Professional Documents

Culture Documents

PP h4120 Tds

Uploaded by

engrmfawadazharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PP h4120 Tds

Uploaded by

engrmfawadazharCopyright:

Available Formats

TASNEE PP H4120 POLYPROPYLENE

DESCRIPTION

TASNEE PP H4120 is a Polypropylene Homopolymer with a Melt Flow Rate (MFR) of 12 g/10min.

TASNEE PP H4120 has good gloss, excellent flow and good mechanical properties.

TYPICAL APPLICATIONS

TASNEE PP H4120 is intended for injection molding for packaging containers, toys, domestic appliances,

garden furniture, caps, closures, boxes and household articles.

TYPICAL PROPERTIES

Physical Method Unit Value

Melt Flow Rate (230°C/2.16 kg) ISO 1133 g/10min 12

Melting Temperature ISO 11357-3 °C 163

Vicat Softening Temperature ISO 306 °C 152

Heat Distortion Temperature @ 0.45 MPa ISO 75-2 °C 102

Density ISO 1183 g/cm3 0.9

Mechanical Method Unit Value

Tensile Strength @ Yield ISO 527-2 MPa 33

Tensile Elongation @ Yield ISO 527-2 % 10

Flexural Modulus (1% Secant) ISO 178 MPa 1400

Charpy Impact Strength (Notched) at 23°C ISO 179/1eA KJ/m2 3.0

Rockwell Hardness ISO 2039-2 R 100

Typical Processing Conditions

Melt Temperature : 210 ~ 260 0C

Mold Temperature : 20 ~ 45 0C

Shrinkage : 1 ~ 2% depending on wall thickness and molding conditions

Note: Processing parameters should only be used as guidelines. The above properties values are not to be construed as specifications.

National Petrochemical Industrialization Marketing Co.

P.O. Box: 26707 Riyadh - 11496 Kingdom of Saudi Arabia

Tel : +966 11 222 2205 Fax : +966 11 417 4198

E-mail: marketing@tasnee.com

Website: www.tasneemarketing.com

Food Contact

The material is manufactured to the highest standards but, special requirements apply to certain applications, such as food

contact end-use. For specific information on regulatory compliance, please contact TASNEE below or our local

representative in your area.

Safety

Workers should be protected from the possibility of skin or eye contact with molten polymer. As minimum precaution,

safety glasses and heat resistance gloves are suggested to prevent mechanical or thermal injury to eyes and hands. Molten

polymer exceeding processing condition requirements may degrade and release, fumes, vapors and unpleasant odor. In

higher concentrations they may cause irritation of the mucus membranes. Fabrication areas should be ventilated to carry

away fumes and vapors. Legislation on the control of emissions and pollution prevention must be observed. If the principles

of sound manufacturing practice are adhered to and the place of work is well ventilated, no health hazards are involved in

processing the material.

The material may burn when supplied with excess heat and oxygen. It should be handled and stored away from contact with

direct flames and/or ignition sources. In burning the material generates considerable heat and may release a dense black

smoke. Fires should be extinguished by heavy foams or dry powder. For further information about safety in handling and

processing please refer to the Material Safety Data Sheet (MSDS).

Storage

The material is packed in 25 kg bags or in bulk containers/bags protecting it from contamination. Storage time of material

longer than 6 months may have a negative influence on the quality of the final product. It is generally recommended to

convert all materials latest within 6 months from delivery date. The material is subjected to degradation by ultra-violet

radiation or by high storage temperatures. Therefore the material must be protected from direct sunlight, temperatures above

40°C and high atmospheric humidity during storage. Further unfavorable storage conditions are large fluctuations in

ambient temperature and high atmospheric humidity. TASNEE will not give any warranty to unfavorable storage conditions

which may lead to quality deterioration such as color change, bad smell and inferior product performance.

Disclaimer

"The information and data contained in this publication is submitted without prejudice, and is based on our current

knowledge, experience and on a limited number of tests". "In view of the many factors that may affect processing and

application, these data do not relieve the receiver of this information from the responsibility of carrying out their own tests

and experiments; neither do they imply any legally binding assurance of certain properties nor of suitability for a specific

purpose of the products made with or on the basis of the information in this publication".

National Petrochemical Industrialization Marketing Co.

P.O. Box: 26707 Riyadh - 11496 Kingdom of Saudi Arabia

Tel : +966 11 222 2205 Fax : +966 11 417 4198

E-mail: marketing@tasnee.com

Website: www.tasneemarketing.com

You might also like

- Tds-Tasnee PP h4120Document2 pagesTds-Tasnee PP h4120أبو أميرNo ratings yet

- Tds Tasnee HD b1258Document2 pagesTds Tasnee HD b1258أبو أميرNo ratings yet

- Tds-Tasnee PP h1030Document2 pagesTds-Tasnee PP h1030أبو أميرNo ratings yet

- Tds-Tasnee PP h2245Document2 pagesTds-Tasnee PP h2245أبو أميرNo ratings yet

- Updated TDS-TASNEE 100 OrangeDocument2 pagesUpdated TDS-TASNEE 100 Orangelamia.elgammalNo ratings yet

- Tasnee LD 1925as: Low Density PolyethyleneDocument2 pagesTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaNo ratings yet

- Tds Tasnee 100 Black Revised in 2022Document2 pagesTds Tasnee 100 Black Revised in 2022Amir NawazNo ratings yet

- Tds Tasnee HD Im2050 Revised in 2022Document2 pagesTds Tasnee HD Im2050 Revised in 2022Amir NawazNo ratings yet

- PA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingDocument2 pagesPA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingVinoth SekarNo ratings yet

- Tds-Tasnee PP h1045Document2 pagesTds-Tasnee PP h1045أبو أميرNo ratings yet

- Tds-Tasnee LD 1925asDocument2 pagesTds-Tasnee LD 1925asأبو أميرNo ratings yet

- Tds-Tasnee LD 0725nDocument2 pagesTds-Tasnee LD 0725nأبو أميرNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- tds-hd5403pdfDocument2 pagestds-hd5403pdfAthonioMourinhoNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Tds Tasnee HD f0455Document2 pagesTds Tasnee HD f0455أبو أميرNo ratings yet

- TDS Polidan TA HF V 1.0 June 2017Document3 pagesTDS Polidan TA HF V 1.0 June 2017valdecirnasatoNo ratings yet

- Material DataDocument3 pagesMaterial DataR.Ranjan PradhanNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- Technical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticDocument1 pageTechnical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticarmandoNo ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- Hdpe Bl3-MarunDocument1 pageHdpe Bl3-MarunChetan PandyaNo ratings yet

- RB206MODocument2 pagesRB206MObobNo ratings yet

- ULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Document2 pagesULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Luis Enrique Ramos PérezNo ratings yet

- Utek PYJ9114 SMC SHEETDocument2 pagesUtek PYJ9114 SMC SHEETFrederik TjonnelandNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- RADILON A CP300K 333 BK Product InfoDocument4 pagesRADILON A CP300K 333 BK Product InfomuthuNo ratings yet

- PDS HEX4460p PE80 1Document3 pagesPDS HEX4460p PE80 1art72 talNo ratings yet

- RB307MODocument2 pagesRB307MObobNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- VG602Document2 pagesVG602LucasNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- BioPBS FZ71PM and FZ71PB Technical Data Sheet For Injection MoldingDocument1 pageBioPBS FZ71PM and FZ71PB Technical Data Sheet For Injection Moldingpaolo.pradaNo ratings yet

- High Flow Polystyrene for Thin Wall PackagingDocument2 pagesHigh Flow Polystyrene for Thin Wall Packagingdrmohamed120No ratings yet

- PP Mosten EH 501: Technical DatasheetDocument2 pagesPP Mosten EH 501: Technical DatasheetBanupriya BalasubramanianNo ratings yet

- RADILONAESL128100NTDocument4 pagesRADILONAESL128100NTRicardoNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Technical Datasheet LITEN FB 75 - EngDocument2 pagesTechnical Datasheet LITEN FB 75 - EngTo RaNo ratings yet

- Colpoly 7331 LV TDSDocument2 pagesColpoly 7331 LV TDSKristjan PosavecNo ratings yet

- Borouge HD168MODocument2 pagesBorouge HD168MOhamza hameedNo ratings yet

- ABS Technical Data SheetDocument1 pageABS Technical Data SheetarmandoNo ratings yet

- Daicel PP: Properties PG2N1Document1 pageDaicel PP: Properties PG2N1Chentouf MohammedNo ratings yet

- Colpoly 736 WAT TDSDocument2 pagesColpoly 736 WAT TDSKristjan PosavecNo ratings yet

- Colpoly 739 S TDSDocument2 pagesColpoly 739 S TDSKristjan PosavecNo ratings yet

- Arkema PEKK kKepstan 8001 TDSDocument3 pagesArkema PEKK kKepstan 8001 TDSstartionlilNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetAdrián SánchezNo ratings yet

- Styrolution PS 485N: High Impact Polystyrene (HIPS)Document2 pagesStyrolution PS 485N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- ALTECH PP-H A 2030/750 GF30 CP: Technical Data SheetDocument2 pagesALTECH PP-H A 2030/750 GF30 CP: Technical Data SheetGufran AhmadNo ratings yet

- PS 416 N - F.T.Document2 pagesPS 416 N - F.T.Inês MorgadoNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Isplen PB180G2MDocument1 pageIsplen PB180G2MTaoufik KheddarNo ratings yet

- Styro Lution Tds 200400070620Document3 pagesStyro Lution Tds 200400070620gv_ScribdNo ratings yet

- Norsodyne H 16239 enDocument1 pageNorsodyne H 16239 enFachrurraziNo ratings yet

- Atlac 430 - 010389Document2 pagesAtlac 430 - 010389Mounir ZerroukNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- MT Series: Three Phase Bridge Power ModulesDocument6 pagesMT Series: Three Phase Bridge Power ModulesengrmfawadazharNo ratings yet

- Z964 Z9641 Ebh de en FRDocument2 pagesZ964 Z9641 Ebh de en FRengrmfawadazharNo ratings yet

- Pureit Excella User Manual PDFDocument31 pagesPureit Excella User Manual PDFengrmfawadazharNo ratings yet

- Service Structure of Engineers - Final On 1st Nov 2016 PDFDocument10 pagesService Structure of Engineers - Final On 1st Nov 2016 PDFSyed Adil JavedNo ratings yet

- A Review On Hydrogen Embrittlement Risk Based Inspection 1688970506Document31 pagesA Review On Hydrogen Embrittlement Risk Based Inspection 1688970506Pranav PramodNo ratings yet

- Irrigation Materials, Tools, Equipment and Structures: What I Need To KnowDocument10 pagesIrrigation Materials, Tools, Equipment and Structures: What I Need To KnowAlmira Mendez100% (2)

- Courtyard As A Building Component ChettiarDocument7 pagesCourtyard As A Building Component ChettiarAkshaya MayakrishnanNo ratings yet

- Housing Quality Standards Guidebook 2013Document34 pagesHousing Quality Standards Guidebook 2013James PilcherNo ratings yet

- Introduction To Steel Reinforcement WorkDocument12 pagesIntroduction To Steel Reinforcement Workalmond2008No ratings yet

- Check List For Installation of Earthing System: Contractor: Sub-ContractorDocument4 pagesCheck List For Installation of Earthing System: Contractor: Sub-ContractorRyn RcioNo ratings yet

- Wavepro-II Catalogue en 1sxh3432001 Rev B 08-2021Document32 pagesWavepro-II Catalogue en 1sxh3432001 Rev B 08-2021Suki GalNo ratings yet

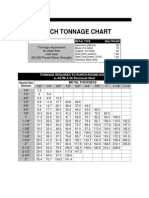

- Punch Tonnage Chart: Tonnage Required To Punch Round Holes in ASTM A-36 Structural SteelDocument1 pagePunch Tonnage Chart: Tonnage Required To Punch Round Holes in ASTM A-36 Structural Steelsmartcad60No ratings yet

- PSV LPG TankDocument8 pagesPSV LPG TankyosafatedenNo ratings yet

- Concrete Pipe vs HDPE Drainage Pipe: A Performance ComparisonDocument15 pagesConcrete Pipe vs HDPE Drainage Pipe: A Performance Comparisonyyanan1118No ratings yet

- Some Notes About Corrosion Coupons InstallationDocument23 pagesSome Notes About Corrosion Coupons InstallationHadi VeyseNo ratings yet

- 5fc5275d6e1cd14138c012f5 - Matsui MC BrochureDocument4 pages5fc5275d6e1cd14138c012f5 - Matsui MC BrochurePedro Del AngelNo ratings yet

- BCM-V U2 Part-A 19-07-2021Document21 pagesBCM-V U2 Part-A 19-07-2021hyperloop707 designNo ratings yet

- CHEVRONS Polypac VeepacDocument18 pagesCHEVRONS Polypac Veepacel haiteNo ratings yet

- Composite Engineering MaterialsDocument69 pagesComposite Engineering MaterialsvialmaNo ratings yet

- Two Way Slab Excel Sheet Vertex Villa Terrace Floor LY LX Ly/Lx RatioDocument15 pagesTwo Way Slab Excel Sheet Vertex Villa Terrace Floor LY LX Ly/Lx RatiokiranNo ratings yet

- PNGFP CatalogueDocument17 pagesPNGFP CatalogueNatasha TahijaNo ratings yet

- CFD-Ch3: 1D Nozzle Flow AnalysisDocument3 pagesCFD-Ch3: 1D Nozzle Flow AnalysisMuhammad HakimNo ratings yet

- Surge CalculationsDocument21 pagesSurge CalculationsHieuNo ratings yet

- Lining of Tank Bottoms 3Document5 pagesLining of Tank Bottoms 3pnonnyNo ratings yet

- Arta 111 - Art and Artisan, Production Process, Medium, Technique, Curation, UnitasDocument60 pagesArta 111 - Art and Artisan, Production Process, Medium, Technique, Curation, UnitasJerwin Samson100% (2)

- Fatigue Ch12Document87 pagesFatigue Ch12Bolaji Suberu100% (1)

- API 570 FormulasDocument2 pagesAPI 570 FormulasArif Mokhtar89% (9)

- Design of Monorail BeamDocument5 pagesDesign of Monorail BeamcadsultanNo ratings yet

- Blatz Ko 1962Document29 pagesBlatz Ko 1962SaHdo AbdelHamidNo ratings yet

- SECTION 211313 Wet Pipe Sprinkler SystemsDocument7 pagesSECTION 211313 Wet Pipe Sprinkler SystemsDanZel DanNo ratings yet

- Welding Advanced Chromium Alloys for High-Temperature ServiceDocument5 pagesWelding Advanced Chromium Alloys for High-Temperature Servicesaji_t1984100% (1)

- (Esben Byskov) Elementary Continuum Mechanics For EveryoneDocument598 pages(Esben Byskov) Elementary Continuum Mechanics For EveryoneMadhushree ProdhanNo ratings yet

- Retail Product GuideDocument74 pagesRetail Product Guideharish GiriNo ratings yet

- Portland CementDocument88 pagesPortland CementShrey Agarwal75% (4)