Professional Documents

Culture Documents

E-1801A-02 November 7 2023

Uploaded by

rizfian1927Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-1801A-02 November 7 2023

Uploaded by

rizfian1927Copyright:

Available Formats

MOPU PRAMESWARI 8

Predictive Maintenance Report

Date : Novemer 7th , 2023

Area : GTC-A

Equip. Name : Lube Oil Cooler GTC A

Tag No. : E-1801A-02

Wo No. :-

Prepared by : Rizfian

Table Of Content

1. Introduction .................................................................................................................... 2

2. Resume of Finding and Recommendation ..................................................................... 2

2.1 Finding .......................................................................................................................... 2

2.2 Recommendation ......................................................................................................... 2

3. Unit Spesification ............................................................................................................ 3

3.1 Equipment Identity ....................................................................................................... 3

3.2 Measurement Point Scheme ........................................................................................ 3

3.3 Analysis Parameter Setting ........................................................................................... 3

4. Measurement Data ......................................................................................................... 4

4.1 Operation Parameter.................................................................................................... 4

4.2 Overall Vibration (IPS RMS) .......................................................................................... 4

4.3 Vibration Spectrum Data .............................................................................................. 5

5. Thermography ................................................................................................................ 8

E-1801A-2 PDM-Prameswari 8 Page 1 of 8

1. Introduction

Predictive Maintenance is a part of maintenance program at MOPU Prameswari 8. The

Purpose of this program is to gain control of plant machinery, significantly reducing

maintenance cost, increasing productivity, improving product quality, achieve plant reliability

and profitability.

2. Resume of Finding and Recommendation

2.1 Finding and Analysis

▪ The highest vibration value is 0.065 at NDE Motor Horizontal (M1X) direction and the

vibrations are acceptable.

▪ Thermal image pattern at motor, bearing NDE fan, and heat exchanger shows normal

condition

2.2 Recommendation

▪ Equipment (Motor and Fan) are acceptable to operated.

▪ Continue monitoring to see the vibrations trending and thermal image pattern.

E-1801A-2 PDM-Prameswari 8 Page 2 of 8

3. Unit Spesification

3.1 Equipment Identity

Equipment : Lube Oil Cooler GTC A

Area : GTC-A

Tag Number : E-1801A-02

Driver : Motor

Connection : V-Belt

Driven : Fan

Power Rate : 7.5 kW

Driver RPM : 1770

Driven RPM : Unknown

Type Support : Flexible

Driver Standard : ISO 10816-3

Driven Standard : ISO 10816-3

Bearing Driver DE : SKF 6308-2RS

Baring Driver NDE : SKF 6207-2RS

Bearing Driven DE : Pillow Block

Bearing Driven NDE : Pillow Block

Number of Blades : 3

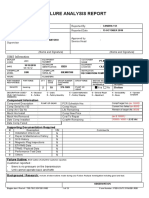

3.2 Measurement Point Scheme

3.3 Analysis Parameter Setting

Analyzer VibXpert II Single channel

AP Set Standard Measurement Vel. /2-1600 Hz/ 2 lin. / Δf 1 Hz

AP Set Bearing Measurement Roll.bear.enve. 800Hz 0.5Hz

Sensor VIB 6.142

Measurement Mode Continous Measurement

E-1801-02 PDM-Prameswari 8 Page 3 of 8

4. Measurement Data

4.1 Operation Parameter

- N/A

4.2 Overall Vibration (IPS RMS)

Standard ISO 10816-3

Alarm(C) 0.18 Danger (D) 0.28

Description Point Unit 7-Oct-23 7-Nov-23

NDE M1X IPS RMS 0.063 0.065

NDE M1Y IPS RMS 0.052 0.049

NDE M1A IPS RMS 0.063 0.052

Motor

DE M2X IPS RMS 0.067 0.055

DE M2Y IPS RMS 0.053 0.058

DE M2A IPS RMS 0.077 0.061

NDE F2X IPS RMS 0.064 0.043

Fan NDE F2Y IPS RMS 0.04 0.024

NDE F2A IPS RMS 0.041 0.046

The overall value of vibrations are acceptable.

E-1801-02 PDM-Prameswari 8 Page 4 of 8

4.3 Vibration Spectrum Data

▪ M1X-Motor NDE X-Axis

▪ M1Y-Motor NDE Y-Axis

▪ M1A-Motor NDE Axial

E-1801-02 PDM-Prameswari 8 Page 5 of 8

▪ M2X-Motor DE X-Axis

▪ M2Y-Motor DE Y-Axis

▪ M2A-Motor DE Axial

E-1801-02 PDM-Prameswari 8 Page 6 of 8

▪ F2X-Fan NDE X-Axis

▪ F2Y-Fan NDE Y-Axis

▪ F2A-Fan NDE Axial

E-1801-02 PDM-Prameswari 8 Page 7 of 8

5. Thermography

Description Thermal Image (0C)

Motor

Bearing Fan DE and NDE

Heat Excangher (in-out)

Based on Thermal Pattern (qualitative method), the equipment is good condition.

E-1801-02 PDM-Prameswari 8 Page 8 of 8

You might also like

- Installation of The Generator and Control Panel Components For Dynamic Gas BlendingDocument49 pagesInstallation of The Generator and Control Panel Components For Dynamic Gas Blendingالمهندسوليدالطويل100% (1)

- Toyota TSB For Error Code P0012Document6 pagesToyota TSB For Error Code P0012Rick McGuireNo ratings yet

- 238 PDFDocument919 pages238 PDFSomadbsi100% (2)

- Diesel Injection Pump Service Manual: Hino E13C Common Rail SystemDocument23 pagesDiesel Injection Pump Service Manual: Hino E13C Common Rail SystemZawzaw HahaooNo ratings yet

- Service Manual: Common Rail System For NISSAN YD1-K2 Type EngineDocument40 pagesService Manual: Common Rail System For NISSAN YD1-K2 Type EngineBryan Edu Curay ZavalaNo ratings yet

- Xe Nâng BTDocument518 pagesXe Nâng BTlê hùng100% (1)

- 690C.D WD PDFDocument134 pages690C.D WD PDFYosmeli Zapata100% (1)

- Technical Operation Manual 180K LN2 ConverterDocument105 pagesTechnical Operation Manual 180K LN2 ConverterMarce Gutiérrez100% (1)

- ML AuxiliaryEngineCompleteManualMAN BW8L20 27Document466 pagesML AuxiliaryEngineCompleteManualMAN BW8L20 27Leonid KolesnikovNo ratings yet

- Service Tool Manual 311 411 413Document86 pagesService Tool Manual 311 411 413Ayra Elevator perkasaNo ratings yet

- Start Up Routine OVF10 PDFDocument12 pagesStart Up Routine OVF10 PDFEng M ElseaidyNo ratings yet

- F5 GTM Concepts Guide v11Document209 pagesF5 GTM Concepts Guide v11Majnu SmNo ratings yet

- 2012-2013 Ssang Yong Rexton Y290 Service ManualDocument1,395 pages2012-2013 Ssang Yong Rexton Y290 Service Manualbogdanxp2000No ratings yet

- Science Grade 7Document8 pagesScience Grade 7Lacus ClyneNo ratings yet

- VEHICLE DIMENSIONS AND SPECIFICATIONSDocument1,138 pagesVEHICLE DIMENSIONS AND SPECIFICATIONSSebastianoNo ratings yet

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Document16 pagesJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunNo ratings yet

- Steam-Turbine Drive CentrifugalDocument28 pagesSteam-Turbine Drive Centrifugalsppram100% (2)

- CH3 Engine TroubleshootingDocument51 pagesCH3 Engine TroubleshootingMigue SalazarNo ratings yet

- MMD - O&m - Appron FeederDocument62 pagesMMD - O&m - Appron FeederEdwin MariacaNo ratings yet

- Rotary KnifeDocument26 pagesRotary Kniferodolfo muñoz magaña100% (1)

- Sample Resume For HRDocument2 pagesSample Resume For HRnapinnvoNo ratings yet

- Improve Product Packaging at Annual Board MeetingDocument9 pagesImprove Product Packaging at Annual Board Meetingizzat89% (9)

- OE Spec GB 400 480V 60Hz Metric 2 14 PDFDocument2 pagesOE Spec GB 400 480V 60Hz Metric 2 14 PDFmuhammad afrizalNo ratings yet

- Telangana Energy Dept Contact NumbersDocument27 pagesTelangana Energy Dept Contact Numbersstarpowerzloans rjyNo ratings yet

- SG10145B Op ManualDocument28 pagesSG10145B Op ManualMohamed Shafik100% (1)

- P-2801B-1 November 08 2023Document9 pagesP-2801B-1 November 08 2023rizfian1927No ratings yet

- G-7501A November 12 2023Document9 pagesG-7501A November 12 2023rizfian1927No ratings yet

- Motor Data Sheet (32-Hal-201ab)Document5 pagesMotor Data Sheet (32-Hal-201ab)Ahmad FaujiNo ratings yet

- K-2801B November 08 2023Document11 pagesK-2801B November 08 2023rizfian1927No ratings yet

- AA-0212C AC4 Sulzer RTA Engines Denis-1 Replaceable PartsDocument22 pagesAA-0212C AC4 Sulzer RTA Engines Denis-1 Replaceable Parts2644909178No ratings yet

- GTCP131-9B APU DetailsDocument17 pagesGTCP131-9B APU DetailsOkky Pangestoe WibowoNo ratings yet

- Section K: Publication NoDocument8 pagesSection K: Publication NoLuis BertaoNo ratings yet

- Cweart7 G0Aal27: C) .Spindle ExtensionDocument3 pagesCweart7 G0Aal27: C) .Spindle Extensionpravat kumar routNo ratings yet

- e-manage ECU Tuning System OverviewDocument23 pagese-manage ECU Tuning System Overviewanthony dizonNo ratings yet

- EASA TYPE CERTIFICATE FOR ROLLS-ROYCE RB211 TRENT 700 SERIES ENGINESDocument9 pagesEASA TYPE CERTIFICATE FOR ROLLS-ROYCE RB211 TRENT 700 SERIES ENGINESObakengNo ratings yet

- EM-1501-04 November 1 2023Document9 pagesEM-1501-04 November 1 2023rizfian1927No ratings yet

- 7 Steps Troubleshooting - Participant Guide PNUP Anak Anakka FINISHDocument61 pages7 Steps Troubleshooting - Participant Guide PNUP Anak Anakka FINISHwaldi merrandanNo ratings yet

- SERVOMECH Mechanical Linear Actuators ATL BSA Series Ordering CodeDocument3 pagesSERVOMECH Mechanical Linear Actuators ATL BSA Series Ordering CodenoonesthereNo ratings yet

- V3 Microsquirt® - Quickstart Guide: Intake Air Temperature SensorDocument4 pagesV3 Microsquirt® - Quickstart Guide: Intake Air Temperature SensorPeter TNo ratings yet

- REHS1385 Introduction of New 3408E and 3412E Hydraulic Electronic Unit InjectorsDocument13 pagesREHS1385 Introduction of New 3408E and 3412E Hydraulic Electronic Unit InjectorsJuan Carlos Galarza CastilloNo ratings yet

- Power Station Engine Generator Vibration Analysis ReportDocument5 pagesPower Station Engine Generator Vibration Analysis ReportDerrick AramNo ratings yet

- toyota 2LDocument7 pagestoyota 2LjefriNo ratings yet

- V-Car Service Training Manual: Engine Performance Instructor GuideDocument52 pagesV-Car Service Training Manual: Engine Performance Instructor GuideAlex PilcoNo ratings yet

- S7 Unae12a 2Document718 pagesS7 Unae12a 2Xuân VinhNo ratings yet

- AG200F 2003 3GX0-ME2 (Supplementary)Document20 pagesAG200F 2003 3GX0-ME2 (Supplementary)loretohNo ratings yet

- Genie sx125 sx105Document301 pagesGenie sx125 sx105affandyNo ratings yet

- S7 Unae12a 3Document601 pagesS7 Unae12a 3Xuân VinhNo ratings yet

- PDK 205481 Kw26-S5-Fse-4q enDocument114 pagesPDK 205481 Kw26-S5-Fse-4q enMostafa MagdyNo ratings yet

- M1832 1932 1942 Sme-ADocument96 pagesM1832 1932 1942 Sme-Azied nasriNo ratings yet

- Nissan Common Rail Yd1 k2 Service ManualDocument4 pagesNissan Common Rail Yd1 k2 Service Manualorlando100% (50)

- Manual TranstectorDocument6 pagesManual TranstectorHoku's NickNo ratings yet

- Section KDocument8 pagesSection KAdolfo Santos0% (1)

- DW115CNC Technical ParametersDocument11 pagesDW115CNC Technical ParametersProfCarlos GamaNo ratings yet

- RElay SSR Motores 2011Document3 pagesRElay SSR Motores 2011Marcelo OlivaresNo ratings yet

- Data Sheet: FeaturesDocument16 pagesData Sheet: FeatureschristianNo ratings yet

- AMK Racing Kit 4 Wheel Drive "Formula Student Electric"Document103 pagesAMK Racing Kit 4 Wheel Drive "Formula Student Electric"abdelmoumene djafer beyNo ratings yet

- Assembly Report: 320 D 948 948 CV - Merdeka MandiriDocument13 pagesAssembly Report: 320 D 948 948 CV - Merdeka MandiriedykuswariNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- United Technologles Pratt&Whitney: Middletown Plant Aircraft Road Middletown, Connecticut 06457Document7 pagesUnited Technologles Pratt&Whitney: Middletown Plant Aircraft Road Middletown, Connecticut 06457amir ghaznaviNo ratings yet

- MM-55-1 - Ballast Water Treatment SystemDocument204 pagesMM-55-1 - Ballast Water Treatment SystemElias Dalens CastroNo ratings yet

- Technical Information - CardanDocument10 pagesTechnical Information - CardanRafael MendesNo ratings yet

- 32283Document44 pages32283Leobardo Genaro Roque NájeraNo ratings yet

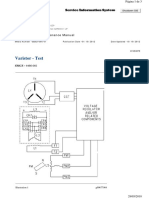

- Varistor - Test (GZP)Document3 pagesVaristor - Test (GZP)Hugo CiprianiNo ratings yet

- Sustainability - Research PaperDocument18 pagesSustainability - Research PapermrigssNo ratings yet

- Duane Grant, A099 743 627 (BIA Sept. 9, 2016)Document12 pagesDuane Grant, A099 743 627 (BIA Sept. 9, 2016)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Water TreatmentDocument6 pagesWater TreatmentSantiago LarrazNo ratings yet

- Remove Fuel Sub TankDocument9 pagesRemove Fuel Sub Tankthierry.fifieldoutlook.comNo ratings yet

- SRV210 - 250TC Spare PartsDocument2 pagesSRV210 - 250TC Spare PartsEnzo SovittiNo ratings yet

- Breaugh Starke PDFDocument30 pagesBreaugh Starke PDFRichard YeongNo ratings yet

- WordPress Introduction: CMS BasicsDocument21 pagesWordPress Introduction: CMS BasicsNgô Ngọc Hải phươngNo ratings yet

- Contoh Skripsi Bahasa Inggris Case StudyDocument18 pagesContoh Skripsi Bahasa Inggris Case StudyRizki Fajrita100% (14)

- 2020会社案内(英語版)Document18 pages2020会社案内(英語版)DAC ORGANIZERNo ratings yet

- HTML MCQDocument22 pagesHTML MCQBuxar Students LifeNo ratings yet

- Pharmacy Perspective on Improving Patient SafetyDocument44 pagesPharmacy Perspective on Improving Patient SafetydicodrNo ratings yet

- Piano: Grade 2: PiecesDocument4 pagesPiano: Grade 2: PiecesnolozeNo ratings yet

- Linkstar RCST Installation Guide: Version DDocument56 pagesLinkstar RCST Installation Guide: Version Djorge_chavez01No ratings yet

- ID Strategi Integrated Marketing Communication Imc Untuk Meningkatkan Loyalitas AngDocument17 pagesID Strategi Integrated Marketing Communication Imc Untuk Meningkatkan Loyalitas AngAiman AzhariNo ratings yet

- Australian Institute For Teaching and School Leadership - AITSLDocument5 pagesAustralian Institute For Teaching and School Leadership - AITSLYu LiNo ratings yet

- TEFL I Course Prepares Students to Teach EnglishDocument8 pagesTEFL I Course Prepares Students to Teach EnglishErma DomosNo ratings yet

- Investigation of Nursing Students Knowledge of and Attitudes About Problem Based LearningDocument4 pagesInvestigation of Nursing Students Knowledge of and Attitudes About Problem Based LearningasdasdasdasNo ratings yet

- Axial Centrifugal FansDocument15 pagesAxial Centrifugal FansAhsan JavedNo ratings yet

- 178 - 7 - Fun For Flyers. Progress Tests - 2017, 4th - 91p.pdf Foods NatureDocument1 page178 - 7 - Fun For Flyers. Progress Tests - 2017, 4th - 91p.pdf Foods NatureYu KoNo ratings yet

- Lembar Jawaban Skillab Evidence Based Medicine (Ebm) Nama: Rafika Triasa NIM: 040427223270003Document11 pagesLembar Jawaban Skillab Evidence Based Medicine (Ebm) Nama: Rafika Triasa NIM: 040427223270003Yahya Darmais FaridNo ratings yet

- Sax AltoDocument2 pagesSax AltoJohnny GervasioNo ratings yet

- From Birth Till Palatoplasty Prosthetic.20Document5 pagesFrom Birth Till Palatoplasty Prosthetic.20Maria FernandaNo ratings yet

- Vocabulario Ingles 3 EsoDocument6 pagesVocabulario Ingles 3 EsoPatri ParrasNo ratings yet

- Report-Teaching English Ministery of EduDocument21 pagesReport-Teaching English Ministery of EduSohrab KhanNo ratings yet