Professional Documents

Culture Documents

Design and Fabrication of Regenerative Braking System

Uploaded by

BT20MEC120 Jyoti ThakurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Fabrication of Regenerative Braking System

Uploaded by

BT20MEC120 Jyoti ThakurCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/352529729

DESIGN AND FABRICATION OF REGENERATIVE BRAKING SYSTEM

Article in International Journal of Engineering Research · June 2021

DOI: 10.33329/ijoer.9.3.1

CITATIONS READS

0 1,903

3 authors:

Milan Lamichhane Surendra Yonjan

Malla Reddy College of Engineering & Technology Malla Reddy College of Engineering & Technology

6 PUBLICATIONS 1 CITATION 3 PUBLICATIONS 1 CITATION

SEE PROFILE SEE PROFILE

Navin Bhetal

3 PUBLICATIONS 1 CITATION

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Design and Fabrication of Regenerative Braking System View project

Finite Element Analysis of a Clutch. View project

All content following this page was uploaded by Milan Lamichhane on 19 June 2021.

The user has requested enhancement of the downloaded file.

International Journal of Engineering Research-Online Vol.9., Issue.3, 2021

A Peer Reviewed International Journal May-June

Articles available online http://www.ijoer.in; editorijoer@gmail.com

RESEARCH ARTICLE ISSN: 2321-7758

DESIGN AND FABRICATION OF REGENERATIVE BRAKING SYSTEM

MILAN LAMICHHANE1*, SURENDRA YONJAN1, NAVIN BHETAL2

1

Department of Mechanical Engineering,

Malla Reddy College of Engineering & Technology, Hyderabad, India

*Nep.ermilan@gmail.com

DOI: 10.33329/ijoer.9.3.1

ABSTRACT

As in today’s world, where there are energy crises and therefore the resources are

depleting at a better rate, there's a requirement of specific technology that recovers

the energy, which gets usually wasted. So, just in case of automobiles one among

these useful technologies is that the regenerative braking system.

Regenerative braking system is an energy recovery mechanism that reduces the speed

of a vehicle by converting its Kinetic Energy. Into a form which will be either used for

energy generation. By the help of Regenerative braking system in automobiles, we can

recover the Kinetic Energy of the vehicle to some extent that's lost during the braking

process.

The converted Kinetic Energy is stored for future use or is fed back to the facility

system of the vehicle. This energy is often stored during a battery or bank of capacitors

for later use. Energy also can be stored with the assistance of a rotating flywheel which

is one among the foremost inexpensive and effective method of storing and

regenerating power. This invention provides energy-storing regenerative braking

system by transmitting the flywheel force as a torque tending to oppose the forward

rotation of a wheel on applying the brakes.

Keywords— Regenerative Braking, Generator, Energy Crises, Energy Recovery,

Capacitors, Flywheel.

1. Introduction effective ways to solve the vehicle emission,

especially for NOx and soot. However, this method

In recent years, there is the Shortage of

is not continually able to reduce the GHG emission

reliable alternative energy sources, increasing

during the lower temperature combustion of this

efficiency and reducing exhaust gas emissions has

technology leads to increasing the fuel penalty.

become the main target of the modern automotive

research. Commercial vehicles like refuse trucks Regenerative energy technology the key

and delivery vehicles lose a great amount of kinetic features of electrified vehicles. It allows the vehicle

energy (K.E) during frequent braking and constant to capture a great amount of the K.E lost during

drive at low speeds on designated city routes, which braking or decelerating for reusing in any ways in

results in higher fuel consumption and Green House Future. So that, energy recovery technology can

Emission Gas (GHG) emission than other on-road significantly bring down the energy consumption of

vehicles. Numerous attempts are made to enhance electrified vehicle, particularly in city operated

sort of vehicles. The technological combination of route. The regenerative braking system is placed

Exhaust Gas Recirculation (EGR) and Diesel within the driven axle to recuperate the braking

Particulate Filter (DPF) after treatment are the energy loss. The boost recuperation system is

1 MILAN LAMICHHANE et al.,

International Journal of Engineering Research-Online Vol.9., Issue.3, 2021

A Peer Reviewed International Journal May-June

Articles available online http://www.ijoer.in; editorijoer@gmail.com

parallelly attached with the mechanical system to taken energy from the battery. These brakes work

recover K.E during the slowing process. This effectively in driving environment such as stop-and-

technology allows commercial vehicles to have an go driving situations especially in town and city.

important improvement of reducing fuel

3. LITERATURE REVIEW

consumption and also emissions. The more energy

the regenerative braking recovers, the less fuel is Sayed Nashi [1] a test bench for testing of

consumed. regenerative braking capability of a Brushless DC

Motor is design and then fabricated according to

2. Working Principle

the model. This project creates awareness to

Regenerative braking is a method that utilizes the engineers and the ideal drivers towards energy

energy from the motor by converting K.E into efficiency and energy conservation. It concludes

electrical energy and fed back to the battery source. that the regenerative braking systems are more

Hypothetically, regenerative braking system can effective and efficient at higher speed and it cannot

convert a good amount of its K.E to charge up the be used as the only brakes in a vehicle as alone this

battery, using the principle as an alternator. system cannot stop the vehicle at sudden braking,

so along with this system Anti-lock braking system

(ABS) can be used. The definite use of this

technology described as in the project in the future

automobiles can help us to a certain level to

sustainable and positive future of energy efficient

world as a part of power that is lost can be

recovered by using this system.

Khushboo Rahim and Mohd. Tanveer [2] the

advantages of regenerative braking system over

conventional braking system are mentioned.

Regenerative braking systems can effectively work

Fig 1.2.1: Normal forward driving condition

at the high temperature ranges and are highly

efficient when compared to the traditional brakes.

They are also more effective at higher speed. The

more often a vehicle stops, the more it can get

benefit from this braking system. Large and heavy

vehicles that runs at higher speeds develops lots of

K.E, so they conserve energy more efficiently. It has

broad scope for further improvements and the

energy conservation.

Tushar L. Patil, Rohit S. Yadav, Abhishek D.,

Mahesh Saggam, Ankul Pratap [3] the procedures

Fig 1.2.2: Regenerative action during braking to increase the efficiency of the regenerative

In regenerative braking mode, the motor is braking system is mentioned. The procedure

used to slow down the vehicle when the driver mentioned was to decrease the weight of the

presses the brake pedal then the electric motor automobile which increase performance. Also, the

works in reverse direction and the vehicle slows usage of super capacitor improves the conversion

down. While running anti-clockwise direction, the rate of energy in regenerative braking system,

motor acts as the generator and recharge the making the automobile compact and have a

batteries as shown in figure (1.2.2). Meanwhile in tendency to increase the efficiency of the system.

figure (1.2.1) shows the vehicle in normal running C. Jagadeesh Vikram, D. Mohan Kumar, Dr.

condition whereas the motor turning forward and P. Naveen Chandra [4] Fabrication process on the

2 MILAN LAMICHHANE et al.,

International Journal of Engineering Research-Online Vol.9., Issue.3, 2021

A Peer Reviewed International Journal May-June

Articles available online http://www.ijoer.in; editorijoer@gmail.com

Regenerative Braking System had been executed as as ultra-capacitors, DC-DC converters and

per the prescribed measures has been taken and flywheels. Ultra-capacitors, which help improve the

the future enhancements should be processed on transient state of the car during startup, provide a

basis of the need of the study. The application of smoother charging characteristic of the battery and

the regenerative braking system is quite crucial in improve the overall performance of the electric

automotive transportation with maximized vehicle system. Ultra-capacitors converters help to

performance in braking. maintain power management in regenerative

braking systems. Finally, flywheels are used to

A. Eswaran, S Ajith, V Karthikeyan, P Kavin,

improve the power recovery process through

S Loganandh [5], the regenerative braking system

automotive wheels.

used in the vehicles fulfill the purpose of saving a

part of the energy lost during braking. Also, it can The main Objectives of the work are

function in the high-temperature range and are

To control the speed of the vehicle and stop it

effective as compared to a conventional braking

quickly and efficiently without sticking.

system. Regenerative braking systems need further

To reduce the reaction time of braking by using

research to develop an improved system that

regenerative braking and generating power by

seizures more energy and stops faster. All vehicles

converting kinetic energy into electrical energy

in motion can get benefit from the system by

and storing in the batteries for any future work.

obtaining energy that would have been lost during

the braking process. The use of more efficient 4 Materials and Methodology

systems results in huge savings in the economy of

Regenerative braking system may not suit

any country.

the basic requirement of braking system alone. This

Ketan Warake, Dr. S. R. Bhahulikar, Dr. N. V. is because of limitation of energy dissipation at very

Satpute [6], the regenerative braking system used high power. The storage and generation systems

in the vehicles fulfill the purpose of saving a part of may not be capable to operate at those levels due

the energy lost during braking. The regenerative to design limitations. Due to critical level of safety

braking system is planned to partially recover the involved with the system, reliability becomes

battery charge lost in braking of the vehicle. The doubtful and it requires a frictional braking system

energy is transformed into heat by friction brake to co-exist with electrical regenerative braking

which is released to the environment. This Energy is system. [8] This forms a hybrid braking system [9],

applied to rotate the rotor of the generator which means:

converting mechanical energy of wheels into the 1. Just like hybrid propulsion systems, there

useful charge of the battery. The regenerative can be many design configurations and

braking system cannot be used as a main braking control strategies.

system of the vehicle. Research shows that a

minimum of 11% battery energy can be recovered 2. Design and control of system should be such

using the regenerative braking system which would that they ensure vehicle’s desired braking

else be wasted to heat in friction brakes. Hence the performance while at the same time

distance traveled between two consecutive capturing as much energy as possible.

charging requirements can be boosted to 10 to 15 During developing strategies, a careful

% using this regenerative braking, when applied in consideration of braking behavior and its

actual vehicles. characteristics with respect to speed, braking

Siddharth K Sheladia, Karan K Patel, Vraj D power, deceleration rate etc. must be made.

Savalia, Rutvik G Savaliya,[7] it is mentioned that The following materials was used for

Regenerative braking can conserve up to 5% to 8% fabrication are first understood and then bought

of waste energy. The systems have been improved from the market. The tabular below shows the

with advanced power electronic mechanisms such materials required with the quantities.

3 MILAN LAMICHHANE et al.,

International Journal of Engineering Research-Online Vol.9., Issue.3, 2021

A Peer Reviewed International Journal May-June

Articles available online http://www.ijoer.in; editorijoer@gmail.com

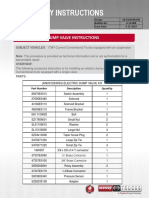

Table 1. List of materials

Sr. No Name of Parts Used Description Quantity

1 Square bar 40*40 Hollow Bar (M.S) 8m

2 Journal Bearing Internal Dia.12mm 2 pieces

3 Brake Wheel Outer Dia.8cm 1 piece

4 Solid Shaft Outer Dia.12mm 1.5m

5 Bicycle Wheel Inner Dia. 12 mm 1 piece

6 Brake Spindle 40*40 Hollow Bar (M.S) 0.6m

7 Sewing Machine Motor 9500 rpm 1 piece

8 Pulley Internal Dia.12mm 2 pieces

9 Pulley Rope V-belt 0.5m

10 LEDs 12v 6 pieces

11 Electric Wires Copper wire 6m

12 D.C Motor Brushed D.C 12v 1 piece

4.1 Procedure • The output of the Geared D.C motor is

connected to L.E.Ds through copper wire.

• First the square bar is cut into an angle of 45

degree and then welded together in order to • The small wheels are placed on the legs to

form a square frame. give movements to the Assembly.

• The square bar is welded at each corner to • The Entire Assembly is colored with Red and

form a table like structure. black Paint to protect form Rust.

• The flat mild steel plate is drilled and welded • 4.2 Fabrication

in the square bar to hold the solid shaft for

brake spindle.

• The Plummer block is fitted over the flat

plate welded on the square frame.

• Solid shaft is inserted in the Plummer block

upon which the bicycle wheel and brake

wheel and pulley are fitted.

• On the Frame the motor is welded.

• The power of the motor is transmitted to the •

Bicycle wheel by the joining the pulley and Fig: Fabrication of the project.

motor with a belt.

4.3 Testing

• The brake wheel is fixed at the tip of the

Geared D.C motor which is fixed upon the The final design after the fabrication is

brake spindle. tested to know that the design is made as per the

requirement and the model should fulfill some

• The L.E.Ds is fixed on the square frame. Mechanical properties. Mechanical testing employs

4 MILAN LAMICHHANE et al.,

International Journal of Engineering Research-Online Vol.9., Issue.3, 2021

A Peer Reviewed International Journal May-June

Articles available online http://www.ijoer.in; editorijoer@gmail.com

a variety of strength tests that can determine the during braking process due to excess heat produced

suitability of component for the intended due to friction. If we could use more efficient

application. systems, the huge savings in the economy of any

country can be obtained.

4.4 Result

5.1 Recommendations

After the successful testing, the model is

operated and the results obtained in various As this project is completely based on the

loading condition are noted and tabulated below. experimental test rig and if this system is applied in

the current working vehicles there are may be some

Table 2. Result Table

problems which may cause uncomfortable for

S. RPM before RPM after Voltage drivers. As regenerative braking system don’t

N brake pedal brake pedal output provide braking at high speed so this system should

pressed pressed be implemented with other forms of Braking

1 500 480 9.34 system like Anti-Lock Braking System (ABS).

Implementing this system in the current

2 900 870 10.88

working vehicle will increase the mass of the vehicle

3 1300 1260 11.81 and occupies additional space. So this factor should

4 1700 1650 12.91 be considered before design of the vehicle so that

this factor could be overcome.

5 2100 2040 13.49

Integrating regenerative braking into a

6 2300 2270 13.89 vehicle requires some changes in the driving style

7 2500 2460 14.49 which depends on the technical configuration of

the system. This takes some time getting used to,

It can be seen from the result tables that the but studies have shown that drivers respond

efficiency of the regenerative braking systems using positively and try to maximize the energy they can

Geared D.C Motor increases as the angular velocity recapture and hereby extend their range.

of the motor increases .So we can say that, the

regenerative braking systems are more efficient as Additionally, the usage of regenerative

higher angular velocities and the recoverable braking is closely linked to eco-driving. If eco-driving

energy increases with increase in the motor speed. approaches are applied by the drivers, this could

The losses are higher at lower speed as we already have considerable effects on traffic flow.

know that the motors are inefficient at lower References

speeds, whereas the losses at higher speeds are

[1] Sayed Nashit, Sufiyan Adhikari, Shaikh

mainly mechanical losses like friction losses and air

Farhan, Srivastava Avinash and Amruta

drag.

Gambhire, ‘Design, Fabrication and Testing

5. Conclusions of Regenerative Braking Test Rig for BLDC

The regenerative braking system used in the Motor’, 2016.

vehicles fulfills the purpose of saving a part of the [2] Khushboo Rahim, and Mohd. Tanveer,

energy lost during braking. This system can be ‘Regenrative Braking System : Review

operated at high temperature range and are Paper’, International Journal on Recent and

efficient as compared to conventional braking Innovaion Trends in Computing and

system. This system requires further research to Communication, 5.5 (2018).

develop a better system that captures more energy,

[3] Tushar L. Patil, Rohit S. Yadav, Abhishek D.

stops faster and has less weight. All vehicles in

Mandhare, Mahesh Saggam, Ankul

motion can benefit from these systems by

Pratap,‘Performance Improvement of

recapturing energy that would have been lost

Regenerative braking system’, International

5 MILAN LAMICHHANE et al.,

International Journal of Engineering Research-Online Vol.9., Issue.3, 2021

A Peer Reviewed International Journal May-June

Articles available online http://www.ijoer.in; editorijoer@gmail.com

Journal of Scientific & Engineering Research

Volume 9, Issue 5, (2018).

[4] C. Jagadeesh Vikram, D. Mohan Kumar, Dr.

P. Naveen Chandra, ‘Fabrication of

Regenerative Braking System’, International

Journal of Pure and Applied Mathematics

Volume 119, (2018).

[5] A. Eswaran, S Ajith, V Karthikeyan, P Kavin, S

Loganandh, ‘Design and Fabrication of

Regenerative Braking System’, International

Journal of Advance Research and Innovative

Ideas in Education-Vol-4 Issue-3 (2018).

[6] Ketan Warake, Dr. S. R. Bhahulikar, Dr. N. V.

Satpute, ‘Design & Development of

Regenerative Braking System at Rear Axle’,

International Journal of Advanced

Mechanical Engineering.Volume 8, Number

2 (2018).

[7] Siddharth K Sheladia, Karan K Patel, Vraj D

Savalia, Rutvik G Savaliya, ‘A Review on

Regenerative Braking Methodology in

Electric Vehicle’, International Journal of

Creative Research Thoughts, Volume 6, Issue

1 (2018).

[8] Ehsani Mehrdad, Gao Yimin, Emadi Ali,

Modern Electric, Hybrid Electric and Fuel Cell

Vehicles, CRC Press, 2010.

[9] Gao, Dr. Yimin, "Regenerative Braking,"

Encyclopedia of Sustainability Science and

Technology, 2012.

6 MILAN LAMICHHANE et al.,

View publication stats

You might also like

- TS2600 - TS3600 Parts Manual 11-2016Document138 pagesTS2600 - TS3600 Parts Manual 11-2016Аленка Дерзкова75% (4)

- Concrete Pump Safety ChecklistDocument15 pagesConcrete Pump Safety ChecklistHaleemUrRashidBangashNo ratings yet

- Design and Analysis of Regenerative Braking System of All-Terrain VehicleDocument5 pagesDesign and Analysis of Regenerative Braking System of All-Terrain VehicleAmit TogreNo ratings yet

- Optional Parts: GP/GLP/GTP15-35AK, RK, TK (D812) (C871)Document336 pagesOptional Parts: GP/GLP/GTP15-35AK, RK, TK (D812) (C871)Kiều Văn Trung100% (1)

- Regenerative Braking System in AutomobilDocument2 pagesRegenerative Braking System in AutomobilAryan AmeenNo ratings yet

- Recent Development and Advancement of Regenerative Braking in Electric BikeDocument4 pagesRecent Development and Advancement of Regenerative Braking in Electric BikeIJMTST-Online JournalNo ratings yet

- REGENRATIVE BRAKING SYSTEM FOR B.E.V BALOGUN DAVID AyooluwaDocument36 pagesREGENRATIVE BRAKING SYSTEM FOR B.E.V BALOGUN DAVID Ayooluwabalogun davidNo ratings yet

- Modification of Existing Regenerative Braking System For Electric VehicleDocument4 pagesModification of Existing Regenerative Braking System For Electric VehicleAvengersNo ratings yet

- Modification of Existing Regenerative Braking System For Electric VehicleDocument7 pagesModification of Existing Regenerative Braking System For Electric VehicleAvengersNo ratings yet

- Acknowledgement:: C. B. ShivayogimathDocument16 pagesAcknowledgement:: C. B. ShivayogimathKiran PatilNo ratings yet

- Recuperation of Kinetic Energy - Regenerative BrakingDocument5 pagesRecuperation of Kinetic Energy - Regenerative BrakingAbhishek KumarNo ratings yet

- Jurnal Teknologi: D S A E R SDocument5 pagesJurnal Teknologi: D S A E R SVivek VikuNo ratings yet

- Electricvehiclerunbybldcmotor PDFDocument57 pagesElectricvehiclerunbybldcmotor PDFSanthoshNo ratings yet

- Department of Mechanical EngineeringDocument23 pagesDepartment of Mechanical EngineeringMail ManNo ratings yet

- Irjet V3i5290Document5 pagesIrjet V3i5290Kuroko TetsuyaNo ratings yet

- Regenerative Braking Project ReportDocument23 pagesRegenerative Braking Project Reportraghu raghuNo ratings yet

- Chapter IDocument19 pagesChapter IRe-Invent ElucidationNo ratings yet

- Regenerative Braking System: Group GuideDocument14 pagesRegenerative Braking System: Group GuidePooja BanNo ratings yet

- Matecconf Eureca2018 02011Document15 pagesMatecconf Eureca2018 02011Aseel QasaimehNo ratings yet

- InTech-Energy Efficiency of Electric Vehicles1Document43 pagesInTech-Energy Efficiency of Electric Vehicles1KaleemNo ratings yet

- Regenerative Braking System in Automobiles: Vishwakarma Institute of Information Technology, Pune, Maharashtra, IndiaDocument2 pagesRegenerative Braking System in Automobiles: Vishwakarma Institute of Information Technology, Pune, Maharashtra, IndiaDawit Getachew MelsselNo ratings yet

- Mini Project ReportDocument24 pagesMini Project ReportbharathahsNo ratings yet

- Recent Trends On Drivetrain Control Strategies and Battery Parameters of A Hybrid Electric VehicleDocument13 pagesRecent Trends On Drivetrain Control Strategies and Battery Parameters of A Hybrid Electric VehicleАлекса КовачићNo ratings yet

- Magnetic Energy HarvestingDocument14 pagesMagnetic Energy HarvestingMahdi BakkarNo ratings yet

- Regenerative Braking Systems (RBS) (Future of Braking Systems)Document4 pagesRegenerative Braking Systems (RBS) (Future of Braking Systems)Sushant VanveNo ratings yet

- Report KaranDocument20 pagesReport KaranKaransinh ZalaNo ratings yet

- BTech Mechanical Engineering Project on Regenerative Braking SystemDocument46 pagesBTech Mechanical Engineering Project on Regenerative Braking Systemkishan chauhanNo ratings yet

- 03paper1010CEPOI PDFDocument7 pages03paper1010CEPOI PDFAfia GujjarNo ratings yet

- OmkarRathod EMDDocument22 pagesOmkarRathod EMDRajesh MetkariNo ratings yet

- Regenerative Braking System A ReviewDocument5 pagesRegenerative Braking System A ReviewIJRASETPublicationsNo ratings yet

- Sae Technical Paper Series: Kaushik RajashekaraDocument11 pagesSae Technical Paper Series: Kaushik RajashekaraManuel LentiNo ratings yet

- NullDocument10 pagesNullMahesh ChavanNo ratings yet

- Regenerative Braking Systems RBS FutureDocument4 pagesRegenerative Braking Systems RBS Futuresmabhibidkar2001No ratings yet

- Modelling and Performance Analysis of Electric Vehicle: International Journal of Ambient Energy May 2021Document9 pagesModelling and Performance Analysis of Electric Vehicle: International Journal of Ambient Energy May 2021rajalingamNo ratings yet

- Theme Project PresentationDocument14 pagesTheme Project PresentationMail ManNo ratings yet

- Energies-16-01950-Vf (Artículo Modelo)Document29 pagesEnergies-16-01950-Vf (Artículo Modelo)Jorge CarrionNo ratings yet

- Modelling and Performance Analysis of Electric VehicleDocument9 pagesModelling and Performance Analysis of Electric VehiclesushruthanNo ratings yet

- Fabrication of Power Production From Exhaust Gas of An EngineDocument6 pagesFabrication of Power Production From Exhaust Gas of An EngineIJRASETPublicationsNo ratings yet

- Hybrid Electrical VehiclesDocument12 pagesHybrid Electrical Vehiclesinsta gramNo ratings yet

- MastersThesisMuhammadArsalanJaleesAbroDocument57 pagesMastersThesisMuhammadArsalanJaleesAbroTanishk AgarwalNo ratings yet

- Vibration Energy Harvesting in Automotive Suspension System: A Detailed ReviewDocument75 pagesVibration Energy Harvesting in Automotive Suspension System: A Detailed ReviewsahayaNo ratings yet

- Minor Report (Final)Document24 pagesMinor Report (Final)Dev DixitNo ratings yet

- Researchon Regenerative Braking Systems AReviewDocument8 pagesResearchon Regenerative Braking Systems AReviewismayilcNo ratings yet

- International Journal of Pure and Applied Mathematics Special Issue on Design and Fabrication of Solar Powered CarDocument10 pagesInternational Journal of Pure and Applied Mathematics Special Issue on Design and Fabrication of Solar Powered CarKANNAN MANINo ratings yet

- Irjet V4i4595 PDFDocument3 pagesIrjet V4i4595 PDFUjash VasaniNo ratings yet

- Solar InteligentDocument37 pagesSolar InteligentPrekshitha NNo ratings yet

- Literature ReviewDocument5 pagesLiterature ReviewPrajay BhavsarNo ratings yet

- Hybrid Electric Two Wheeler IJSRDV6 I21255Document6 pagesHybrid Electric Two Wheeler IJSRDV6 I21255shridhar muthuNo ratings yet

- Engineering Rox - Regenerative Braking SystemDocument7 pagesEngineering Rox - Regenerative Braking SystemVivek SinghNo ratings yet

- Design and Fabrication of Regenerative Braking SystemDocument5 pagesDesign and Fabrication of Regenerative Braking Systemrachida.bouhtitchNo ratings yet

- 2008-01-0085 - Model - Based - Design - HEV - Final - 1 10 08 PDFDocument10 pages2008-01-0085 - Model - Based - Design - HEV - Final - 1 10 08 PDFrathorsumit2006No ratings yet

- The Practicality of Solenoids For Motor DevelopmentDocument20 pagesThe Practicality of Solenoids For Motor DevelopmentAnthony ValiaveeduNo ratings yet

- Converting Conventional Bike Into E-Bike: Design & Fabrication "A Concept"Document11 pagesConverting Conventional Bike Into E-Bike: Design & Fabrication "A Concept"International Journal of Technology and Emerging Sciences (IJTES)No ratings yet

- Energies: A Comparative Analysis of Brake-by-Wire Smart Actuators Using Optimization StrategiesDocument22 pagesEnergies: A Comparative Analysis of Brake-by-Wire Smart Actuators Using Optimization StrategiesRoxta ArunNo ratings yet

- Ijirt152663 PaperDocument6 pagesIjirt152663 PaperAbdirizak Mohamed HassanNo ratings yet

- Mini Project Report Phase 2Document21 pagesMini Project Report Phase 2bharathahsNo ratings yet

- Esgin Skaboard PDFDocument11 pagesEsgin Skaboard PDFJimmy Joel ColqueNo ratings yet

- Development of Bi-Polar Plate Design of PEM Fuel Cell Using CFD TechniquesDocument23 pagesDevelopment of Bi-Polar Plate Design of PEM Fuel Cell Using CFD TechniquesGaurav JadhavNo ratings yet

- Regenerative Braking Project ReportDocument19 pagesRegenerative Braking Project ReportsyedsheryNo ratings yet

- JETIR1904N63Document5 pagesJETIR1904N63harshitaNo ratings yet

- SolenoidalpropulsionDocument9 pagesSolenoidalpropulsionUTTAM RAJNo ratings yet

- Microsoft Excel-Based Tool Kit for Planning Hybrid Energy Systems: A User GuideFrom EverandMicrosoft Excel-Based Tool Kit for Planning Hybrid Energy Systems: A User GuideNo ratings yet

- Energy Storage in Grids with High Penetration of Variable GenerationFrom EverandEnergy Storage in Grids with High Penetration of Variable GenerationNo ratings yet

- PublishedDocument33 pagesPublishedMoses Jomike Michael RajagiriNo ratings yet

- Regenerative Braking Control Under Sliding Braking Condition of Electric Vehicles With Switched Reluctance Motor Drive SystemDocument13 pagesRegenerative Braking Control Under Sliding Braking Condition of Electric Vehicles With Switched Reluctance Motor Drive SystemBT20MEC120 Jyoti ThakurNo ratings yet

- Implementation of Optimized Regenerative Braking in Energy Efficient Driving StrategiesDocument20 pagesImplementation of Optimized Regenerative Braking in Energy Efficient Driving StrategiesBT20MEC120 Jyoti ThakurNo ratings yet

- Design and Fabrication of Regenerative Braking in EVDocument6 pagesDesign and Fabrication of Regenerative Braking in EVVIVA-TECH IJRINo ratings yet

- How can we reduce CO2 emissions from cars by 2030Document12 pagesHow can we reduce CO2 emissions from cars by 2030TaiNo ratings yet

- Iveco EUROCARGO RANGEDocument3 pagesIveco EUROCARGO RANGEChe VarianNo ratings yet

- 395 - ExcavatorDocument12 pages395 - ExcavatorhendrynNo ratings yet

- AMT 115 Midterm Module 2Document7 pagesAMT 115 Midterm Module 2Earl Michaelo R. KalacasNo ratings yet

- Safety RegulationsDocument9 pagesSafety RegulationsWill Front100% (1)

- JohnDeere MarineApplicationsDocument12 pagesJohnDeere MarineApplicationsPablo GrassiNo ratings yet

- 1995 Dodge Ram Service ManualDocument1,754 pages1995 Dodge Ram Service Manualattitude0330No ratings yet

- InventoryDocument15 pagesInventoryshahfaisal gfgNo ratings yet

- Liste Codes Pannes MERCEDES (Anglais)Document24 pagesListe Codes Pannes MERCEDES (Anglais)jbdepannageauto76No ratings yet

- American Car November 2015 PDFDocument116 pagesAmerican Car November 2015 PDFlarsNo ratings yet

- Lc4 2001 SpecificationsDocument3 pagesLc4 2001 SpecificationsRemo BrunoNo ratings yet

- 300-080-11 RSPC1 Instalation ManualDocument24 pages300-080-11 RSPC1 Instalation ManualLuis A DuarteNo ratings yet

- Doosan 11.0t 16.0t Diesel Forklifts BrochureDocument6 pagesDoosan 11.0t 16.0t Diesel Forklifts BrochureDavisTranNo ratings yet

- 1VWBN7A35CCXXXXXXDocument18 pages1VWBN7A35CCXXXXXXMarwan LabiodNo ratings yet

- Greaves Price List MRP - W e F 23-11-2017Document139 pagesGreaves Price List MRP - W e F 23-11-2017dulichand50% (2)

- Narnarayan Shastri Institute of Technology: Presentation OnDocument20 pagesNarnarayan Shastri Institute of Technology: Presentation Onhellovers60No ratings yet

- Turbogas MatchingDocument42 pagesTurbogas MatchingAbdouni El HoucineNo ratings yet

- Mewp Pre-Use Inspection Checklist: DocumentationDocument1 pageMewp Pre-Use Inspection Checklist: DocumentationPrimelift Safety Resources LimitedNo ratings yet

- BulletinD17E DaihatsuDocument5 pagesBulletinD17E DaihatsuMunawar Sher MuhammadNo ratings yet

- JJJHDocument60 pagesJJJHJesus A. Alvarez GutierrezNo ratings yet

- A-16-008 17MY Conventional Dump Valve InstallationDocument13 pagesA-16-008 17MY Conventional Dump Valve InstallationPhil B.No ratings yet

- Vitara Brezza PDFDocument8 pagesVitara Brezza PDFpatsan007No ratings yet

- Perkins PC3009 PDFDocument40 pagesPerkins PC3009 PDFYudie AjeNo ratings yet

- Automatic Transmission (At) Flush Procedure - Nissandiesel ForumsDocument8 pagesAutomatic Transmission (At) Flush Procedure - Nissandiesel ForumsJohnnyLarsonNo ratings yet

- Report PDFDocument60 pagesReport PDFvinesh mani100% (1)

- Perkins 1106D Technical DataDocument8 pagesPerkins 1106D Technical DataalcoholahmedNo ratings yet