Professional Documents

Culture Documents

DHA-7 Manual F 60101-03

Uploaded by

rupeshkumar642mdsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DHA-7 Manual F 60101-03

Uploaded by

rupeshkumar642mdsCopyright:

Available Formats

DHA-7

Downhole Hydrophone Array

P/N 60101-03 Rev. F

May 6, 2012

Operation Manual

GEOMETRICS, INC.

2190 Fortune Drive

San Jose, CA 95131 USA

Tel: (408) 954-0522

Fax: (408) 954-0902

sales@geometrics.com

support@geometrics.com

www.geometrics.com

COPYRIGHT © 2011, 2012

Table of Contents

1 – INTRODUCTION ....................................................................................................... 4

2 – SYSTEM COMPONENTS........................................................................................ 5

2.1 CABLE.................................................................................................................. 5

2.1.1 Hydrophones ............................................................................................... 6

2.1.2 Hydrophone Preamplifiers.......................................................................... 6

2.1.3 Lead Cable Connector Terminations.......................................................... 6

2.1.4 Tail Weight.................................................................................................. 8

2.1.5 Meter Marks................................................................................................ 8

2.1.6 Cable Reel................................................................................................... 9

2.2 POWER SUPPLY AND REQUIREMENTS ................................................................ 10

2.2.1 DHA-7/MicroEel Battery Pack ................................................................. 10

2.2.2 Power Consumption.................................................................................. 11

2.2.3 AC Battery Charger .................................................................................. 12

3 – SYSTEM SET-UP.................................................................................................... 13

3.1 INTERCONNECTIONS........................................................................................... 13

3.2 DEPLOYMENT .................................................................................................... 13

3.3 BATTERY CHARGING ......................................................................................... 14

4 – APPENDIX ............................................................................................................... 15

4.1 CONNECTOR WIRING ......................................................................................... 15

4.2 CALIBRATION..................................................................................................... 16

4.3 SPECIFICATIONS ................................................................................................. 17

4.4 WARRANTY AND SERVICE ................................................................................. 18

DHA-7 Downhole Hydrophone Array Operation Manual Page 2 of 18

Rev. F 050612 du

List of Figures

Figure 1. DHA-7 Downhole Hydrophone Array connected to a Geode seismograph with

laptop PC controller. ................................................................................................... 4

Figure 2. Array cable with hydrophone element and preamplifier pod............................. 5

Figure 3. Lead cable connector terminations (NK-27 termination not shown). ................ 7

Figure 4. Tail weight.......................................................................................................... 8

Figure 5. Meter mark. ........................................................................................................ 9

Figure 6. DHA-7/MicroEel Battery Pack with AC battery charger................................. 10

Figure 7. Detail of DHA-7/MicroEel Battery Pack. ........................................................ 11

Figure 8. DHA-7/MicroEel-D Battery Pack wiring......................................................... 15

DHA-7 Downhole Hydrophone Array Operation Manual Page 3 of 18

Rev. F 050612 du

1 – Introduction

The DHA-7 Downhole Hydrophone Array (Figure 1) is designed for high-resolution

seismic borehole imaging. It is ideal for shallow gas and mining investigations,

earthquake engineering and foundation studies, and teaching and research. The array is

suited for use in water-filled, cased and uncased, wide- to narrow-diameter boreholes.

The DHA-7 uses unique proprietary polymer hydrophones, which unlike ceramic

hydrophones are non-shattering and require no export license when used in the downhole

configuration. Polymer hydrophones provide superior performance and durability under

the rigors of borehole applications with a stable signal response up to 10 kHz.

Figure 1. DHA-7 Downhole Hydrophone Array connected to a Geode seismograph with laptop PC

controller.

This manual provides operating instructions, including description of the DHA-7 system

components, setup, calibration, and warranty.

DHA-7 Downhole Hydrophone Array Operation Manual Page 4 of 18

Rev. F 050612 du

2 – System Components

The standard DHA-7 Downhole Hydrophone Array system includes the following items:

Active section cable with integrated lead cable and tail eye bolt, wound on reel

Tail weight (6-kg) with stainless steel shackle

DHA-7/MicroEel Battery Pack

Universal AC battery charger for the DHA-7/MicroEel Battery Pack

CD with support documents (*.pdf) including the operations manual, connector

wiring tables, and hydrophone calibration plots

2.1 Cable

The active section consists of a series of pods, the number equaling the number of

channels ordered, either 12 or 24 as a standard; other channel counts are available

through custom order. The largest channel number is always wired as the deepest

hydrophone. Each pod contains one hydrophone and one preamplifier that are in-line

molded to a multi-conductor cable with a polyurethane encasement (Figure 2). The cable

itself is triple-sealed with an abrasion-resistant polyurethane jacket and contains a Kevlar

center stress core. The available pod intervals range from 1 to 5 m in length; the interval

can be as small as 0.5 m through custom order.

Figure 2. Array cable with hydrophone element and preamplifier pod.

The lead and active sections are one integrated piece, with no interconnection on the

cable in between the two sections. The total maximum length, including the lead and the

active section, is 400 m.

DHA-7 Downhole Hydrophone Array Operation Manual Page 5 of 18

Rev. F 050612 du

2.1.1 Hydrophones

The array uses Geometrics’ unique proprietary polymer hydrophones. The hydrophone

incorporates design features offering superior performance compared to previous

polymer hydrophone designs as well as the traditional PZT ceramic-type hydrophones.

Specifically, it is non-shattering and incorporates an isolating platform, making it

immune to cable-borne energy. In addition, other design aspects allow its response to

acoustic pressure alone to dominate the output.

2.1.2 Hydrophone Preamplifiers

The true differential preamplifier used with the hydrophone is of a single-pole low-cut

and a single pole high-cut design. The low-cut frequency is determined by the ½π RC

time constant which is related to the element capacitance and the input resistance of the

preamplifier front-end. The preamplifier features exceptionally low noise. Nominal

element capacitance is 5 nF at 22 degrees C. The design also provides full voltage

regulation at each preamplifier. The voltage regulator isolates each channel from the

other which is desired when all preamplifiers share a common power bus.

2.1.3 Lead Cable Connector Terminations

The standard topside lead cable termination is a Y-type with one 61-socket connector

(PT06J-24-61S) for analog output, and one 4-pin connector [PT06A-8-4P(SR)] for power

connection to the DHA-7/MicroEel Battery Pack (Figure 3). As an option, the analog

output termination may be ordered with a 27-socket connector (NK-27-21C) instead of

the 61-socket connector. Adaptor cables are also available to connect to seismographs

with other analog input connector types.

DHA-7 Downhole Hydrophone Array Operation Manual Page 6 of 18

Rev. F 050612 du

61-socket

connector

4-pin

connector

Figure 3. Lead cable connector terminations (NK-27 termination not shown).

DHA-7 Downhole Hydrophone Array Operation Manual Page 7 of 18

Rev. F 050612 du

2.1.4 Tail Weight

The tail end of the active section includes about one meter of extra cable with an

integrated stainless steel tail eye bolt used to receive the 6-kg stainless steel tail weight

(Figure 4). The tail weight must be attached to the tail eye bolt with the supplied

interconnecting stainless steel shackle. The use of other tail weights of a different

configuration and/or weight is not recommended.

Figure 4. Tail weight.

2.1.5 Meter Marks

The array cable may be ordered with meter marks as a custom option. The marks appear

on the lead cable as slight bulb-outs with the measurement value indicated (Figure 5).

Measurements start at the active section and span the length of the lead cable to the

topside end. The in-line arrow indicates the decrement direction and the cross-line arrow

indicates the exact position of the indicated measurement value.

DHA-7 Downhole Hydrophone Array Operation Manual Page 8 of 18

Rev. F 050612 du

Figure 5. Meter mark.

2.1.6 Cable Reel

The array is shipped wound on a reel for storage, transport, and deployment. The reel is

fully composed of certified (US-07OP HT) wood, to comply with international shipping

regulations.

DHA-7 Downhole Hydrophone Array Operation Manual Page 9 of 18

Rev. F 050612 du

2.2 Power Supply and Requirements

The array is powered by the DHA-7/MicroEel Battery Pack. The battery pack is

rechargeable using the included AC battery charger.

2.2.1 DHA-7/MicroEel Battery Pack

The DHA-7/MicroEel Battery Pack (Figure 6) contains two 12V DC deep discharge (5

Amp-hour) sealed lead-acid batteries used in a ±12V DC differential power

configuration. The array power lead is connected to the battery pack via the 4-socket

connector located on the right-hand side of the battery pack. This connector is also used

to connect the AC battery charger. Next to the connector is a grounding post (¼”-20 bolt

and nut).

AC battery

charger

Battery

Pack

Figure 6. DHA-7/MicroEel Battery Pack with AC battery charger.

DHA-7 Downhole Hydrophone Array Operation Manual Page 10 of 18

Rev. F 050612 du

The battery pack front panel includes a Power ON/OFF switch, a VOLTAGE (Volts)

meter, a CURRENT (Amps) meter with the associated +/- polarity switches for each

respective meter (Figure 7). The metering provides a method of measuring the individual

battery voltage and current being supplied to the array.

Figure 7. Detail of DHA-7/MicroEel Battery Pack.

The DHA-7 is designed to be powered by the DHA-7/MicroEel Battery Pack; use of

another power source is not advised and could damage the array and void the warranty.

In addition, under no circumstances should power to the array be shared with another

instrument.

2.2.2 Power Consumption

Each hydrophone preamplifier draws approximately ±10.8 mA per channel. Based on

this draw, a 12-channel array has a total current of 130 mA, and a 24-channel array has a

total current of 260 mA. The battery pack, with two 5 Amp-hour batteries, should have

sufficient capacity to power the array for the desired length of time. If the batteries are

fully charged, a 24-channel array can be powered continuously for approximately 19

hours (5 Amp-hours divided by 260 mA).

The actual operating time will vary depending on the state, temperature, and age of the

batteries. The ideal battery operation temperature is between 41 to 77 degrees F (5 to 25

DHA-7 Downhole Hydrophone Array Operation Manual Page 11 of 18

Rev. F 050612 du

degrees C). Long-term exposure to temperatures above 106 degrees F (41 degrees C) can

shorten the life of the batteries. As temperature decreases, the available battery capacity

and performance are reduced; however, this is not a permanent condition and capacity

will be recovered as temperature rises.

2.2.3 AC Battery Charger

The AC Battery Charger is suitable for use anywhere in the world with a universal input

from 90V AC to 264V AC. The output is 1.5 Amps constant current at 24V DC.

Depending on the recharging mode of the charger and the state of the batteries, output

levels will vary.

DHA-7 Downhole Hydrophone Array Operation Manual Page 12 of 18

Rev. F 050612 du

3 – System Set-up

3.1 Interconnections

The procedure for setting up the DHA-7, DHA-7/MicroEel Battery Pack, and

seismograph interconnections is as follows.

1) With the battery pack power switch in the OFF position, connect the 4-pin power

connector on the cable lead to the 4-socket power connector on the battery pack.

2) Move the battery pack power switch to the ON position. The CURRENT and

VOLTAGE meters will turn on and indicate the status of the batteries.

Toggle the +/- switch next to the CURRENT meter to measure battery draw for

each polarity. Each current measurement should read approximately 130 mA for

a 12-channel array and 260 mA for a 24-channel array.

Next, toggle the +/- switch next to the VOLTAGE meter to measure battery

potential for each polarity. The voltage should read from 11.8V DC to 13.4V DC

for each battery. The array will operate with a minimum voltage of

approximately 10.8V DC depending in the length of the cable lead. Recharge the

battery pack (see Section 3.3) immediately when the minimum permissible

voltage is reached.

3) Connect the analog output connector on the cable lead to the seismograph and

check for incoming signal. It is also recommended that the seismograph gain be

set to the lowest possible setting.

For ideal testing conditions allowing optimal hydrophone response, it is

recommended that the hydrophone section of each pod not be in direct contact

with any solid surface, such as other parts of the cable.

3.2 Deployment

Tightly fasten the interconnecting stainless steel shackle between the tail eye bolt and the

tail weight to avoid loss of the weight down the borehole.

Use of other tail weights of a different configuration and/or weight are not recommended.

Most arrays are easily deployed off the reel by hand or a small winch may be desired.

Avoid rubbing the cable jacket on sharp or rough edges, such as the top of the well

casing.

DHA-7 Downhole Hydrophone Array Operation Manual Page 13 of 18

Rev. F 050612 du

3.3 Battery Charging

A new DHA-7/MicroEel Battery Pack should be charged for a minimum of 20 hours

prior to use. In addition, the temperature when the charging occurs should be between 41

to 77 degrees F (5 to 25 degrees C). If charging takes place above 77 degrees F (25

degrees C), the time required for a full charge will increase and the potential recharge

cycles will be reduced.

The procedure for charging the battery pack is as follows.

1) Plug the battery charger into an AC outlet and connect the 4-pin connector on the

charger cable to the 4-socket connector on the battery pack. Open the battery

pack enclosure vent located between the case latches to allow gas venting during

the charge cycle.

2) Switch the battery pack power switch to the ON position (the power switch must

be ON to charge the internal batteries from the external charger). The VOLTAGE

and CURRENT meters will turn on and indicate the status of the batteries.

3) The charger changes the recharging mode based on the state of the batteries, as

well, the values of the VOLTAGE and CURRENT meters will vary depending on

the cycle mode of the charger. There is an LED on the charger to indicate

charging status.

A lit LED indicates that the charger has power and is properly functioning.

An orange LED indicates that the charger is in charging mode with a constant

current of approximately 1.5 Amps.

A flashing LED indicates that the charger is in deep-discharge charging pulse

mode and charging starts at 0.5V DC, giving pulse currents up to 5V DC. This

has the effect of removing loose sulphation formed during the deep-discharge

state of the batteries.

A green LED indicates that the charger is in standby mode and the current slowly

reduces to zero.

Recharge the battery pack after every 6 to 8 hours of use. It will not harmed if left on a

continuous charge past the normal recharge time; however, continuous charging for

extended periods of time will reduce the life of the batteries. Therefore, it is

recommended that a continuous charge be limited to no more than 1 week.

The battery pack will lose capacity without use. A battery pack in storage must be

recharged at least every 6 months or sulphation will reduce the storage capacity.

Depending on the charging, depth of discharge, and use conditions, the expected number

of recharge cycles is usually between 500 and 1000.

DHA-7 Downhole Hydrophone Array Operation Manual Page 14 of 18

Rev. F 050612 du

4 – Appendix

4.1 Connector Wiring

Wiring tables for the lead cable are included on the serialized CD included with each

shipment. Channel 1 is always wired as the shallowest hydrophone.

Figure 8 shows the battery pack-to-array wiring.

Figure 8. DHA-7/MicroEel-D Battery Pack wiring.

DHA-7 Downhole Hydrophone Array Operation Manual Page 15 of 18

Rev. F 050612 du

4.2 Calibration

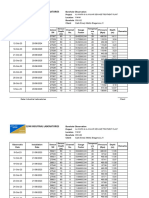

All hydrophone channels of any given array have been low-frequency calibrated over a

band from 0 to 200 Hz as a quality control measurement. The performance band defined

by the low-cut of the polymer film capacitance and input resistance of 10 Hz, and a high-

cut of 10 kHz has been demonstrated to be “predictably flat” over a entire band.

Significant testing has demonstrated that the low frequency calibration of the hydrophone

is 99.99% representative of the broadband response up to 10 kHz. This low frequency

calibration is performed by the substitution method where a known calibrated reference is

compared with the unknown hydrophone channel under calibration. The calibrated

reference and the unknown are placed in a sealed chamber into which white noise is

injected. A dual channel FFT analyzer is used to compare the response of the two and the

resulting transfer function indicates the response in dB of the unknown in terms of

sensitivity relative to 1V per µPa and phase.

All hydrophone channels in the array are guaranteed to be within a ± 1 dB relative span.

The calibration plots for each hydrophone are provided on the serialized CD included

with each shipment.

DHA-7 Downhole Hydrophone Array Operation Manual Page 16 of 18

Rev. F 050612 du

4.3 Specifications

Electrical

Hydrophone Sensor type Proprietary Polymer

Sensors per group One

Frequency response 10 Hz to 10,000 Hz ± 1.0 dB

Capacitance 5 nF at 22˚C

Sensitivity -196 dB re 1 Volt per 1 µPa

Sensitivity with depth < 1.0 dB over 400 m depth

Sensitivity with acceleration < -70 dB re 1 Volt per g

Preamplifier Type Ultra-low noise differential

Gain 6 dB

Current 11 mA per channel

Power ±12V DC DHA-7/MicroEel Battery Pack on surface

Physical

Cable Type Multi-conductor with polyurethane jacket

Topside: Y-type with one 61-socket connector (or 27-socket

connector) and one 4-pin connector

Termination

Tail: 1-m (3.28-ft) long with stainless steel swivel and 6-kg (13.2-

lb) weight

Maximum total length 400 m (or 1,300 ft) (lead plus active section)

Strength member Kevlar center stress core

Outside diameter 13.5 mm (0.53 in)

12 channels: 0.12 kg/m (0.08 lbs/foot)

Weight

24 channels: 0.15 kg/m (0.10 lbs/foot)

Bend radius 12.7 cm (5 in)

Working load 273 kg (600 lbs)

Breaking strength 909 kg (2,000 lbs)

Active section Channels 12 or 24 standard; other counts available*

1 to 5 m (or 3 to 15 ft) standard; other intervals available with

Group Interval

a minimum of 0.5 m (or 18 in)*

Outside diameter

41.3 mm (1.63 in)

(hydrophone)

Length (hydrophone) 30.5 cm (12 in)

Weight (hydrophone) 0.16 kg (0.35 lbs)

Bend radius 22.9 cm (9 in)

Environmental

Depth Operating maximum 400 m (or 1,300 ft)

Temperature Operating range -10˚C to +70˚C

Storage range -40˚C to +70˚C

*Please contact the factory to discuss your requirements. ~\DHA-7_v9a_ds.doc

DHA-7 Downhole Hydrophone Array Operation Manual Page 17 of 18

Rev. F 050612 du

4.4 Warranty and Service

Geometrics warrants the Model DHA-7 system for 3 months. Warranties commence on

the date of shipment. If the equipment fails during the applicable warranty period,

Geometrics will repair or replace the defective item at its factory in San Jose, California

at no charge to the customer for parts and labor. The cost to ship the equipment to

Geometrics' factory and back to the customer's site is for the customer's account. Repairs

might be done at a local service center, if available, nearest customer location.

Geometrics must be notified within 7 days of system failure for any warranty claim.

Geometrics must establish to its satisfaction that failures have not been the result of abuse

or improper deployment of the system. Warranties are void for damage caused by

incorrectly applying power, including over-voltage and reverse voltage.

The limited warranty stated herein is in lieu of all other warranties expressed or implied

(including the implied warranties of merchantability and fitness for a particular purpose)

and of all other obligations or liability on the part of Geometrics, and Geometrics neither

assumes nor authorizes any person to assume for it any other liability. Geometrics shall

not be liable for special, incidental, or consequential damages of any nature (including,

but not limited to lost revenue or profits) with respect to any merchandise or services

sold, delivered or rendered hereunder.

Should the instrument or any part thereof need to be returned to the factory for servicing,

please contact the Customer Service Department via email at support@geometrics.com or

telephone at 408-954-0522. Be ready to provide the serial number and an explanation of

the problem. You will be issued an RMA number and instructions for shipping the

instrument.

DHA-7 Downhole Hydrophone Array Operation Manual Page 18 of 18

Rev. F 050612 du

You might also like

- RXD7 Service ManualDocument71 pagesRXD7 Service ManualFerreirinha Andrade Luis CarlosNo ratings yet

- AN-1849 An Audio Amplifier Power Supply Design: Application ReportDocument17 pagesAN-1849 An Audio Amplifier Power Supply Design: Application ReportJuzt AdhitNo ratings yet

- C2 25kvDocument12 pagesC2 25kvLuis MurilloNo ratings yet

- Tema1 (1) .0 TKMOD IM 1.13 ENDocument70 pagesTema1 (1) .0 TKMOD IM 1.13 ENxspectroxNo ratings yet

- Service Manual: CFS-1085SDocument32 pagesService Manual: CFS-1085SelezaregilsjaNo ratings yet

- Sony MZ-R900 Service ManualDocument50 pagesSony MZ-R900 Service ManualSam NixonNo ratings yet

- LAHTI PREC - EN - TPL-400 - User - GuideDocument38 pagesLAHTI PREC - EN - TPL-400 - User - GuideJoaquimNo ratings yet

- Enterprise WLAN Antenna v1 4Document226 pagesEnterprise WLAN Antenna v1 4JtudeNo ratings yet

- Generator ProtectionDocument128 pagesGenerator ProtectionZokiNo ratings yet

- A38 Capacitance Transmitter ManualDocument24 pagesA38 Capacitance Transmitter ManualSudhakarNo ratings yet

- S6 - Rev 1.5Document88 pagesS6 - Rev 1.5SergNo ratings yet

- CAN - Wiring: Notes On The Wiring of CAN-Bus Systems and The Cable SelectionDocument18 pagesCAN - Wiring: Notes On The Wiring of CAN-Bus Systems and The Cable SelectionbuitanmanNo ratings yet

- Cenelec Spec Hd629-1Document28 pagesCenelec Spec Hd629-1Shona Balaji80% (5)

- Field Cabling Guidelines For INTRON-D / INTRON-D Plus / INTRON-X SystemsDocument36 pagesField Cabling Guidelines For INTRON-D / INTRON-D Plus / INTRON-X Systemsmelek.kharrat.workNo ratings yet

- User Manual Aqua-ScopeDocument39 pagesUser Manual Aqua-ScopeMiguel LaraNo ratings yet

- GET7005J Busway Pub 9-12-10Document44 pagesGET7005J Busway Pub 9-12-10Man MadhanNo ratings yet

- Philips Mod 21pt9470-55 - 44 - 21sl9 - Chasis Sk8.0l CADocument36 pagesPhilips Mod 21pt9470-55 - 44 - 21sl9 - Chasis Sk8.0l CACarlos MedinaNo ratings yet

- GDL 330 001 403 R10 en FieldCablingGuidelinesDocument36 pagesGDL 330 001 403 R10 en FieldCablingGuidelinesJose JohnNo ratings yet

- EMSCO Drwks. ELECTROHOIST V C&O PDFDocument186 pagesEMSCO Drwks. ELECTROHOIST V C&O PDFalex albinoNo ratings yet

- SN65HVD82 Robust RS-485 Transceiver: 6 7 A B 3 4 2 1 RE RDocument32 pagesSN65HVD82 Robust RS-485 Transceiver: 6 7 A B 3 4 2 1 RE RAmir Reza BeheshtianNo ratings yet

- Aman Technical - Handbook PDFDocument70 pagesAman Technical - Handbook PDFeliahud100% (1)

- Iec 309.1-1988Document66 pagesIec 309.1-1988mad_geniusNo ratings yet

- Telect Cable ManagementDocument0 pagesTelect Cable ManagementLuis Angel Cortes BuitragoNo ratings yet

- Fibre Optic Underground Cable Technical SpecificationDocument7 pagesFibre Optic Underground Cable Technical SpecificationAbhinav SinhaNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- Connection Cable SelectionDocument258 pagesConnection Cable SelectionGiovanni TrinidadNo ratings yet

- Cheesemd 2Document7 pagesCheesemd 2Guillermo Gómez MiñonesNo ratings yet

- GCS0004Document21 pagesGCS0004RazkulNo ratings yet

- Vol III Ted 300 Section IIIDocument204 pagesVol III Ted 300 Section IIIYazhisai SelviNo ratings yet

- Technical - Handbook - OMAN CABLES PDFDocument70 pagesTechnical - Handbook - OMAN CABLES PDFSahul HameedNo ratings yet

- Reference Design Report For A 12 W Pow Er Supply Using Tinysw Itch - 4 Tny288PgDocument36 pagesReference Design Report For A 12 W Pow Er Supply Using Tinysw Itch - 4 Tny288PgVinayNo ratings yet

- LM2594MXDocument44 pagesLM2594MXtecnicogato27No ratings yet

- Broadband CouplingDocument81 pagesBroadband CouplingShane VerpNo ratings yet

- Cable Catalogue Havells LT HTDocument54 pagesCable Catalogue Havells LT HTSanjeev DhariwalNo ratings yet

- Slua 660 ADocument17 pagesSlua 660 AKuni KazeNo ratings yet

- QCS 2010 Section 21 Part 14 Structured Cabling SystemsDocument5 pagesQCS 2010 Section 21 Part 14 Structured Cabling Systemsbryanpastor106No ratings yet

- Mechanical RF Phase - ShifterDocument33 pagesMechanical RF Phase - ShifterutammarryNo ratings yet

- AN-1031 TIA/EIA-422-B Overview: Application ReportDocument11 pagesAN-1031 TIA/EIA-422-B Overview: Application Reportreza_azadNo ratings yet

- Busway Ge PDFDocument44 pagesBusway Ge PDFHotaruSanNo ratings yet

- Indramat Conexoes EletricasDocument100 pagesIndramat Conexoes EletricasjocimarNo ratings yet

- THVD1500 500 Kbps RS-485 Transceivers With 8-kV IEC ESD ProtectionDocument29 pagesTHVD1500 500 Kbps RS-485 Transceivers With 8-kV IEC ESD ProtectionsyahabdulrizalNo ratings yet

- Current-Source DC-DC ConverterDocument53 pagesCurrent-Source DC-DC ConverterpepenitoNo ratings yet

- 16 Samss 519Document10 pages16 Samss 519hisham.yousefNo ratings yet

- An2674 Application Note: PCB Layout Guidelines For Spear3XxDocument22 pagesAn2674 Application Note: PCB Layout Guidelines For Spear3XxPep DizNo ratings yet

- CAN - Wiring: Notes On The Wiring of CAN-Bus Systems and The Cable SelectionDocument18 pagesCAN - Wiring: Notes On The Wiring of CAN-Bus Systems and The Cable Selectionamadeo magnusNo ratings yet

- Harman Kardon HKTS-2 Service ManualDocument21 pagesHarman Kardon HKTS-2 Service ManualAlejandro AlcubierreNo ratings yet

- Optical If SDocument11 pagesOptical If SHenry ChanNo ratings yet

- RSER200-4 HW Mod Description 300993CDocument26 pagesRSER200-4 HW Mod Description 300993CTEUKU100% (9)

- Cabling SystemDocument162 pagesCabling Systemstefan998877No ratings yet

- LV XLPE Underground Cable SpecificationDocument7 pagesLV XLPE Underground Cable Specificationferva bashirNo ratings yet

- F5121D Service ManualDocument40 pagesF5121D Service ManualMarcelo LilloNo ratings yet

- Lc-32le350m enDocument70 pagesLc-32le350m encandraNo ratings yet

- TDA5100Document39 pagesTDA5100JGAR2009No ratings yet

- E NSC-En Catalog1Document192 pagesE NSC-En Catalog1Mihai Bogdan ScanghelNo ratings yet

- 50 Ohms 01 2012 200dpiDocument44 pages50 Ohms 01 2012 200dpiAriel Martinez NNo ratings yet

- ELECTRICAL SYSTEM FOR BARC DESALINATION FACILITYDocument63 pagesELECTRICAL SYSTEM FOR BARC DESALINATION FACILITY9044nksNo ratings yet

- Ow 02Document1 pageOw 02rupeshkumar642mdsNo ratings yet

- Water Table ObservationDocument2 pagesWater Table Observationrupeshkumar642mdsNo ratings yet

- Water Table ObservationDocument2 pagesWater Table Observationrupeshkumar642mdsNo ratings yet

- Seismic Survey M.A.S.W. Final Appendix-000 - A Seismic LinesDocument3 pagesSeismic Survey M.A.S.W. Final Appendix-000 - A Seismic Linesrupeshkumar642mdsNo ratings yet

- Ow 02Document1 pageOw 02rupeshkumar642mdsNo ratings yet

- Determination of The Point Load Strength Index of Rock and Application To Rock Strength ClassificationsDocument11 pagesDetermination of The Point Load Strength Index of Rock and Application To Rock Strength ClassificationsconiNo ratings yet

- 002 SillitoeDocument14 pages002 Sillitoesebastian tiriraNo ratings yet

- Effects of Kahramanmaras Earthquakes in South of Turkey On Livestock ActivitiesDocument10 pagesEffects of Kahramanmaras Earthquakes in South of Turkey On Livestock ActivitiesIJAR JOURNALNo ratings yet

- Empirical Correlation Between CaliforniaDocument94 pagesEmpirical Correlation Between CaliforniaRefilwe MoorosiNo ratings yet

- Traffic Signals PuzzleDocument11 pagesTraffic Signals Puzzlesabir aliNo ratings yet

- Unit 1: My Hobbies Lesson 1: Getting Started-My Favourite HobbyDocument15 pagesUnit 1: My Hobbies Lesson 1: Getting Started-My Favourite HobbyLinhtram LêNo ratings yet

- Ad 304Document1 pageAd 304srinimehaNo ratings yet

- Minerals Engineering: Duncan M. Smythe, Annegret Lombard, Louis L. CoetzeeDocument10 pagesMinerals Engineering: Duncan M. Smythe, Annegret Lombard, Louis L. Coetzeefaouzi rachidNo ratings yet

- (Form GNQ 15B) FrickCompPrestartChecklistDocument2 pages(Form GNQ 15B) FrickCompPrestartChecklisteugene mejidanaNo ratings yet

- GR 12 Notes On Audit Reports Eng AfrDocument2 pagesGR 12 Notes On Audit Reports Eng AfrmvelonhlemsimangoNo ratings yet

- Internship at Darson Industries (PVT) LimitedDocument48 pagesInternship at Darson Industries (PVT) LimitedFuRqan HameEd67% (3)

- Asturo Sandblasting Guns enDocument3 pagesAsturo Sandblasting Guns enHonoluluNo ratings yet

- SSRN Id4067211Document53 pagesSSRN Id4067211mnpxzdsqs8No ratings yet

- Ceramage: Light-Curing Microhybrid CompositeDocument3 pagesCeramage: Light-Curing Microhybrid CompositeVero GrambergNo ratings yet

- PS 5.1.2 Enthalpy CalculationsDocument3 pagesPS 5.1.2 Enthalpy Calculationsrichard.gross62No ratings yet

- Introduction To The Philosophy of Social ResearchDocument240 pagesIntroduction To The Philosophy of Social ResearchRob Londs100% (1)

- Seismic Retrofit in Hospitals Using Fluid ViscousDocument6 pagesSeismic Retrofit in Hospitals Using Fluid ViscousDeyanira Sayuri Yangali HerreraNo ratings yet

- Fauziah Ratna Hapsari: About MeDocument3 pagesFauziah Ratna Hapsari: About MeFauziah Ratna HapsariNo ratings yet

- Appsense CurriculumDocument2 pagesAppsense CurriculumAnkita AnantNo ratings yet

- Process data sheet for spent caustic degassing drumDocument4 pagesProcess data sheet for spent caustic degassing drumChakravarthy BharathNo ratings yet

- Laser Shock Forging-A Novel in Situ Method DesignedDocument16 pagesLaser Shock Forging-A Novel in Situ Method DesignedEstefania CovarrubiasNo ratings yet

- Roots of EquationsDocument31 pagesRoots of EquationsGzim RamadaniNo ratings yet

- Are Humans Really Beings of LightDocument14 pagesAre Humans Really Beings of LightmazhmiNo ratings yet

- Wilhelmy Plate - WikipediaDocument2 pagesWilhelmy Plate - Wikipediaprecious omokhaiyeNo ratings yet

- Thematic Teaching in Basic EducationDocument13 pagesThematic Teaching in Basic EducationCyryhl Gutlay100% (1)

- Jadual Waktu SPM 2010Document2 pagesJadual Waktu SPM 2010sallehGNo ratings yet

- Pseudo-Chomsky ThreeDocument4 pagesPseudo-Chomsky ThreeTyler ShortNo ratings yet

- Unit - 1 Introduction To Managerial EconomicsDocument44 pagesUnit - 1 Introduction To Managerial EconomicsAashik k XavierNo ratings yet

- Processing and Quality Evaluation of Guava SquashDocument3 pagesProcessing and Quality Evaluation of Guava SquashShailendra RajanNo ratings yet

- On Completion 211 International School ProjectDocument2 pagesOn Completion 211 International School ProjectVed BaralNo ratings yet

- UPP PE Tank Sump Installation GuideDocument32 pagesUPP PE Tank Sump Installation GuidelowiyaunNo ratings yet