0.13 0.10 0.06 0.04

38.10 thru 43.15 0.13 0.25 0.20 0.13 0.08

43.18 thru 53.31 0.15 0.25 0.20 0.13 0.08

53.34 thru 63.47 0.18 0.25 0.20 0.13 0.08

63.50 thru 73.63 0.20 0.25 0.20 0.13 0.08

73.66 thru 83.79 0.23 0.25 0.20 0.13 0.08

* ID Tolerances are not applicable to Grade SDE

A.4 Heat Treatment

All tubing purchased to this specification will be stress relieved unless otherwise specified. This treatment has only a slight

effect on the hardness but enables the tubing to withstand moderate cold forming. In this condition, the tubing is used for the

bulk of mechanical applications requiring moderate ductility, good finish, and little or no cold forming.

When tubes are to be expanded, sharply bent or subject to other cold forming, a full anneal can be specified. This treatment

greatly reduces the hardness and strength of the tubing.

A.5 Special Shape Tubing

A.5.1 Square and Rectangular – Square and rectangular tubing is ordinarily mandrel drawn but may be made by sink

drawing. Mandrel drawing insures reasonably square inside corners and aids in reducing bulging or concave sides.

A.5.2 Hexagonal – Hexagonal tubing is ordinarily made with a circular hole and specified by the distance across the flats and

by the inside diameter.

A.6 Machinability Ratings

Machinability ratings of stress relieved tubing are given in Table II below:

TABLE II

MACHINABILITY RATINGS

Machinability Approximate Machinability Approximate

Steel Steel

Rating Turning Speed Rating Turning Speed

Designation Designation

(1212 = 100) sfpm smpm (1212 = 100) sfpm smpm

1010 52 86 26.2 1025 58 98 29.9

1015 53 88 26.8 1030 68 114 34.7

1018 66 111 33.8 1110 70 118 36.0

1020 58 98 29.9 1115 89 150 45.7

This document is restricted and may not be sent outside International Truck and Engine Corporation or reproduced without permission from

Corporate Technical Standards. Suppliers are required to assume all patent liability. ã2001 by International Truck and Engine Corporation.

OCTOBER 2001 Page 2 of 3

NUMBER: TITLE CURRENT ISSUE DATE:

CEMS A-10, PART II, APPX Mechanical Steel Tubing Part II - Cold Drawn Butt October 2001

Welded Mechanical Steel Tubing - Appendix

A.7 Pricing – Analysis & Restricted Tolerances Extras – Grades SDE & MDE

Analysis & restricted tolerance extras for grades SDE & MDE are given in Table III below.

TABLE III

ANALYSIS AND RESTRICED TOLERANCES (GRADES SDE & MDE) EXTRAS

SAE Restricted Tolerance Extras (Grades SDE & MDE)*

Percent

Steel Percent

Of Base

Designa- Restriction Of Base

Price

tion Price

1010 Base Within 80% of either the standard OD or ID Tolerance 5

1015 1 Within 80% of both the standard OD and ID Tolerance 10*

1018 5 Within 50 to 80% of either the standard OD or ID Tolerance 10

1020 2 Within 50 to 80% of both the standard OD and ID Tolerance 15*

1025 3 Within 30 to 50% of either the standard OD or ID Tolerance 20

1030 15 Within 30 to 50% of both the standard OD and ID Tolerance 30*

* ID tolerances are not applicable to Grades SDE.

A.8 Availability and Comparative Prices

For specific availability and relative costs, see “Appendix – General Information, CEMS A-10, Part I.

This document is restricted and may not be sent outside International Truck and Engine Corporation or reproduced without permission from

Corporate Technical Standards. Suppliers are required to assume all patent liability. ã2001 by International Truck and Engine Corporation.

OCTOBER 2001 Page 3 of 3

You might also like

- Assessment in Special Inclusive Education 13th Edition Salvia Solutions ManualDocument9 pagesAssessment in Special Inclusive Education 13th Edition Salvia Solutions ManualAmandaPrestonqajbg100% (12)

- JDM A22 - Rev 06-1987Document8 pagesJDM A22 - Rev 06-1987Reginaldo SantosNo ratings yet

- Din en Iso 4042Document7 pagesDin en Iso 4042aldairlopesNo ratings yet

- SAE AMS 5529j-2012Document5 pagesSAE AMS 5529j-2012Mehdi MokhtariNo ratings yet

- SAE - AMS 4050hv004Document9 pagesSAE - AMS 4050hv004Nilesh PatilNo ratings yet

- 02 Samss 011Document26 pages02 Samss 011Florante NoblezaNo ratings yet

- Ford Spot Weld SpecDocument12 pagesFord Spot Weld SpecJonathan Davies0% (1)

- CEMS A 10 Part IIDocument8 pagesCEMS A 10 Part IIaldairlopesNo ratings yet

- CEMS A 10 Part I APPXDocument80 pagesCEMS A 10 Part I APPXaldairlopesNo ratings yet

- Alloy 6022 Sheet: Higher Strength With Improved FormabilityDocument6 pagesAlloy 6022 Sheet: Higher Strength With Improved Formabilitywulfgang66No ratings yet

- CEMS A 10 Part IDocument24 pagesCEMS A 10 Part IaldairlopesNo ratings yet

- Mil DTL 25995CDocument7 pagesMil DTL 25995CShruthi RavindranathNo ratings yet

- SAE AMS5699 - RevGDocument8 pagesSAE AMS5699 - RevGLynn AlgerNo ratings yet

- En 10305 1 Sunny SteelDocument6 pagesEn 10305 1 Sunny Steelmohamed belkadiNo ratings yet

- Surface Vehicle StandardDocument8 pagesSurface Vehicle Standardwilian_coelho3309No ratings yet

- Sae Ams 5515L-2013Document6 pagesSae Ams 5515L-2013Mehdi MokhtariNo ratings yet

- Surface Vehicle Standard: Rev. SEP1997Document11 pagesSurface Vehicle Standard: Rev. SEP1997Angel HernándezNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- Inconel 112-DatasheetDocument1 pageInconel 112-DatasheetrobertNo ratings yet

- Tdoct2014b EngDocument2 pagesTdoct2014b Engmahmoud abuelmgdNo ratings yet

- 2024 Aluminium SheetDocument1 page2024 Aluminium SheetGeorge ChachlakisNo ratings yet

- Aerospace Material Specification: Plating, ZincDocument11 pagesAerospace Material Specification: Plating, ZincSURYAS63No ratings yet

- JNC Cables PDFDocument30 pagesJNC Cables PDFVasudev AgrawalNo ratings yet

- 028120-SPL-001 Shop Fabrication Bend Rev. CDocument12 pages028120-SPL-001 Shop Fabrication Bend Rev. CRokan PipelineNo ratings yet

- 20 EMT and Conduit Submittal SheetDocument2 pages20 EMT and Conduit Submittal SheetAhmed mahmoudNo ratings yet

- Web Datasheet A2.2Document7 pagesWeb Datasheet A2.2ks2000n1No ratings yet

- Surface Vehicle StandardDocument7 pagesSurface Vehicle Standardwilian_coelho3309No ratings yet

- Sae Ams 5555e-2013Document5 pagesSae Ams 5555e-2013Mehdi MokhtariNo ratings yet

- Thyssenkrupp Steels For Enameling Product Information Steel enDocument6 pagesThyssenkrupp Steels For Enameling Product Information Steel enle hoangNo ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- Sae J120-2002Document21 pagesSae J120-2002Marcos Rosenberg100% (1)

- Code of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Document11 pagesCode of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Sarbendu PaulNo ratings yet

- Technical Specification For ACSR Conductor, 24F OPGWDocument3 pagesTechnical Specification For ACSR Conductor, 24F OPGWMd MohsinNo ratings yet

- AMS4016MDocument5 pagesAMS4016M黄当甲No ratings yet

- Duplex Beaune 2010Document10 pagesDuplex Beaune 2010aliNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- RMS.1001 - Rivian Aluminium Extrusions RMS-1001, Rev-02Document9 pagesRMS.1001 - Rivian Aluminium Extrusions RMS-1001, Rev-02JOECOOL67No ratings yet

- Aerospace Material Specification: Nickel, Sheet and Strip Low (0.02 Max) Carbon AnnealedDocument5 pagesAerospace Material Specification: Nickel, Sheet and Strip Low (0.02 Max) Carbon AnnealedMehdi MokhtariNo ratings yet

- Astm A387 A387m 1992Document6 pagesAstm A387 A387m 1992Alberto Alexander RodriguezNo ratings yet

- Ams 5510 RDocument6 pagesAms 5510 RikkuhNo ratings yet

- Sae Ams 4353-2014Document5 pagesSae Ams 4353-2014Hani YilmazNo ratings yet

- Aerospace Material SpecificationDocument9 pagesAerospace Material SpecificationRoohi KatnoriaNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- MS20001PDocument5 pagesMS20001PthomasNo ratings yet

- 2 SmaDocument38 pages2 SmaKeima Junichirou katsuragiNo ratings yet

- Aerospace Material Specification: Tolerances Corrosion and Heat-Resistant Steel TubingDocument3 pagesAerospace Material Specification: Tolerances Corrosion and Heat-Resistant Steel TubingTetianaNo ratings yet

- Cems A 9Document20 pagesCems A 9Engenharia APedroNo ratings yet

- Domex 420 MCDocument2 pagesDomex 420 MCHugo RodriguezNo ratings yet

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocument4 pagesHome About Us Products & Market Media Contact: Minimum Standard RequirementsMohamed AlkharashyNo ratings yet

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocument4 pagesHome About Us Products & Market Media Contact: Minimum Standard RequirementsAtiqur RahmanNo ratings yet

- Alluminium SheetsDocument7 pagesAlluminium SheetsVaibhav ShuklaNo ratings yet

- Core 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Document8 pagesCore 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Nguyen03No ratings yet

- ELT-05-ET-TS-0003 - Specification For Welding Consumable For 9% Ni Steel - R0Document12 pagesELT-05-ET-TS-0003 - Specification For Welding Consumable For 9% Ni Steel - R0jorgekarlosprNo ratings yet

- Materials System SpecificationDocument25 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- Jed-050m 008 eDocument5 pagesJed-050m 008 egsuoagNo ratings yet

- June 19, 2012Document9 pagesJune 19, 2012ahmed.abdelmegeed78No ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Sae Ams 4340G-2018Document6 pagesSae Ams 4340G-2018Hani YilmazNo ratings yet

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFDocument21 pagesSpec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFanuj sharmaNo ratings yet

- Material Specification: Astm A 193 Gr. B7: Ed-2021Document2 pagesMaterial Specification: Astm A 193 Gr. B7: Ed-2021Precision EngineeringNo ratings yet

- DIN EN 10130 (Parte 1-2)Document14 pagesDIN EN 10130 (Parte 1-2)aldairlopesNo ratings yet

- Eds G 1101Document6 pagesEds G 1101aldairlopesNo ratings yet

- UntitledDocument13 pagesUntitledaldairlopesNo ratings yet

- DIN EN ISO 6272-1: November 2011Document14 pagesDIN EN ISO 6272-1: November 2011aldairlopesNo ratings yet

- DIN EN 10025-2: Hot Rolled Products of Structural SteelsDocument34 pagesDIN EN 10025-2: Hot Rolled Products of Structural SteelsaldairlopesNo ratings yet

- DIN EN 10268: December 2013Document15 pagesDIN EN 10268: December 2013aldairlopesNo ratings yet

- UntitledDocument8 pagesUntitledaldairlopesNo ratings yet

- EN ISO 2813: Determination of Specular Gloss of Non-Metallic Paint Films at 20°, 60° and 85°Document10 pagesEN ISO 2813: Determination of Specular Gloss of Non-Metallic Paint Films at 20°, 60° and 85°aldairlopesNo ratings yet

- UntitledDocument6 pagesUntitledaldairlopesNo ratings yet

- DIN EN 10131: Deutsche NormDocument14 pagesDIN EN 10131: Deutsche NormaldairlopesNo ratings yet

- Din en 10111Document14 pagesDin en 10111aldairlopesNo ratings yet

- Carbon Structural Steel: Standard Specification ForDocument3 pagesCarbon Structural Steel: Standard Specification ForaldairlopesNo ratings yet

- Continuously Hot-Dip Zinc Coated Low Carbon Steel Sheet and Strip For Cold FormingDocument15 pagesContinuously Hot-Dip Zinc Coated Low Carbon Steel Sheet and Strip For Cold FormingaldairlopesNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument8 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsDocument12 pagesChromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsaldairlopesNo ratings yet

- Astm B117Document12 pagesAstm B117aldairlopesNo ratings yet

- Engineering Material Specification: Not To Be Used For New DesignDocument3 pagesEngineering Material Specification: Not To Be Used For New DesignaldairlopesNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument14 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- Engineering Material Specification: Approval From The Sheet Metal Tech ClubDocument8 pagesEngineering Material Specification: Approval From The Sheet Metal Tech ClubaldairlopesNo ratings yet

- Engineering Material SpecificationDocument10 pagesEngineering Material SpecificationaldairlopesNo ratings yet

- Engineering Material SpecificationDocument9 pagesEngineering Material SpecificationReginaldo SantosNo ratings yet

- Incropera - 003 PDFDocument10 pagesIncropera - 003 PDFaldairlopesNo ratings yet

- Incropera - 004 PDFDocument10 pagesIncropera - 004 PDFaldairlopesNo ratings yet

- Din 53504 (2009)Document18 pagesDin 53504 (2009)aldairlopesNo ratings yet

- Incropera - 002 PDFDocument10 pagesIncropera - 002 PDFaldairlopesNo ratings yet

- Incropera - 005 PDFDocument10 pagesIncropera - 005 PDFaldairlopesNo ratings yet

- Deconstructing PR (Thomas Mickey)Document169 pagesDeconstructing PR (Thomas Mickey)Anca IoanaNo ratings yet

- ItemDocument6 pagesItemIsmail OsmanNo ratings yet

- STPM Maths T Sem 1 Trial 2014 P1 Port Dickson AnswerDocument2 pagesSTPM Maths T Sem 1 Trial 2014 P1 Port Dickson AnswerKenneth ChanNo ratings yet

- Nay Aung CV - FormDocument3 pagesNay Aung CV - FormTECHNO ProductionNo ratings yet

- Selection of Welding Process For Hardfacing in Carbon SteelDocument11 pagesSelection of Welding Process For Hardfacing in Carbon SteelKuthuraikaranNo ratings yet

- Chapter 3 Hopes & DreamsDocument5 pagesChapter 3 Hopes & DreamsSyahrudin BaharsyahNo ratings yet

- Tip#5) - Some Cool SCANF Tricks: Find Out Some of The Unheard Scanf Tricks That You Must KnowDocument17 pagesTip#5) - Some Cool SCANF Tricks: Find Out Some of The Unheard Scanf Tricks That You Must KnowGauri BansalNo ratings yet

- Discrete Fourier Series (DFS) and Discrete Fourier Transform (DFT)Document49 pagesDiscrete Fourier Series (DFS) and Discrete Fourier Transform (DFT)yadavsticky5108No ratings yet

- Vmware Vsphere: Optimize and Scale (V7) : (Vsos7)Document3 pagesVmware Vsphere: Optimize and Scale (V7) : (Vsos7)Etti Roi NoirNo ratings yet

- BSCS Functioanl EnglishDocument5 pagesBSCS Functioanl Englishfizzabasharat44No ratings yet

- Leaflet GVPF 750 - 1000M Mec-EnDocument2 pagesLeaflet GVPF 750 - 1000M Mec-EnRené Rocha MolinaNo ratings yet

- BATCH 8 MajorDocument52 pagesBATCH 8 MajorHemsundar ArepallyNo ratings yet

- Games PDFDocument42 pagesGames PDFNarlin VarelaNo ratings yet

- Test 61-70Document87 pagesTest 61-70Nova LifeKarnalNo ratings yet

- Chapter 9 Flow in Closed ConduitsDocument10 pagesChapter 9 Flow in Closed ConduitsWellington FloresNo ratings yet

- 86m Engineers Handbook V.2 Main Engines - Issue 1 2005Document65 pages86m Engineers Handbook V.2 Main Engines - Issue 1 2005Sama OdirNo ratings yet

- DM Lite - Hdmi Over Catx Receiver, Surface Mount: Hd-Rx-101-C-EDocument3 pagesDM Lite - Hdmi Over Catx Receiver, Surface Mount: Hd-Rx-101-C-ESales AdministratorNo ratings yet

- MGT 406 - Chapter 1Document18 pagesMGT 406 - Chapter 1Bilal AfzalNo ratings yet

- Java Garbage CollectionsDocument7 pagesJava Garbage CollectionskasimNo ratings yet

- DCCA Accessibility Code Standard Final Nov 2016Document68 pagesDCCA Accessibility Code Standard Final Nov 2016sultanprinceNo ratings yet

- H013-E-EQP-STS-DE-I-E-024 Inteligent Mechanical Device Monitoring SystemDocument27 pagesH013-E-EQP-STS-DE-I-E-024 Inteligent Mechanical Device Monitoring SystemRushabh ShahNo ratings yet

- Tonkaflo Pump AS O&M Manual 90 140 225 400 KZ KT FRM PDFDocument90 pagesTonkaflo Pump AS O&M Manual 90 140 225 400 KZ KT FRM PDFMikhail Tibes SoaresNo ratings yet

- 9.write The Short Notes On Laser ScanningDocument4 pages9.write The Short Notes On Laser Scanningمحمد تانزيم ابراهيمNo ratings yet

- HydraulicDocument8 pagesHydraulicOsama OmayerNo ratings yet

- Relative and Absolute Dating PDFDocument192 pagesRelative and Absolute Dating PDFPeeyush Kumar0% (1)

- NSEP Above MasDocument63 pagesNSEP Above MasMDPCOS SCHOOLNo ratings yet

- Habeeb Ullah: PHD Competition Industrial and Information EngineeringDocument9 pagesHabeeb Ullah: PHD Competition Industrial and Information EngineeringEngr. Babar AliNo ratings yet

- PPR Method StatementDocument53 pagesPPR Method StatementDiaa Gobran100% (1)

- Data Sheet 1250kw Cat 3512 PrimeDocument6 pagesData Sheet 1250kw Cat 3512 Primevictoros27No ratings yet