Professional Documents

Culture Documents

Scania Communicator 300 Industrial Engines and Power Generation Engines DC09, DC13, DC16, OC16 Marine Engines DI09, DI13, DI16

Uploaded by

Ben ThreadwellOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scania Communicator 300 Industrial Engines and Power Generation Engines DC09, DC13, DC16, OC16 Marine Engines DI09, DI13, DI16

Uploaded by

Ben ThreadwellCopyright:

Available Formats

Installation manual

C300

Scania Communicator 300

Industrial engines and

Power Generation engines

DC09, DC13, DC16, OC16

Marine engines

DI09, DI13, DI16

03:06 Issue 4.0 en-GB

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

Changes from the previous issue............................................................................ 3

C300 – Scania Communicator 300......................................................................... 4

Overview ............................................................................................................. 4

Control unit C300................................................................................................ 6

Fitting the control unit....................................................................................... 10

Fitting and earthing the antenna ........................................................................ 12

Routing of coaxial cables for antenna ............................................................... 13

Antenna connection........................................................................................... 14

Verification of installation with adapter cable 99 667 ..................................... 16

Final check ........................................................................................................ 16

03:06 Issue 4.0 en-GB 2

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

Changes from the previous issue

Changes from the previous issue

The changes made in this document compared with the previous issue are marked

with a line in the left-hand margin. The changes are also described below.

• New connector for Stage V Overview.

• Connection of harness-to-harness connector in section E89F: System connection.

• New information in section Fitting the control unit.

• New section Antenna connection.

03:06 Issue 4.0 en-GB 3

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

C300 – Scania Communicator 300

2

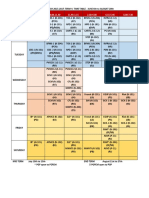

Overview 1 3

Scania Communicator 300 communicates with Fleet Manager Portal (FMP) via 3G C4000X C4000

and GPRS. If reception between the FMP and RTC node is poor, communication is

affected. Scania Communicator is available in several different versions, adapted for

different markets depending on the SIM card standard. U20B U20C

C300 has one control unit (1), one antenna (2), one adapter cable harness (3), one ca- 1

ble harness (4) and one coaxial cable (5). C4098

5 C4125

2

Note: E89F E89D E89C

The adapter cable (3) is not required for Stage V engines. C300 is then connected di- 4

rectly to C4125 on the engine.

M1B1

393 905

When placing the order, the cable harness (4) can be selected in lengths of 3 m, 4.5

m or 6 m. System overview, Scania Communicator 300.

1. Control unit

Note: 2. Antenna

3. Adapter cable harness (does not apply to Stage V)

3 m cable harness applies only to Stage V engines.

4. Cable harness

5. Coaxial cable

The coaxial cable (5) is supplied in a length of 2.7 m. The adapter cable harness (3)

has a voltage supply that must be connected to 30 voltage on the engine starter motor.

The following harness-to-harness connector differs depending on the configuration,

see illustration on the right:

Notes Designation Remark

1 C4098 All engines except Stage V

03:06 Issue 4.0 en-GB 4

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Notes Designation Remark

2 C4125 Stage V

03:06 Issue 4.0 en-GB 5

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Control unit C300

Overview of the control unit 1

Contact Use Note

housing

E89B USB port Not used

E89C GSM/3G/4G antenna Fakra, violet

E89D GNSS antenna Fakra, blue

E89F

E89E Connection for accessories Not used

E89F System connection 15-pin, MCP 2.8 E89E

E89G eCall connection Not used E89G

E89B

E89D

E89C

393 908

Overview, Control unit C300

1. Status LED

03:06 Issue 4.0 en-GB 6

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

E89F: System connection 15 12 9 6 3

Pins Use Note

14 11 8 5 2

1 System power 30 voltage

2 Wake-up signal 15 voltage 13 10 7 4 1

3 Wake-up signal from ALM control unit Not used

395 100

4 CAN communication (yellow), internal CAN1 high

CAN bus

5 Secondary wake-up signal (not used) Not used Harness-to-component connector E89F

6 Activation signal, switch S176 Not used

7 CAN communication (yellow), internal CAN1 low

CAN bus

8 Not used

9 Shielding/protection, CAN bus Not used

10 CAN communication (blue), external CAN Not used

bus

11 CAN communication (blue), external CAN Not used

bus (termination)

12 Status, switch S176 Not used

13 CAN communication (blue), external CAN Not used

bus

14 CAN communication (blue), external CAN Not used

bus (termination)

15 System earth 31-voltage

03:06 Issue 4.0 en-GB 7

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Connection of harness-to-harness connector C4098 to E89F

If only the connector kit has been ordered and the Scania cable harness is not avail-

able, connect the cable harness as follows: 4 3

5 2

E89F pin Use Connected to

C4098 pin

6 1

1 System power 1

414 372

2 Wake-up signal 3

4 CAN communication (yellow), internal 4 Harness-to-harness connector C4098 on the engine, viewed from the electrical cable

CAN bus input side.

7 CAN communication (yellow), internal 5

CAN bus

15 System earth 2

Note:

When the connector kit is used, the electrical cables to pins 4 and 7 must be twisted

40 turns per metre.

03:06 Issue 4.0 en-GB 8

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Connection of harness-to-harness connector C4125 to E89F

If only the connector kit has been ordered and the Scania cable harness is not avail-

able, connect the cable harness as follows:

E89F pin Use Connected to

C4125 pin

5 1

1 System power 1

2 Wake-up signal 3 6 2

4 CAN communication (yellow), internal 6 7 3

CAN bus

8 4

7 CAN communication (yellow), internal 7

CAN bus

15 System earth 2

Note:

397 852

When the connector kit is used, the electrical cables must be twisted 40 turns per me-

tre. Harness-to-harness connector C4125, viewed from the electrical cable input side.

03:06 Issue 4.0 en-GB 9

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Fitting the control unit 175,5

53 140

REQUIREMENT!

40 100

• Fit the control unit in the vicinity of the electrical panel in a dry and dust-free en-

vironment. 8

• Do not splice the control unit cable harness.

100

• The harness-to-component connector of the control unit must be facing down- 6

wards.

160

178

Scania recommends placing the control unit in a casing that protects against dust and

moisture and meets IP52. Leave at least 70 mm clearance (A) for the control unit

connector.

1. Remove the control unit bracket.

A

392 730

2. Mark holes for the control unit bracket.

3. Drill holes with a diameter of 6 mm and fit the bracket.

4. Fit the control unit.

Dimensional diagram, control unit and bracket.

5. Disconnect the battery voltage.

6. Connect the adapter cabling to the engine harness-to-harness connector C4000.

Connection C4000X on the adapter cabling can be used in the same way as

C4000.

7. Connect adapter cabling connection M1B1 to the connection for 30 voltage on

the starter motor.

8. Connect the control unit cable harness to the adapter cabling via C4098.

9. Connect the battery voltage.

To connect C300, there is either a cable harness with ready lengths or a loose con-

nector kit. Kit 2 805 919 is used for connection to C300. For connection to C4125,

use kit 2 805 918 and for C4098 use kit 2 805 917.

03:06 Issue 4.0 en-GB 10

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

For more information on connecting the engine, see 03:01 Electrical system.

03:06 Issue 4.0 en-GB 11

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Fitting and earthing the antenna

The antenna must be positioned externally on a flat horizontal surface. If the antenna

is to be fitted on a vehicle, you must take into account the direction of travel of the

vehicle (1). The antenna is approximately 270 mm high. 1

In order to obtain the best range during transmission, the surface must be made of

metal so that it acts as an earthing system. The earthing system also shields the an- 270

tenna from the wiring in the roof. If the surface is made of plastic, a metal earthing

system can be positioned on the underside of the surface. The diameter of the earth-

ing system must be at least 500 mm. Position the radio antenna on the metal covered

part of the surface in order to obtain an earthing system.

REQUIREMENT!

393 906

• If the antenna is positioned on a curved surface, the radius must be greater than Direction of travel and dimensions of the antenna.

2,000 mm.

• The washer securing the antenna must have electrical contact with the earthing

system. Remove any surface treatment from the part of the earthing system that

has electrical contact with the washer.

• When installing on marine applications, it is important that the earthing system is 130

separated from the hull.

IMPORTANT!

84

The distance to other antennas and external metal objects must be at least 300 mm.

393 907

Dimensions of antenna base.

03:06 Issue 4.0 en-GB 12

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

1. Drill a hole with a diameter of 50 mm through the surface and any earthing sys-

tem.

2. Fit the antenna (1) in the hole with the direction of travel that is indicated in the

illustration on the previous page.

3. Fit the washer (2) and tighten the screw on top of the antenna base. Tightening

torque 5 Nm.

4. Fit the lock nut (3). Tightening torque 5 Nm.

E89C

Routing of coaxial cables for antenna

REQUIREMENT!

• If the coaxial cable is bent, the bending radius should be at least 50 mm. 1

• Connect several coaxial cables in series if the distance between C300 and the an-

tenna requires it. E89D 2

• Position the harness-to-component connectors in a dry and dust-free environ- 3

392 729

ment.

Overview, antenna.

Do not route coaxial cables together with other cables. Other cables can disrupt the

signals in the coaxial cables. Coaxial cables can, however, cross other cables without

any risk of electromagnetic interference.

03:06 Issue 4.0 en-GB 13

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Antenna connection

To connect an antenna to the unit if the Scania cable harness is not available, use the

connector kit provided and connect the cables according to the tables below.

C1

A1

C2

B2

E89 U20 Function Colour

1 C4098 GSM/3G/4G Violet B1

2 C4125 GPS/Glonass Blue

The connectors are adapted to a cable with the following dimensions, see illustration

420 040

on the right:

Dimen- Detail view of coaxial cable.

Detail Designation Note

sions

A1 Outer diameter 3.3 ± 0.2 mm

Jacket A

Wall thickness 0.30 mm nom

B2 Outer diameter 2.7 mm

Shield B

B1 Aluminium foil, thickness 0.05 mm

Mesh cover min 75%

C1 Diameter of inner conductor 0.8 mm

Wall thickness 0.6 mm nom

Inner conduc-

Number of wires 7 nom

tor C

Wire diameter max 0.26

Diameter of conductor nom 2.1 mm

C2 Dielectric foam PP nom 2.1 mm

03:06 Issue 4.0 en-GB 14

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Electrical properties at 20°C:

Designation Note

Maximum conductor resistance / length

52 ohms / 1,000 m

in m

Capacitance ≤ 90 pF/m

Average impedance 50 ±3 ohm

Cable type RTK 031

03:06 Issue 4.0 en-GB 15

© Scania CV AB 2020, Sweden

INSTALLATION

MANUAL

C300 – Scania Communicator 300

Verification of installation with adapter cable

99 667

Note:

C300 needs the engine speed, GNSS position and Engine number from CAN to com-

plete the automatic registration.

Fault codes may be generated by SDP3 if another antenna than the Scania antenna is

used. These fault codes can usually be ignored.

• Connect SDP3 by connecting measuring cable 99 667 to C300.

• Go through Guide to check installation.

Final check

336 367

Use CSTT to confirm that the vehicle has been automatically registered.

03:06 Issue 4.0 en-GB 16

© Scania CV AB 2020, Sweden

You might also like

- Scania DC09, DC13, DC16 Industrial Engines - Electrical System - CompressedDocument40 pagesScania DC09, DC13, DC16 Industrial Engines - Electrical System - CompressedMaurice ConnorNo ratings yet

- Fault Code 498 Engine Oil Level Sensor Circuit - Voltage Above Normal, or Shorted To High SourceDocument13 pagesFault Code 498 Engine Oil Level Sensor Circuit - Voltage Above Normal, or Shorted To High SourceAhmedmah100% (1)

- Service Bulletin Details Speed Sensor and Parameter Settings for Volvo I-Shift TransmissionsDocument6 pagesService Bulletin Details Speed Sensor and Parameter Settings for Volvo I-Shift TransmissionsMuhamedomar Jojo Jojo100% (5)

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- Harmonic Excitation and Response Spectrum AnalysisDocument54 pagesHarmonic Excitation and Response Spectrum AnalysisAayisha S AHAMED100% (1)

- BMW E39 E53 Low-to-High OBC Retrofit Kit PN 65900308455Document14 pagesBMW E39 E53 Low-to-High OBC Retrofit Kit PN 65900308455SAIDNo ratings yet

- Scania j1939 FMSDocument80 pagesScania j1939 FMSzibetto67% (3)

- Can BusDocument81 pagesCan BusCarlos Ramirez VillarrealNo ratings yet

- Tohatsu 2 Stroke Service Manual 1992 2000Document329 pagesTohatsu 2 Stroke Service Manual 1992 2000Adi Peterfi97% (38)

- Scania DI09, DI13, DI16 Marine Engines - CAN Interface PDFDocument81 pagesScania DI09, DI13, DI16 Marine Engines - CAN Interface PDFMihai PopaNo ratings yet

- Piston Cleaning Ring Sl2016-620Document2 pagesPiston Cleaning Ring Sl2016-620Parthiban Nagarajan100% (1)

- 372SSL20V3 Service Master Components PDFDocument2 pages372SSL20V3 Service Master Components PDFAnthony PozoNo ratings yet

- ENIGMA CablesDocument36 pagesENIGMA CablesVicente PerezNo ratings yet

- 840D - FB1 Description of Functions - Basic Machine PDFDocument1,808 pages840D - FB1 Description of Functions - Basic Machine PDFJoão Paulo Moreira Santos BarbosaNo ratings yet

- Profile Shakeel Carpentry Joinery WorksDocument46 pagesProfile Shakeel Carpentry Joinery WorksShakeel Ahmad100% (1)

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- Nice 3000 New VersionDocument115 pagesNice 3000 New VersionSyed iliyas67% (3)

- CAN Interface SCANIADocument80 pagesCAN Interface SCANIAManuel Solar Rigoni Dinky89% (9)

- YASHICA MAT-124 User's ManualDocument34 pagesYASHICA MAT-124 User's Manuallegrandew100% (1)

- Fms Prep ScaniaDocument80 pagesFms Prep Scaniaipdown4250% (2)

- Syringe Infusion Pump S300: Technical SpecificationDocument1 pageSyringe Infusion Pump S300: Technical SpecificationJonathan Flores Gutang100% (1)

- BWM 0000823 01Document13 pagesBWM 0000823 01AliNo ratings yet

- Cme2100 Quick Manual English v.3.0 0Document59 pagesCme2100 Quick Manual English v.3.0 0mgugiNo ratings yet

- ECB AII0182 - C1 Mk3 To Mk4 Retrofit Kits - OverviewDocument2 pagesECB AII0182 - C1 Mk3 To Mk4 Retrofit Kits - OverviewRoman AlarconNo ratings yet

- CAN Interface For FMS: Important!Document10 pagesCAN Interface For FMS: Important!abo mhdeNo ratings yet

- CAN Interface For FMS General: Important!Document12 pagesCAN Interface For FMS General: Important!Daniel Henrique PiovesaniNo ratings yet

- WEG cfw11 Manual Do Usuario Adendo Mec e F G e Modular 10001192070 Manual Portugues BRDocument14 pagesWEG cfw11 Manual Do Usuario Adendo Mec e F G e Modular 10001192070 Manual Portugues BRReginaldo SouzaNo ratings yet

- FB3 1102 enDocument813 pagesFB3 1102 enJackam kamNo ratings yet

- SINAMICS V20 Supplement Harmonic CurrentsDocument4 pagesSINAMICS V20 Supplement Harmonic Currentsraulest50No ratings yet

- Service Bulletin: AB Volvo PentaDocument3 pagesService Bulletin: AB Volvo Pentaanees ahmedNo ratings yet

- C2000 ManualDocument539 pagesC2000 ManualantonioNo ratings yet

- Motion Control Drives D21 3 Complete English 2022Document582 pagesMotion Control Drives D21 3 Complete English 2022Teddy NickolayevskyNo ratings yet

- SINAMICS Drives D21 3 Complete English 2019Document540 pagesSINAMICS Drives D21 3 Complete English 2019Jesús SosaNo ratings yet

- CE1000Document581 pagesCE1000Mike WilsonNo ratings yet

- Varitel Ingenieria Electronica S.A. Manual SummaryDocument452 pagesVaritel Ingenieria Electronica S.A. Manual SummaryFernando Sanchez FerisNo ratings yet

- Mercedes EGR ValvDocument6 pagesMercedes EGR ValvqasmaouiNo ratings yet

- SRS Light IlluminatedDocument6 pagesSRS Light IlluminatedWadu DetutsNo ratings yet

- Omron SYSMAC-C Series: Bit DeviceDocument6 pagesOmron SYSMAC-C Series: Bit DeviceJeydson StorchNo ratings yet

- Ready-To-Use Configuration: Sepam Serie 20Document8 pagesReady-To-Use Configuration: Sepam Serie 20Eric Vinicius RodriguesNo ratings yet

- LCM Module: Industrial Co., LTDDocument18 pagesLCM Module: Industrial Co., LTDelectropicNo ratings yet

- Catálogo Motores Iman PermanenteDocument32 pagesCatálogo Motores Iman Permanentemass72No ratings yet

- Je 02190004Document2 pagesJe 02190004Yang LiNo ratings yet

- 2014 01 01 MAN-cats-parts-catalogueDocument16 pages2014 01 01 MAN-cats-parts-catalogueNooR Aldeen AboIrmailaNo ratings yet

- Alarmes CTVDocument588 pagesAlarmes CTVJessica RoyNo ratings yet

- Control It: Hardware (Ac800 M/C) & SoftcontrollerDocument74 pagesControl It: Hardware (Ac800 M/C) & SoftcontrollerDoc_LACNo ratings yet

- DVIN0006 M800 OEM WRX78 Installation DocumentDocument22 pagesDVIN0006 M800 OEM WRX78 Installation DocumentBUKURU JumaNo ratings yet

- DC 15 XXDocument88 pagesDC 15 XXBogdan VisochkovNo ratings yet

- Diagnostics GuideDocument714 pagesDiagnostics GuideAmin ZamaniNo ratings yet

- CGC 400 Data Sheet 4921240426 UK - 2016.10.10Document11 pagesCGC 400 Data Sheet 4921240426 UK - 2016.10.10bacNo ratings yet

- Electrical Installation Can Interface Issue 10Document93 pagesElectrical Installation Can Interface Issue 10Ricardo LunaNo ratings yet

- EmpirBus NXT CCM User Manual Ver 1 2Document16 pagesEmpirBus NXT CCM User Manual Ver 1 2nkemotNo ratings yet

- Operator E-Jets News Rel 037Document9 pagesOperator E-Jets News Rel 037jivomirNo ratings yet

- CAN Interface For FMS General: Important!Document12 pagesCAN Interface For FMS General: Important!noranNo ratings yet

- M800 OEM WRX78 Installation DocumentDocument10 pagesM800 OEM WRX78 Installation DocumentRaheel FaroukNo ratings yet

- 11 - A - Communication ModuleDocument5 pages11 - A - Communication ModuleHari PrashannaNo ratings yet

- 840DDocument818 pages840DCicero MelloNo ratings yet

- (A5ml) SX-DSV02931 R1 3e 170220Document38 pages(A5ml) SX-DSV02931 R1 3e 170220tuxNo ratings yet

- 42pfl5609 32pfl5409Document90 pages42pfl5609 32pfl5409dibbenduNo ratings yet

- G110M G120D G120P G120C ET200pro 4.7SP10 Prod Info 0418 en-USDocument6 pagesG110M G120D G120P G120C ET200pro 4.7SP10 Prod Info 0418 en-USFelipe Polix BarbosaNo ratings yet

- SM MVU20 Ver1.0 ENDocument10 pagesSM MVU20 Ver1.0 ENRaetchi VladNo ratings yet

- Proxy ProbesDocument3 pagesProxy Probesabhinay guptaNo ratings yet

- 2467378ENEN Kit Instalare g30 Kidney GrillDocument20 pages2467378ENEN Kit Instalare g30 Kidney GrillBogdan DSANo ratings yet

- Sales Engineering Information: 8.13 FMS Connector / CDM For CF and XF SeriesDocument6 pagesSales Engineering Information: 8.13 FMS Connector / CDM For CF and XF SeriesSzervizcentrum EuroNo ratings yet

- Rand RDocument232 pagesRand RNoureddine YahiaouiNo ratings yet

- DVIN0014 M800 Plug-In To WRX 9-10 Installation NotesDocument21 pagesDVIN0014 M800 Plug-In To WRX 9-10 Installation NotesOlga Beaty MasterNo ratings yet

- Management Quality ManagementDocument7 pagesManagement Quality ManagementJasmine LimNo ratings yet

- Comparison and Evaluation of Anti-Windup PI Controllers: Xin-Lan Li, Jong-Gyu Park, and Hwi-Beom ShinDocument6 pagesComparison and Evaluation of Anti-Windup PI Controllers: Xin-Lan Li, Jong-Gyu Park, and Hwi-Beom ShinsaeedNo ratings yet

- Atoms and MoleculesDocument4 pagesAtoms and MoleculesShwetaNo ratings yet

- Monopolistic screening in the labor marketDocument6 pagesMonopolistic screening in the labor marketKand HroppaNo ratings yet

- Term 4 Time Table & Exam Schedule.Document4 pagesTerm 4 Time Table & Exam Schedule.Anonymous FD3MCd89ZNo ratings yet

- Sem NotesDocument39 pagesSem NotesN NandiniNo ratings yet

- Uncertainty in Measurements - Lab ReportDocument4 pagesUncertainty in Measurements - Lab ReportStaniaNo ratings yet

- Challenges of Deep Excavation for KVMRT StationsDocument85 pagesChallenges of Deep Excavation for KVMRT StationsAlwin AntonyNo ratings yet

- Prof. Hanumant Pawar: GeomorphologyDocument15 pagesProf. Hanumant Pawar: GeomorphologySHAIK CHAND PASHANo ratings yet

- ICs Interface and Motor DriversDocument4 pagesICs Interface and Motor DriversJohn Joshua MontañezNo ratings yet

- ST 30 PDFDocument2 pagesST 30 PDFafiffathin_akramNo ratings yet

- Travelstar 25GS, 18GT, & 12GN: Quick Installation GuideDocument2 pagesTravelstar 25GS, 18GT, & 12GN: Quick Installation Guidebim2009No ratings yet

- Fibre OpticDocument16 pagesFibre OpticJoanna BaileyNo ratings yet

- Assignment 5: Engineering Utilities IiDocument4 pagesAssignment 5: Engineering Utilities IiRex SabersonNo ratings yet

- Communication TasksDocument19 pagesCommunication Taskswaqas08100% (4)

- Recent Progress in Medium-Mn Steels Made With New Designing Strategies A ReviewDocument8 pagesRecent Progress in Medium-Mn Steels Made With New Designing Strategies A ReviewMATHEWS LIMA DOS SANTOSNo ratings yet

- Trends in Maternal Mortality: Executive SummaryDocument16 pagesTrends in Maternal Mortality: Executive SummarykansaNo ratings yet

- Organograma ASME IX Art. I PDFDocument4 pagesOrganograma ASME IX Art. I PDFfabiocorreasilvaNo ratings yet

- Srikanth Aadhar Iti CollegeDocument1 pageSrikanth Aadhar Iti CollegeSlns AcptNo ratings yet

- Agile Assignment 2Document2 pagesAgile Assignment 2Sameen ShakeelNo ratings yet

- UntitledDocument1 pageUntitledMoizur RahmanNo ratings yet

- Eng 8 LP4Document3 pagesEng 8 LP4Fe JanduganNo ratings yet

- The Origins Development and Possible Decline of The Modern StateDocument65 pagesThe Origins Development and Possible Decline of The Modern StateJasper Jade MartinNo ratings yet