Professional Documents

Culture Documents

Tds-Tasnee PP h1045

Uploaded by

أبو أميرOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tds-Tasnee PP h1045

Uploaded by

أبو أميرCopyright:

Available Formats

TASNEE PP H1045 POLYPROPYLENE

DESCRIPTION

TASNEE PP H1045 is a Polypropylene Homopolymer with a Melt Flow Rate (MFR) of 4.5 g/10min.

TASNEE PP H1045 is designed for high extrusion speed lines to make stretch tapes, offering low water-carry-

over and low shrinkage. Good balance of strength, shrinkage, splitting tendency. It is compliant to food contact

regulations. Typical applications are weaving tapes for carpet backing, geo-textiles and industrial and sport

fabrics.

TYPICAL PROPERTIES

Physical Method Unit Value

Melt Flow Rate (230°C/2.16 kg) ISO 1133 g/10min 4.5

Melting Temperature ISO 3146 °C 163

Vicat Softening Temperature ISO 306 °C 152

Heat Distortion Temperature @ 455 KPa ISO 75-2 °C 85

Density ISO 1183 g/cm3 0.9

Mechanical Method Unit Value

Tensile Strength @ Yield ISO 527-2 MPa 34

Tensile Elongation @ Yield ISO 527-2 % 9

Flexural Modulus (1% Secant) ISO 178 MPa 1500

Izod Impact Strength (Notched) at 23 °C ISO 180-1A J/m 35

Rockwell Hardness ISO 2039-2 R 100

Typical Processing Conditions*

Extrusion Temperatures : 200 ~ 260 °C

Water Bath Temperature : 15 ~ 40 °C

Orientation Temperatures

Hot plate : 100 ~ 140 °C

Hot rolls : 100 ~ 140 °C

Oven air : 140 ~ 180 °C

Draw Ratio : 1:6 to 1:8

Annealing Temperature : 150 ~ 170 °C

* Processing parameters should only be used as guidelines.

FOOD CONTACT STATUS

TASNEE Polypropylene grade complies with recommendations and statutory regulations in the USA and

European Union countries regarding packaging materials intended to come in contact with foodstuff. For more

details, please, contact TASNEE below or our representative in your area.

SAFETY

The Material Safety Data Sheet (MSDS) contains information regarding health, safety and waste considerations

for TASNEE Polypropylene grade. TASNEE urges each customer or recipient of MSDS to study it carefully to

become aware of and understand the hazards associated with product. The customer should consider consulting

reference works or individuals who are experts in ventilation, toxicology or fire prevention, as necessary or

appropriate to use and understand the data contained in the MSDS.

STORAGE

Polypropylene material should be stored in a cool, dry place with adequate ventilation and absence of direct

sunlight. Storage under improper conditions may initiate degradation process, adversely influencing

processability, properties and visual aspect of transformed articles.

DISCLAIMER

"The information in this publication without prejudice, and is based on our current knowledge and experience

and on a limited number of tests".

"In view of the many factors that may affect processing and application, these data do not relieve the receiver of

this information from the responsibility of carrying out their own tests and experiments; neither do they imply

any legally binding assurance of certain properties or of suitability for a specific purpose of the products made

with or on the basis of the information in this publication".

NATIONAL PETROCHEMICALS INDUSTRIALIZATION MARKETING COMPANY

P.O.Box: 26707 Tel: +966 1 473 4559

Riyadh 11496 Fax: +966 1 473 4580

Kingdom of Saudi Arabia www.tasnee.com

You might also like

- Tds-Tasnee PP h1030Document2 pagesTds-Tasnee PP h1030أبو أميرNo ratings yet

- Tds-Tasnee PP h2245Document2 pagesTds-Tasnee PP h2245أبو أميرNo ratings yet

- Tds-Tasnee PP h4120Document2 pagesTds-Tasnee PP h4120أبو أميرNo ratings yet

- PP h4120 TdsDocument2 pagesPP h4120 TdsengrmfawadazharNo ratings yet

- Tds Tasnee HD b1258Document2 pagesTds Tasnee HD b1258أبو أميرNo ratings yet

- Tds Tasnee 100 Black Revised in 2022Document2 pagesTds Tasnee 100 Black Revised in 2022Amir NawazNo ratings yet

- Tds Tasnee HD f0455Document2 pagesTds Tasnee HD f0455أبو أميرNo ratings yet

- Updated TDS-TASNEE 100 OrangeDocument2 pagesUpdated TDS-TASNEE 100 Orangelamia.elgammalNo ratings yet

- Tds Tasnee HD Im2050 Revised in 2022Document2 pagesTds Tasnee HD Im2050 Revised in 2022Amir NawazNo ratings yet

- Rilsamid® Aesno TL: Main CharacteristicsDocument2 pagesRilsamid® Aesno TL: Main Characteristicsjuliushasan2No ratings yet

- RB206MODocument2 pagesRB206MObobNo ratings yet

- TDS PEEK Filament 1Document2 pagesTDS PEEK Filament 1Krzysztof KardachNo ratings yet

- TDS PEEK Filament PDFDocument2 pagesTDS PEEK Filament PDFRui MatiasNo ratings yet

- BESN Noir P20 TLDocument2 pagesBESN Noir P20 TLjuliushasan2No ratings yet

- Material DataDocument3 pagesMaterial DataR.Ranjan PradhanNo ratings yet

- Daicel PP: Properties PG2N1Document1 pageDaicel PP: Properties PG2N1Chentouf MohammedNo ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- TDS Phi 003Document2 pagesTDS Phi 003dalgido rojano quirozNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- TDS Polidan TA HF V 1.0 June 2017Document3 pagesTDS Polidan TA HF V 1.0 June 2017valdecirnasatoNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- PDS HEX4460p PE80 1Document3 pagesPDS HEX4460p PE80 1art72 talNo ratings yet

- TDS e 006Document2 pagesTDS e 006Paolo VelasquezNo ratings yet

- PS 416 N - F.T.Document2 pagesPS 416 N - F.T.Inês MorgadoNo ratings yet

- ALTECH ABS A 2020/100 GF20: Technical Data SheetDocument1 pageALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- RTP 102 Polypropylene (PP) Glass Fiber: Product Data Sheet & General Processing ConditionsDocument1 pageRTP 102 Polypropylene (PP) Glass Fiber: Product Data Sheet & General Processing ConditionsarmandoNo ratings yet

- 3M Neoprene High Performance Rubber & Gasket Adhesive 1300LDocument6 pages3M Neoprene High Performance Rubber & Gasket Adhesive 1300LIventNo ratings yet

- Tpo 0030 RTP 4920 1620 Uv IsoDocument2 pagesTpo 0030 RTP 4920 1620 Uv IsoVenkata ChadaNo ratings yet

- RTP 299 X 90078 SSC 63023Document2 pagesRTP 299 X 90078 SSC 63023kls.thorodinsonNo ratings yet

- TOTAL Polystyrene 1441: Material DatasheetDocument3 pagesTOTAL Polystyrene 1441: Material DatasheetAlbert FortunatoNo ratings yet

- Epoxy Component Prepreg: Typical Applications: General Purpose - VisualDocument3 pagesEpoxy Component Prepreg: Typical Applications: General Purpose - VisualJohnnyNo ratings yet

- Tasnee LD 1925as: Low Density PolyethyleneDocument2 pagesTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaNo ratings yet

- Starflam PA66 25VDocument2 pagesStarflam PA66 25VjahabarsathickNo ratings yet

- Tds hd5403pdfDocument2 pagesTds hd5403pdfAthonioMourinhoNo ratings yet

- HD5301AADocument2 pagesHD5301AAAnonymous K8jq6tYGNo ratings yet

- PP Mosten EH 501: Technical DatasheetDocument2 pagesPP Mosten EH 501: Technical DatasheetBanupriya BalasubramanianNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetAdrián SánchezNo ratings yet

- Vesbo PPR EnglishDocument50 pagesVesbo PPR Englishcool.boys4200No ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Repsol Isplen PB195K3MDocument1 pageRepsol Isplen PB195K3MMary HudsonNo ratings yet

- Styro Lution Tds 200400070620Document3 pagesStyro Lution Tds 200400070620gv_ScribdNo ratings yet

- VG621 PPGF30 BorealisDocument3 pagesVG621 PPGF30 BorealisLeandro LacerdaNo ratings yet

- FT TOTAL CARTER EP 1500-2200-3000 (Anglais)Document1 pageFT TOTAL CARTER EP 1500-2200-3000 (Anglais)Olivier DupNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- Styron ATECH 1175 DatasheetDocument3 pagesStyron ATECH 1175 DatasheetbobNo ratings yet

- PPH 4069Document1 pagePPH 4069tranoNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- HJ311AIDocument3 pagesHJ311AIdignityymartNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- ALTECH PP-H A 2030/750 GF30 CP: Technical Data SheetDocument2 pagesALTECH PP-H A 2030/750 GF30 CP: Technical Data SheetGufran AhmadNo ratings yet

- Isplen PB180G2MDocument1 pageIsplen PB180G2MTaoufik KheddarNo ratings yet

- Out of Autoclave Epoxy Component Prepreg: Typical Applications: General Purpose - VisualDocument3 pagesOut of Autoclave Epoxy Component Prepreg: Typical Applications: General Purpose - VisualJohnnyNo ratings yet

- Styrolution PS 485N: High Impact Polystyrene (HIPS)Document2 pagesStyrolution PS 485N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- BioPBS FZ71PM and FZ71PB Technical Data Sheet For Injection MoldingDocument1 pageBioPBS FZ71PM and FZ71PB Technical Data Sheet For Injection Moldingpaolo.pradaNo ratings yet

- POM - KEPITAL F20-03 - Standard GradeDocument2 pagesPOM - KEPITAL F20-03 - Standard GradeMadhav RajpurohitNo ratings yet

- VG602Document2 pagesVG602LucasNo ratings yet

- Tds-Tasnee LD 1925asDocument2 pagesTds-Tasnee LD 1925asأبو أميرNo ratings yet

- Tds-Tasnee LD 0725nDocument2 pagesTds-Tasnee LD 0725nأبو أميرNo ratings yet

- Tds-Tasnee LD 1925asDocument2 pagesTds-Tasnee LD 1925asأبو أميرNo ratings yet

- Tds-Tasnee PP h4260mDocument1 pageTds-Tasnee PP h4260mأبو أميرNo ratings yet

- Tds-Tasnee PP h4260mDocument1 pageTds-Tasnee PP h4260mأبو أميرNo ratings yet

- Product DatasheetDocument1 pageProduct Datasheetأبو أميرNo ratings yet

- Aqueous Absorption of Nitrogen Oxides Induced by - ThesisDocument194 pagesAqueous Absorption of Nitrogen Oxides Induced by - ThesisabhijeetksagarNo ratings yet

- Column Chromatography - Principle, Procedure, ApplicationsDocument1 pageColumn Chromatography - Principle, Procedure, ApplicationsSahiba ChadhaNo ratings yet

- Kineticsprelims 2010Document2 pagesKineticsprelims 2010Clarissa AlfaroNo ratings yet

- Biochar and Its Composites: Ashok Kumar Nadda EditorDocument241 pagesBiochar and Its Composites: Ashok Kumar Nadda EditorLiliana BeruNo ratings yet

- Astm G3Document10 pagesAstm G3Mayra Lizeth Mayorga LaguadoNo ratings yet

- מעגלים ספרתיים- פתרון (חלקי ומבולגן) לתרגיל בית 2 - 2012Document5 pagesמעגלים ספרתיים- פתרון (חלקי ומבולגן) לתרגיל בית 2 - 2012RonNo ratings yet

- Biochemistry 4th Edition Mathews Test Bank 1Document36 pagesBiochemistry 4th Edition Mathews Test Bank 1loribowersbwknifoyxe100% (23)

- Task 1: Volumetric Analysis (Titration)Document3 pagesTask 1: Volumetric Analysis (Titration)Obby-GiftMwambaKachecheNo ratings yet

- KNUST Thermodynamics 1 - 141117Document117 pagesKNUST Thermodynamics 1 - 141117KhojoNo ratings yet

- Penetrant Testing ReportDocument8 pagesPenetrant Testing ReportBabar Ali BaigNo ratings yet

- Determination of Vapor PressureDocument5 pagesDetermination of Vapor PressureAbhinav AnandNo ratings yet

- Human AST Protocol Book v1 Ab263881 (Website)Document32 pagesHuman AST Protocol Book v1 Ab263881 (Website)Oanna ChippNo ratings yet

- Astm D5542 - 2004Document10 pagesAstm D5542 - 2004Teymur RegenmaisterNo ratings yet

- The Behavior of Silica in Geothermal Brine From Dieng Geothermal Power Plant, Indonesia PDFDocument6 pagesThe Behavior of Silica in Geothermal Brine From Dieng Geothermal Power Plant, Indonesia PDFAngga Ario TirtaNo ratings yet

- Advantages of Burying A PipeDocument1 pageAdvantages of Burying A PipeSharun SureshNo ratings yet

- Chapter 10: Gases Topic 10.1: Gases in The Air True / FalseDocument8 pagesChapter 10: Gases Topic 10.1: Gases in The Air True / FalseFaizanAusNo ratings yet

- Group 2 QPDocument11 pagesGroup 2 QPmNo ratings yet

- CHT 8 and 10 HW 4 SolutionDocument4 pagesCHT 8 and 10 HW 4 SolutionCharleruanNo ratings yet

- Brainmaster Tanzania g3 Scie Monthly Test 2024Document4 pagesBrainmaster Tanzania g3 Scie Monthly Test 2024salumfahreezNo ratings yet

- D 7566 - 18 PDFDocument34 pagesD 7566 - 18 PDFitbwng100% (1)

- Chemistry IGCSE Edexcel QP-3 June 2016Document20 pagesChemistry IGCSE Edexcel QP-3 June 2016Sheikh AfnanNo ratings yet

- SCH3U Periodic Table TrendsDocument7 pagesSCH3U Periodic Table TrendsSteve M Hall100% (1)

- Plasmadyeing 200320162358Document24 pagesPlasmadyeing 200320162358Ayman SebaeiNo ratings yet

- Speciality PolymersDocument63 pagesSpeciality PolymersChini ChineeNo ratings yet

- Ap Unit7 Worksheet AnswersDocument5 pagesAp Unit7 Worksheet Answersburcak gecNo ratings yet

- Exact Method For Calculating Longitudinal Bending Moment of A ShipDocument15 pagesExact Method For Calculating Longitudinal Bending Moment of A ShipMahmudul Hasan TanvirNo ratings yet

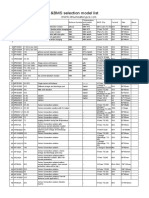

- LLT PCB Model List ADocument2 pagesLLT PCB Model List AÁlvaro Satué Crespo100% (1)

- Azeotropic DistillationDocument3 pagesAzeotropic DistillationibikgibikNo ratings yet

- Optimization of Machining Parameters in Electro Chemical Machining of Al5059 - SiC - MoS2 Composites Using Taguchi MethodDocument5 pagesOptimization of Machining Parameters in Electro Chemical Machining of Al5059 - SiC - MoS2 Composites Using Taguchi MethodFathurrahman GultomNo ratings yet

- 2 - 11 July 2000 Copenhagen: Preparatory ProblemsDocument50 pages2 - 11 July 2000 Copenhagen: Preparatory ProblemsJoni WaldyNo ratings yet