Professional Documents

Culture Documents

Paper For Group 1

Uploaded by

Nasis DerejeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper For Group 1

Uploaded by

Nasis DerejeCopyright:

Available Formats

Development of ARM-based Embedded System

for Robot Applications

Shouqian Yu, Weihai Chen, Li Li, Jianglei Qin

School of Automation Science and Electrical Engineering

Beijing University of Aeronautics and Astronautics

Beijing 100083, China

yushouqian@sina.com, whchen55@163.com

Abstract—Based on the combination of advanced RISC system requirements. [4, 5, 6, 7]. As the core device of an

microprocessor (ARM), DSP and ARM-Linux, this paper embedded system, the embedded microprocessor can be an 8-,

introduces an approach for developing embedded robot control 16- or 32-bit microprocessor. Because of the limitation from

systems. The design of embedded control system includes four the lower performance such as low running speed, low

aspects, i.e., system structure, functions, hardware, and software

addressing capability and high power consumption, etc, the 8-

design. In the development of the system, some features are

included such as hierarchy structure, modular hardware, and or 16-bit microprocessors cannot meet the requirements of

structured software, to make the system suitable for a variety of some complex embedded applications. In the field of the 32-

robots applications through some hardware adjustment and bit embedded system application, ARM (Advanced RISC

software customization only. The effectiveness of proposed Machine) gains tremendous success. [8, 9, 10, 11]. Generally

approach has been verified by a straight line motion speaking, the ARM-kernel microprocessors present as smaller

demonstration of a 6-DOF series manipulator size, lower power consumption, lower cost, and relatively

higher performance, etc. For instance, with a plenty of register

Keywords— Embedded control system, ARM, controller,

and high instruction executing speed, most of data operations

robot application

are completed in registers. Besides, the ARM-kernel

I. INTRODUCTION microprocessors have advantages in addressing flexibility,

With the development of the science and technology, the facility and higher execution efficiency as well as fixed

application of robots will be significantly increased in a lengths of instructions, and so on. An embedded operating

number of fields, such as outer space exploration, ocean system can be encapsulated in ARM, to accomplish complex

resource exploitation, etc.[1, 2, 3]. However, no matter what algorithms and to finish a variety of tasks instead of personal

purpose for utilizing the robots, almost all of them are made computers.

up of two parts, the mechanical body and the control system. This paper firstly introduces the configuration of the

The mechanical body not only represents the basic embedded system, and then presents a robot control system bd

characteristic of a robot, but also determines that it is an on an embedded operating system and ARM as well as DSP. At

unmanned system. Dealing with tasks in dangerous and the end, the article illuminates an experiment that using the

complex environments, the robot should be entitled the developed system for controlling a 7-DOF serial robot.

abilities of thinking and making decisions to some extents,

moreover, it needs multi motors work together coordinately II. STRUCTURE OF THE EMBEDDED SYSTEM

for the motion control of a robot. All of these demand complex An embedded system is made up of the embedded

algorithms including motion control algorithm and pattern operating system and the hardware supporting the operating

recognition algorithm. As far as we know, it is difficult for system. The embedded operating system is the console of an

robots we discussed above to carry a computer with them as a embedded system, which is mainly used for controlling

motion control system, meanwhile, it is also impossible for the devices of information processing as well as user interfaces.

robot control system with only low-performance The hardware components of embedded systems should

microprocessors to deal with so many complex calculations. conform to specific applications, so that there are strict

Fortunately, it is just a possible solution to overcome these limitations on them, such as cost, function, size, weight and

difficulties through developing embedded systems and 32-bit power consumption, etc.

microprocessors. The software of embedded systems has the following

An embedded system is a special-purpose computer characteristics:

system, which is completely encapsulated by the device it 1) The development of embedded software is closely

controls, so there are some specific requirements for each relative to the hardware. The embedded software is

system, such as functions, reliability, cost, size, and power implemented on certain hardware platform, dealing

consumption, etc. Based on the computer technology, an with some parts of hardware-software co-design on

embedded system is designed for specific-application with device drivers.

hardware and software that could be tailored to adapt the

1-4244-0025-2/06/$20.00 ©2006 IEEE RAM 2006

2) Codes with both high efficiency and high reliability. ASB are all high performance bus designed with larger

Due to the limited and precious memory space for bandwidth, and supporting multi-master equipment and multi-

program running in the embedded system, it is slave equipment. Actually APB is a secondary bus providing

necessary to take the code efficiency into account AHB/ASB with a simply extending as low power consumption

during programming. For a real-time operating system, and interface. APB is connected with AHB or ASB through

the processor should rigidly deal with all kinds of tasks the bridge. The architecture of S3C2410 is AHB+APB, as

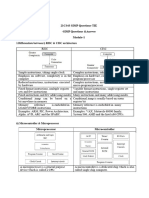

produced asynchronously. Besides, an embedded shown in Fig.1, it is the interior architecture of S3C2410.

software system is supposed to have some capabilities

such as exception handling and quick reset, etc.

3) The software should been solidified into FLASH or ARM920T S3C2410

ROM. Generally, to improve both executing speed and

system reliability, and as well, to reduce system-reset

time, the embedded software will be downloaded and

solidified into FLASH or ROM of the target device.

Hardware of an embedded system has the following LCD controller / NAND Flash controller /

AHB to APB

characteristics: O uter memory controller / i nterrupt

Bridge

controller / USB mainframe

1) Small size and high integration. An embedded system

is a minimum system without a lot of components

needless for target functions.

2) Low power consumption and fine electromagnetic

compatibility performance. It is capable of working in UART0,1,2 / IIC / IIS /

bad environments and supporting quick restart when Timer0~3(PWM) and Timer4

GPIO / USB equipment /

the system is dead. / RTC / ADC

SPI0,1

III. SYSTEM FUNCTIONS AND DESIGN Figure 1 The architecture of S3C2410

The main purpose of this design is to meet the requirements of

controlling the multi- robots system, meanwhile, to pay The client controller is designed on DSP called

attention to some characteristics, such as: size, weight and TMS320LF2407, which performs low power consumption,

power consumption, etc. to which the robot is sensitive. flexible instruction set and facility for internal operations in

addition to the high-speed calculation capability. The whole

A. Hardware Architecture hardware architecture of the system is shown in Fig2.

The server controller is suggested to adopt S3C2410

supplied by Samsung as its CPU. The S3C2410 is a 16/32-bit,

A/D Sensor

266MHz, low power consumption, and high performance The server

Analog

RISC microprocessor with ARM920T as its kernel [5, 6], Controller

which is particularly suitable for real-time control. Meanwhile, S3C2410 Digital I/O

Optic-

it supports Window CE、Palm OS、Symbian OS、Linux and

isolator

real-time operating system, etc. LCD

Moreover, S3C2410 supplies abundant equipment inside to Analog output

bring down the cost of the whole system and there is no need

of collocating excess equipment any more. The function of

integrated circuit include: separate 16KB instruction Cache

and 16KB data Cache, MMU virtual memory management,

The client 1 The client n

LCD controller, supporting NAND Flash system induction, DSP

… DSP

outside memory controller, three-channels UART, four-

channels DMA, four-channels PWM timer, 117 currency I/O

PWM

interface, 24-channels outer interrupt recourse, RTC with

Encoder signal

calendar, 8-channels 10bit ADC and touch screen interface, Optic-

A/D

IIC-BUS interface, IIS-BUS interface, USB mainframe, USB isolator

equipment, two-channels SPI, and interior PLL clock times

Analog input

frequent count. The peripheral inside the chip is connected

with the bus inside of the chip as well.

The bus inside chip of S3C2410 adopts advanced Figure 2 The hardware structure of the system

microprocessor bus architecture (AMBA). AMBA includes

advanced high-performance bus (AHB), advanced system bus The characteristics for the client controller can be shown

(ASB), and advanced peripheral bus (APB). Both AHB and as following:

1) The server controller inspects and controls the state of resources such as PWM, AD, I/O interface and QEP circuit,

the system as well as responds to the instructions from where QEP circuit inputs encoder signals coming from servo

the console, and then send data and instructions to the motor and realize the four-time frequent count to analyze

client controller; whether the motor is stalled or is out of its order. UART in

2) Communication bus, local bus, are available for LF2407 chip is used as the interface with the server controller.

communicating with other controller; The client controller controls the speed and position of the

3) Multi sensor information, such as pose, position, depth, motor according to the command and data from the server

height, speed, and acceleration sensors, can be controller by utilizing the forward feedback and backward

integrated directly through designed interface. feedback algorithms. The client controller itself is a complete

4) PWM signals are available for adjusting the speed and controller with CPU itself, memory, input-output systems and

position of the motor to control the speed and pose of interrupts. It can operate independently according to the

robots. memorized program and thus to decrease the workload of the

5) A/D collection is available. Through watching the A/D server controller. In addition, there are three extendable

value of working voltage and current, it can realize to methods for communication between server controller and the

control system or record the state.

client controller: bus communication, serial port

6) I/O control is available for inspecting and control the

communication, and two ports RAM communication.

peripheral switch data.

Furthermore, the recorded data in the system is used for There are differences in control algorithms for unlike type

setting the parameter storage, moving path or recording of robots, the difference is mainly shown by their server

relative inspecting data; through dealing with the information, algorithms. The server algorithms are based on the specific

the control algorithm is finally realized by gathering, counting tasks that the robot will carry out. Generally, a robot system

the data from different sensors and synthesizing multi-sensors’ needs only a server controller as the brain; the numbers of

information together. several client controllers are dependent on the specific task

requirements. Through simply adjusting a few interfaces or

B. Module Function and Design to add/delete some sensors will make the hardware suitable for

various tasks. A server controller prototype is illustrated in

The server controller, the peripheral device module

Figure 3

includes S3C2401, SDRAM, NAND FLASH and crystal

oscillators which are the basic elements of system running,

and power interface, RS485 bus interface, A/D interface, I/O

interface, PWM interface, client-communication interface and

LCD interface, etc.

S3C2410 has been integrated itself with several general-

purpose peripheral components, so its resources are available

for the channels as A/D and I/O directly. For example, two on-

chip UARTs are respectively used for RS485 and client-

communication interfaces. To prevent external disturbances,

these ports are isolated by high-speed optic-isolator

HCPL2630. SDRAM is available for the storage of running

program code, NAND FLASH save the startup code and

document system. Electrical power system uses a LM275-5

and two S1117, to realize the conversion of 24V-5V, 5V-2.3V

and 5V-1.8V. And a special reset chip is used for reset.

The server controller manages the whole system and

carries out the main arithmetic steps. While dealing with

signals fed back by sensors and sending commands to client Figure 3 Server controller prototype

controllers with respect to these signals, the server controller

receives signals from client controllers to estimate their states The sizes of controllers are shown as following: The

in order to send data and commands. Moreover the server measurement of server controller is 60 mm ×45 mm ×35 mm,

controller is in charge of human- machine interface, driving total power consumption is about 5V×200mA, where the CPU

LCD, displaying simple interface and state information. module holds 3.3V×30mA. A client controller is designed

The client controller includes TMS320LF2407, SDRAM, with backboard format, its measurement is 75mm×45mm×55

NAND FLASH, and crystal oscillator which are the basic mm. Comparing with 5V×1000mA which is the power

elements for the system running, it also includes power consumption of a CPU module for PC104, the controllers

interface, RS485 bus interface, A/D interface, I/O interface, discussed above have lower power consumption.

PWM interface, server-communication interface and LCD

interface, etc. TMS320LF2407 integrated itself with some

general peripheral as well, so it can directly use the system IV. SOFTWARE DESIGN

The operating system is one of the most important parts in requirements of real-time operations. In terms of software,

the whole system. It is in charge of managing all available real-time presents in the operating time limited of every

resource and distributing them among different tasks in order. process in the software system. Real-Time Operating should

According to different resource distribution strategies, there satisfy the demand of time limit, if not, the system will be

are two kinds of the operating system: one is Real-Time considered as invalidity even if the logic is right.

Operating System; the other is Time-Sharing Operating In order to inspect the system, the states of the system must

System. be collected and pass to the client controller in time, and then,

This system software is based on the RTLinux which is the client controller will find the next executing step according

Real-Time and multi-tasks operating system. RTLinux is to this information. Linux itself is a Time-Sharing Operating

changed from the kernel of Linux by adding RTLinux kernel System, so its design aims are to optimize the average

control between the process of Linux and hardware interrupt. performances of each process in the whole system. But this

It carries out a virtual interrupt mechanism in the kernel of goal counters to the controllable of high response speed and

RTLinux. limited response time which are demanded by Real-Time

Software design can be described as following: To Operating System. Its kernel adopts time-sharing arithmetic,

transplant the OS, design driving programming, package the and the accuracy of the timer is very low. The process used for

system state collection is easily disturbed by other processes,

API functions, disassemble and design multitasks, program

even get no response in a long time (may be as long as 0.6s or

control algorithms for the server and the client controller, etc.

longer). This situation may cause the system unable to get the

Based on the requirement from real-time control, it is made up

current state information and out of control. This is vital for

of two parts: one is the hardware part available for collecting

the system. So this state collection needs to be completed by a

the system state; the other is the standard Linux process. The

Real-Time process.

standard Linux process is made up of the programs for server-

RTLinux is a hardware real-time system rebuild from the

clients driver communication, client interface and the kernel of

kernel of Linux. As shows in fig2, there are two parts in the

system control, etc. The client controller is available for RTLinux: one part is the rebuilding of the kernel of Linux,

running the program. forming a small RTLinux real-time kernel within the kernel of

The architecture of system software is shown in Figure 4. Linux. This kernel provides an interrupt process of short time

lapse which can not be lapsed and rapped by Linux, and some

bottom real-time and interrupt control processes. The other

Interrupt control

User program part is a Linux standard model which provides RTLinux

hardware

Application Programming Interface (API). Through these API

the real-time task can be founded, deleted, transferred and

controlled. So in terms of the application of RTLinux, there

Linux kernel RTLinux Kernel

are two fields: one is real-time field, the other is non-real-time

field. There are many ways to communication between these

LCD driver two fields, such as FIFO and memory. While the functions in

Real-Time task real-time field satisfy the demand of real-time, it counters the

The client driver design principle of RTLinux that is making the kernel as

simply as possible, making the work in the real-time kernel

model as few as possible and if it can be finished in Linux

Figure 4 Software architecture of system without effecting the real-time operation, it should be finished

in Linux.

A. The embedded operating systems Linux in RTLinux is in charge of the initialization of

system and equipment and the management of dynamic

The system software is based on Real-Time Operating resources. RTLinux finishes hardware real-time task by using

Systems. In the field of the embedded, real-time is a very

static distribution memory, because when there is no memory

important concept. Real-Time systems are a kind of computer

resource, the hard real-time operation is not available for the

systems which complete certain functions in certain time, and

blocked thread.

give the right response to outer asynchronous events.

Since resources of the hardware of the embedded system

The kernel of Real-Time systems is to complete a pre-

defining operation in certain time; otherwise it would cause are limited, so that RTLinux can not be directly used as the

some serious consequences, such as bring down the operating system. Based on the actual application, the whole

performance or even cause the system breakdown. It is system can be customized, and stored in a Flash with less

necessary to point out that the Real-Time system does not capacity through configuring kernel, cutting down the shell

mean that the response and operating speed of the system is and the embedded C library. In this paper the system RTLinux

very high. Furthermore, cooperating software and hardware is mentioned above has been customized, the operating system

essential to realize the real time operation. Firstly, it is adopts MMU (Memory Manage Unit) that has been included

necessary to make sure that the hardware fulfills the in ARM9.

B. The Server-Client Controller Communication Program V. EXPERIMENT STUDIES

The client controller can be considered as an equipment of In this section, we present an experiment to verify the

the server controller. The server-client controller communication performance of our design by utilizing a 6-DOF serial robot.

program is the driver program for equipment of Linux. The The basic idea of the experiment issues that: Firstly, the robot

equipment driver is the software layer between client program is located in its initial position. Then, it moves along x-axis

and hardware. And as same as the kernel, the driver is run in positive direction to x = 200mm. Finally, it moves along x-

the highest level of the system, and all the recourse in the axis negative direction to x = -200mm. The whole process of

system is available for it. the experiment shows from Figure 5 to Figure 7.

Usually there are two kinds of methods of using equipment

driver: the first is to add the equipment driver to the kernel as

a load model dynamic. The model is a part of the kernel, but it

is independent, and it is not compiled into the kernel. The

second way is to compile the equipment driver into the kernel

as a part of the kernel code. When the driver is used

frequently, the second way is more suitable. So in this paper,

the second way is used.

In addition, Linux divided the equipments into three kinds:

character equipment, block equipment and network

equipment. The character equipment can be call on by the

character flow and this is very convenient for the control of

(a) Simulation (b) Actual motion

motor. RS485 bus communication is used in the system, so the

Figure 5 A 6-DOF robot is located in its initial position

client controller is considered as the character equipment. The

server controller send control data and signal by sending

ASCII character string to the client controller, and the client

controller respond to the server controller by returning ASCII

character string as well. In order to use the client driver, the

user needs to call the open system to start the equipment and

then return an equipment descriptor. When the user process

wants to send commands to the client controller, it call the

write program of the driver, then the write program will copy

the character string of the command to output buffer. Driver

program passes the code from output buffer to the client

controller practically.

The key of the arithmetic is the synchronization

(a) Simulation (b) Actual motion

performance between the server and the client controllers.

Figure 6 The 6-DOF robot moves along x-axis positive direction

Synchronization performance plays an important role in the

work of multi-controllers. Before data transmitted, the server

controller sends signals with a receiver mark and only the

module with the same mark number is able to receive the

following data. When the corresponding client controller

receives the signal, it will send an answer signal to the server

controller. For the synchronization of their work, the

processors are supposed to use the bus respectively. To make

synchronization among the multi- controller communication

and to prevent signal conflict as well, each of processors use

an I/O port and all of them are connected together. Therefore,

when a controller is either receiving or transmitting data, it

sends out high-potential signals to other controllers showing

(a) Simulation (b) Actual motion

that the bus is busy now and the controllers receive the signals

will not transmit data, preventing bus conflict. This approach Figure 7 The 6-DOF robot moves along x-axis negative direction

proved to be feasible by practice. By utilization of this

approach, synchronization of multi-processor work will be The motion cycle can be described as follows:

fine without bus conflict. 1) Locate the robot in its initial position P0(0, − 270, 250)

For the system, the operations of sensor data include as shown in Fig. 5, where Fig.5(a) is the simulation

acquiring, checking, extracting and processing will be done results with the pose of the end-effector and joint

according to NMEA0183 standard, facilitating for system angles, Fig.5(b) is the picture from actual robot .

upgrade.

2) Move the robot from P0 to P1(200, − 270, 250) as shown ACKNOWLEDGMENT

in Fig.6, where Fig.6(a) is the simulation results with the This work were supported by natural science foundation of

pose of the end-effector and joint angles, Fig.6(b) is China under the research project 50375008, 60575052, and

the motion picture from actual robot. 863 program of China under the research project

3) Move the robot from P1 to P2(−200, − 270, 250) as 2002AA421160

shown in Fig.7, where Fig.7(a) is the simulation results

with the pose of the end-effector and joint angles,

REFERENCES

Fig.7(b) is the motion picture from actual robot.

In this control system, the server controller (S3C2410) [1] R. M. Murray, Z. X. Li, S. S. Sastry. “A Mathematical

Introduction to Robotic Manipulation”, America: CRC Press,

calculates the coordinate values of 1000 position points at the 1994.

first time, which are sent to all of the client controllers through [2] W. H. Chen, G. L. Yang, Edwin H. L. Ho, and I. M. Chen,.

RS485 bus and downloaded into their FLASH. Each of the “Interactive Motion Control of Modular Reconfigurable

client controllers carries out these points and asks for more Manipulators”, Proceeding of the 2003 IEEE/RSJ Inter.

500 points until 500 points have been finished. This approach Conference on Intelligent Robots and Systems Las Vegas,

Nevada. October 2003.

is used for reducing interaction time between server and client

[3] L. Romdhance, “Design and analysis of a hybrid serial parallel

controllers, improving the synchronization performance of the manipulator”, Mechanism and Machine Theory, 1999, Vol. 34:

serial robot and increasing track precision. In addition, by 1037-1055.

utilization of an ARM-kernel microprocessor, all of the [4] K. Yaghmour, “Building Embedded Linux Systems”,. America,

actions are accomplished by the robot itself rather than a O’Reilly, 2004.

computer. [5] Michael Barr, “Programming Embedded Systems in C and

C++” , America: O’Reilly, 2001

In this experiment, the client controllers are PowerCube [6] J. Catsoulis. ”Designing Embedded Hardware”. America:

controller fabricated by Amtec company because we use the O’Reilly, 2001

PowerCube modules to build a robot system [14]. There is a [7] L. P. Yan, H. Zeng, K. Song, “Analysis and Design for

RS485 communication card will be needed to realize the Embedded Intelligent Family Gateways”, Control and

communication between server and client controllers. Automation, 2005, 2: 14-16.

[8] T. Z. Sun, W. J. Yuan, and H. F. Zhang, “Manual for Embedded

The experiment shows that this control system has the Design and Linux Driver Development: Based on ARM9

advantage in stability, fine real-time performance and general- Microprocessors”, Beijing: Publishing House of Electronics

purpose capability. Besides, it is capable of working in Industry, 2005

hazardous and complex environments. [9] Y. Chen, M. Li, Y. Yang. “Analysis and Practice of Open-Code

Embedded System Software: Based on SKYEYE and ARM

Development Platform”, Beijing: Beijing University of

VI. CONCLUSION Aeronautics and Astronautics Press, 2003

The embedded robot control system designed in this paper is [10] L. G. Zhou, . Foundation and Practice for ARM Microprocessors,

Beijing: Beijing University of Aeronautics and Astronautics

applied to a 6-DOF serial robot and performs fine Press, 2003

characteristics of reliability, real-time and general-purpose [11] J. G. Li, X. Y. Nie, and Z. M. Jiang, “Development

capability. Moreover its small size and low power Specifications for ARM Application Systems”, Beijing:

consumption fulfill the requirements. Without computer, the Tsinghua University Press, 2003

control system can carries out the control arithmetic on the [12] H. P., Liu, W. J Wang, and Y. Jiang, “Application and

Development on C Language for TMS320LF240x DSP”,

server controller (ARM) and control the client controllers Beijing: Beijing University of Aeronautics and Astronautics

(DSP) through bus. Thus the robot is entitled the ability of Press, 2003

making decision independently to some extent. So far, there [13] S. Wang, J. J. Li, and J. H. Liang, “Embedded Autopilot Design

are some shortcomings in this developed embedded control of Micro-Robots”, Journal of Beijing University of Aeronautics

system as well, such as the design of control arithmetic and and Astronautics, 2005, 31(7): 775-779

improvement of functions, on which further study should be [14] http://www.powercube.com

conducted.

You might also like

- Prosim Beta Manual-06!16!2011Document62 pagesProsim Beta Manual-06!16!2011alvaro2005No ratings yet

- Embedded Systems (All Units)Document250 pagesEmbedded Systems (All Units)ezhiltham0% (2)

- Embedded System DesignDocument22 pagesEmbedded System Designtrail meNo ratings yet

- Course FileDocument36 pagesCourse FileElakkiya N.SNo ratings yet

- Prepared By:: Carmina Y. YabutDocument20 pagesPrepared By:: Carmina Y. YabutBrave WarriorNo ratings yet

- Digital Electronics, Computer Architecture and Microprocessor Design PrinciplesFrom EverandDigital Electronics, Computer Architecture and Microprocessor Design PrinciplesNo ratings yet

- 16504-Home Automation SystemDocument23 pages16504-Home Automation SystemuddinnadeemNo ratings yet

- EE6602 2 Marks With Answer KeyDocument20 pagesEE6602 2 Marks With Answer KeyLogesh50% (2)

- EmbededsystemDocument31 pagesEmbededsystemsonalNo ratings yet

- Embedded ARM11Document195 pagesEmbedded ARM11vedhajuval100% (1)

- Arm Cortex m3 and m4 Mcu ArchitectureDocument7 pagesArm Cortex m3 and m4 Mcu ArchitecturerockingjoeNo ratings yet

- Arm Manual Ver3.2 (Modyfideraj)Document83 pagesArm Manual Ver3.2 (Modyfideraj)Srikanth SriNo ratings yet

- Arm 32Document20 pagesArm 32Surbhi Pal0% (1)

- ARM ArchitectureDocument16 pagesARM ArchitectureS S0% (1)

- Lecture-1 ARM Cortex M4-Based System PDFDocument36 pagesLecture-1 ARM Cortex M4-Based System PDFAnandNo ratings yet

- TargetLink Product-InformationDocument48 pagesTargetLink Product-Informationmazher_ecNo ratings yet

- Open-Source Robotics and Process Control Cookbook: Designing and Building Robust, Dependable Real-time SystemsFrom EverandOpen-Source Robotics and Process Control Cookbook: Designing and Building Robust, Dependable Real-time SystemsRating: 3 out of 5 stars3/5 (1)

- Getting Started MC 10Document25 pagesGetting Started MC 10quochungkdNo ratings yet

- Lec 074821Document340 pagesLec 074821Mohamed Rashed100% (2)

- Embedded Systems - Question Bank (AU-CBE, ECE-R2007)Document36 pagesEmbedded Systems - Question Bank (AU-CBE, ECE-R2007)Dr. N.ShanmugasundaramNo ratings yet

- Embedded System - Question Bank (BE-ECE, VII Semester, R2008)Document52 pagesEmbedded System - Question Bank (BE-ECE, VII Semester, R2008)Dr. N.Shanmugasundaram100% (2)

- A Practical Application of ARM Cortex M3Document19 pagesA Practical Application of ARM Cortex M3Kang YiNo ratings yet

- 1.0 Introduction To Emedded SystemsDocument10 pages1.0 Introduction To Emedded Systemssunstable bornNo ratings yet

- EWSDocument4 pagesEWSMohit VekariaNo ratings yet

- 5 2marksDocument22 pages5 2marksElakkiya N.SNo ratings yet

- Embedded Systems Lab Manual: Sriindu College of Engineering and TechnologyDocument83 pagesEmbedded Systems Lab Manual: Sriindu College of Engineering and TechnologyShilpa MNo ratings yet

- Chapter TwoDocument14 pagesChapter TwoAbdissaTadeseNo ratings yet

- 21CS43 SIMP Questions-TIEDocument60 pages21CS43 SIMP Questions-TIEVivek TgNo ratings yet

- ARM Micro Controller Differences Between Microprocessor and MicrocontrollerDocument18 pagesARM Micro Controller Differences Between Microprocessor and Microcontrollersrc e-solutionsNo ratings yet

- Unit 2 - Learning MaterailDocument52 pagesUnit 2 - Learning MaterailPILLARISETTY KARTHIK 2021-CSE UGNo ratings yet

- It 2354 QBDocument28 pagesIt 2354 QBlogu87No ratings yet

- ES Notes1 (R19) IV ECE 1-2 UNITSDocument66 pagesES Notes1 (R19) IV ECE 1-2 UNITSgootydhanalakshmi2003No ratings yet

- Gip UNIT IDocument39 pagesGip UNIT IjesudosssNo ratings yet

- 3 RD ChapterDocument6 pages3 RD ChaptergouttNo ratings yet

- Files 1510298855 27889 PDFDocument151 pagesFiles 1510298855 27889 PDFDãyäñidhï ÑæïkNo ratings yet

- Arm Processor: by Neha Dewangan Guest Faculty Sos in Electronics & Photonics, PrsuDocument14 pagesArm Processor: by Neha Dewangan Guest Faculty Sos in Electronics & Photonics, PrsuNeha DewanganNo ratings yet

- Unit I Embedded Computing: 2 Marks QuestionsDocument28 pagesUnit I Embedded Computing: 2 Marks Questionslogu87No ratings yet

- Embedded Systems Design ProcessDocument51 pagesEmbedded Systems Design ProcesssamNo ratings yet

- Fatima Michael College of Engineering & Technology: UNIT-1 Embedded Computing Two MarksDocument23 pagesFatima Michael College of Engineering & Technology: UNIT-1 Embedded Computing Two MarksrameshdurairajNo ratings yet

- Assignment 1Document23 pagesAssignment 1TAMMINEDI GANESH PRASAD 222010311030No ratings yet

- MOD1MCESDocument4 pagesMOD1MCESanandita chalamalasettiNo ratings yet

- ERTS Two Mark With Answers 2021-2022Document18 pagesERTS Two Mark With Answers 2021-2022Ashok KumarNo ratings yet

- Module 1Document18 pagesModule 1Rohit AnejaNo ratings yet

- Embedded and Real Time Systems Question BankDocument45 pagesEmbedded and Real Time Systems Question BankChandra MathiNo ratings yet

- Ece Embed Ed SystemDocument27 pagesEce Embed Ed SystemlakshmigajendranNo ratings yet

- Implementing The Arm7 Soft Core Processor in FpgaDocument7 pagesImplementing The Arm7 Soft Core Processor in FpgaMuthe MuraliNo ratings yet

- Minor LastDocument67 pagesMinor LastMusharraf AliNo ratings yet

- B.tech EeeprojectDocument97 pagesB.tech EeeprojectVamsi SakhamuriNo ratings yet

- Embedded and Real-Time Operating Systems: Course Code: 70439Document76 pagesEmbedded and Real-Time Operating Systems: Course Code: 70439SrikanthNo ratings yet

- EMBEDDED SYSTEM-unit-1Document119 pagesEMBEDDED SYSTEM-unit-112 EE234 Santhosh kumar sNo ratings yet

- Embedded-and-Real-Time-Systems-2 Marks FinalDocument20 pagesEmbedded-and-Real-Time-Systems-2 Marks FinalranjaniNo ratings yet

- Report EsdDocument37 pagesReport Esdkumarabhishekranjan0786No ratings yet

- 13 Vol 49 No 1Document6 pages13 Vol 49 No 1guezaki6636No ratings yet

- EMBEDDED SYSTEMS - INTRODUCTIONDocument39 pagesEMBEDDED SYSTEMS - INTRODUCTIONsrinivasarao vuppanapalliNo ratings yet

- Embedded System In Industrial View: Industrial Embedded SystemsDocument36 pagesEmbedded System In Industrial View: Industrial Embedded SystemsPriya KosuriNo ratings yet

- Unit 1Document20 pagesUnit 1prabhavathysund8763No ratings yet

- Compare These Arm Architectures: ARM7TDMI and ARM9TDMI. AnswerDocument6 pagesCompare These Arm Architectures: ARM7TDMI and ARM9TDMI. Answersatinder singhNo ratings yet

- Bahir Dar University ARM Architecture DocumentDocument16 pagesBahir Dar University ARM Architecture DocumentAbG Compilation of VideosNo ratings yet

- Embedded Systems - Quick GuideDocument55 pagesEmbedded Systems - Quick GuideOdunayo AkinladeNo ratings yet

- EC 6703 2marks QB Upto Nov 2018Document22 pagesEC 6703 2marks QB Upto Nov 2018Vijayanand SNo ratings yet

- As Old GrowDocument14 pagesAs Old GrowTemesgenNo ratings yet

- Embedded System In Industrial View: An Overview of Key ConceptsDocument36 pagesEmbedded System In Industrial View: An Overview of Key ConceptsJayesh VasavaNo ratings yet

- Ec2042 2 MarksDocument56 pagesEc2042 2 Marksanand_duraiswamyNo ratings yet

- UNIT-1 Embedded Computing Two Marks: 2. in What Ways CISC and RISC Processors Differ?Document23 pagesUNIT-1 Embedded Computing Two Marks: 2. in What Ways CISC and RISC Processors Differ?rajeshkumardhandapanNo ratings yet

- Unit 1: Introduction To Embedded SystemsDocument49 pagesUnit 1: Introduction To Embedded SystemsJoel100% (1)

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- FoN OneDocument65 pagesFoN OneNasis DerejeNo ratings yet

- ML Ch-4 Artificial Neural NetworkDocument54 pagesML Ch-4 Artificial Neural NetworkNasis DerejeNo ratings yet

- ML Ch-4 Artificial Neural NetworkDocument54 pagesML Ch-4 Artificial Neural NetworkNasis DerejeNo ratings yet

- FoN TwoDocument40 pagesFoN TwoNasis DerejeNo ratings yet

- Online Bus Ticket Reservation SystemDocument18 pagesOnline Bus Ticket Reservation Systemsurajmali4067No ratings yet

- Student Union Voting System For Wolkite UniversityDocument3 pagesStudent Union Voting System For Wolkite UniversityNasis DerejeNo ratings yet

- Student Union Voting System For Wolkite University FinalDocument25 pagesStudent Union Voting System For Wolkite University FinalNasis DerejeNo ratings yet

- Student Union Voting System For Wolkite University FinalDocument10 pagesStudent Union Voting System For Wolkite University FinalNasis DerejeNo ratings yet

- ML Ch-1 Introduction To ML 1Document35 pagesML Ch-1 Introduction To ML 1Nasis DerejeNo ratings yet

- Web Design and Programming CH 1Document22 pagesWeb Design and Programming CH 1Nasis DerejeNo ratings yet

- SAD ProjectDocument12 pagesSAD ProjectNasis DerejeNo ratings yet

- SAD ProjectDocument12 pagesSAD ProjectNasis DerejeNo ratings yet

- Web CH 2 - Part IDocument33 pagesWeb CH 2 - Part INasis DerejeNo ratings yet

- Student Union Voting System For Wolkite University FinalDocument10 pagesStudent Union Voting System For Wolkite University FinalNasis DerejeNo ratings yet

- Web CH 5 - PHP Part 2Document38 pagesWeb CH 5 - PHP Part 2Nasis DerejeNo ratings yet

- Web CH 2 - Part IDocument33 pagesWeb CH 2 - Part INasis DerejeNo ratings yet

- Question Three and FourDocument11 pagesQuestion Three and FourNasis DerejeNo ratings yet

- Online Bus Ticket Reservation SystemDocument18 pagesOnline Bus Ticket Reservation Systemsurajmali4067No ratings yet

- Web CH 5 - PHP Part 1Document41 pagesWeb CH 5 - PHP Part 1Nasis DerejeNo ratings yet

- Materials 1 5Document64 pagesMaterials 1 5Nasis DerejeNo ratings yet

- Web CH 5 - PHP Part 2Document38 pagesWeb CH 5 - PHP Part 2Nasis DerejeNo ratings yet

- Software Engineering Tools and PracticesDocument37 pagesSoftware Engineering Tools and PracticesNasis DerejeNo ratings yet

- Web CH 4 JavaScript IIDocument41 pagesWeb CH 4 JavaScript IINasis DerejeNo ratings yet

- Chapter04 - High Level DesignDocument18 pagesChapter04 - High Level DesignNasis DerejeNo ratings yet

- 2024 ICPC Ethiopian CPC Tamiru Dereje PLACEDocument1 page2024 ICPC Ethiopian CPC Tamiru Dereje PLACENasis DerejeNo ratings yet

- Distributed System 1 PDFDocument9 pagesDistributed System 1 PDFNasis DerejeNo ratings yet

- Chap 5Document8 pagesChap 5Nasis DerejeNo ratings yet

- Paper For Group 5Document8 pagesPaper For Group 5Nasis DerejeNo ratings yet

- Chapter06 - Version ControlDocument59 pagesChapter06 - Version ControlNasis DerejeNo ratings yet

- Policy Design FinallDocument7 pagesPolicy Design FinallNasis DerejeNo ratings yet

- Assignment 1: Computer ArchitectureDocument8 pagesAssignment 1: Computer ArchitectureAmirulRoslanNo ratings yet

- Living in The IT Era: East West Mindanao College IncDocument6 pagesLiving in The IT Era: East West Mindanao College IncPrincess Jhobie Celin DivinagraciaNo ratings yet

- Class 9th ComputerDocument8 pagesClass 9th ComputerArslan NaveedNo ratings yet

- SiemensDocument6 pagesSiemensbala_paiNo ratings yet

- 1 - Basic Computer OrganizationDocument88 pages1 - Basic Computer OrganizationshabanaNo ratings yet

- Input Output OrganizationDocument65 pagesInput Output OrganizationKelvinNo ratings yet

- Vehicle Buses Electronics ComponentsDocument5 pagesVehicle Buses Electronics ComponentsMustafa Özdemir100% (1)

- Ehtc HARDDocument65 pagesEhtc HARDSamNo ratings yet

- TMS320C55x Technical Overview: Literature Number: SPRU393 February 2000Document43 pagesTMS320C55x Technical Overview: Literature Number: SPRU393 February 2000aldo_suviNo ratings yet

- NS Series Programming Manual Section 5 Troubleshooting and Maintenance Error MessagesDocument19 pagesNS Series Programming Manual Section 5 Troubleshooting and Maintenance Error MessagesmrksotNo ratings yet

- 2 Information Sheet 1.1-2Document13 pages2 Information Sheet 1.1-2jhon lurym delos santosNo ratings yet

- Parallel Processing PDFDocument33 pagesParallel Processing PDFDeepshikha MehtaNo ratings yet

- Manual Placa de BazaDocument37 pagesManual Placa de BazaBogdan CatrinescuNo ratings yet

- 8255 Programmable Peripheral Interface ModesDocument54 pages8255 Programmable Peripheral Interface Modesmariyal eceNo ratings yet

- A. Nagoor Kani - Microprocessor (8085) and Its Applications-McGraw-Hill Education (2005) PDFDocument392 pagesA. Nagoor Kani - Microprocessor (8085) and Its Applications-McGraw-Hill Education (2005) PDFGulrez M40% (5)

- Micro Notes - Chapter 2Document7 pagesMicro Notes - Chapter 2Haann NoiNo ratings yet

- How Motherboards Work: Understanding the Role of Bus SpeedDocument2 pagesHow Motherboards Work: Understanding the Role of Bus SpeedA gopalNo ratings yet

- Microprocessor Programming and Interfacing: Computing ConceptsDocument9 pagesMicroprocessor Programming and Interfacing: Computing ConceptsKaushikperikaNo ratings yet

- Microprocessor and Peripherals Interfacing-ECC501Document48 pagesMicroprocessor and Peripherals Interfacing-ECC501Mohil KhareNo ratings yet

- IT 236: Microprocessor and Computer ArchitectureDocument2 pagesIT 236: Microprocessor and Computer ArchitectureWave WoNo ratings yet

- IBM 5150 Technical Reference 6322507 APR84Document309 pagesIBM 5150 Technical Reference 6322507 APR84nvr735iNo ratings yet

- TFT 240x320 Driver ILI9320 PDFDocument115 pagesTFT 240x320 Driver ILI9320 PDFEdwin Javier Garavito HernándezNo ratings yet

- Css Module 4 Tle 9 Revised2Document24 pagesCss Module 4 Tle 9 Revised2Ardee DuculanNo ratings yet

- EE6502 MPMC UNIT 1-5 (Read-Only)Document607 pagesEE6502 MPMC UNIT 1-5 (Read-Only)Rajasekaran ThangarajuNo ratings yet