Professional Documents

Culture Documents

Anshuman Th4 Experiment10 1401e5d4

Uploaded by

Aayushman SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anshuman Th4 Experiment10 1401e5d4

Uploaded by

Aayushman SinghCopyright:

Available Formats

Name: Anshuman Roll no: 200157 Batch No: Th-4

Set-2 Exp-5: Plane Strain Fracture Toughness

1. Title: Effect of notch length on the tensile properties and measurement of fracture

toughness of aluminum

2. Objective: To understand the effect of notch length on the tensile properties of pure

aluminum. In addition, measurement of fracture toughness of aluminum sample using ASTM

E399.

3. Requirements of the experiment:

a) Flat tensile samples of aluminum with different notch length

b) Standard compact tension (CT) sample for measurement of fracture toughness

c) Universal Testing Machine (UTM)

d) Vernier calliper

Initial dimensions of the aluminum sample:

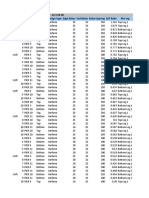

Notch length(mm) Initial gauge Initial Initial width(mm)

length(mm) thickness(mm)

3.5 30 2.45 10

5 30 2.45 10

6.5 30 2.45 10

8 30 2.45 10

Plot of engineering strain vs engineering stress:

Effect of the notch length on the mechanical properties:

Notch length(mm) Ultimate tensile strength % Elongation up to fracture

(MPa)

3.5 90.977 8.43

5 69.981 7.03

6 48.718 5.97

8 24.832 4.16

Major conclusion from these values:

With increase in the length of the notch UTS of the materials decreases and therefore the

elongation of the material also decreases implying decrease in strength.

Load vs Displacement curve from given data:

Load vs Displacement

12

10

8

Load (kN)

0

0.00000000000 0.50000000000 1.00000000000 1.50000000000 2.00000000000

Displacement (mm)

From graph

PQ= 8.4725 kN

Calculation of KQ

B=5.8mm

W=25.46mm

a=13.041

a/W=0.51 this condition is satisfied

a,B >=2.5*(Kq/yield stress)^2

Pmax =38.671

Pmax >= 1.10*8.4725 this condition is also not satisfied

f(a/W) =10.033

KQ = PQ /(B√W) * f(a/W)

KQ= 8.4725 /(5.8*(25.46)^1/2*10.033

=2.9045kNm^-1.5

General questions and answers:

1. What is stress concentration and stress concentration factor?

Stress concentrations are places where stress is higher than elsewhere, stress concentration

factor is ratio of maximum stress to nominal stress of a cross section.

2. What is stress intensity factor? What is the relationship between stress intensity factor,

stress, and crack length?

The stress intensity factor is a precise indicator of the elastic strain energy present in a

cracked stressed material. Stress intensity at any point is directly proportional to applied load

on the material.

The relationship between stress intensity factor, stress, and crack length is given by σ√πa.

3. What is fracture toughness? What does ‘I’ mean in KIC?

Fracture toughness defines the resistance of brittle materials to crack propagation under

stress, if the longer the crack, the lower the stress needed to fracture.

I represents Mode I stress-intensity.

4. Explain the effect of thickness on the fracture toughness. What is plane strain and plane

stress fracture toughness?

Thickness increases fracture toughness. After peaking, specimen thickness lowers fracture

toughness.

Fracture toughness is lowest under plane strain situations.

Plane strain fracture toughness is the key stress intensity component in mode I loading under

plane strain conditions.

5. What is compact tension specimen?

ASTM and ISO standard notched specimens include compact tension specimens (CT).

Fracture mechanics and corrosion testing use compact tension specimens to determine

material fracture toughness and fatigue crack propagation.

Using a notched sample and a laboratory fatigue test machine to apply cyclic force through

pins in the holes creates a fatigue crack.

You might also like

- Ce 14444 Lab7Document5 pagesCe 14444 Lab7Owen Francis Arles MaongatNo ratings yet

- cvp342 2Document7 pagescvp342 2Alok Kumar MeenaNo ratings yet

- UIT-ahyan Ince2Document23 pagesUIT-ahyan Ince2Md MehtabNo ratings yet

- VrubfirbDocument8 pagesVrubfirb9245126694No ratings yet

- Steel Fibre Reinforced ConcreteDocument7 pagesSteel Fibre Reinforced ConcretePradeesh JNo ratings yet

- Exercises On Fracture MechanicsDocument33 pagesExercises On Fracture Mechanicsyaswanth199260% (5)

- Deep - Beam With Cover Page v2Document13 pagesDeep - Beam With Cover Page v2abdoNo ratings yet

- MBM Lab ReportDocument11 pagesMBM Lab ReportPavan Kalyan PNo ratings yet

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- Size Effect On Shear Strength of RC Beams Using HSC Without Shear ReinforcementDocument16 pagesSize Effect On Shear Strength of RC Beams Using HSC Without Shear ReinforcementHuda JawadNo ratings yet

- Flexural TestDocument8 pagesFlexural TestNawaf Al-TamimiNo ratings yet

- Fatigue Life Assessment of Bolted Connections: Aliou Badara Camara, Fabienne PennecDocument8 pagesFatigue Life Assessment of Bolted Connections: Aliou Badara Camara, Fabienne Pennecprraaddeej chatelNo ratings yet

- 1 Tutorial Questions Mee 309Document5 pages1 Tutorial Questions Mee 309Moshood AdeleyeNo ratings yet

- Material Yr1 - Tutorial 6Document16 pagesMaterial Yr1 - Tutorial 6Ahmed TahaNo ratings yet

- Cumulative Fatigue Damage AnalysisDocument5 pagesCumulative Fatigue Damage AnalysisdonaNo ratings yet

- Strut Design SheetDocument84 pagesStrut Design SheetHafiz Kamarudin100% (2)

- 2.2 Strengthening The T Elements With Carbon Fiber Reinforced Polymer PlatesDocument11 pages2.2 Strengthening The T Elements With Carbon Fiber Reinforced Polymer PlatesdhruvgokuNo ratings yet

- Fracture Mechanics ExercisesDocument33 pagesFracture Mechanics Exercises2luckystar100% (1)

- Josh Munsayac - 10 TestingRebar - 1 29 24Document8 pagesJosh Munsayac - 10 TestingRebar - 1 29 24Adam MirandaNo ratings yet

- Tension and Torsion TestsDocument19 pagesTension and Torsion Testsyeast taeNo ratings yet

- Group 2 - Experiment No. 5 Tensile TestDocument5 pagesGroup 2 - Experiment No. 5 Tensile TestSevi DumpNo ratings yet

- Shear Design of A Hollow Core SlabDocument17 pagesShear Design of A Hollow Core SlabjrandeepNo ratings yet

- RAD CourseworkDocument12 pagesRAD CourseworkAlfieNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Vaneshwar Sahu Paper PDFDocument7 pagesVaneshwar Sahu Paper PDFDida KhalingNo ratings yet

- SheetDocument15 pagesSheetHossam Sallam100% (1)

- 10 - Tavio-ITS PDFDocument8 pages10 - Tavio-ITS PDFMuhammad IchsanNo ratings yet

- Numerical Studies On Impact Response of Reinforced Concrete Beams Using FE SoftwareDocument18 pagesNumerical Studies On Impact Response of Reinforced Concrete Beams Using FE SoftwareMohamed YasserNo ratings yet

- Minimum Reinforcement in RC BeamsDocument7 pagesMinimum Reinforcement in RC BeamsNguyen KhoiNo ratings yet

- Assignment 2Document2 pagesAssignment 2spal1715No ratings yet

- Prestressed DesignDocument10 pagesPrestressed DesignMario FeghaliNo ratings yet

- Prestressed DesignDocument10 pagesPrestressed DesignErmal BeqirajNo ratings yet

- BaitapDocument10 pagesBaitapChuoiEmNo ratings yet

- Tensile Test Report - COMPLETEDocument9 pagesTensile Test Report - COMPLETEJasanta Jinor50% (2)

- Constraint Loss Correction Enhancing Transferability of F 2023 EngineeringDocument13 pagesConstraint Loss Correction Enhancing Transferability of F 2023 Engineeringjose carlos julca eleraNo ratings yet

- Investigation of The Size Effect in Shear of Steel Fiber Reinforced Concrete (SFRC) Slender BeamsDocument8 pagesInvestigation of The Size Effect in Shear of Steel Fiber Reinforced Concrete (SFRC) Slender Beamsalbertofer123No ratings yet

- Numerical Modelling of Large Scale Steel Fibre Reinforcedreinforced Concrete Beams Failing in ShearDocument11 pagesNumerical Modelling of Large Scale Steel Fibre Reinforcedreinforced Concrete Beams Failing in ShearChris LumyNo ratings yet

- Thesis On Fretting Fatigue in Railway AxlesDocument6 pagesThesis On Fretting Fatigue in Railway Axlespamelasmithlittlerock100% (2)

- Plate #2 Tensile TestDocument6 pagesPlate #2 Tensile TestChristian D. AllanaNo ratings yet

- 01028393Document9 pages01028393Powerranger2.0No ratings yet

- Signature RedactedDocument158 pagesSignature RedactedFerdinandVelesNo ratings yet

- Reinforced High-Strength Concrete Beams in FlexureDocument11 pagesReinforced High-Strength Concrete Beams in FlexureAndrei IancuNo ratings yet

- Prediction of Fatigue Life by Crack Growth Analysis: Original ArticleDocument9 pagesPrediction of Fatigue Life by Crack Growth Analysis: Original ArticleAmine KhalfallahNo ratings yet

- M 004 ExercisesDocument33 pagesM 004 ExercisesKannan MuthusamyNo ratings yet

- 1 s2.0 S0734743X99001499 MainDocument29 pages1 s2.0 S0734743X99001499 Main037 SANTHOSH K RNo ratings yet

- 1 s2.0 S1350630722006033 MainDocument18 pages1 s2.0 S1350630722006033 Mainimanz5No ratings yet

- SeminarDocument24 pagesSeminarJyothishkumar MNo ratings yet

- TENSILE Lab SheetDocument4 pagesTENSILE Lab SheetKerem Taha TekinNo ratings yet

- MPSC MES Mains Test SeriesDocument29 pagesMPSC MES Mains Test SeriesSanket BagadeNo ratings yet

- Composite StructuresDocument25 pagesComposite StructuresVivek Premji100% (1)

- Bending Tests: 3-Point and 4-Point BendingDocument20 pagesBending Tests: 3-Point and 4-Point BendingTuấn NguyễnNo ratings yet

- Comparative Analysis of Spectral andDocument14 pagesComparative Analysis of Spectral andAlvin ReynaldiNo ratings yet

- Tensile Test Lab ReportDocument4 pagesTensile Test Lab ReportElisha NissiNo ratings yet

- Tensile Lab Engineering MaterialsDocument9 pagesTensile Lab Engineering MaterialsOmar A-gNo ratings yet

- 09.material Lab Report (Lacx) IVDocument14 pages09.material Lab Report (Lacx) IVJack JongNo ratings yet

- Plastic Analysis Lab ReportDocument11 pagesPlastic Analysis Lab ReportAsyiqindinia100% (1)

- AS3600 LosseseDocument13 pagesAS3600 LossesezfanNo ratings yet

- Exp 1 ErianeDocument20 pagesExp 1 ErianeEriane GarciaNo ratings yet

- Shearing Resistance of Steel Fiber Reinforced Self Consolidating Concrete Beams Without StirrupsDocument8 pagesShearing Resistance of Steel Fiber Reinforced Self Consolidating Concrete Beams Without StirrupsSheik MohamedNo ratings yet

- EC2 Crack Width and Stress LimitationDocument11 pagesEC2 Crack Width and Stress LimitationselinaNo ratings yet

- EXPERIMENT-3 SET-2 - AAYUSHMAN - 200010 - 584e2dbbDocument10 pagesEXPERIMENT-3 SET-2 - AAYUSHMAN - 200010 - 584e2dbbAayushman SinghNo ratings yet

- 2 - Letter HeadDocument1 page2 - Letter HeadAayushman SinghNo ratings yet

- Payment Schedule 1Document1 pagePayment Schedule 1Aayushman SinghNo ratings yet

- On ItoDocument2 pagesOn ItoAayushman SinghNo ratings yet

- Materials 15 07573Document16 pagesMaterials 15 07573Aayushman SinghNo ratings yet

- JOHANSSON (2003) - Composite Action in Connection Regions of Concrete-Filled Steel Tube ColumnsDocument18 pagesJOHANSSON (2003) - Composite Action in Connection Regions of Concrete-Filled Steel Tube ColumnsRenata MartiniNo ratings yet

- Fatigue Life Analysis of Ramp Door Ferry Ro-Ro GT 1500 Using Finite Element MethodDocument8 pagesFatigue Life Analysis of Ramp Door Ferry Ro-Ro GT 1500 Using Finite Element Methodgunawan.MSJR gunawan.MSJRNo ratings yet

- ASME Horizontal Vessel Analysis - Friction 0.025 PDFDocument10 pagesASME Horizontal Vessel Analysis - Friction 0.025 PDFSyed Zain AliNo ratings yet

- Gen RC Building Tutorial 1490305167Document40 pagesGen RC Building Tutorial 1490305167VijayNo ratings yet

- IESAV - 2b. Design of Prestressed Transfer PlateDocument39 pagesIESAV - 2b. Design of Prestressed Transfer PlateMelinda GordonNo ratings yet

- Ductility Characteristics of Partially Restrained Beam-to-Column Composite Connections in Concrete Filled Square TubesDocument11 pagesDuctility Characteristics of Partially Restrained Beam-to-Column Composite Connections in Concrete Filled Square TubesPrapa KaranNo ratings yet

- Applying The Asme Codes: Plant Piping and Pressure Vessels: James A. WingateDocument3 pagesApplying The Asme Codes: Plant Piping and Pressure Vessels: James A. WingateRyan FisherNo ratings yet

- Newcombe, 2010, Multistorey TimberDocument86 pagesNewcombe, 2010, Multistorey Timberprisciliano1No ratings yet

- Fundamental Governing Equations For Hydraulic FracturingDocument16 pagesFundamental Governing Equations For Hydraulic FracturingRanggaNo ratings yet

- Long Front Wall 25 at 150Document10 pagesLong Front Wall 25 at 150kuttyNo ratings yet

- 1.1. General: Seismic Performance of Steel On Different Span ArrangementsDocument7 pages1.1. General: Seismic Performance of Steel On Different Span ArrangementsChetan PatilNo ratings yet

- Da Pped BeamsDocument31 pagesDa Pped BeamsjeanfatNo ratings yet

- Aisc Steel Construction Manual 13 TH 26Document31 pagesAisc Steel Construction Manual 13 TH 26Fritzie VegaNo ratings yet

- 1 Expt No.: 04: - Name: Yash Sharma - Roll No: 190040134 - Batch: S2Document3 pages1 Expt No.: 04: - Name: Yash Sharma - Roll No: 190040134 - Batch: S2yashika bairwaNo ratings yet

- Izmir Institute of Technology Department of Mechanical Engineering ME150 Materials Science and Engineering IDocument17 pagesIzmir Institute of Technology Department of Mechanical Engineering ME150 Materials Science and Engineering Iahmet şahinNo ratings yet

- Analysis of Effect of Structural Irregularity in Multistorey Building Under Seismic LoadingDocument8 pagesAnalysis of Effect of Structural Irregularity in Multistorey Building Under Seismic LoadingBehroz BehzadNo ratings yet

- Understanding Frequency Domain Viscoelasticity in AbaqusDocument13 pagesUnderstanding Frequency Domain Viscoelasticity in Abaqussaeed-21No ratings yet

- Home WorkDocument152 pagesHome Workra44993541No ratings yet

- Model GDKDocument21 pagesModel GDKCristian BarbuceanuNo ratings yet

- Benchmark Cases For Advanced Design of Structural Steel ConnectionsDocument26 pagesBenchmark Cases For Advanced Design of Structural Steel Connectionswendydy6No ratings yet

- 53:030 Soil Mechanics 3 S.H. DescriptionDocument4 pages53:030 Soil Mechanics 3 S.H. Descriptionkaas1992No ratings yet

- Fractography, Fluidity, and Tensile Properties of Aluminum/Hematite Particulate CompositesDocument6 pagesFractography, Fluidity, and Tensile Properties of Aluminum/Hematite Particulate CompositesAugusto OliveiraNo ratings yet

- Module 4 Shear Force Bending MomentDocument32 pagesModule 4 Shear Force Bending MomentTarun Kumar100% (1)

- Chapter 8 - Rock TestingDocument52 pagesChapter 8 - Rock TestingZulaikha Kamal67% (3)

- Laterally Loaded Rock Socket Design - A Review of The P-Y Curve Design ApproachDocument9 pagesLaterally Loaded Rock Socket Design - A Review of The P-Y Curve Design ApproachmyplaxisNo ratings yet

- Saman A. Abdullah-A Reliability-Based Deformation Capacity Model For ACI 318 Compliant Special Structural Walls PDFDocument12 pagesSaman A. Abdullah-A Reliability-Based Deformation Capacity Model For ACI 318 Compliant Special Structural Walls PDFRomanbabu OinamNo ratings yet

- 12 PLAXISBulletinDocument24 pages12 PLAXISBulletinMark ChanNo ratings yet

- MB4 (Rafter To Corner Column)Document63 pagesMB4 (Rafter To Corner Column)Crystal JaneNo ratings yet

- SOM Lab ManualDocument32 pagesSOM Lab ManualMuhammad Junaid100% (1)

- Bamboo Moso MechaDocument13 pagesBamboo Moso MechaYopNo ratings yet