Professional Documents

Culture Documents

Equipment Perf. Check

Equipment Perf. Check

Uploaded by

ENOD CONTROL E INSPECCION S.A.C.Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment Perf. Check

Equipment Perf. Check

Uploaded by

ENOD CONTROL E INSPECCION S.A.C.Copyright:

Available Formats

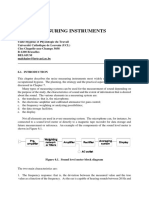

Equipment performance check :

Ulllll

The calibration and performance of manual ultrasonic test

system can be checked using the IIW - V1 block.

Normal Probe :

S : System Sensitivity check, with the hole signal set to 75%

screen height, minimum 40 dB reserved gain required.

R : Resolution check [ ability to produce separate indication ]

The signals from the 85, 91 and 100 mm distances should be

displayed on the screen without overlapping.

D2 : Dead zone, signal from hole indicates 10 mm or less.

D1 : Dead zone, signal from hole indicates, 5 mm or less.

P : Checks sound generating ability of the system. With the

gain at maximum, 5 full screen signals from the 23 mm

Perspex insert, using a 2 MHz probe should be obtained.

R1 and R2 : Range calibration and Horizontal Linearity.

Angle Probe :

E: Beam exit point, when the signal from the radius

becomes maximum, the exit point of the probe coincides

with the center mark of the scale on the face of the block.

S: Sensitivity check. with the signal from the radius set to

100%, minimum 40 dB reserved gain required.

R: Range calibration for angle probe.

A1: and A2: Angle check, when the signal from the hole

becomes maximum, the exit point of the probe may coincide

with one of the marks on the face of the block to indicate

the refracted beam angle of the probe.

Horizontal Linearity : For accurately locating reflectors, a linear

distance scale is essential.

A 100 mm range is accurately calibrated from location R1.

With the probe at position R2, signals should appear exactly

at 12.5, 25, 37.5 and 50 th division on the screen. A signal

position deviation by more than 1% indicates, non linear

distance scale. This check should be carried out over the

maximum range used for actual testing.

The ultrasonic instrument must provide linear vertical

presentation within +/- 5% of the full screen height.

Screen Height Linearity : Using a viscous couplant, a normal

beam probe is positioned at a suitable location of the block

to give a 2 : 1 ratio of amplitudes between two steady

signals. When the attenuator is changed in 2 dB steps, the

smaller amplitude signal must remain 50% of the larger

amplitude within +/- 5% of full screen height.

Amplitude Control Linearity : The accuracy of the amplitude

control of the ultrasonic equipment is also essential.

Using a viscous couplant, a normal beam probe is

positioned on the block to produce a 80% steady signal.

With the attenuator changing by 2 dB steps, the signal

amplitude shall change corresponding to the figure given

below. A deviation of +/- 5% is considered acceptable.

A 50% signal, when reduced by –24 dB, should be

clearly detectable. ( Dynamic range )

Signal to Noise ratio : After setting a signal to 20% screen

height, the gain is further increased till the base line noise

equals 20%. The difference in gain is the signal to noise

ratio and indicates the quality of the amplifier.

K. Chatterjee, 75643 Center for NDT P 00 Rv 04 Self study material.

You might also like

- Acceptance Criteria For Ultrasonic Testing: ProbeDocument5 pagesAcceptance Criteria For Ultrasonic Testing: Probehamdi mallouliNo ratings yet

- Angle Beam InspectionDocument10 pagesAngle Beam InspectionMahade Hasan DipuNo ratings yet

- Ultrasonic Testing: Weld Inspection Using AWS D1.1Document65 pagesUltrasonic Testing: Weld Inspection Using AWS D1.1CLIFFORDPANo ratings yet

- Draft PAUT Specification 16.11.18Document14 pagesDraft PAUT Specification 16.11.18teopan PanNo ratings yet

- Ultrasonic Testing of Welds in Accordance With AWS D1Document5 pagesUltrasonic Testing of Welds in Accordance With AWS D1Woodrow FoxNo ratings yet

- Cảm biến siêu âm- intelligent ultrasonic level meterDocument43 pagesCảm biến siêu âm- intelligent ultrasonic level meterNguyen LuanNo ratings yet

- TG550 Service ManualDocument27 pagesTG550 Service ManualĐinh Văn ĐoànNo ratings yet

- NDT-P-032, Ca - Libration of UT Instrument.Document3 pagesNDT-P-032, Ca - Libration of UT Instrument.Mohamed HassanNo ratings yet

- v1 Block Calibration in UtDocument1 pagev1 Block Calibration in Utjaimin100100% (4)

- Medical Device Technical Specifications ArmeniaDocument27 pagesMedical Device Technical Specifications ArmeniaKartik PrabhakarNo ratings yet

- 421m AGC-Leveler With Mic/Line Input: He Symetrix 421M Is A Sophisticated Audio Gain Controller, But What ItDocument2 pages421m AGC-Leveler With Mic/Line Input: He Symetrix 421M Is A Sophisticated Audio Gain Controller, But What Itmr.sanyNo ratings yet

- Y1 - Scope ExptDocument9 pagesY1 - Scope Exptasantejayden88No ratings yet

- Microsonic Zws-24 CD QSDocument10 pagesMicrosonic Zws-24 CD QSrocidiazNo ratings yet

- Distance & Sensitivity CalDocument8 pagesDistance & Sensitivity CalFadoju Kolade Stephen100% (1)

- UT Equipment Calibration ProcedureDocument14 pagesUT Equipment Calibration ProcedureSantanu Saha100% (5)

- Lab 03Document5 pagesLab 03umerNo ratings yet

- Manual Ultrasonic Testing - WeldDocument5 pagesManual Ultrasonic Testing - Weldkiki270977No ratings yet

- Screen Height Linearity - Asme VDocument2 pagesScreen Height Linearity - Asme VAngelTinocoNo ratings yet

- Lab 03Document5 pagesLab 03SI ButtNo ratings yet

- Calibration Steps Using Ultrasonic Flaw DetectorDocument7 pagesCalibration Steps Using Ultrasonic Flaw DetectorShahazad ShaikNo ratings yet

- Calibration of Ultrasonic Flaw Detection SystemDocument3 pagesCalibration of Ultrasonic Flaw Detection SystemalzakiNo ratings yet

- Vna Noise Measurment Tech.Document6 pagesVna Noise Measurment Tech.anwar sayeedNo ratings yet

- Calibration of The Testing SystemDocument11 pagesCalibration of The Testing SystemZanuardi YahyaNo ratings yet

- UT Test ProcedureDocument21 pagesUT Test ProcedureAmit HasanNo ratings yet

- NDT NDT (Ultra Sonic Test) : Detailed Specifications of Ultrasonic Flaw Detector NOVOTEST UD-1 ScanDocument3 pagesNDT NDT (Ultra Sonic Test) : Detailed Specifications of Ultrasonic Flaw Detector NOVOTEST UD-1 ScanBob Yeltsin SitompulNo ratings yet

- VHF Omni-Directional Range (VOR)Document2 pagesVHF Omni-Directional Range (VOR)Shkelzen Goxhaj100% (1)

- Ultrasonic Testing ProcedureDocument4 pagesUltrasonic Testing ProcedureAradea Permana100% (1)

- Genelec Monitor Setup Guide 2011Document17 pagesGenelec Monitor Setup Guide 2011Bubu PokoNo ratings yet

- Ut Written InstructionDocument6 pagesUt Written Instructionmm100% (1)

- Waveform Monitor/Vectorscope, PM 5661 Waveform Monitor/Vectorscope, SC-H, PM 5661/70Document6 pagesWaveform Monitor/Vectorscope, PM 5661 Waveform Monitor/Vectorscope, SC-H, PM 5661/70Roberto BarbieriNo ratings yet

- Tofd Calibration: (8) : ChecksDocument6 pagesTofd Calibration: (8) : ChecksLương Hồ Vũ0% (1)

- 10 Hints For Making Successful Noise Figure Measurements: Keysight TechnologiesDocument20 pages10 Hints For Making Successful Noise Figure Measurements: Keysight TechnologiesHelen PerezNo ratings yet

- Thandar TG550 UserDocument43 pagesThandar TG550 Usertechnical-manualsNo ratings yet

- NoiseTemp HelpfileDocument4 pagesNoiseTemp HelpfilemortizNo ratings yet

- EYE DiagramDocument10 pagesEYE DiagramNuwan WeerasekaraNo ratings yet

- Use of OscilloscopeDocument13 pagesUse of Oscilloscopesonja_ŽarićNo ratings yet

- DCS Original (2) FinalDocument46 pagesDCS Original (2) FinalRaji RNo ratings yet

- 225 Lock-In Amplifier: 225.02 Bentham Instruments LTDDocument12 pages225 Lock-In Amplifier: 225.02 Bentham Instruments LTDMitchell Guy KenneyNo ratings yet

- Lab FinalDocument47 pagesLab FinalRaji RNo ratings yet

- UD2301 OverviewDocument17 pagesUD2301 OverviewВладислав ДурневNo ratings yet

- Noise6 PDFDocument16 pagesNoise6 PDFkskumargieNo ratings yet

- Av-17 Professional Ramp Tester Users Manual: AV-17 VERSION 3.04 and Up - Starting November 2017Document16 pagesAv-17 Professional Ramp Tester Users Manual: AV-17 VERSION 3.04 and Up - Starting November 2017maury6969No ratings yet

- Sound Engineering PDFDocument16 pagesSound Engineering PDFkskumargieNo ratings yet

- Wandel & Goltermann Spm19 DatasheetDocument6 pagesWandel & Goltermann Spm19 Datasheetsuleiman hewadiNo ratings yet

- Antenna MeasurementsDocument10 pagesAntenna MeasurementsTariq SaboeraliNo ratings yet

- 5L4N SMDocument144 pages5L4N SMPetar PetrovicNo ratings yet

- AFG Thurlby Thandar Tg230Document4 pagesAFG Thurlby Thandar Tg230onafetsNo ratings yet

- Polarity Test Procedure: Application and Technical Support For Audio Precision APWIN UsersDocument2 pagesPolarity Test Procedure: Application and Technical Support For Audio Precision APWIN Userspolanco999No ratings yet

- Ex No 15 STUDY AND EXPERIMENT ON ULTRASONIC FLAW DETECTOR (MODEL Einstein - II TFT)Document10 pagesEx No 15 STUDY AND EXPERIMENT ON ULTRASONIC FLAW DETECTOR (MODEL Einstein - II TFT)Jagajith Sathis Chandran NairNo ratings yet

- 3800 IndicatorDocument3 pages3800 IndicatorP Shashidhar Chavan0% (1)

- DC Mail - UrlDocument3 pagesDC Mail - UrlkrishnaNo ratings yet

- 9 IndexDocument25 pages9 IndexbuturcasNo ratings yet

- Pass Ultrasound Physics Exam Review Match the AnswersFrom EverandPass Ultrasound Physics Exam Review Match the AnswersRating: 4 out of 5 stars4/5 (4)

- Adaptive Filter: Enhancing Computer Vision Through Adaptive FilteringFrom EverandAdaptive Filter: Enhancing Computer Vision Through Adaptive FilteringNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Pass Ultrasound Physics Exam Study Guide ReviewFrom EverandPass Ultrasound Physics Exam Study Guide ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- Training Economics of Petroleum RefiningDocument4 pagesTraining Economics of Petroleum RefiningENOD CONTROL E INSPECCION S.A.C.No ratings yet

- 4 - Codes and Regulations MotorsDocument6 pages4 - Codes and Regulations MotorsENOD CONTROL E INSPECCION S.A.C.No ratings yet

- 01-01-4011-R0 (Simbología P&IDs)Document1 page01-01-4011-R0 (Simbología P&IDs)ENOD CONTROL E INSPECCION S.A.C.No ratings yet

- TWI UT Training Question Bank UltrasonicDocument85 pagesTWI UT Training Question Bank UltrasonicENOD CONTROL E INSPECCION S.A.C.No ratings yet

- MT Illustrations - Figures 1Document41 pagesMT Illustrations - Figures 1ENOD CONTROL E INSPECCION S.A.C.No ratings yet

- Dokumen - Tips - Zte ZXSDR Bts Structure and PrincipleDocument65 pagesDokumen - Tips - Zte ZXSDR Bts Structure and PrincipleEze Alexander IkNo ratings yet

- Paulo Bonavides Ciencia Politica Cap 12Document28 pagesPaulo Bonavides Ciencia Politica Cap 12Isabelly VieiraNo ratings yet

- Philips MCM530, MCM-590 PDFDocument76 pagesPhilips MCM530, MCM-590 PDFDaniel FagundesNo ratings yet

- Participle Clauses Exercises 4 5 6 7 AnsDocument4 pagesParticiple Clauses Exercises 4 5 6 7 Ansruby Javaid21No ratings yet

- Locking of Hene Laser Modes Induced by Synchronous Intracavity ModulationDocument3 pagesLocking of Hene Laser Modes Induced by Synchronous Intracavity ModulationMohamad paidarNo ratings yet

- Airport Chart HKT - VTSPDocument34 pagesAirport Chart HKT - VTSPaoonjaiNo ratings yet

- Dtic Ada038803Document703 pagesDtic Ada038803jrcsarmaNo ratings yet

- Call Admission ControlDocument86 pagesCall Admission Controlbr 55No ratings yet

- Regulation of Government of The Republic of Indonesia Number 46 of 2021Document71 pagesRegulation of Government of The Republic of Indonesia Number 46 of 2021Rr Sekar AyuNo ratings yet

- 6505 Piranha Manual (GERMAN)Document6 pages6505 Piranha Manual (GERMAN)Francisco Zarate TapiaNo ratings yet

- Crude Oil Tankers: K-Gauge CLS Tank Gauging SystemDocument19 pagesCrude Oil Tankers: K-Gauge CLS Tank Gauging SystemCem BozNo ratings yet

- Transmitting Chokes For VHF and UHFDocument2 pagesTransmitting Chokes For VHF and UHFOctavian S.No ratings yet

- Mimo LetterDocument4 pagesMimo Letterwaqas1166No ratings yet

- Acc Harga JualDocument1 pageAcc Harga JualAldesvia PutriNo ratings yet

- FaultMemoryList VIN7-B914278 PDFDocument2 pagesFaultMemoryList VIN7-B914278 PDFZakaria ElNo ratings yet

- User'S Guide: MODEL 7511WDocument32 pagesUser'S Guide: MODEL 7511WMartin CerdaNo ratings yet

- BKK13103Document23 pagesBKK13103MUHAMMAD ALIFF QAYYUM BIN ABDULLAH MoeNo ratings yet

- Scx20 21 Brochure en LRDocument6 pagesScx20 21 Brochure en LRPapa StasNo ratings yet

- Revisiones BTS SingleRan HuaweiDocument13 pagesRevisiones BTS SingleRan HuaweiOscar floresNo ratings yet

- Man Instr DPS110Document100 pagesMan Instr DPS110Agus SulistioNo ratings yet

- 6.976 High Speed Communication Circuits and Systems Advanced Frequency SynthesizersDocument51 pages6.976 High Speed Communication Circuits and Systems Advanced Frequency SynthesizersAhmed mohyNo ratings yet

- Satellite EclipseDocument22 pagesSatellite EclipseAma WeshNo ratings yet

- Đinh Thị Thanh. Chapter 2. Unit 3.21.4Document6 pagesĐinh Thị Thanh. Chapter 2. Unit 3.21.4Ma Minh HươngNo ratings yet

- Ald Maintenance Link Failure Alarm TutorialDocument16 pagesAld Maintenance Link Failure Alarm TutorialRv Salazar100% (1)

- 26G Radar Level MeterDocument14 pages26G Radar Level Meterilopera1971No ratings yet

- 14 - CPL Questions - Communication ProcDocument24 pages14 - CPL Questions - Communication ProcMoshiurRahmanNo ratings yet

- Ces Deck Oper TankerDocument388 pagesCes Deck Oper TankerPrzemysław BieleckiNo ratings yet

- GALI-39Document4 pagesGALI-39nguyentienduy1512No ratings yet

- HY OT SW WP SVR100 EN 210212Document7 pagesHY OT SW WP SVR100 EN 210212Predrag VojtNo ratings yet

- Icao Annex 10 Aeronauticaltelecommunicationsvolumev-AeronauticalDocument42 pagesIcao Annex 10 Aeronauticaltelecommunicationsvolumev-AeronauticalJeremia SigalinggingNo ratings yet