Professional Documents

Culture Documents

G-7501A November 12 2023

Uploaded by

rizfian19270 ratings0% found this document useful (0 votes)

11 views9 pagesVibration report

Original Title

G-7501A_November_12_2023

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVibration report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views9 pagesG-7501A November 12 2023

Uploaded by

rizfian1927Vibration report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

MOPU PRAMESWARI 8

Predictive Maintenance Report

Date : November 12th , 2023

Area : TEG

Equip. Name : HP Flare K.O Drump Pump A

Tag No. : G-7501A

Wo No. :-

Prepared By : Rizfian

Table Of Content

1. Introduction .................................................................................................................... 2

2. Resume of Finding and Recommendation ..................................................................... 2

2.1 Finding .......................................................................................................................... 2

2.2 Recommendation ......................................................................................................... 2

3. Unit Spesification ............................................................................................................ 3

3.1 Equipment Identity ....................................................................................................... 3

3.2 Measurement Point Scheme ........................................................................................ 3

3.3 Analysis Parameter Setting ........................................................................................... 3

4. Measurement Data ......................................................................................................... 4

4.1 Operation Parameter.................................................................................................... 4

4.2 Overall Vibration and Trends (IPS RMS) ....................................................................... 4

4.3 Vibration Spectrum Data .............................................................................................. 5

5. Thermography ................................................................................................................ 9

G-7501A PDM-Prameswari 8 Page 1 of 9

1. Introduction

Predictive Maintenance is a part of maintenance program at MOPU Prameswari 8. The

Purpose of this program is to gain control of plant machinery, significantly reducing

maintenance cost, increasing productivity, improving product quality, achieve plant reliability

and profitability.

2. Resume of Finding and Recommendation

2.1 Finding and Analysis

▪ Vibration for all point measurement is acceptable with the highest vibration value 0.058 at

DE Motor axial direction.

▪ Thermal image pattern at motor and pump shows normal condition.

2.2 Recommendation

▪ Equipment (motor and pump) are acceptable to operated.

▪ Continue monitoring to see the trending and thermal image pattern.

G-7501A PDM-Prameswari 8 Page 2 of 9

3. Unit Spesification

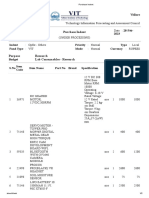

3.1 Equipment Identity

Equipment : HP Flare KO Drum Pump A

Area : TEG

Tag Number : G-7501A

Driver : Motor

Connection : Coupling (Disc)

Driven : Centrifugal Pump

Power Rate : 1.1 kW

Driver RPM : 1668

Driven RPM : 1750

Type Support : Rigid

Driver Standard : ISO 10816-3

Driven Standard : ISO 10816-3

Bearing Driver DE : Unknown

Baring Driver NDE : Unknown

Bearing Driven DE : Unknown

Bearing Driven NDE : Unknown

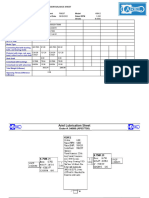

3.2 Measurement Point Scheme

3.3 Analysis Parameter Setting

Analyzer VibXpert II Single channel

AP Set Standard Measurment Vel. /2-1600 Hz/ 2 lin. / Δf 1 Hz

AP Set Bearing Measurement Roll.bear.enve. 800Hz 0.5Hz

Sensor VIB 6.142

Measurement Mode Continous Measurement

G-7501A PDM-Prameswari 8 Page 3 of 9

4. Measurement Data

4.1 Operation Parameter

2023

No Description th th

Limit Unit

Oct 11 Nov 12

1 P Suction 0 2 Psi

2 P Discharge 0 7 Psi

4.2 Overall Vibration and Trends (IPS RMS)

Standard ISO 10816-3

Alarm (C) 0.075 Danger (D) 0.18

Description Point Unit 11-Oct-23 12-Nov-23

NDE M1H IPS RMS 0.036 0.04

NDE M1V IPS RMS 0.044 0.03

NDE M1A IPS RMS 0.075 0.05

Motor

DE M2H IPS RMS 0.052 0.047

DE M2V IPS RMS 0.029 0.027

DE M2A IPS RMS 0.079 0.058

DE P1H IPS RMS 0.044 0.03

DE P1V IPS RMS 0.042 0.028

Pump NDE P2H IPS RMS 0.043 0.024

NDE P2V IPS RMS 0.042 0.022

NDE P2A IPS RMS 0.033 0.02

The trend show that the motor and pump vibrations were decreased and acceptable.

G-7501A PDM-Prameswari 8 Page 4 of 9

4.3 Vibration Spectrum Data

▪ M1H-Motor NDE Horizontal

▪ M1V-Motor NDE Vertical

▪ M1A-Motor NDE Axial

G-7501A PDM-Prameswari 8 Page 5 of 9

▪ M2H-Motor DE Horizontal

▪ M2V-Motor DE Vertical

▪ M2A-Motor DE Axial

G-7501A PDM-Prameswari 8 Page 6 of 9

▪ P1H-Pump DE Horizontal

▪ P1V-Pump DE Vertical

▪ P2H-Pump NDE Horizontal

G-7501A PDM-Prameswari 8 Page 7 of 9

▪ P2V-Pump NDE Vertical

▪ P2A-Pump NDE Axial

G-7501A PDM-Prameswari 8 Page 8 of 9

5. Thermography

Description Thermal Image (0C)

Motor

Pump

Based on Thermal Pattern (qualitative method), the equipment is good condition.

G-7501A PDM-Prameswari 8 Page 9 of 9

You might also like

- P-2801B-1 November 08 2023Document9 pagesP-2801B-1 November 08 2023rizfian1927No ratings yet

- E-1801A-02 November 7 2023Document8 pagesE-1801A-02 November 7 2023rizfian1927No ratings yet

- K-2801B November 08 2023Document11 pagesK-2801B November 08 2023rizfian1927No ratings yet

- EM-1501-04 November 1 2023Document9 pagesEM-1501-04 November 1 2023rizfian1927No ratings yet

- P-7638 Minipack - 1Document17 pagesP-7638 Minipack - 1Okky Pangestoe WibowoNo ratings yet

- Sesi-Tspl-Opn-Sop-Btg-001 (Idf)Document14 pagesSesi-Tspl-Opn-Sop-Btg-001 (Idf)shubham vermaNo ratings yet

- V-2158-101-A-884 - 3 Inspection and Test Procedure For PumpsDocument80 pagesV-2158-101-A-884 - 3 Inspection and Test Procedure For PumpsMessaoud Goutas100% (1)

- Data Motor Induksi Kerja PraktekDocument13 pagesData Motor Induksi Kerja PraktekChandro MarcelinusNo ratings yet

- QC1BM Up 20221201Document6 pagesQC1BM Up 20221201mo mokterNo ratings yet

- Suprava Mam Indent2 PDFDocument2 pagesSuprava Mam Indent2 PDFDhansukh JaladiNo ratings yet

- Fire Pump Proposal Summary: WeightDocument3 pagesFire Pump Proposal Summary: WeightDerkung Benowat100% (1)

- CH3 Engine TroubleshootingDocument51 pagesCH3 Engine TroubleshootingMigue SalazarNo ratings yet

- QC2BM Up 20221130Document6 pagesQC2BM Up 20221130mo mokterNo ratings yet

- Motor Data Sheet (32-Hal-201ab)Document5 pagesMotor Data Sheet (32-Hal-201ab)Ahmad FaujiNo ratings yet

- BGPP Aje 200 Pe F12 2301 000 0001 e 0Document21 pagesBGPP Aje 200 Pe F12 2301 000 0001 e 0vivekvijayan16No ratings yet

- RAF-917-10-36-P219 RET670 F51 Comp SATDocument9 pagesRAF-917-10-36-P219 RET670 F51 Comp SATSARAVANAN ANo ratings yet

- 7.14 CP14571 Blower PackageDocument29 pages7.14 CP14571 Blower PackageIsaias de la CruzNo ratings yet

- SPECIFICATION FOR GENERAL ROTARY PD PUMPS (Rev.0) (P-1201 To P-1206, P-1402 To P-1405)Document7 pagesSPECIFICATION FOR GENERAL ROTARY PD PUMPS (Rev.0) (P-1201 To P-1206, P-1402 To P-1405)Panisa BanimaNo ratings yet

- QC3BM Up 20221130Document6 pagesQC3BM Up 20221130mo mokterNo ratings yet

- Mercruiser Ignition TimingDocument18 pagesMercruiser Ignition TimingsteveNo ratings yet

- SRP 1212Document27 pagesSRP 1212waleedyehia100% (4)

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- ABB Generator SpecificationDocument14 pagesABB Generator SpecificationSathish KumarNo ratings yet

- AA-0212C AC4 Sulzer RTA Engines Denis-1 Replaceable PartsDocument22 pagesAA-0212C AC4 Sulzer RTA Engines Denis-1 Replaceable Parts2644909178No ratings yet

- C18 Industrial Engine WRH00001 - Sensor Eg GroupDocument2 pagesC18 Industrial Engine WRH00001 - Sensor Eg GroupBlog Teknisi100% (1)

- Va Panero-Muban DocumentDocument14 pagesVa Panero-Muban DocumentMUHAMMAD ISMAILNo ratings yet

- Technical & Operation Manual (NP-180-002)Document105 pagesTechnical & Operation Manual (NP-180-002)Marce Gutiérrez100% (1)

- Cat 14M Blade Tilt (Tip) CylDocument2 pagesCat 14M Blade Tilt (Tip) CylSHANENo ratings yet

- Operating, Maintenance, Repair and Troubleshooting Instructions For TheDocument186 pagesOperating, Maintenance, Repair and Troubleshooting Instructions For TheBudi ArtantoNo ratings yet

- Siemens Motor 2HP - 1800 Rpm1MB2121-1AB41-6AG3Document6 pagesSiemens Motor 2HP - 1800 Rpm1MB2121-1AB41-6AG3marco antonio ramos melendezNo ratings yet

- Agitator Spreadsheet DetailsDocument7 pagesAgitator Spreadsheet DetailsAndrewNo ratings yet

- JBL0435 GRD ZAIN Report - Rev - ADocument77 pagesJBL0435 GRD ZAIN Report - Rev - AEhtesham AliNo ratings yet

- Engine Reference1 PDFDocument2 pagesEngine Reference1 PDFKevin RomeroNo ratings yet

- Fire Pump Proposal Summary: List Mult Net WeightDocument3 pagesFire Pump Proposal Summary: List Mult Net WeightDerkung BenowatNo ratings yet

- Dynamic Braking Chapter 9Document28 pagesDynamic Braking Chapter 9pabloNo ratings yet

- Distribution Business Unit Cummins Field Service Report Pal EngineersDocument1 pageDistribution Business Unit Cummins Field Service Report Pal EngineersPrabhu VijayakumaranNo ratings yet

- Fandeck Vibration AnalysisDocument20 pagesFandeck Vibration AnalysisHASSAN SK MD100% (1)

- Design Data & References: Unit Tag StationDocument12 pagesDesign Data & References: Unit Tag StationAdnan AttishNo ratings yet

- Himadri Report 09-12-2021Document3 pagesHimadri Report 09-12-2021Sekhar Tellakula [Sands]No ratings yet

- Shutdown SIS: Wheel Loader 972H Wheel Loader A7G 972H Wheel Loader A7G00001-UP (MACHINE) POWERED BY C13 EngineDocument2 pagesShutdown SIS: Wheel Loader 972H Wheel Loader A7G 972H Wheel Loader A7G00001-UP (MACHINE) POWERED BY C13 EngineStar SealNo ratings yet

- Ariel Compressor Balance SheetDocument130 pagesAriel Compressor Balance Sheetariel.garayNo ratings yet

- Cat 14M Centershift CylinderDocument2 pagesCat 14M Centershift CylinderSHANENo ratings yet

- Maintenance: and Operating Manual For Gearbox Type ZF WDocument104 pagesMaintenance: and Operating Manual For Gearbox Type ZF WTansu MavunacıNo ratings yet

- 1CK11135 ReferenciaDocument1 page1CK11135 ReferenciaWilder OportoNo ratings yet

- Generator Manual 1Document392 pagesGenerator Manual 1Gopal Radhakrishnan100% (5)

- Ga, Datasheet and Thickener MechanismDocument11 pagesGa, Datasheet and Thickener MechanismBallNo ratings yet

- Ariel Performance: Compressor Data: Driver DataDocument1 pageAriel Performance: Compressor Data: Driver Datavlcmstne04No ratings yet

- GR-MPO2109-G30-0013 - Instrument Data Sheet For Reverse Rotation Switch and Vib. Sensor - Rev - 0Document31 pagesGR-MPO2109-G30-0013 - Instrument Data Sheet For Reverse Rotation Switch and Vib. Sensor - Rev - 0Zidny Alfyan BarikNo ratings yet

- CAT 16M Blade Lift CylinderDocument2 pagesCAT 16M Blade Lift CylinderSHANENo ratings yet

- RAF-917-10-36-P220 RET670 F67 Comp SATDocument8 pagesRAF-917-10-36-P220 RET670 F67 Comp SATSARAVANAN ANo ratings yet

- Data Motor & Pump-1Document29 pagesData Motor & Pump-1naspauzanNo ratings yet

- 1) SCP-200-460-HA (280kw, 4 Pole) Data SheetDocument6 pages1) SCP-200-460-HA (280kw, 4 Pole) Data Sheetنايفف بن عبداللهNo ratings yet

- NEMA Motor Data: 1LE2221-2AB11-4AA3 MLFB-Ordering DataDocument1 pageNEMA Motor Data: 1LE2221-2AB11-4AA3 MLFB-Ordering DataAlejandro VazNo ratings yet

- Submersible PumpDocument105 pagesSubmersible PumpRamKS80100% (1)

- FO-InD-HAL-PR-001 - Inspection Work Order Form - RevG - 2019!11!01 - PHE Oses Frac EquipmentDocument1 pageFO-InD-HAL-PR-001 - Inspection Work Order Form - RevG - 2019!11!01 - PHE Oses Frac EquipmentRico100% (1)

- Accepteance Test Data SheetDocument3 pagesAccepteance Test Data SheetArdian20No ratings yet

- VF003 - Level Gauge (ALL) PDFDocument21 pagesVF003 - Level Gauge (ALL) PDFPhạm Tấn PhướcNo ratings yet

- Topomapping For Firewater Pump-OdsDocument49 pagesTopomapping For Firewater Pump-OdsRashyd RidhaNo ratings yet

- (Model Information) : LCD Color TelevisionDocument5 pages(Model Information) : LCD Color TelevisionАртём ДончуковNo ratings yet

- Forte III Spec Sheet v061Document1 pageForte III Spec Sheet v061Kenny SharpensteenNo ratings yet

- Coursera KTLNF9NLR4CS PDFDocument1 pageCoursera KTLNF9NLR4CS PDFVictor JimenezNo ratings yet

- Perimeter 8 Specifications - July2022 - V6 - 240207 - 101351Document3 pagesPerimeter 8 Specifications - July2022 - V6 - 240207 - 101351dorodriguezvNo ratings yet

- NIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationDocument6 pagesNIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationKshitija100% (1)

- Beapr635 inDocument2 pagesBeapr635 inluis andre tapia cruzNo ratings yet

- Water Conveyance With Syphons: September, 2000 (Rev 2009)Document19 pagesWater Conveyance With Syphons: September, 2000 (Rev 2009)Sameer ShrivastavaNo ratings yet

- Ficha Tecnica Rotametro 7510 PDFDocument2 pagesFicha Tecnica Rotametro 7510 PDFJohn Armely Arias GuerreroNo ratings yet

- DM No. 341 s.2023Document5 pagesDM No. 341 s.2023Jennifer PomarNo ratings yet

- Schneider - CatalogoDocument40 pagesSchneider - CatalogoGiulietta CarotoneNo ratings yet

- 5 - Certificado InmetroDocument5 pages5 - Certificado InmetroDanilo MarinhoNo ratings yet

- Principles of Purchasing Nd1 Bam 117Document36 pagesPrinciples of Purchasing Nd1 Bam 117Alexander GabrielNo ratings yet

- Hydraulic Lab ReportDocument2 pagesHydraulic Lab ReportAllaFonteNo ratings yet

- ManualDocument109 pagesManualAmerican Caribbean100% (1)

- Horquillas CascadeDocument56 pagesHorquillas CascadeBeatriz Miranda Mellado100% (1)

- CAL-00-E-0004 Rev-1 ELECTRICAL CABLE SIZINGDocument5 pagesCAL-00-E-0004 Rev-1 ELECTRICAL CABLE SIZINGtceterexNo ratings yet

- Sap PP Configuration DocumentDocument75 pagesSap PP Configuration DocumentRafaelCasagrandeNo ratings yet

- 1 - Case Interview Marathon WorkshopDocument6 pages1 - Case Interview Marathon WorkshopHải Anh Nguyễn LươngNo ratings yet

- 100 Leads in 90 DaysDocument5 pages100 Leads in 90 DaysAjay GomesNo ratings yet

- Price Forecasting & Anomaly Detection For Agricultural Commodities in IndiaDocument13 pagesPrice Forecasting & Anomaly Detection For Agricultural Commodities in IndiaAction ReplayNo ratings yet

- Enrolling An Android Device in InTuneDocument15 pagesEnrolling An Android Device in InTuneRai DuNo ratings yet

- Forcepoint Next Generation Firewall NGFW Administrator Virtual Instructor-Led Training September2020Document5 pagesForcepoint Next Generation Firewall NGFW Administrator Virtual Instructor-Led Training September2020lakbabi1035No ratings yet

- Week 2 Arithmetic Sequence Finding The NTH TermDocument9 pagesWeek 2 Arithmetic Sequence Finding The NTH TermSchievvie AbanillaNo ratings yet

- ASHRAE Journal - VAV System Duct Main DesignDocument5 pagesASHRAE Journal - VAV System Duct Main DesignJhoNo ratings yet

- BS 5446-2Document34 pagesBS 5446-21limonataNo ratings yet

- Instruction Manual Safety SystemDocument99 pagesInstruction Manual Safety SystemAndrey AndreyNo ratings yet

- Actighost Rapid Gel™: Technical Data SheetDocument1 pageActighost Rapid Gel™: Technical Data SheetShajid HoshainNo ratings yet

- RRB PO PRELIMS Quants (Day-11) 164983111818Document16 pagesRRB PO PRELIMS Quants (Day-11) 164983111818surya ponnadaNo ratings yet

- Measure in Inch and CMDocument1 pageMeasure in Inch and CMIrena Agatha SimanjuntakNo ratings yet

- Anti-Reflux System User ManualDocument6 pagesAnti-Reflux System User ManualGillianne Mae VargasNo ratings yet