Professional Documents

Culture Documents

P-2801B-1 November 08 2023

Uploaded by

rizfian19270 ratings0% found this document useful (0 votes)

13 views9 pagesVibration Analysis

Original Title

P-2801B-1_November_08_2023

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVibration Analysis

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views9 pagesP-2801B-1 November 08 2023

Uploaded by

rizfian1927Vibration Analysis

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

MOPU PRAMESWARI 8

Predictive Maintenance Report

Date : November 08th , 2023

Area : DPCU

Equip. Name : Lube Oil Pump Refrigerant Compressor B No.1

Tag No. : P-2801B-1

Wo No. :-

Prepared By : Hermawan & Rizfian

Table Of Content

1. Introduction .................................................................................................................... 2

2. Resume of Finding and Recommendation ..................................................................... 2

2.1 Finding .......................................................................................................................... 2

2.2 Recommendation ......................................................................................................... 2

3. Unit Spesification ............................................................................................................ 3

3.1 Equipment Identity ....................................................................................................... 3

3.2 Measurement Point Scheme ........................................................................................ 3

3.3 Analysis Parameter Setting ........................................................................................... 3

4. Measurement Data ......................................................................................................... 4

4.1 Operation Parameter.................................................................................................... 4

4.2 Overall Vibration and Trends (IPS RMS) ....................................................................... 4

4.3 Vibration Spectrum Data .............................................................................................. 5

5. Thermography ................................................................................................................ 9

P-2801B-1 PDM-Prameswari 8 Page 1 of 9

1. Introduction

Predictive Maintenance is a part of maintenance program at MOPU Prameswari 8. The

Purpose of this program is to gain control of plant machinery, significantly reducing

maintenance cost, increasing productivity, improving product quality, achieve plant reliability

and profitability.

2. Resume of Finding and Recommendation

2.1 Finding and Analysis

▪ The overall vibration for all measurement point is acceptable.

▪ The highest vibration is 0.087 IPS RMS on NDE Pump Vertical (P2V) direction were stable

from previous measurement. The spectrum shows dominant frequency at 298Hz, indicates

resonance and transmitted from refrigerant compressor.

2.2 Recommendation

▪ Equipment (motor and pump) are acceptable to operated.

▪ Continue monitoring to see the vibration trending and thermal image pattern.

P-2801B-1 PDM-Prameswari 8 Page 2 of 9

3. Unit Spesification

3.1 Equipment Identity

Equipment : Lube Oil Pump Refrigerant Compressor B No.1

Area : DPCU

Tag Number : P-2801B-1

Driver : Motor

Connection : Coupling

Driven : Gear Pump

Power Rate : 0.7kW

Driver RPM : 1665

Driven RPM : 1665

Type Support : Rigid

Driver Standard : ISO 10816-3

Driven Standard : ISO 10816-3

Bearing Driver DE : 6204-2Z

Baring Driver NDE : 6204-2Z

Bearing Driven DE : Bushing

Bearing Driven NDE : Bushing

3.2 Measurement Point Scheme

3.3 Analysis Parameter Setting

Analyzer VibXpert II Single channel

AP Set Standard Measurment Vel. /2-1600 Hz/ 2 lin. / Δf 1 Hz

AP Set Bearing Measurement Roll.bear.enve. 800Hz 0.5Hz

Sensor VIB 6.142

Measurement Mode Continous Measurement

P-2801B-1 PDM-Prameswari 8 Page 3 of 9

4. Measurement Data

4.1 Operation Parameter

N/A

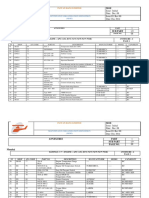

4.2 Overall Vibration and Trends (IPS RMS)

Standard ISO 10816-3

Alarm(C) 0.18 Danger (D) 0.28

Description Point Unit 21-Sep-23 10-Oct-23 08-Nov-23

NDE M1H IPS RMS 0.061 0.056 0.03

NDE M1V IPS RMS 0.041 0.039 0.06

NDE M1A IPS RMS 0.037 0.026 0.06

Motor

DE M2H IPS RMS 0.042 0.053 0.044

DE M2V IPS RMS 0.052 0.052 0.063

DE M2A IPS RMS 0.044 0.033 0.031

DE P1H IPS RMS 0.083 0.069 0.064

DE P1V IPS RMS 0.056 0.084 0.074

Pump NDE P2H IPS RMS 0.138 0.084 0.066

NDE P2V IPS RMS 0.075 0.085 0.087

NDE P2A IPS RMS 0.041 0.047 0.031

The trends show that the motor vibrations were stable within the acceptable level.

The trends show that the pump vibrations were stable within the acceptable level.

P-2801B-1 PDM-Prameswari 8 Page 4 of 9

4.3 Vibration Spectrum Data

▪ M1H-Motor NDE Horizontal

▪ M1V-Motor NDE Vertical

▪ M1A-Motor NDE Axial

P-2801B-1 PDM-Prameswari 8 Page 5 of 9

▪ M2H-Motor DE Horizontal

▪ M2V-Motor DE Vertical

▪ M2A-Motor DE Axial

P-2801B-1 PDM-Prameswari 8 Page 6 of 9

▪ P1H-Pump DE Horizontal

▪ P1V-Pump DE Vertical

▪ P2H-Pump NDE Horizontal

P-2801B-1 PDM-Prameswari 8 Page 7 of 9

▪ P2V-Pump NDE Vertical

▪ P2A-Pump NDE Axial

P-2801B-1 PDM-Prameswari 8 Page 8 of 9

5. Thermography

Description Thermal Image (0C)

Motor

Coupling and Pump

Based on Thermal Pattern (qualitative method), the equipment is good condition.

P-2801B-1 PDM-Prameswari 8 Page 9 of 9

You might also like

- G-7501A November 12 2023Document9 pagesG-7501A November 12 2023rizfian1927No ratings yet

- E-1801A-02 November 7 2023Document8 pagesE-1801A-02 November 7 2023rizfian1927No ratings yet

- K-2801B November 08 2023Document11 pagesK-2801B November 08 2023rizfian1927No ratings yet

- EM-1501-04 November 1 2023Document9 pagesEM-1501-04 November 1 2023rizfian1927No ratings yet

- P-7638 Minipack - 1Document17 pagesP-7638 Minipack - 1Okky Pangestoe WibowoNo ratings yet

- ML AuxiliaryEngineCompleteManualMAN BW8L20 27Document466 pagesML AuxiliaryEngineCompleteManualMAN BW8L20 27Leonid KolesnikovNo ratings yet

- Va Panero-Muban DocumentDocument14 pagesVa Panero-Muban DocumentMUHAMMAD ISMAILNo ratings yet

- Himadri Report 09-12-2021Document3 pagesHimadri Report 09-12-2021Sekhar Tellakula [Sands]No ratings yet

- Suprava Mam Indent2 PDFDocument2 pagesSuprava Mam Indent2 PDFDhansukh JaladiNo ratings yet

- 75-160kW Parts ManualDocument81 pages75-160kW Parts ManualANDRESNo ratings yet

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- SPECIFICATION FOR GENERAL ROTARY PD PUMPS (Rev.0) (P-1201 To P-1206, P-1402 To P-1405)Document7 pagesSPECIFICATION FOR GENERAL ROTARY PD PUMPS (Rev.0) (P-1201 To P-1206, P-1402 To P-1405)Panisa BanimaNo ratings yet

- CH3 Engine TroubleshootingDocument51 pagesCH3 Engine TroubleshootingMigue SalazarNo ratings yet

- Kaviatasi SPECTRUMDocument3 pagesKaviatasi SPECTRUMhamdzanNo ratings yet

- Engine Overhaul Minggu 11Document106 pagesEngine Overhaul Minggu 11Renaldi ArdiansyahNo ratings yet

- Power Station Engine Generator Vibration Analysis ReportDocument5 pagesPower Station Engine Generator Vibration Analysis ReportDerrick AramNo ratings yet

- Isuzu Engines 6HK1 M. Serv.Document222 pagesIsuzu Engines 6HK1 M. Serv.Miguel100% (2)

- 1 Service ManualDocument486 pages1 Service ManualАлександрNo ratings yet

- Toyota 2LDocument7 pagesToyota 2LjefriNo ratings yet

- Ade 447 Workshop Manual Abby PDFDocument164 pagesAde 447 Workshop Manual Abby PDFDani Quirante Flaaut Etc83% (6)

- Bettis RPE Series PDFDocument31 pagesBettis RPE Series PDFJohn CruzNo ratings yet

- 100 615 - DE - Booster - 1pump - Standby - SubmittalDocument10 pages100 615 - DE - Booster - 1pump - Standby - SubmittalEfrain CorroNo ratings yet

- CM 470iiDocument4 pagesCM 470iiChachou MohamedNo ratings yet

- 12c IRN100-200HP-2S Parts Manual 22186472 Rev.B 2003Document86 pages12c IRN100-200HP-2S Parts Manual 22186472 Rev.B 2003lourdes100% (1)

- Vibration Analysis Report Of: Ongc Petro Addition LTDDocument6 pagesVibration Analysis Report Of: Ongc Petro Addition LTDVinod RushinathNo ratings yet

- TOYOTA i-ART Common Rail System PDFDocument12 pagesTOYOTA i-ART Common Rail System PDFpaulo valentini100% (1)

- Detailed Bbu For LT SWGR r.01 (Color)Document1 pageDetailed Bbu For LT SWGR r.01 (Color)sourav dasNo ratings yet

- Sesi-Tspl-Opn-Sop-Btg-001 (Idf)Document14 pagesSesi-Tspl-Opn-Sop-Btg-001 (Idf)shubham vermaNo ratings yet

- Repair Manual For Iveco Nef Engines F4GE0484E - F4GE0684F - F4HE0684JDocument258 pagesRepair Manual For Iveco Nef Engines F4GE0484E - F4GE0684F - F4HE0684JbfscarreiraNo ratings yet

- Automatic Bottle Indexing Machine With Geneva Mechanism: Presented byDocument14 pagesAutomatic Bottle Indexing Machine With Geneva Mechanism: Presented byDeepak ChaurasiaNo ratings yet

- Denso CR HP3 Nissan-Pathfinder YD2k2Document11 pagesDenso CR HP3 Nissan-Pathfinder YD2k2james santiago100% (2)

- Data Motor Induksi Kerja PraktekDocument13 pagesData Motor Induksi Kerja PraktekChandro MarcelinusNo ratings yet

- 2 Phase VerticalDocument4 pages2 Phase VerticalJAZEEL ALAVINo ratings yet

- Mercruiser Ignition TimingDocument18 pagesMercruiser Ignition TimingsteveNo ratings yet

- Technical & Operation Manual (NP-180-002)Document105 pagesTechnical & Operation Manual (NP-180-002)Marce Gutiérrez100% (1)

- V-2158-101-A-884 - 3 Inspection and Test Procedure For PumpsDocument80 pagesV-2158-101-A-884 - 3 Inspection and Test Procedure For PumpsMessaoud Goutas100% (1)

- Specification For Fuel Hydrant Pumps (Rev.0) - (p1102 To P-1105)Document9 pagesSpecification For Fuel Hydrant Pumps (Rev.0) - (p1102 To P-1105)Panisa Banima100% (1)

- C 7 ENGINE APU (ATA 49,71,72,73,74,75,76,77,79,80) MumbaiDocument2 pagesC 7 ENGINE APU (ATA 49,71,72,73,74,75,76,77,79,80) Mumbaiarun RajannaNo ratings yet

- 130p-024a (MSR) .Document2 pages130p-024a (MSR) .King SadNo ratings yet

- Apu Component Monitoring: On Condition PartsDocument2 pagesApu Component Monitoring: On Condition PartsMarcial Lawrence Louie B. RizoNo ratings yet

- 1557-301021-National Care HospitalDocument1 page1557-301021-National Care HospitalRizwanNo ratings yet

- Calculo de Una Bomba SolarDocument8 pagesCalculo de Una Bomba SolarOscarPerezCongaNo ratings yet

- RH - 15Document1 pageRH - 15David César TirolliNo ratings yet

- Alternador AVK - DSG DIG Instalacion Servicio y MantenimientoDocument595 pagesAlternador AVK - DSG DIG Instalacion Servicio y MantenimientoMartin FloresNo ratings yet

- Design Data & References: Unit Tag StationDocument12 pagesDesign Data & References: Unit Tag StationAdnan AttishNo ratings yet

- JBL0435 GRD ZAIN Report - Rev - ADocument77 pagesJBL0435 GRD ZAIN Report - Rev - AEhtesham AliNo ratings yet

- 9-88960 - en F4be0484e SMDocument196 pages9-88960 - en F4be0484e SMTeknik Makina100% (2)

- BGPP Aje 200 Pe F12 2301 000 0001 e 0Document21 pagesBGPP Aje 200 Pe F12 2301 000 0001 e 0vivekvijayan16No ratings yet

- Manual Honda ActuadorDocument11 pagesManual Honda ActuadorLuis MurrietaNo ratings yet

- Bivhuiser 2023 868Document8 pagesBivhuiser 2023 868Mathías Huillca CameronNo ratings yet

- Sabp G 013Document15 pagesSabp G 013Eagle Spirit100% (1)

- New Holland Engines F4be0454b F4be0484d F4be0484e F4be0684b Repair ManualDocument20 pagesNew Holland Engines F4be0454b F4be0484d F4be0484e F4be0684b Repair Manualpatricia100% (33)

- Puesta A Punto InyeccionDocument41 pagesPuesta A Punto Inyeccionjosechus150No ratings yet

- SM 667TA-CASE-NewHolland EN PDFDocument143 pagesSM 667TA-CASE-NewHolland EN PDFjulianmata100% (3)

- BFWT Repair Report 02 Feb 2022Document11 pagesBFWT Repair Report 02 Feb 2022Haitham AbdEl-TawabNo ratings yet

- Prueb y Ajuste Sist - Hidr. Ventilador D8TDocument13 pagesPrueb y Ajuste Sist - Hidr. Ventilador D8TRODRIGO HERNANDEZNo ratings yet

- Engine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemDocument3 pagesEngine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemEm sulistio100% (1)

- Gui de Consumiveis 4Document5 pagesGui de Consumiveis 4mardonio andradeNo ratings yet

- B122 - Tma03Document7 pagesB122 - Tma03Martin SantambrogioNo ratings yet

- Dokumen - Pub - Bobs Refunding Ebook v3 PDFDocument65 pagesDokumen - Pub - Bobs Refunding Ebook v3 PDFJohn the First100% (3)

- Solved Simplex Problems PDFDocument5 pagesSolved Simplex Problems PDFTejasa MishraNo ratings yet

- Technology Management 1Document38 pagesTechnology Management 1Anu NileshNo ratings yet

- Principals' Leadership Styles and Student Academic Performance in Secondary Schools in Ekiti State, NigeriaDocument12 pagesPrincipals' Leadership Styles and Student Academic Performance in Secondary Schools in Ekiti State, NigeriaiqraNo ratings yet

- Networker Performance Tuning PDFDocument49 pagesNetworker Performance Tuning PDFHarry SharmaNo ratings yet

- Chemistry Form 4 Daily Lesson Plan - CompressDocument3 pagesChemistry Form 4 Daily Lesson Plan - Compressadila ramlonNo ratings yet

- DC 7 BrochureDocument4 pagesDC 7 Brochures_a_r_r_yNo ratings yet

- Leigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Document6 pagesLeigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Lue SolesNo ratings yet

- Lesson PlanDocument2 pagesLesson Plannicole rigonNo ratings yet

- Appendix - Pcmc2Document8 pagesAppendix - Pcmc2Siva PNo ratings yet

- Outdoor Air Pollution: Sources, Health Effects and SolutionsDocument20 pagesOutdoor Air Pollution: Sources, Health Effects and SolutionsCamelia RadulescuNo ratings yet

- Traveling Salesman ProblemDocument11 pagesTraveling Salesman ProblemdeardestinyNo ratings yet

- Blue Prism Data Sheet - Provisioning A Blue Prism Database ServerDocument5 pagesBlue Prism Data Sheet - Provisioning A Blue Prism Database Serverreddy_vemula_praveenNo ratings yet

- Hdfs Default XML ParametersDocument14 pagesHdfs Default XML ParametersVinod BihalNo ratings yet

- Electives - ArchitDocument36 pagesElectives - Architkshitiz singhNo ratings yet

- II 2022 06 Baena-Rojas CanoDocument11 pagesII 2022 06 Baena-Rojas CanoSebastian GaonaNo ratings yet

- DQ Vibro SifterDocument13 pagesDQ Vibro SifterDhaval Chapla67% (3)

- DNA ReplicationDocument19 pagesDNA ReplicationLouis HilarioNo ratings yet

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 pagesUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcNo ratings yet

- Digital MetersDocument47 pagesDigital MetersherovhungNo ratings yet

- 74HC00D 74HC00D 74HC00D 74HC00D: CMOS Digital Integrated Circuits Silicon MonolithicDocument8 pages74HC00D 74HC00D 74HC00D 74HC00D: CMOS Digital Integrated Circuits Silicon MonolithicAssistec TecNo ratings yet

- Ozone Therapy - A Clinical Review A. M. Elvis and J. S. EktaDocument5 pagesOzone Therapy - A Clinical Review A. M. Elvis and J. S. Ektatahuti696No ratings yet

- C - Amarjit Singh So Bhura SinghDocument5 pagesC - Amarjit Singh So Bhura SinghRohit JindalNo ratings yet

- Dynamics of Machinery PDFDocument18 pagesDynamics of Machinery PDFThomas VictorNo ratings yet

- OZO Player SDK User Guide 1.2.1Document16 pagesOZO Player SDK User Guide 1.2.1aryan9411No ratings yet

- Carriage RequirementsDocument63 pagesCarriage RequirementsFred GrosfilerNo ratings yet

- Guidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17Document5 pagesGuidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17zqhnazNo ratings yet

- Organization and Management Module 3: Quarter 1 - Week 3Document15 pagesOrganization and Management Module 3: Quarter 1 - Week 3juvelyn luegoNo ratings yet

- ME Eng 8 Q1 0101 - SG - African History and LiteratureDocument13 pagesME Eng 8 Q1 0101 - SG - African History and Literaturerosary bersanoNo ratings yet