Professional Documents

Culture Documents

Lithium Beneficiation Concept

Uploaded by

saxon zvinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lithium Beneficiation Concept

Uploaded by

saxon zvinaCopyright:

Available Formats

1486 Mainway Meadows +263 774 338 085

+263 719 341 974

Waterfalls +263 712 503 073

P.O. Box 4820 info@skyworld.co.zw

Harare. Twitter/skyworldconsulta

ncy

Lithium Beneficiation: Lithium Carbonate Production from Spodumene

1.0 Introduction

Zimbabwe has largest Lithium deposits in Africa and 5th largest globally. Zimbabwe has been exporting Lithium

Ores since 70s and recently the government introduced a Statutory Instrument making it mandatory to export

Lithium as Concentrate outlawing exporting raw Lithium. The SI was a good initiative but concentrates are at the

low end of value addition. The Lithium grade which we do possess is mainly Spodumene which has higher Lithium

content than Brines from South America which are now accounting for 60% of world lithium. There is need to

encourage the production of Lithium Carbonate and Lithium Hydroxide which are key components in Lithium

Battery manufacturing.

Lithium is a metal commonly used in batteries like the rechargeable ones found in laptops, cellphones, and electric

cars as well as in ceramics and glass. It is the lightest metal on Earth and is soft enough to be cut with a knife when

in its elemental form.

Lithium carbonate is a stable white powder that is a key intermediary in the lithium market because it can be

converted into specific industrial salts and chemicals—or processed into pure lithium metal. The value addition of

Lithium from ores to Lithium Carbonate will increase the value as currently a ton of Lithium Carbonate is going for

US$84 000 on the International market. There is need to conduct research if it will be sustainable to set up such

plants viz-a -v reserves.

2.0 Lithium Carbonate Production Process

Lithium carbonate and lithium hydroxide are the two lithium compounds employed for battery cathode production,

with carbonate currently making up the bulk of usage.

The spodumene produced by hard rock mining requires further processing to produce carbonate – a particularly

energy intensive, and therefore costly, process.

Processing from Minerals

Of the five minerals, spodumene is the most commonly used for lithium production. After it is mined, spodumene is

heated to 2012 degrees Fahrenheit and then cooled to 149 degrees. It's then crushed and roasted again, this time

with concentrated sulfuric acid. Ultimately, sodium carbonate, or soda ash, is added, and the resulting lithium

carbonate is crystallized, heated, filtered, and dried.

In the complex production required to transform spodumene concentrate into lithium compounds such as lithium

carbonate or lithium hydroxide, calcination plays a key role in not one, but two parts of the process, making it an

essential technique in efforts to exploit this increasingly important lithium ore.

While the beneficiation of lithium from brines has long been the primary focus of commercial efforts, spodumene –

a pegmatite ore – is becoming more desirable as a result of its high lithium content and the exploding demand for

lithium-ion batteries.

Calcination, often referred to as roasting in this setting, is one of the more common processing techniques used

throughout the extraction of lithium from spodumene. Calcination is an essential tool in the conversion of

spodumene concentrates to lithium compounds, with two key roles in the process. Through calcination, both

decrepitation and acid roasting can be achieved in the effort to produce lithium carbonate and lithium hydroxide for

use in lithium-ion batteries or other applications.

Directors: S. Zvina, F.G.Chisadza

Directors: S. Zvina, F.G.Chisadza

3.0 Benefits

The production of Lithium Carbonate which is a key component in Li-ion battery manufacturing will enable

Zimbabwe to attract those interested in battery manufacturing as we would be having the key component being

assembled in Zimbabwe. The production of Lithium Carbonate will enable us to move into battery manufacturing

in line with the mantra "Nyika Inovakwa Nevene Vayo".

The nation will be a beneficiary of the Lithium boom and moving from being a net exporter of raw material but to

be a key player in the EV sector.

The production of Lithium Carbonate and battery manufacturing locally will enable the nation to attract entities that

are involved in the manufacturing of electrical cars thus venturing into forward integration in the EV sector.

Employment creation along the value chain

Increased foreign currency generation.

Promotion of green energy as the Lithium Batteries are also used in homes and telecommunications to power base

stations.

The installation of off grid solar systems will be a reality as the batteries will be manufactured locally thus

acceleration of the attainment of Upper Mid Income Economy by 2030.

Production of Air-conditioners

Concept written by Saxon Zvina representing Skyworld Consultancy Services

Directors: S. Zvina, F.G.Chisadza

You might also like

- Hazardous Area Classifications (SANS10108)Document4 pagesHazardous Area Classifications (SANS10108)cvbns0% (1)

- MATLS 4I03 Assignment 2Document3 pagesMATLS 4I03 Assignment 2RoyNo ratings yet

- ASTM G75 - 0determination of Slurry Abrasivity PDFDocument25 pagesASTM G75 - 0determination of Slurry Abrasivity PDFnolanjc100% (1)

- Firing Systems in Power PlantsDocument54 pagesFiring Systems in Power PlantsamarparimiNo ratings yet

- Base Metals ConceptDocument3 pagesBase Metals Conceptsaxon zvinaNo ratings yet

- An Overview of Commercial Lithium ProductionDocument7 pagesAn Overview of Commercial Lithium ProductionVijay WilfredNo ratings yet

- Lithium Commodity ChainDocument16 pagesLithium Commodity ChainazylenbNo ratings yet

- What Is Lithium CarbonateDocument8 pagesWhat Is Lithium CarbonateNurAneesaNo ratings yet

- Lithium by Joice A. OberDocument6 pagesLithium by Joice A. OberMaria José FuturoNo ratings yet

- History of Copper Industry in TuticorinDocument35 pagesHistory of Copper Industry in TuticorinVaishnavi Jayakumar0% (1)

- Arcilla Quimica 'Patentes'Document11 pagesArcilla Quimica 'Patentes'Juan BautistaNo ratings yet

- Talison Lithium Overview of Chemicals PlantDocument17 pagesTalison Lithium Overview of Chemicals PlanthortalemosNo ratings yet

- Electrolytic Zinc Works - Nomination.V5Document24 pagesElectrolytic Zinc Works - Nomination.V5Mehdi AğayiNo ratings yet

- 15 - PRO 673 - Lithium - Extraction - From - Salt - Brine - Technology - Summary - Dec - 22Document3 pages15 - PRO 673 - Lithium - Extraction - From - Salt - Brine - Technology - Summary - Dec - 22AnthonyNo ratings yet

- Corppub IronOreDocument12 pagesCorppub IronOremelbourne00No ratings yet

- Chapter 4Document24 pagesChapter 4EcoConsciousEyeNo ratings yet

- How China Is Winning The Race For Africa's Lithium - Financial TimesDocument12 pagesHow China Is Winning The Race For Africa's Lithium - Financial TimesAleksandar SpasojevicNo ratings yet

- Peruvian Operations: Fast Facts..Document2 pagesPeruvian Operations: Fast Facts..Washington BobadillaNo ratings yet

- Nickel ProcessesDocument30 pagesNickel ProcessesIlham Ridwan100% (2)

- Hindustan Zinc Limited ReportDocument103 pagesHindustan Zinc Limited ReportManu Jain100% (3)

- Hindustan Zinc Limited ReportDocument102 pagesHindustan Zinc Limited ReportAlen AugustineNo ratings yet

- Hindustan Zinc LimitedDocument418 pagesHindustan Zinc LimitedPuneet Jaroli100% (1)

- Informe - 468 - 18-11-2022bDocument44 pagesInforme - 468 - 18-11-2022bMadahi Katherine Garcia MedranoNo ratings yet

- Chrome Report 4Document38 pagesChrome Report 4ahmedkhidryagoub100% (1)

- How To Neutralize H2so4Document5 pagesHow To Neutralize H2so4Aminaa AminaaNo ratings yet

- Will Cheap Asian HPAL Save The EV Industry From Its Looming SuccessDocument10 pagesWill Cheap Asian HPAL Save The EV Industry From Its Looming SuccessDartwin ShuNo ratings yet

- Li Fuentes, Prod. UsosDocument11 pagesLi Fuentes, Prod. UsosJosé Vivanco NúñezNo ratings yet

- Mrs HadebeDocument13 pagesMrs HadebenathykhumaloNo ratings yet

- A Look at The Lithium Clay Projects - Trabajo Rec Reservas Litio Arcillas y MetalurgiaDocument10 pagesA Look at The Lithium Clay Projects - Trabajo Rec Reservas Litio Arcillas y Metalurgiaigor colladoNo ratings yet

- LITHIUM Potential Environmental Impacts of Lithium MiningDocument9 pagesLITHIUM Potential Environmental Impacts of Lithium Miningrendy1087No ratings yet

- 15 Days Industrial Training Report File: On Sinter & LDP (10/03/2017-24/03/2017)Document21 pages15 Days Industrial Training Report File: On Sinter & LDP (10/03/2017-24/03/2017)Prashant Kumar mishraNo ratings yet

- Jiangsu Lithium Carbonate PlantDocument4 pagesJiangsu Lithium Carbonate PlantpetroloritoNo ratings yet

- Gultom 2020 IOP Conf. Ser.: Earth Environ. Sci. 413 012015Document7 pagesGultom 2020 IOP Conf. Ser.: Earth Environ. Sci. 413 012015imran united722No ratings yet

- Ausmelt Technology For Lead and Zinc Processing: February 2008Document16 pagesAusmelt Technology For Lead and Zinc Processing: February 2008Mohammad SoltaniNo ratings yet

- Carbon Anode Production Plant PDFDocument94 pagesCarbon Anode Production Plant PDFRay Romey100% (1)

- 12108040-Zinc Extraction in Contrast With ISP Process PDFDocument20 pages12108040-Zinc Extraction in Contrast With ISP Process PDFSachin MourNo ratings yet

- Lead Extraction: Sinter Plant-Blast Furnace: June 2015Document26 pagesLead Extraction: Sinter Plant-Blast Furnace: June 2015asdffdfdNo ratings yet

- Lightening Up Our LivesDocument6 pagesLightening Up Our Livesrsnagpal2006No ratings yet

- Applications - Copper Compounds - Copper SulphateDocument2 pagesApplications - Copper Compounds - Copper SulphateLaura GreenNo ratings yet

- S.A.R.T. Process: Andina's Volcan Gold ProjectDocument9 pagesS.A.R.T. Process: Andina's Volcan Gold Projecthdlopez92No ratings yet

- Acid Pressure Leaching of Copper Sulfides: Delivering Smarter SolutionsDocument4 pagesAcid Pressure Leaching of Copper Sulfides: Delivering Smarter SolutionsSerchecko JaureguiNo ratings yet

- CorpPub EnergyDocument12 pagesCorpPub EnergyCamilaNo ratings yet

- Lido-African Night Sky ProfileDocument14 pagesLido-African Night Sky ProfileA.GOKHAN KEBAPCIOGLUNo ratings yet

- (Geography) Location Factors - Aluminium, Copper, Natural Gas Refining, Petroleum Refining, Synthetic Fibers MrunalDocument12 pages(Geography) Location Factors - Aluminium, Copper, Natural Gas Refining, Petroleum Refining, Synthetic Fibers MrunalKranti KumarNo ratings yet

- Iluka Pro Rata Entitlement Offer Appendix Mineral Sands Industry OverviewDocument16 pagesIluka Pro Rata Entitlement Offer Appendix Mineral Sands Industry OverviewGiang NguyenNo ratings yet

- Lithium: Choosing The Right Analysis MethodDocument2 pagesLithium: Choosing The Right Analysis MethodDavid Bolívar FigueroaNo ratings yet

- Volta Pakistan AccumulatorsDocument5 pagesVolta Pakistan AccumulatorsAdeel RanaNo ratings yet

- Lithium Australia Batteries LMFP The Future of Lithium Ion BatteriesDocument2 pagesLithium Australia Batteries LMFP The Future of Lithium Ion BatteriesOkkar MaungNo ratings yet

- CandidDocument5 pagesCandidAbhishek SinghNo ratings yet

- Preliminary Feasibility Study Confirms Cinovec As Potentially Low Cost Lithium Carbonate ProducerDocument23 pagesPreliminary Feasibility Study Confirms Cinovec As Potentially Low Cost Lithium Carbonate ProducerSudarshan ChoudharyNo ratings yet

- Zinc PresentationDocument24 pagesZinc PresentationRaman SrivastavaNo ratings yet

- AQL - Aqualithium Business Plan 22 - WebDocument32 pagesAQL - Aqualithium Business Plan 22 - WebyaklyNo ratings yet

- Nickel / Cobalt Laterite ProcessesDocument30 pagesNickel / Cobalt Laterite ProcessesAsriNo ratings yet

- ALTA2018NCC Keynote KathySoleKathrynCSoleConsultingDocument24 pagesALTA2018NCC Keynote KathySoleKathrynCSoleConsultingMandunduKashindi SamuelNo ratings yet

- Gold LeachDocument8 pagesGold LeachChristian Charles Umboh100% (2)

- POWER RESOURCES NotesDocument30 pagesPOWER RESOURCES NotesEman HassanNo ratings yet

- 13 Factsheet Lithium GBDocument6 pages13 Factsheet Lithium GBlewislee59No ratings yet

- Sterlite Industries Limited: The Federation of UniversitiesDocument21 pagesSterlite Industries Limited: The Federation of Universitieskohinoor_roy5447No ratings yet

- AntimonyDocument4 pagesAntimonyabhay_pratap_2No ratings yet

- Summary of Guillaume Pitron's The Rare Metals WarFrom EverandSummary of Guillaume Pitron's The Rare Metals WarRating: 4 out of 5 stars4/5 (1)

- What’S in Your Car: A Poetic Ride Through the Periodic TableFrom EverandWhat’S in Your Car: A Poetic Ride Through the Periodic TableNo ratings yet

- Money, Finance, Business and Investing: Beginners Basic Guide to Investments - Boxed SetFrom EverandMoney, Finance, Business and Investing: Beginners Basic Guide to Investments - Boxed SetNo ratings yet

- Gr8 EVM - Lithosphere Home Notes - 2023-24 - Final EditedDocument6 pagesGr8 EVM - Lithosphere Home Notes - 2023-24 - Final Editedparijaatwaghmare21No ratings yet

- Chapter 5 - Combustion EquipmentDocument50 pagesChapter 5 - Combustion EquipmentrrhoshackNo ratings yet

- White CementDocument4 pagesWhite CementMohamed GamalNo ratings yet

- Maitree Joshi ProjectDocument76 pagesMaitree Joshi Projectmaitreejoshi3No ratings yet

- Geo19 5 EconomicGeography 1 PDFDocument101 pagesGeo19 5 EconomicGeography 1 PDFsadhanareddyNo ratings yet

- Mitra MiningDocument1 pageMitra MiningDadan Saefudin RosidiNo ratings yet

- 1 s2.0 S0959652622033212 MainDocument12 pages1 s2.0 S0959652622033212 MainOriza Adi FernandaaNo ratings yet

- Session-1-Introduction and Coke MakingDocument51 pagesSession-1-Introduction and Coke MakingHeroNo ratings yet

- Review MTD Okt HJS - STC - 291021Document25 pagesReview MTD Okt HJS - STC - 291021sarjuNo ratings yet

- Service RequestDocument12 pagesService RequestDanang Yudi MiswarNo ratings yet

- Phuthi Steelmaking 2020Document147 pagesPhuthi Steelmaking 2020OUSSAMA BEN OMARNo ratings yet

- SADC - EnglishDocument5 pagesSADC - EnglishAhmad BayhaqiNo ratings yet

- The Five Processes of Gasification - ALL Power LabsDocument1 pageThe Five Processes of Gasification - ALL Power Labs7kkqg42m6cNo ratings yet

- SSAB - Green Steel FoundryDocument11 pagesSSAB - Green Steel FoundryWen wei LeeNo ratings yet

- Electrostatic PrecipitatorDocument12 pagesElectrostatic PrecipitatorchandraNo ratings yet

- Blackwater Rail CorridorDocument2 pagesBlackwater Rail CorridorjumpyNo ratings yet

- ALLISON BUTTS Metallurgical Problem 51 100Document50 pagesALLISON BUTTS Metallurgical Problem 51 100Hazel ZarrafogluNo ratings yet

- Iron Making Unit 4Document87 pagesIron Making Unit 4Micky SahuNo ratings yet

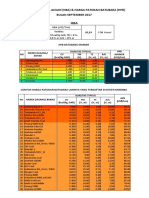

- Harga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) Bulan September 2017Document4 pagesHarga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) Bulan September 2017Buddhi BhaskaraNo ratings yet

- Chapter 3 - Mineral and Power Resources: NCERT Solutions For Class 8 Social Science GeographyDocument2 pagesChapter 3 - Mineral and Power Resources: NCERT Solutions For Class 8 Social Science GeographyKalpna SharmaNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument9 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAbdo MajidNo ratings yet

- R U N G T A M I N e S L I M I T e DDocument16 pagesR U N G T A M I N e S L I M I T e DRAMODSNo ratings yet

- Earth Science 1st Quarterly Assessment ReviewersDocument3 pagesEarth Science 1st Quarterly Assessment ReviewersMark JedrickNo ratings yet

- Netlog IndonesiaDocument1 pageNetlog Indonesiaheri sutiknoNo ratings yet

- Fuels, Furnaces & Refractories 4Document6 pagesFuels, Furnaces & Refractories 4PRAKHAR SINGHNo ratings yet

- ES301 Engineering-Economics Chapter-5 Depreciation PDFDocument14 pagesES301 Engineering-Economics Chapter-5 Depreciation PDFSandra WendamNo ratings yet