Professional Documents

Culture Documents

MSH AuditGuide Confined-Space

Uploaded by

Pankaj PandeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSH AuditGuide Confined-Space

Uploaded by

Pankaj PandeyCopyright:

Available Formats

Confined space audit

– guide

Approved: July 2020

Level 2, 1 Adelaide Terrace East Perth Western Australia 6004

Postal address: Locked Bag 100 East Perth WA 6892

Telephone: 1800 SAFE MINE (1800 7233 64)

ResourcesSafety@dmirs.wa.gov.au

www.dmirs.wa.gov.au

Table of contents

Introduction ........................................................................................................................... 3

1 Confined space............................................................................................................... 6

2 Confined space hazards ................................................................................................. 7

3 Risk management......................................................................................................... 14

4 Design, manufacture, supply and modification considerations ...................................... 17

5 Training and competency ............................................................................................. 20

6 Isolation and atmospheric requirements ....................................................................... 22

7 Emergency response equipment .................................................................................. 24

8 Accident / incident investigation .................................................................................... 25

Confined space audit – guide Page 2 of 25

Introduction

The confined space audit has been developed to promote safety in managing confined space entry in

the Western Australian (WA) mining industry.

The audit was trialled a number of times by inspectors from the Department of Mines, Industry

Regulation and Safety (DMIRS). The content was then reviewed and updated, and the sections

reordered, as part of continuous improvement, and in June 2020 was approved to be a published

audit.

DMIRS encourages WA mining operators to use these documents to perform regular confined space

audits at their sites.

The confined space audit should be read and utilised in conjunction with the mandatory Australian

Standard AS2865 Confined Spaces and the Mines Safety and Inspection Act 1994 (MSIA) and Mines

Safety and Inspection Regulations 1995 (MSIR).

Where, in the intent, the word “verify” is used, this means that it is a regulatory requirement, which is

mandatory and has to be complied with. Where, in the intent, the word “ensure” is used, it is not a

mandatory requirement, but it does indicate good practice.

List of abbreviations

AS Australian Standard

c. clause (of the Australian Standard)

cc. clauses (of the Australian Standard)

DMIRS Department of Mines, Industry Regulation and Safety

ISO International Standards Organisation

JHA Job Hazard Analysis

MSIA Mines Safety and Inspection Act 1994

MSIR Mines Safety and Inspection Regulations 1995

OSH Occupational safety and health

PPE Personal protective equipment

r. Regulation (of the MSIR)

rr. Regulations (of the MSIR)

s. Section (of the MSIA)

ss. Sections (of the MSIA)

SHRep Safety and health representative

SRS DMIRS online Safety Regulation System

Glossary

Airborne contaminant

Any contaminant present in the air that may be harmful to persons.

Atmospheric monitoring

The continuous measurement of oxygen concentration or airborne contaminants over an

uninterrupted period of time.

Atmospheric testing

The measurement of oxygen concentration or airborne contaminants.

Confined space audit – guide Page 3 of 25

Competent person

Person who is appointed or designated by the employer to perform specified duties which the person

is qualified to perform by knowledge, training and experience.

Confined space

An enclosed or partially enclosed space that is not intended or designed primarily for human

occupancy, within which there is a risk of one or more of the following:

(a) An oxygen concentration outside the safe oxygen range.

(b) A concentration of airborne contaminant that may cause impairment, loss of consciousness or

asphyxiation.

(c) A concentration of flammable airborne contaminant that may cause injury from fire or explosion.

(d) Engulfment in a stored free-flowing solid or a rising level of liquid that may cause suffocation or

drowning.

Confined space entry

When a person’s head or upper body is within the boundary of the confined space.

NOTE: Inserting an arm for the purpose of atmospheric testing is not considered as entry to a

confined space.

Contaminant

Any dust, fume, mist, vapour, biological matter, gas or other substance in liquid or solid form, the

presence of which may be harmful to persons.

Engulfment

The immersion or envelopment of a person by a solid or liquid (e.g. ore, slurry, scale, sand, coal,

fertiliser, chemical and other substances in a powder or granular form) that is stored within the

confined space.

Hot work

Welding, thermal or oxygen cutting, heating, including fire-producing or spark-producing operations

that may increase the risk of fire or explosion.

Self-contained breathing apparatus (SCBA)

A portable respirator that supplies oxygen, air or other respirable gas from a source carried by the

user.

Stand-by person (or sentry)

A competent person assigned to remain on the outside of, and in close proximity to, the confined

space and capable of being in continuous communication with and, if practical, observing those

inside. In addition, where necessary, the competent person may operate and monitor equipment for

the safety of personnel in the confined space and initiate emergency response.

Task-related hazard

In respect to a confined space, exposure to a hazard because of the task being conducted on or in

the confined space.

Written authority

A document that gives permission for entry into a confined space and the conduct of tasks associated

with the confined space.

NOTE: The written authority is sometimes known as an 'entry permit', 'access authority' or 'permit to

work'.

Confined space audit – guide Page 4 of 25

Further information

Documentation referred to in this audit can be found via the links below:

Acts and Regulations, Department of Justice www.legislation.wa.gov.au

- Mines Safety and Inspection Act 1994

www.legislation.wa.gov.au/legislation/statutes.nsf/law_a515.html

- Mines Safety and Inspection Regulations 1995

www.slp.wa.gov.au/legislation/statutes.nsf/law_s4641.html

Australian Standard AS 2865: Confined spaces

Australian Standard AS 1674: Safety in welding and allied processes

Mining safety publications, Department of Mines, Industry Regulation and Safety (DMIRS),

www.dmp.wa.gov.au/Safety/Mining-Safety-publications-16162.aspx

Confined spaces code of practice, Safe Work Australia, 2016.

https://www.safeworkaustralia.gov.au/system/files/documents/1705/mcop-confined-spaces-v3.pdf

Confined space audit – guide Page 5 of 25

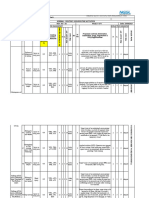

1 Confined space

Requirements and standards associated with confined space.

Point Standard Guideline

1.1 Confined spaces on the site have Intent:

been identified using the correct To verify that all potential confined spaces are

definition within AS2865. identified consistently with the current legislation.

Personnel:

Safety and health personnel, safety and health

representatives, and relevant employees

(operations, maintenance and contractors).

Method:

Review relevant site register/process/procedures,

JHA, SWP or SOP’s etc. relating to confined space

classification. Review if employees and employers

use the confined space identification principles

outlined in AS 2865 c. 3.2.1. Visual inspection to

determine if an enclosed or partially enclosed

space is identified as a non-confined space, review

the risk assessment that has been completed to

validate this determination.

Refer to AS 2865 cc. 1.5.5, 3.1.1, 2.9.1, 2.9.2, 2.9.3

and 3.2.1.

1.2 Confined spaces that may be Intent:

introduced to site as a result of To verify that all new potential confined spaces are

changes in plant, or during identified consistently with the current legislation.

construction activities are identified

Personnel:

as part of the change management

process. Safety and health personnel, safety and health

representatives, and relevant employees

(operations, maintenance and contractors).

Method:

Review relevant site process/procedures, JHA,

SWP or SOP’s etc. relating to confined space

classification. Review relevant site

processes/procedures relevant to change

management relating to introduction of confined

spaces. Review if employees and employers use

the confined space identification principles outlined

in AS 2865 c3.2.1.

Refer to AS 2865 cc. 1.5.5, 2.4.5, 3.1.1 and 3.2.1.

Confined space audit – guide Page 6 of 25

2 Confined space hazards

Requirements and standards associated with confined space hazards.

Point Standard Guideline

2.1 For any confined space, the Intent:

hazards associated with To verify that all hazards associated with the tasks

conducting tasks in or on the being conducted in the confined space are

confined space shall be identified. identified prior to conducting the tasks.

Personnel:

Supervisors, relevant employees (operations,

maintenance and contractors), safety and health

representatives, and safety and health personnel

and emergency response coordinators and teams.

Method:

Review documents to ensure they identify all

hazards associated with the task being carried out

within the confined space e.g.

A reduction in the oxygen concentration

Oxygen enriched atmospheres

The use of chemicals

Airborne containments

Noise

Temperature

Radiation within the confined spaces

Unsafe entry and exit or unsafe surfaces

Inadequate lighting

Exposed live electrical conductors

Fall from heights

Refer to AS 2865 c3.1.1 and 3.1.2.

Confined space audit – guide Page 7 of 25

Point Standard Guideline

2.2 No person shall enter a confined Intent:

space unless – To verify that all confined space entries are

(a) review of the risk assessment conducted safely.

has been completed in Personnel:

accordance with Clauses 3.3.1

Permit-to-work officers, persons conducting tasks

and 3.3.5;

associated with confined spaces (including the

(b) written authority is provided to, standby person), supervisors, relevant employees

or completed by, the person (operations, maintenance and contractors).

responsible for direct control of

Method:

the tasks in the confined

space; Check that confined space entries are made under

the sites permit to work system or a similar system.

(c) the written authority includes

Inspect that signs and barriers are erected at each

any risk control measures or

entry/exit points to prevent unauthorised access.

precautions necessary,

Inspect that the sentry is aware of their role and the

including the number of stand-

tasks they need to perform and are able to monitor

by persons required, for the

all entry/exit points to prevent unauthorised entry.

safe entry and execution of the

Interview site personnel or working groups to

tasks;

assess whether they are aware of the confined

(d) they are advised of, space permit to work system and understand the

understand and comply with requirements before making an entry.

the requirements of the written

Refer to AS 2865 c. 3.4.29.

authority;

(e) a record of their presence in

the confined space is

maintained;

(f) signs and protective barriers

are erected to prevent entry of

persons not involved in the

tasks; and

(g) appropriate and sufficient

arrangements have been

made for the initiation of

emergency response and,

where necessary, rescue of

persons from the confined

space

Confined space audit – guide Page 8 of 25

Point Standard Guideline

2.3 A safe system of work is Intent:

implemented to eliminate or To verify that the risk of falling from height is

minimise falling from height risks identified and managed adequately.

when conducting tasks associated

Personnel:

with a confined space.

Persons conducting tasks associated with confined

spaces (including employees and contractors),

supervisors, and permit-to-work officers.

Method:

Review if the risk assessment appropriately

identifies the hazard of falling from height and

addresses these hazards. Verify that there is a risk

assessment when a falling from height hazard is

present when working in or around a confined

space. Verify that fall protection systems have been

implemented and individuals are competent and

trained to utilise them when there is a falling from

height hazard. Interview site personnel or working

groups to assess whether they have read and

understood the risk assessment, including

identifying and managing falling from height risks

associated with the tasks. Inspect if all entry points

are barricaded where there is a potential from a

falling at heights hazard.

Refer to AS 2865 c. 3.4.29. (f) and MSIR rr. 4.4 and

4.5.

2.4 Risk control measures shall require Intent:

– To verify the provision and effectiveness of a

(a) Provision of a standby person standby person or persons during a confined space

or persons; or entry; or an equal or better system.

(b) Systems of work methods and Personnel:

controls that provide an equal Persons conducting tasks associated with confined

or better safety outcome to that spaces (including employees and contractors),

provided by a standby person supervisors, and permit-to-work officers.

(see Clause 1.5.20).

Method:

Verify if a confined space sentry has been assigned

as a standby person or persons as required. If a

standby person is not assigned, verify that an equal

or better system of work method and control has

been implemented. Verify that the standby person

is able to communicate and monitor continuously all

personnel conducting tasks within the confined

space. Verify that communication equipment used

in the confined space are effective for the task.

Verify that personnel are entering and or exiting

from ONE designated entry point and that other

possible entry/exit points are barricaded and or

controlled. Interview the standby person to assess

whether he or she understands the sentry role and

has the ability to continuously monitor the safety of

all personnel inside the space.

Refer to AS 2865 c. 3.4.30.

Confined space audit – guide Page 9 of 25

Point Standard Guideline

2.5 Before a person enters a confined Intent:

space, and where it is technically To verify that the space is only entered or occupied

feasible to do so, the atmosphere when the atmosphere is safe.

of the confined space shall have –

Personnel:

(a) a safe oxygen range;

Supervisors, relevant employees (operations,

(b) airborne contaminants that maintenance and contractors), safety and health

may cause impairment, loss of representatives, safety and health personnel, and

consciousness or asphyxiation Ventilation Officer.

reduced to below the relevant Method:

exposure standards; and

Verify that the risks assessments addresses the

(c) a concentration of flammable requirements for gas testing/monitoring while tasks

airborne contaminant below are being conducted inside the confined space.

5% LEL Review other records/documents such as work

permits or procedures provide guidance on how

often gas testing should be conducted and when

gas monitoring is required.

Refer to AS 2865 cc. 3.4.31.

Confined space audit – guide Page 10 of 25

Point Standard Guideline

2.6 Where flammable airborne Intent:

contaminants are present in the To verify that adequate control measures are

atmosphere of a confined space, implemented for entries into a confined space with

the following requirements shall an unsafe atmospheric condition.

apply:

Personnel:

(a) Except in case of emergency

Persons conducting tasks associated with confined

response, entry shall not be

spaces (including employees and contractors),

permitted where the

supervisors, maintenance personnel, and safety

concentration of flammable

and health personnel.

airborne contaminants in the

atmosphere is 5% LEL or Method:

greater, or where the oxygen Verify that site policy/procedure does not allow

concentration of the entry into a confined space when an unsafe

atmosphere exceeds 23.5%. atmospheric condition is detected. Inspect and

(b) Where persons have entered assess that supplied-air respiratory protection

or are conducting tasks in a systems are available, accessible to relevant

confined space and the personnel and well maintained. Verify that relevant

concentration of flammable personnel are trained in the use of the supplied-air

airborne contaminant in the respiratory protections systems.

atmosphere of the confined Refer to AS2865 cc. 3.4.32 and MSIR 9.12

space has been found to be

greater than 5% LEL and less

than 10% LEL, the persons

shall be removed unless

continuous monitoring with a

suitably calibrated explosive

(flammable) atmospheric

substance detector is used in

the confined space at all times

while persons are present.

(c) Where the concentration of

flammable airborne

contaminant in the atmosphere

of a confined space has been

found to be 10% LEL or

greater, no persons shall

remain in the confined space.

Confined space audit – guide Page 11 of 25

Point Standard Guideline

2.7 Where the hierarchy of risk control Intent:

measures cannot provide a To verify that adequate control measures are

concentration of oxygen in the implemented for entry into a confined space with an

atmosphere greater than 19.5% or unsafe atmospheric condition.

the airborne contaminants that

Personnel:

may cause impairment, loss of

consciousness or asphyxiation Persons conducting tasks associated with confined

cannot be reduced to below the spaces (including employees and contractors),

relevant exposure standards, no supervisors, maintenance personnel, and safety

persons shall enter the confined and health personnel.

space unless they are equipped Method:

with supplied-air respiratory Verify that the site has a policy/procedure for the

protection and where appropriate, use of protective respiratory equipment whilst in a

personal protective equipment. confined space. Review training competencies for

individual utilising protective respiratory equipment

(fit test, utilisation etc.) Verify that the supplied-air

respiratory protections systems are readily

available, accessible to relevant personnel, well

maintained and calibrated/certified as per the OEM

recommendations.

Refer to AS2865 c3.4.33

2.8 Equipment shall be provided as Intent:

follows: To verify that suitable and well-functioning

(a) Suitable equipment shall be equipment is utilised for conducting tasks

provided including, where associated with a confined space.

necessary, equipment for – Personnel:

(i) personal protection; Persons conducting tasks associated with confined

(ii) emergencies including spaces (including employees and contractors),

rescue; supervisors, and safety and health personnel.

Method:

(iii) first aid;

Verify that gas monitors are regularly tested,

(iv) communication; and calibrated and serviced as per the OEM’s

(v) fire suppression. recommendations. Verify that the communication

equipment utilised such as radios are in good

(b) The equipment shall be working condition. Verify that the PPE, emergency

appropriate to the tasks to be equipment, first aid kit etc. are available and in

conducted in the confined good working condition. Verify that the fire

space, and maintained in a extinguishers available are serviced regularly and

proper working condition of the correct type.

Refer to AS 2865 c3.4.34 and MSIR r. 4.1.

Confined space audit – guide Page 12 of 25

Point Standard Guideline

2.9 Prior to a written authority being Intent:

cancelled, all tasks in the confined To verify that no person or unauthorised equipment

space shall cease and all persons are inside the confined space prior to putting the

shall be removed from the confined space online.

space.

Personnel:

Permit-to-work officers, persons conducting tasks

associated with confined spaces (including

employees and contractors), and supervisors.

Permit officer/issuer, persons entering the space,

process/maintenance personnel,

process/maintenance supervisors, safety advisors.

Method:

Verify that the confined space entry procedure

includes the process/requirements of cancelling a

confined space entry permit. Verify that confined

space are cleaned and empty prior to cancelling the

confined space entry permit. Interview site

personnel or working groups to assess whether

they understand the confined space permit to works

system and the requirements to cancel the permit.

Refer to AS 2865 c3.4.35.

Confined space audit – guide Page 13 of 25

3 Risk management

Requirements and standards associated with risk management.

Point Standard Guideline

3.1 A methodology is established Intent:

for the management of risks To verify the site have a system for the identification of

associated with confined hazards and management of risks associated with work

spaces. in or on confined spaces.

Personnel:

Managers and supervisors, training personnel, safety

and health personnel, and employees (operations,

maintenance and contractors).

Method:

View the site policies and procedures relating to

confined spaces to ensure they cover:

Hazard identification

Risk assessment

Risk control measures

Operational experience

Products and services

Legal requirements

Key roles and responsibilities

Confined space entry requirements

Inspection, calibration and maintenance activities on

confined space safety equipment.

Refer to AS 2865 cc. 2.7, 2.9.1, 2.9.3 and MSIA s. 9(1)

3.2 Consultation takes place Intent:

between the stakeholders, or To verify that consultation takes place with appropriate

their representatives, when personnel when implementing the risk management

implementing the risk systems for the confined spaces.

management systems for the

Personnel:

confined spaces in

accordance with the relevant Relevant employees including: Safety and health

provisions of the MSIA. personnel, safety and health representatives,

operations, maintenance, contractors and supervisory

personnel.

Method:

Interview personnel if they have been consulted with or

involved in developing risk assessments for work in

confined spaces. Interview personnel to determine if

there have been communications for any change in

procedures or requirements. View confined space

permits and JHAs for evidence of review and

agreement from those entering the confined space.

Refer to AS 2865 c. 2.5.1. MSIA s. 9(1)

Confined space audit – guide Page 14 of 25

Point Standard Guideline

3.3 A risk assessment shall be Intent:

conducted by a competent To verify that competent personnel complete risk

person or persons before assessment for controls to be implemented prior to

conducting any tasks confined space entry.

associated with the confined

Personnel:

space. The assessment shall

be documented and take into Supervisors, relevant employees (operations,

account at least the following: maintenance and contractors), safety and health

representatives, and safety and health personnel.

(a) The hazards of the

confined space. Method:

(b) The tasks required to be View completed risk assessments and ensure

conducted, including the individuals involved hold the competence required e.g.

need to enter the process operators, maintenance, dangerous goods,

confined space. hygiene, and safety etc. View completed risk

assessments to ensure they cover such controls as

(c) The range of methods by

Some factors to consider when undertaking a risk

which the tasks can be

assessment of a confined space are listed in AS 2865

conducted.

c. 3.3.2.

(d) The hazards involved and

Refer to AS2865 c. 3.3.

associated risks involved

with the actual method

selected and equipment

proposed to be used.

(e) Emergency response

procedures.

(f) The competence of the

persons to conduct the

tasks.

3.4 The risk assessment shall be Intent:

reviewed and revised To verify that a formal procedure exists to review and

whenever there is evidence to revise the relevant risk assessments whenever there is

indicate that there is a change evidence to indicate that there is a change in the risk.

in the risk. To ensure that “stop criteria” or “change” is defined to

trigger the review process. This can be a change in

scope of work, isolations requirements, weather

conditions, other adjacent tasks, etc.

Personnel:

Permit-to-work officers, persons conducting tasks

associated with confined spaces (including the standby

person), supervisors, relevant employees (operations,

maintenance and contractors).

Method:

Interview if work crew and supervisor review and revise

their risk assessment (JHA or similar) when there is a

change in the risk. Inspect and observe if the task being

conducted inside the confined space is consistent with

the approved permits and JHA (or similar). Review if

there are other safety systems (such as permit to work

system, supervision, training, etc.) that manage a

change in scope or condition.

Refer to AS 2865 c. 3.3.5.

Confined space audit – guide Page 15 of 25

Point Standard Guideline

3.5 When multiple tasks are Intent:

being conducted in and To verify that one task does not detrimentally affect

around the confined space, a other tasks that occur concurrently in/around the

safe system of work is confined space.

implemented to ensure each

Personnel:

task is safe to carry out.

Persons conducting tasks associated with confined

spaces (including employees and contractors),

supervisors, maintenance planners, and permit-to-work

officers.

Method:

Review if risk assessments identify hazards from other

tasks that may detrimentally affect the tasks being

conducted. Inspect if control measures are

implemented for the identified hazards. Interview work

groups to assess whether they are aware of other tasks

occurring that may impact the tasks they are performing

and the hazards that may affect their working

conditions.

Refer to AS 2865 c. 3.3.5.

3.6 If a risk assessment identifies Intent:

a risk to health or safety To verify that an assessment is made to eliminate the

arising from the tasks to be risk of exposing personnel to confined space hazards

conducted in a confined whenever practicable.

space, the risk shall be

Personnel:

eliminated or, if this is not

possible, minimized by the Safety and health personnel, safety and health

implementation of appropriate representatives, and relevant employees (operations,

risk control measures. The maintenance and contractors).

risk control measures shall be Method:

documented. View examples of risk assessments/process or

procedures that identify and recommend conducting

tasks from outside the confined space. View examples

of plant or equipment modifications that result in

eliminating or reducing the need to enter a confined

space. Interview working groups to assess whether they

understand the hazards and the required control

measures for the task they are performing.

Refer to AS 2865 c. 3.4.1.

Confined space audit – guide Page 16 of 25

4 Design, manufacture, supply and modification

considerations

Requirements and standards associated with design, manufacture, supply and modification

considerations.

Point Standard Guideline

4.1 The need to conduct work Intent:

inside a confined space is To verify that the confined space shall be designed and

minimised. manufactured to minimise –

The need to enter the confined space

The risk associated with conducting tasks within the

confined space

Personnel:

Managers, engineers, designers, consultants,

purchasing personnel, and safety and health personnel.

Method:

Check if documents such as Engineering or Technical

Standards, Procurement standards, Management of

Change Procedure or others processes, procedures,

SOP, SWP’s etc. Consider minimising the need for

confined space entry. The design for a confined space

should minimise the need to enter the confined space

for maintenance or other purposes in alignment to the

hierarchy of control.

Refer to AS 2865 c. 2.4.1, MSIA ss. 9 and 14 and MSIR

Part 6.

4.2 The risks associated with Intent:

conducting work in a confined To verify that the means of entry to and exit from the

space when required are space should be minimized. The safety of entry to and

minimised through design and exit from a confined space is increased when openings

manufacture. are large in comparison to the persons and their

equipment that have to pass through them.

Personnel:

Managers, engineers, designers, consultants,

purchasing personnel, and safety and health personnel.

Method:

Check if documents such as Engineering or Technical

Standards, Procurement standards, Management of

Change Procedure or others processes, procedures,

SOP, SWP’s etc. Include the need to risk assess tasks

required to be performed in a confined space. Risks

involved in conducting tasks in a confined space should

be minimized at the design stage and during initial

installation of equipment. Maintenance tasks required to

be completed in confined spaces are minimised in

duration and frequency through equipment design, and

understanding failure modes to ensure minimum task

exposure (e.g. FMECA).

Refer to AS 2865 c. 2.4.1, MSIA ss. 9 and 14 and MSIR

Part 6.

Confined space audit – guide Page 17 of 25

Point Standard Guideline

4.3 Openings for entry to and exit Intent:

from a confined space are of To verify (except for boilers and pressure vessels) at

adequate size to permit least one entry must have an aperture of not less than:

rescue of all persons who

may enter the confined 450 mm long by 400 mm wide, if rectangular,

space. 450 mm in diameter, if circular,

450 mm major and 400 mm minor axes,

respectively, if elliptical,

or other suitable means of meeting this intent.

Personnel:

Engineering or technical personnel, maintenance

personnel or other relevant employees.

Method:

Inspect entry and exit openings, are of an adequate

size to permit rescue of all employee’s carrying out

tasks in the confined space.

Refer to AS 2865 c. 2.4.2.

4.4 Any modification made to a Intent:

confined space does not To verify, that any modifications made to a confined

detrimentally affect the safe space have not detrimentally affected the safe means of

means of entry to, exit from, entry to, exit from, or the tasks being carried out in the

or the tasks being carried out confined space.

in the confined space.

Personnel:

Engineering or technical personnel, maintenance

personnel or other relevant employees, such as

process employees.

Method:

Check if site has implemented a Management of

Change Procedure. Interview process and maintenance

workers to determine if modifications have been made.

Review past engineering projects that are associated

with confined space modifications to ensure risk

assessments were completed for the modification.

Review maintenance procedures to ensure that work in

the confined space ceases if maintenance activities

increase the risk associated with entry/exit from the

confined space or impedes work in the confined space.

Refer to AS 2865 c. 2.4.3 and MSIR Part 6.

Confined space audit – guide Page 18 of 25

Point Standard Guideline

4.5 Any confined spaces that are Intent:

reclassified as a non-confined To ensure that any confined space that has been

space have undergone reclassified as a non-confined space, has undergone

sufficient changes in structure sufficient changes to make it suitable for human

or usage to eliminate (without occupancy without the need for risk control measures to

the need for risk control be implemented. To verify that hazards are identified

measures) all possible and managed for the reclassified space and associated

sources of inherent hazards tasks.

that define a confined space.

Personnel:

Engineering or technical personnel, maintenance

personnel or other relevant employees, such as

process employees.

Method:

Check if site has implemented a Confined Space

Reclassification Procedure. Verify examples of

reclassified confines spaces that do not require risk

control measures. Interview process and maintenance

workers to determine if reclassification of confined

spaces occurs in accordance with the procedure and

standard.

Refer to AS 2865 c. 2.4.6, MSIA s 9.1

Confined space audit – guide Page 19 of 25

5 Training and competency

Requirements and standards associated with training and competency.

Point Standard Guideline

5.1 All persons with tasks Intent:

associated with a confined To verify that all personnel assigned tasks have the

space have been trained and required training and competency to conduct their tasks

assessed as competent to relating to confined spaces.

conduct those associated

Personnel:

tasks in regards to a confined

space. Managers (all levels), training personnel, safety and

health personnel, safety and health representatives,

and employees (operations, maintenance and

contractors).

Method:

Check that all employees including sub-contractors who

have job tasks associated with confined space have

completed confined space training and been assessed

as competent including the sentry and gas tester.

Interview personnel conducting tasks associated with

confined spaces for their understanding of the confined

space entry management system. Verify that the

training requirements associated with confined spaces

cover:

Design, manufacture, install or modify a confined

space.

Participate in confined space risk management

process.

Control confined space hazards.

Enter and conduct tasks in or on a confined space.

Participate in confined space stand-by roles (initial

rescue procedures).

Participate in emergency response (this includes

making persons aware to follow emergency

response procedures are all times, and avoid the

spontaneous reaction to immediately enter and

attempt rescue).

Refer to AS 2865 cc. 2.6.1, 2.8.3, 2.9.1, 2.9.3 and

Appendix D and MSIR r. 4.13.

Confined space audit – guide Page 20 of 25

Point Standard Guideline

5.2 Persons are reassessed at Intent:

appropriate intervals to To verify that all personnel conducting tasks associated

maintain their competency to with confined spaces maintain their competency in

conduct tasks associated with relevant legislation and procedures.

confined spaces.

Personnel:

Managers and supervisors, training personnel, safety

and health personnel, and employees (operations,

maintenance and contractors).

Method:

Check if personnel conducting tasks associated with

confined spaces have been retrained and reassessed

as per site requirements. Check the site requirements

are based on a risk assessment showing reassessment

requirements. Check the site requirement defines the

maximum time between entries to maintain competence

(how often skills associated with confined space work

are utilised)

Refer to AS 2865 c. 2.6.1 and MSIR r. 4.13.

5.3 Records are maintained of Intent:

confined space training and To verify that the site keeps a record of all training and

competencies achieved. assessment that is carried out for confined spaces.

Personnel:

Supervisors, training personnel, safety and health

personnel.

Method:

View training and assessment records for site

personnel involved in confined space related tasks.

Refer to AS 2865 cc. 2.6.2, 2.9.3 and MSIR r. 4.13.

Confined space audit – guide Page 21 of 25

6 Isolation and atmospheric requirements

Requirements and standards associated with isolation and atmospheric testing.

Point Standard Guideline

6.1 Prior to any person entering a Intent:

confined space, all potentially To verify that all energy sources have been effectively

hazardous services, identified, controlled and managed to eliminate or

(including all process minimise exposure to personnel.

services) normally connected

Personnel:

to that space shall, where it is

possible to do so, be isolated Permit-to-work officers, operations personnel,

in order to prevent – maintenance personnel (electrical), and supervisors.

(a) The introduction of any Method:

materials, contaminants, Review the isolation procedure for the relevant confined

agents or conditions space to ensure it includes an effective isolation list that

harmful to persons identifies all plant, equipment, and hazardous services

occupying the confined for confined space entry, and it recommends adequate

space; and method of isolation appropriate to the level of risk

(b) The activation or involved. Inspect all isolation points listed are isolated

energizing in any way of and the method of isolation is consistent with the risk

equipment or services assessment/processes or procedure. Interview work

that could pose a risk to groups to assess whether they understand the

the health or safety of isolations and permit-to-work systems.

persons within the Refer to AS 2865 cc. 3.4.5, 3.4.7, 3.4.8 and MSIR r. 6.2

confined space.

6.2 Where necessary, the Intent:

confined space shall be To verify that a safe system of work is implemented to

cleared of contaminants by ensure that personnel are not exposed to harmful

use of a suitable purging contaminants.

agent. The purging agent or

Personnel:

any gas used for ventilation

purposes shall not be pure Permit-to-work officers, maintenance and operation

oxygen or a gas mixtures with personnel, persons conducting tasks associated with

an oxygen concentration confined spaces (including employees and contractors),

greater than 21%. and supervisors.

Method:

Review if the risk assessment recommends cleaning

the space prior to entry. Inspect if the confined space is

cleared of contaminants. Review the risk assessment to

make sure purging of flammable/combustible gas

systems such as natural gas, LPG, ammonia, or

hydrogen lines takes place. Review the purging process

to make sure it uses a suitable purging agent. Interview

site personnel or working groups to assess whether

they are aware of the atmospheric hazards and

understand the requirements to purge the space.

Refer to AS 2865 c. 3.4.11.

Confined space audit – guide Page 22 of 25

Point Standard Guideline

6.3 Ventilation of a confined Intent:

space should be natural, To verify that a confined space is only entered or

forced or by mechanical occupied if the atmospheric condition inside the space

means to establish and is safe.

maintain a safe atmosphere.

Personnel:

This ventilation should be

continued throughout the Persons conducting tasks associated with confined

period of occupancy. spaces (including employees and contractors),

ventilation officers, and supervisors.

Method:

Inspect if the ventilation system installed is consistent

with the risk assessment. Inspect if the ventilation

system installed is adequate for the type of task being

conducted inside the space e.g. natural ventilation may

be adequate for a person doing an internal inspection of

a cleaned tank, but forced or mechanical ventilation

maybe required for welding inside a tank. Interview site

personnel or working groups to assess whether they

are aware of the atmospheric hazards and understand

the requirements to implement ventilations control.

Refer to AS 2865 c. 3.4.17

6.4 Atmospheric testing or Intent:

monitoring shall be conducted To verify that atmospheric testing or monitoring is

in a manner consistent with conducted in a manner consistent with the risk

the hazards identified in the assessment.

risk assessment of the

Personnel:

confined space. No person

shall enter a confined space Permit-to-work officers, persons conducting tasks

to conduct atmospheric associated with confined spaces (including the gas

testing or monitoring without a tester), ventilation officers, and supervisors.

written authority. Method:

Check if the atmospheric test results are recorded and

reviewed and if they are done consistently as per the

risk assessment.

Review that the correct gases are tested (as identified

by the relevant risk assessments). Verify that a

calibrated type of gas monitor that is suitable for the

task is utilised. Check if the site regularly inspects, tests

and calibrates their gas monitors as per the OEM’s

recommendations. Interview site personnel or working

groups to assess whether they are aware of the

atmospheric hazards and understand the requirements

for the atmospheric testing or monitoring.

Refer to AS 2865 c. 3.4.22

Confined space audit – guide Page 23 of 25

7 Emergency response equipment

Requirements and standards associated with emergency response equipment.

Point Standard Guideline

7.1 The employer has adequate Intent:

emergency response To verify that the emergency response plan can be

equipment and resources to executed effectively.

meet the requirements of the

Personnel:

confined space work being

carried out onsite, as per the Managers and supervisors, persons conducting tasks

emergency response plan. associated with confined spaces (including employees

and contractors), and emergency response personnel.

Method:

Inspect the emergency response facility to ensure the

equipment and resources (listed as per the rescue plan)

are adequate (personnel and equipment) available and

accessible to respond to confined space emergencies.

Refer to MSIR r. 4.30(2)(c)(vii).

7.2 Appropriate emergency Intent:

response and first aid To verify that emergency response and first aid

procedures and provisions procedures are in place for the confined spaces being

shall be identified, planned, entered, relevant emergency response and first aid

established and rehearsed. equipment is available and the procedures are

rehearsed as necessary for their effectiveness.

Personnel:

Emergency response personnel, persons conducting

tasks associated with confined spaces (including the

standby person), and supervisors.

Method:

Review the risk assessment, rescue plans or other

associated documents outlining the emergency

response and first aid procedures for confined spaces.

View attendance records for personnel involved in

rehearsing emergency response and first aid

procedures.

Refer to AS 2865 cc. 2.8.1, 2.9.1, 2.9.3 and MSIR

r. 4.30(2)(c)(iv).

Confined space audit – guide Page 24 of 25

Point Standard Guideline

7.3 Those persons involved in an Intent:

emergency response shall be To verify that a system is in place to make emergency

made aware of the conditions response personnel aware of the specific conditions

and the number of persons in present in a confined space should an emergency arise.

the confined space prior to

Personnel:

any entry.

Supervisors, emergency response coordinators and

members.

Method:

View log books, sign in/out sheets, permits, etc.

Interview ER department to ensure they are aware

when confined space activities occur on-site and what

the specific conditions surround each entry are

(including the number of people in the confined space)

allowing for enough competent personnel and the

equipment to be available (as per the rescue plan) prior

to any entry.

Refer to AS 2865 cc. 2.8.2, 3.4.29(e) and MSIR r. 4.30.

8 Accident / incident investigation

Requirements and standards associated with accident / incident investigation.

Point Standard Guideline

8.1 The employer investigates Intent:

incidents associated with To verify that reported confined space incidents are

confined spaces. investigated within a reasonable time.

Personnel:

Safety and health personnel, safety and health

representatives, and employees (operations,

maintenance and contractors) who may have been

involved in an incident or investigation.

Method:

Interview relevant employees to determine if incidents

and near misses are investigated or if incidents are

occurring and either not being reported or investigated.

View documentations to verify that site has developed

and implemented some form of incident management

system Review the site’s incident logbook or similar

system to determine if previous incidents, were

investigated appropriately. Review incident reports.

Refer to MSIA ss.11 and 11A.

Confined space audit – guide Page 25 of 25

Point Standard Guideline

8.2 All actions arising from Intent:

investigations of confined To verify that all recommended actions have been

space entry incidents, have implemented.

been implemented.

Personnel:

Safety and health personnel, safety and health

representatives, and employees (operations,

maintenance and contractors) who may have been

involved in an incident or investigation.

Method:

Field verify if incident investigation recommendations

have been implemented. Verify if incident investigation

recommendations have been extended to include other

similar systems, equipment or scenarios. Interview

employees to verify if incident investigation

recommendations are promptly addressed.

Refer to MSIA s. 9.1(1).

8.3 Confined space incident Intent:

reports, findings and controls To verify that the relevant personnel have been

are communicated to all provided with information to gain a better understanding

relevant personnel including of the incident and the controls implemented so

contactors. employees aren’t exposed to hazards.

Personnel:

Safety and health personnel, safety and health

representatives, and employees (operations,

maintenance and contractors) who may have been

involved in an incident or investigation.

Method:

Review the available documentation regarding how

incident investigation reports are shared with

employees. Available documentation may include face

to-face briefings, emails or intranet postings to

employees, posted hard-copy information, handouts, or

minutes of safety meetings. Interview employees

ensure they received and understood the information

provided.

Refer to MSIA s. 9.1(1).

Confined space audit – guide Page 26 of 25

You might also like

- Confined Space ProcedureDocument14 pagesConfined Space Procedurewanazuadi100% (1)

- Confined Space ProcedureDocument9 pagesConfined Space Procedurelucky414No ratings yet

- Working Around ExcavationDocument15 pagesWorking Around ExcavationMerle Marthen Maatoke20 005No ratings yet

- Confined Space Entry ProcedureDocument24 pagesConfined Space Entry ProcedureAlexander KlmNo ratings yet

- Hse Documents-Confined Space Entry ProcedureDocument9 pagesHse Documents-Confined Space Entry Proceduretumelo makgabutlaneNo ratings yet

- Confined Space EntryDocument15 pagesConfined Space EntryEnginnering Section100% (1)

- DroppedObjectsPreventionStandard - Eng 05 05 17 PDFDocument15 pagesDroppedObjectsPreventionStandard - Eng 05 05 17 PDFAndrew LiddellNo ratings yet

- MSH CoP GroundControlDocument16 pagesMSH CoP GroundControlASISTENTE DE PLANEAMIENTONo ratings yet

- Safety Risk Assessmnet and Safe Systems of WorkDocument29 pagesSafety Risk Assessmnet and Safe Systems of WorkghtyNo ratings yet

- Confined Space Management PlanDocument32 pagesConfined Space Management PlanNii Ashiii100% (1)

- PRO424Document9 pagesPRO424Kostan AbdillahNo ratings yet

- CP - 105 - Safety Task Analysis-Job Hazard AnalysisDocument10 pagesCP - 105 - Safety Task Analysis-Job Hazard AnalysisYusufNo ratings yet

- Assurance Verification Practitioners Guide 2018 PDFDocument53 pagesAssurance Verification Practitioners Guide 2018 PDFlanchu100% (1)

- Rig Supervisor Handout NewDocument103 pagesRig Supervisor Handout NewNISAR DEENNo ratings yet

- Pro438 Standard OperatingDocument11 pagesPro438 Standard OperatingViệt Đặng XuânNo ratings yet

- SPML Environment Health and Safety ManualDocument119 pagesSPML Environment Health and Safety ManualDasari VenkateshNo ratings yet

- Microsoft Word - Annexe F - Principal Contractors OHS and Risk Management Requirements - v1 3Document63 pagesMicrosoft Word - Annexe F - Principal Contractors OHS and Risk Management Requirements - v1 3Satvik BhattNo ratings yet

- Erection MOS Part#2 Rev.02-16 - Aug-2023Document76 pagesErection MOS Part#2 Rev.02-16 - Aug-2023Humayoun KhanNo ratings yet

- 002 Majnoon Site Specific HSE PlanDocument18 pages002 Majnoon Site Specific HSE Planالحاج راضي راضيNo ratings yet

- Confined Spaces: Code of PracticeDocument40 pagesConfined Spaces: Code of PracticeLi ChenNo ratings yet

- Waleed Hassan, 00551188, Vivid Institute of Occupational Safety & Health-940Document19 pagesWaleed Hassan, 00551188, Vivid Institute of Occupational Safety & Health-940qadeesbhatti09511No ratings yet

- Working at Heights ProcedureDocument26 pagesWorking at Heights ProcedureardodotNo ratings yet

- HSE Plan For RSPL ProjectDocument10 pagesHSE Plan For RSPL ProjectSaibabu SiripurapuNo ratings yet

- WSH Manual Marine Industries PDFDocument360 pagesWSH Manual Marine Industries PDFzaidiNo ratings yet

- Confined-Space Entry ProgramDocument16 pagesConfined-Space Entry Programamjadkhan6573833No ratings yet

- Confined Space Safety in Water Storage Tank Specifications: Material Safety Data SheetsDocument2 pagesConfined Space Safety in Water Storage Tank Specifications: Material Safety Data Sheetsprabhu74No ratings yet

- Excavation WorkDocument46 pagesExcavation WorkKarthikeyan Lakshmanan100% (1)

- Risk Based Verfication of Large Offshore Systems UK ABS ArticleDocument33 pagesRisk Based Verfication of Large Offshore Systems UK ABS ArticlemashanghNo ratings yet

- Simultaneous Operations (SIMOPS) HSE Procedure for Pars Oil & Gas CompanyDocument24 pagesSimultaneous Operations (SIMOPS) HSE Procedure for Pars Oil & Gas CompanyOsman KozuNo ratings yet

- Sample - First Aid ProcedureDocument16 pagesSample - First Aid ProcedurefedericoNo ratings yet

- 1904 CON HSE KAG JSA 001 Rev.a JSA and Safety ProcedureDocument20 pages1904 CON HSE KAG JSA 001 Rev.a JSA and Safety ProcedureAhmad AladdenNo ratings yet

- Confined Space Procedure BardavcolDocument11 pagesConfined Space Procedure BardavcolAhmed IbrahimNo ratings yet

- AI-VO-PRC-004 R1 Procedure For Inspection DefermentDocument14 pagesAI-VO-PRC-004 R1 Procedure For Inspection Defermentkhairie rahimNo ratings yet

- Spe 46642 MSDocument17 pagesSpe 46642 MSanaghaNo ratings yet

- As 2865 Safe Work in Confined SpaceDocument48 pagesAs 2865 Safe Work in Confined SpaceLau Zam100% (1)

- Fall Protection Plan: QPS Services - Occupational Health and Safety Management System Fall Protection Plan Page 1 of 8Document8 pagesFall Protection Plan: QPS Services - Occupational Health and Safety Management System Fall Protection Plan Page 1 of 8HeleenNo ratings yet

- Safe Work Method Statement: Excavation, Trenching and Underground ServicesDocument5 pagesSafe Work Method Statement: Excavation, Trenching and Underground ServicesMorhne RufinNo ratings yet

- Vessel Cleaning ProcedureDocument9 pagesVessel Cleaning ProcedureAbdul Hakam Mohamed Yusof100% (1)

- Cse ProcedureDocument24 pagesCse ProcedureMuhammad Usman100% (1)

- MSH G RefugeChambersUGminesDocument52 pagesMSH G RefugeChambersUGminesTraining NurfalahNo ratings yet

- PdfsDocument360 pagesPdfsalper saltasNo ratings yet

- SBPL-Confined Space Rescue PlanDocument14 pagesSBPL-Confined Space Rescue Plannoushad e tNo ratings yet

- 2 - Hazards Indentification PlanDocument27 pages2 - Hazards Indentification PlanasanNo ratings yet

- HAZOP ReportDocument27 pagesHAZOP ReportMuhammad.Saim100% (3)

- 501 2012 6 28 27 39 561Document26 pages501 2012 6 28 27 39 561MITHILESH KUMARNo ratings yet

- Ensuring Safety Through Organization and Responsibility A Quality Procedure Manual For Site Safety PlansDocument39 pagesEnsuring Safety Through Organization and Responsibility A Quality Procedure Manual For Site Safety PlansMohammed Amer PashaNo ratings yet

- Vacuum Truck Safety ProgramDocument13 pagesVacuum Truck Safety ProgramUros Todorovic100% (2)

- Cop Confined SpacesDocument40 pagesCop Confined SpacesTharaka Perera100% (1)

- PRO422 Safety SignageDocument7 pagesPRO422 Safety SignageAsyraf HakeemNo ratings yet

- Permit To Work Procedure (10.11.2018)Document20 pagesPermit To Work Procedure (10.11.2018)Bebe BucătaruNo ratings yet

- Underground Mine Ground Control CodeDocument72 pagesUnderground Mine Ground Control CodeJannela yernaiduNo ratings yet

- Evaluation of Asset Integrity Management System (AIMS) : GuideDocument28 pagesEvaluation of Asset Integrity Management System (AIMS) : GuideEdwin TorresNo ratings yet

- Confined Space Procedure: ScopeDocument9 pagesConfined Space Procedure: Scopeandi permanaNo ratings yet

- Tailings Storage Facilities in Western Australia: Code of PracticeDocument24 pagesTailings Storage Facilities in Western Australia: Code of PracticeJuan Pablo Henríquez ValenciaNo ratings yet

- SimopsDocument24 pagesSimopsgilbertotiburcio100% (1)

- OMV Yemen EPF Project Job Safety AnalysisDocument12 pagesOMV Yemen EPF Project Job Safety Analysissayuj karuvathil100% (1)

- Hse Management PlanDocument23 pagesHse Management PlanDavis EzieNo ratings yet

- Confined Space Entry PlanDocument12 pagesConfined Space Entry PlanMansoor BabarNo ratings yet

- Aircraft System Safety: Assessments for Initial Airworthiness CertificationFrom EverandAircraft System Safety: Assessments for Initial Airworthiness CertificationNo ratings yet

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Material Handling (Manual & Mechanical)Document9 pagesMaterial Handling (Manual & Mechanical)Asaf Ibn RasheedNo ratings yet

- Does & Don'ts For Safe Operation of 140 T CraneDocument3 pagesDoes & Don'ts For Safe Operation of 140 T CranePankaj PandeyNo ratings yet

- #Hiradec - DeaeratorDocument6 pages#Hiradec - DeaeratorPankaj PandeyNo ratings yet

- 021 Finalsmp - PheDocument6 pages021 Finalsmp - PhePankaj PandeyNo ratings yet

- CO2 System PresentationDocument23 pagesCO2 System PresentationPankaj PandeyNo ratings yet

- Co2 Gas Flooding SystemDocument6 pagesCo2 Gas Flooding SystemPankaj PandeyNo ratings yet

- 5.#hiradec - CWPDocument7 pages5.#hiradec - CWPPankaj PandeyNo ratings yet

- C2.Hiradec - ONLINE SEALING ON PIPES (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Document2 pagesC2.Hiradec - ONLINE SEALING ON PIPES (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyNo ratings yet

- C5. HIRADEC - #Cutting and WeldingDocument2 pagesC5. HIRADEC - #Cutting and WeldingPankaj PandeyNo ratings yet

- #Hiradec - Heat ExchangerDocument5 pages#Hiradec - Heat ExchangerPankaj PandeyNo ratings yet

- Hydra HiradecDocument1 pageHydra HiradecPankaj PandeyNo ratings yet

- 31.# Hiradec-CSTDocument2 pages31.# Hiradec-CSTPankaj PandeyNo ratings yet

- C4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachineDocument2 pagesC4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachinePankaj PandeyNo ratings yet

- C3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Document1 pageC3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyNo ratings yet

- List of Medical Oxygen Gas Suppliers For Home UseDocument19 pagesList of Medical Oxygen Gas Suppliers For Home Usemadhur03No ratings yet

- #Hiradec - Cooling TowerDocument8 pages#Hiradec - Cooling TowerPankaj PandeyNo ratings yet

- 24.DG Hiradec CDocument2 pages24.DG Hiradec CPankaj PandeyNo ratings yet

- 28.# Hiradec-SUMP Pit PumpsDocument1 page28.# Hiradec-SUMP Pit PumpsPankaj PandeyNo ratings yet

- List of Medical Oxygen Gas Suppliers For Home UseDocument19 pagesList of Medical Oxygen Gas Suppliers For Home Usemadhur03No ratings yet

- Safety in Gas CuttingDocument5 pagesSafety in Gas Cuttingvidhya sagarNo ratings yet

- Job Safety and Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document23 pagesJob Safety and Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)elias mwiineNo ratings yet

- Safety Stat FormulaeDocument6 pagesSafety Stat FormulaePankaj PandeyNo ratings yet

- Varaha Sahasranama Stotram summaryDocument13 pagesVaraha Sahasranama Stotram summaryshreeNo ratings yet

- Healthcare Hazard Control: Introduction P1: OMD552 Hospital Waste Management UNIT-1Document31 pagesHealthcare Hazard Control: Introduction P1: OMD552 Hospital Waste Management UNIT-1Saravanakumar MNo ratings yet

- Job Description Technical Safety EngineerDocument3 pagesJob Description Technical Safety EngineerAsghar BhattiNo ratings yet

- (2021) ISO 22341 (1st Edn)Document28 pages(2021) ISO 22341 (1st Edn)Dennis Mok100% (5)

- Example Risk Assessment For Food Preparation, Cooking and ServiceDocument5 pagesExample Risk Assessment For Food Preparation, Cooking and ServiceSiva Prasad100% (1)

- Journal of Natural Gas Science and Engineering: Ke Shan, Jian Shuai, Kui Xu, Wei ZhengDocument11 pagesJournal of Natural Gas Science and Engineering: Ke Shan, Jian Shuai, Kui Xu, Wei ZhengEfari BahcevanNo ratings yet

- Motor Maintenance PDFDocument1 pageMotor Maintenance PDFAbdul HadiNo ratings yet

- Managing Crowds Safely: A Guide For Organisers at Events and VenuesDocument63 pagesManaging Crowds Safely: A Guide For Organisers at Events and VenuesCarla Sofia do Nascimento PalmaNo ratings yet

- 1 s2.0 S0950423011001434 Main PDFDocument10 pages1 s2.0 S0950423011001434 Main PDFmatt8724No ratings yet

- Beyond Zero - AMEC Stuart BaileyDocument20 pagesBeyond Zero - AMEC Stuart BaileyJohnny MartinezNo ratings yet

- Incident Prevention Incident PreventionDocument37 pagesIncident Prevention Incident PreventionHidayah DayahNo ratings yet

- Environmental Management Plan GuidelinesDocument23 pagesEnvironmental Management Plan GuidelinesMianNo ratings yet

- SyllabusDocument21 pagesSyllabusVinensia NanlohyNo ratings yet

- Risk Based Inspection course overviewDocument66 pagesRisk Based Inspection course overviewmurali67% (6)

- 18 Ships Particular For Risk AssessmentDocument33 pages18 Ships Particular For Risk AssessmentKunal SinghNo ratings yet

- 53.1 - OSH Construction Management Plan v3.1 EnglishDocument30 pages53.1 - OSH Construction Management Plan v3.1 EnglishchumairabbasNo ratings yet

- Occupational Health HazardsDocument9 pagesOccupational Health HazardsAswin Magesh100% (1)

- Risk Assessment Tables GuidanceDocument6 pagesRisk Assessment Tables GuidanceBhargav BbvsNo ratings yet

- Scaffolding HIRADocument15 pagesScaffolding HIRAlina ekawatiNo ratings yet

- NDRRMC Harmonized Disaster Response Standard Operating Procedures SOPDocument1 pageNDRRMC Harmonized Disaster Response Standard Operating Procedures SOPGretchen Sua100% (8)

- ISM Notes PDFDocument138 pagesISM Notes PDFAjay BirareNo ratings yet

- Quantitative Risk AssessmentDocument33 pagesQuantitative Risk AssessmentAqiel Siraj - El - Sayyid AdamNo ratings yet

- Oil Gas Offshore Safety Case (Risk Assessment) : August 2016Document44 pagesOil Gas Offshore Safety Case (Risk Assessment) : August 2016Andi SuntoroNo ratings yet

- PDFDocument362 pagesPDFBrais Comesaña MartínezNo ratings yet

- Risk Assessment of Subsea Pipeline Due To InstallaDocument15 pagesRisk Assessment of Subsea Pipeline Due To InstallaAlaaeldin ElshazliNo ratings yet

- Fire Risk Assessment Rev 001Document4 pagesFire Risk Assessment Rev 001Mohamed Hadjkacem100% (1)

- SNC Lavalin Safety ManualDocument150 pagesSNC Lavalin Safety ManualmeddyfarrahNo ratings yet

- QRA - Nandan ShandilyaDocument26 pagesQRA - Nandan ShandilyaNandan Shandilya50% (2)

- Risk Management PlanDocument14 pagesRisk Management PlanRajeeva Atukorale100% (2)

- DEKRA Process Safety Experts for Risk Management and Safety ComplianceDocument8 pagesDEKRA Process Safety Experts for Risk Management and Safety ComplianceNishir Shah100% (1)

- Group 4 Written ReportDocument15 pagesGroup 4 Written ReportKezNo ratings yet