Professional Documents

Culture Documents

CMTL - Group3 Lab Report 4 Compressive Strength

Uploaded by

Christian Kyle BeltranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CMTL - Group3 Lab Report 4 Compressive Strength

Uploaded by

Christian Kyle BeltranCopyright:

Available Formats

In Partial Fulfillment of

The Requirements for the Course

Construction Materials and Testing Laboratory (CECMAT1L)

Presented to the Faculty of the

College of Engineering

National University - Fairview

COMPRESSIVE STRENGTH OF CONCRETE

Section:

CE23

Submitted by:

Banez, Alexa Marie

Dahiroc, Janine Alyssa

Garcia, Shakira Amber

Santos, Jeanne Russell

Submitted to:

Engr. Rogel Exequiel E. Talagtag

Date Submitted:

November 11, 2023

I. Introduction

By all means, the compressive strength of concrete is closely intertwined with the selection and

utilization of aggregates. Aggregates, which typically consist of sand, gravel, or crushed stone, are

fundamental components in concrete mixes. They not only occupy a significant portion of the mix by

volume but also significantly influence the material's mechanical properties, including compressive

strength. The choice of aggregates, their size distribution, and their quality are paramount

considerations in concrete mix design. Well-graded aggregates with a balanced range of particle

sizes help optimize the packing of particles within the mix, reducing voids and enhancing the

concrete's overall density. This, in turn, contributes to improved compressive strength, as a denser

and more homogenous mixture can better resist the crushing forces applied to it.

Moreover, the shape and surface texture of aggregates also play a pivotal role in determining the

compressive strength of concrete. Angular and rough-textured aggregates provide better interlocking

and adhesion within the matrix, leading to higher compressive strength. Conversely, rounded and

smooth aggregates may result in lower strength due to reduced mechanical interlock. Therefore,

understanding the aggregate properties and how they interact with the cement paste is essential for

achieving the desired compressive strength in concrete. Engineers and concrete mix designers must

carefully balance these factors to tailor the concrete mixture to the specific requirements of a project,

whether it's a high-strength structural application or a more workable and cost-effective mix for non-

structural uses. In essence, the judicious use of aggregates in concrete serves as a cornerstone for

achieving the desired compressive strength and, by extension, the long-term performance and

durability of concrete structures.

II. Summary of Experiment

III. Data

CONCRETE 1 CONCRETE 1 CONCRETE 1

DIAMETER 101.6 99 104.14

(mm)

HEIGHT 203.2 207 203

(mm)

AREA (mm 2) 8107.32 7697.69 8517.75

Figure 1. Concrete test 1

Figure 2. Concrete test 2

Figure 3. Concrete test 3

WOOD 3

WOOD 2

WOOD 1

Figure 4. Concrete after the Compressive test.

IV. Computations

COMPRESSIVE STRENGTH OF CONCRETE

P

σ=

A

P = force (N) applied at the fracture point

A = the cross-sectional area (mm)

CONCRETE 1:

61650 N

σ=

8107.32 mm

= 7.604 MPa

CONCRETE 2:

58400 N

σ=

7697.69 mm

= 7.587 MPa

CONCRETE 3:

49500 N

σ=

8517.75 mm

= 5.811 MPa

CONCRETE 1 CONCRETE 2 CONCRETE 3

APPLIED 61650 58400 49500

FORCE(N)

COMPRESSIVE 1102.867 1100.401 842.814

STRENGTH (psi)

V. Findings

VI. Conclusion

VII. Things Learned from the Experiment

VIII. Reference

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Statistics For Absolute Beginners (Second Edition) (Oliver TheobaldDocument144 pagesStatistics For Absolute Beginners (Second Edition) (Oliver Theobaldcispas2000No ratings yet

- RCC Lab Report - 2Document15 pagesRCC Lab Report - 2Razn NhemaphukiNo ratings yet

- HRSGDocument21 pagesHRSGrabia2090No ratings yet

- CMT Lab 4 (8.5 X 13 In)Document12 pagesCMT Lab 4 (8.5 X 13 In)cmharvinaNo ratings yet

- Simulation of Masonry Wall Using Concrete Damage Plasticity ModelDocument4 pagesSimulation of Masonry Wall Using Concrete Damage Plasticity Modelحيدر الهنداويNo ratings yet

- Rebounding Method Application of Strcuture Concrete Compression Strength Detecting in Datong AreaDocument5 pagesRebounding Method Application of Strcuture Concrete Compression Strength Detecting in Datong Areaimmanuel nauk elokpereNo ratings yet

- Maria - MWCNT and CNF Cementitious Nanocomposites For Enhanced Strength and ToughnesDocument6 pagesMaria - MWCNT and CNF Cementitious Nanocomposites For Enhanced Strength and ToughnesShan RatnayakeNo ratings yet

- Steel Fibre Reinforced ConcreteDocument7 pagesSteel Fibre Reinforced ConcretePradeesh JNo ratings yet

- Ce November 2021 Refresher Pantino 4 Sec PDFDocument4 pagesCe November 2021 Refresher Pantino 4 Sec PDFYoshjordan LambNo ratings yet

- 6.average Flexurel Strength N/mm2: Length Breadth DepthDocument3 pages6.average Flexurel Strength N/mm2: Length Breadth DepthSudip MukhopadhyayNo ratings yet

- RCD 02 Flexural Analysis of BeamDocument13 pagesRCD 02 Flexural Analysis of BeamJohn Kenneth RuizNo ratings yet

- Flexural Performance of Reinforced Concrete Beams With A Layer of Expansive SHCC-2012-Hae Jun YangDocument5 pagesFlexural Performance of Reinforced Concrete Beams With A Layer of Expansive SHCC-2012-Hae Jun YangsardarumersialNo ratings yet

- bài dịch tiếng anhDocument8 pagesbài dịch tiếng anhKhanh TuanNo ratings yet

- Finalexamanswerschemebfc34702 28original 29Document14 pagesFinalexamanswerschemebfc34702 28original 29NurNo ratings yet

- The Reinforced Concrete Beam Deflection and Cracking Behavior With Additional Fiber SteelDocument5 pagesThe Reinforced Concrete Beam Deflection and Cracking Behavior With Additional Fiber SteelNamaku AndaNo ratings yet

- 4 Elastic Modulus and Strength of Hollow Concrete Block Masonry With Refrence To The Effect of Lateral TiesDocument10 pages4 Elastic Modulus and Strength of Hollow Concrete Block Masonry With Refrence To The Effect of Lateral Tiessunil reddy0% (1)

- 07a80105 Prestressedconcrete PDFDocument8 pages07a80105 Prestressedconcrete PDFPar NawNo ratings yet

- Numerical Modelling of Large Scale Steel Fibre Reinforcedreinforced Concrete Beams Failing in ShearDocument11 pagesNumerical Modelling of Large Scale Steel Fibre Reinforcedreinforced Concrete Beams Failing in ShearChris LumyNo ratings yet

- (2017 Nilforoush Et Al.) - Influence of Surface Reinforcement, Member Thickness and Cracked Concrete On Tensile Capacity of Anchor BoltsDocument14 pages(2017 Nilforoush Et Al.) - Influence of Surface Reinforcement, Member Thickness and Cracked Concrete On Tensile Capacity of Anchor BoltsmanoelmangabeiraNo ratings yet

- Publ en 462 VSU PaperDocument6 pagesPubl en 462 VSU PapertinchofranNo ratings yet

- Size Effect On Shear Strength of RC Beams Using HSC Without Shear ReinforcementDocument16 pagesSize Effect On Shear Strength of RC Beams Using HSC Without Shear ReinforcementHuda JawadNo ratings yet

- Parametric Study of Laterally Loaded Pil PDFDocument15 pagesParametric Study of Laterally Loaded Pil PDFAhmed RamadanNo ratings yet

- Study On Deep BeamsDocument16 pagesStudy On Deep Beamsshailesh patilNo ratings yet

- NDT ReportDocument15 pagesNDT ReportBukayoNo ratings yet

- Einforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcreteDocument24 pagesEinforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcretemuradNo ratings yet

- Einforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcreteDocument24 pagesEinforced Oncrete: Bridge Design Manual - 2002 Reinforced Concretetonying86No ratings yet

- Strengthening of Reinforced Concrete Beam Column Joint Under Seismic Loading Using ANSYSDocument5 pagesStrengthening of Reinforced Concrete Beam Column Joint Under Seismic Loading Using ANSYSkali1No ratings yet

- Relationship Between Compressive Split Tensile of Self Compacting ConcreteDocument12 pagesRelationship Between Compressive Split Tensile of Self Compacting Concretesanthu256100% (1)

- Chapter 3b-Concrete Mix DesignDocument16 pagesChapter 3b-Concrete Mix DesignPaul SsewankamboNo ratings yet

- The University of Dar Es SalaamDocument6 pagesThe University of Dar Es SalaamChris AdaminovicNo ratings yet

- FR C PresentationDocument41 pagesFR C PresentationsivarajNo ratings yet

- Cement and Concrete Research: Alessandro P. Fantilli, Hirozo Mihashi, Paolo ValliniDocument13 pagesCement and Concrete Research: Alessandro P. Fantilli, Hirozo Mihashi, Paolo ValliniJuliana SanchezNo ratings yet

- CIV3506 2022 Assign2 Exemplary2Document33 pagesCIV3506 2022 Assign2 Exemplary2Neil WayneNo ratings yet

- Flexural Behavior of High-Strength Concrete Beams Confined With Stirrups in Pure Bending ZoneDocument7 pagesFlexural Behavior of High-Strength Concrete Beams Confined With Stirrups in Pure Bending ZoneAdnane OURABAHNo ratings yet

- Unified Strain-Based Procedure To Obtain Design: P-M Interaction Curves of Slender RC Wall SectionsDocument12 pagesUnified Strain-Based Procedure To Obtain Design: P-M Interaction Curves of Slender RC Wall SectionsAchilles TroyNo ratings yet

- Figure 9.1. Materials and Equipments Utililzed For The Determination of Compressive StrengthDocument7 pagesFigure 9.1. Materials and Equipments Utililzed For The Determination of Compressive StrengthKaren LovedorialNo ratings yet

- Solution To Final Exam Paper-T2-2021Document12 pagesSolution To Final Exam Paper-T2-2021Adrian VuNo ratings yet

- Numerical Analysis of Masonry-In Filled Reinforced Concrete FramesDocument19 pagesNumerical Analysis of Masonry-In Filled Reinforced Concrete FramesKhumbu XettriNo ratings yet

- Plaxis On The Use of The Shotcrete Udsm For Modelling Concrete 2016Document22 pagesPlaxis On The Use of The Shotcrete Udsm For Modelling Concrete 2016tpgggkNo ratings yet

- RC Part-I Flexure 2021 SVDocument47 pagesRC Part-I Flexure 2021 SVSebastián Cruz PongutáNo ratings yet

- Shear Strength Between Concrete LayerDocument6 pagesShear Strength Between Concrete LayerAndrian FirmansyahNo ratings yet

- 1994 LourencoDocument34 pages1994 LourencoDavid Salomão Pinto Castanho BizarroNo ratings yet

- Micro-Modeling of Masonry Infilled RC Moment Resisting Frames To Investigate Arrangement of Compressive Diagonal StrutsDocument16 pagesMicro-Modeling of Masonry Infilled RC Moment Resisting Frames To Investigate Arrangement of Compressive Diagonal StrutsCristian SANo ratings yet

- 01 Eurogeo 2000 - PavimentosDocument4 pages01 Eurogeo 2000 - PavimentosRômulo GomesNo ratings yet

- CconfinedDocument7 pagesCconfinedchaitanya krishnaNo ratings yet

- Simulations of Cohesive Fracture Behavior of Reinforced Concrete by A Fracture-Mechanics-Based Damage ModelDocument16 pagesSimulations of Cohesive Fracture Behavior of Reinforced Concrete by A Fracture-Mechanics-Based Damage ModelAndres Rodelo SeguraNo ratings yet

- Coeficient Seism DisertatieDocument30 pagesCoeficient Seism Disertatieflavian_gafitaNo ratings yet

- Rr210102 Strength of Materials IDocument8 pagesRr210102 Strength of Materials ISrinivasa Rao GNo ratings yet

- Flexural TestDocument8 pagesFlexural TestNawaf Al-TamimiNo ratings yet

- Lab Report U1 (Workability)Document11 pagesLab Report U1 (Workability)SYaz WAniNo ratings yet

- SMiRT-23 Impact Paper-FinalDocument10 pagesSMiRT-23 Impact Paper-FinalMrigendra Nath RayNo ratings yet

- 1994 - Lourenco - Analysis of Masonry Structures With Interface ElementsDocument35 pages1994 - Lourenco - Analysis of Masonry Structures With Interface ElementsroccaNo ratings yet

- Example 7.5Document4 pagesExample 7.5Richardson Chavez TaypeNo ratings yet

- Compressive Strength TestDocument8 pagesCompressive Strength TestBeaver CaraNo ratings yet

- Mto Curvatura ManderDocument17 pagesMto Curvatura ManderSergio Echeverría RNo ratings yet

- Confinement Effects On The Steel-Concrete Bond Strength 2012Document13 pagesConfinement Effects On The Steel-Concrete Bond Strength 2012Saurabh PednekarNo ratings yet

- XC Tension StiffeningDocument6 pagesXC Tension StiffeningLuis C. Pérez Tato100% (1)

- Preboard 2 DesignDocument7 pagesPreboard 2 DesignApril Benosa100% (1)

- Anshuman Th4 Experiment10 1401e5d4Document5 pagesAnshuman Th4 Experiment10 1401e5d4Aayushman SinghNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- CE202 grp3 Chap1 5Document50 pagesCE202 grp3 Chap1 5Christian Kyle BeltranNo ratings yet

- Footing ScheduleDocument1 pageFooting ScheduleChristian Kyle BeltranNo ratings yet

- Design Report FinalDocument72 pagesDesign Report FinalChristian Kyle BeltranNo ratings yet

- Gantt Final To Print Na ThisDocument6 pagesGantt Final To Print Na ThisChristian Kyle BeltranNo ratings yet

- Preliminary SizesDocument1 pagePreliminary SizesChristian Kyle BeltranNo ratings yet

- Updated With 0.0036 Drift Chap 3Document69 pagesUpdated With 0.0036 Drift Chap 3Christian Kyle BeltranNo ratings yet

- N I C e - BylawsDocument5 pagesN I C e - BylawsChristian Kyle BeltranNo ratings yet

- Bill of Quantity 040219Document125 pagesBill of Quantity 040219Christian Kyle BeltranNo ratings yet

- Christian Kyle S. Beltran - NU Fairview 06192020Document1 pageChristian Kyle S. Beltran - NU Fairview 06192020Christian Kyle BeltranNo ratings yet

- CMTL - Group3 Lab Report 6 DensityDocument5 pagesCMTL - Group3 Lab Report 6 DensityChristian Kyle BeltranNo ratings yet

- CMPM Q3 SolutionDocument2 pagesCMPM Q3 SolutionChristian Kyle BeltranNo ratings yet

- Module 2 Diffrential Calculus P1Document1 pageModule 2 Diffrential Calculus P1Christian Kyle BeltranNo ratings yet

- Beltran-Written#1-Blue ScholarDocument4 pagesBeltran-Written#1-Blue ScholarChristian Kyle BeltranNo ratings yet

- CE202 grp3 Chap1 5Document50 pagesCE202 grp3 Chap1 5Christian Kyle BeltranNo ratings yet

- Module 1 AlgebraDocument2 pagesModule 1 AlgebraChristian Kyle BeltranNo ratings yet

- Peer Evaluation Form For Ethnographic Research Paper: N.callado@feudiliman - Edu.ohDocument5 pagesPeer Evaluation Form For Ethnographic Research Paper: N.callado@feudiliman - Edu.ohChristian Kyle BeltranNo ratings yet

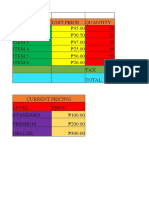

- Menu Item Unit Price Quantity Item 1 35.00 20 Item 2 30.50 15 Item 3 37.00 40 Item 4 25.00 40 Item 5 56.00 35 Item 6 26.00 25 TAX TotalDocument2 pagesMenu Item Unit Price Quantity Item 1 35.00 20 Item 2 30.50 15 Item 3 37.00 40 Item 4 25.00 40 Item 5 56.00 35 Item 6 26.00 25 TAX TotalChristian Kyle BeltranNo ratings yet

- Miguel Ryan R. Arcilla: ObjectivesDocument1 pageMiguel Ryan R. Arcilla: ObjectivesChristian Kyle BeltranNo ratings yet

- Items PHP Price USD PriceDocument4 pagesItems PHP Price USD PriceChristian Kyle BeltranNo ratings yet

- Chapter2 ThesisDocument17 pagesChapter2 ThesisJoe Yuan Julian Mambu67% (3)

- Tingi - Tingi Cultural Phenomena in The PhilippinesDocument10 pagesTingi - Tingi Cultural Phenomena in The PhilippinesChristian Kyle Beltran100% (1)

- Items PHP Price USD PriceDocument4 pagesItems PHP Price USD PriceChristian Kyle BeltranNo ratings yet

- FKB My First Book of AnimalsDocument22 pagesFKB My First Book of Animalsrooivalkza0% (1)

- Media and Informatio N Literacy: Christian Kyle S. Beltran STEM 12-SimplicityDocument7 pagesMedia and Informatio N Literacy: Christian Kyle S. Beltran STEM 12-SimplicityChristian Kyle BeltranNo ratings yet

- The Science of Sociology and Anthropology: Week 3Document22 pagesThe Science of Sociology and Anthropology: Week 3Christian Kyle BeltranNo ratings yet

- Table 2Document1 pageTable 2Christian Kyle BeltranNo ratings yet

- Chapter 2 Review of Related Literature ADocument17 pagesChapter 2 Review of Related Literature AChristian Kyle BeltranNo ratings yet

- Hydraulic Actuator Bulldozer Powered by DC Motors: MethodologyDocument3 pagesHydraulic Actuator Bulldozer Powered by DC Motors: MethodologyChristian Kyle BeltranNo ratings yet

- Media and Informatio N Literacy: Christian Kyle S. Beltran STEM 12-SimplicityDocument7 pagesMedia and Informatio N Literacy: Christian Kyle S. Beltran STEM 12-SimplicityChristian Kyle BeltranNo ratings yet

- Culture & Society, Its Nature and Dynamics Human Variations: Week 2Document41 pagesCulture & Society, Its Nature and Dynamics Human Variations: Week 2Christian Kyle BeltranNo ratings yet

- Testing Template - Plan and Cases CombinedDocument3 pagesTesting Template - Plan and Cases Combinedapi-19980631No ratings yet

- Ticket - Abibus PDFDocument1 pageTicket - Abibus PDFJosephNo ratings yet

- Case Analysis: A Simple Strategy at Costco: Informative Background InformationDocument15 pagesCase Analysis: A Simple Strategy at Costco: Informative Background InformationFred Nazareno CerezoNo ratings yet

- IBEC BPL System ArchitectureDocument2 pagesIBEC BPL System ArchitectureAleksandar ConevNo ratings yet

- CHAPTER 2 Principles of MarketingDocument41 pagesCHAPTER 2 Principles of MarketingASHIMA THAPANo ratings yet

- Labour and Human Resource Issues in Industry 4.0: A Case Study Report OnDocument20 pagesLabour and Human Resource Issues in Industry 4.0: A Case Study Report OnNPMYS23100% (1)

- Nigeria Country Profile - 0Document4 pagesNigeria Country Profile - 0Nden SohbutNo ratings yet

- Talent Neuron NewsletterDocument2 pagesTalent Neuron NewsletterTalent NeuronNo ratings yet

- Materials Science and Engineering ADocument10 pagesMaterials Science and Engineering Akhudhayer1970No ratings yet

- Research On Restaurant DesignDocument20 pagesResearch On Restaurant DesignCrizalene Caballero100% (1)

- Design Calculation of Braking System (Landcruiser) : AbstractDocument4 pagesDesign Calculation of Braking System (Landcruiser) : AbstractDr. Aung Ko LattNo ratings yet

- Application For Type Aircraft Training: Farsco Training Center IR.147.12Document1 pageApplication For Type Aircraft Training: Farsco Training Center IR.147.12benyamin karimiNo ratings yet

- Types of Annuity & Intra Year Compounding: Dr. Anubha GuptaDocument15 pagesTypes of Annuity & Intra Year Compounding: Dr. Anubha GuptarashmipoojaNo ratings yet

- Packages: Khidmatul A'WaamDocument4 pagesPackages: Khidmatul A'WaamAltaaf IzmaheroNo ratings yet

- Device Protocol - v2.2.4Document81 pagesDevice Protocol - v2.2.4Aston MartinNo ratings yet

- Helicoil Plus en 0100Document56 pagesHelicoil Plus en 0100Khổng MạnhNo ratings yet

- CHAPTER ONE Structural GeologyDocument46 pagesCHAPTER ONE Structural GeologyAfolabi Eniola AbiolaNo ratings yet

- SIFI-131 Fire Protection in Electrical Equipment RoomsDocument8 pagesSIFI-131 Fire Protection in Electrical Equipment RoomsemiljanlazeNo ratings yet

- 02 IG4K TechnologiesDocument47 pages02 IG4K TechnologiesM Tanvir AnwarNo ratings yet

- Assessment Form (Indoor)Document14 pagesAssessment Form (Indoor)Mark Tally0% (1)

- Crisostomo Vs Courts of Appeal G.R. No. 138334 August 25, 2003Document5 pagesCrisostomo Vs Courts of Appeal G.R. No. 138334 August 25, 2003RGIQNo ratings yet

- GM1. Intro To FunctionsDocument5 pagesGM1. Intro To FunctionsGabriel Benedict DacanayNo ratings yet

- DQI and Use Mentors JDDocument2 pagesDQI and Use Mentors JDLunaltNo ratings yet

- Maneesh Misra CV - 1Document3 pagesManeesh Misra CV - 1Rohit KarhadeNo ratings yet

- As 29 Provisions Contingent Liabilities and Contingent AssetsDocument38 pagesAs 29 Provisions Contingent Liabilities and Contingent AssetsAayushi AroraNo ratings yet

- Map of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectDocument10 pagesMap of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectAltanochir AagiiNo ratings yet

- HPDocument71 pagesHPRazvan OracelNo ratings yet

- Science, Technology and SocietyDocument2 pagesScience, Technology and SocietyHamieWave TVNo ratings yet