Professional Documents

Culture Documents

Anticorr

Uploaded by

Батырхан Избасар0 ratings0% found this document useful (0 votes)

2 views3 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views3 pagesAnticorr

Uploaded by

Батырхан ИзбасарCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

1st sliide: Crude oil and its compositions.

Crude oil is a complex mixture cinsisting 200 or more

different organic compounds and hydrocarbons, containing carbon, hydrogen, sulfur, nitrogen,

oxygen. Crude oik is created when animal and plant matter undergoes complex decomposition

deep underground under high temperature and pressure. This a very slow process and that’s why

crude oil is considered to be a non – renewable energy source.Even though the composition of

crude oil will be different depending on where crude oil is extracted. The composition varies

widely depending on where and how the petroleum was formed. Different crude contains

different combinations and concentrations.

2nd slide: There are three main hydrocarbons that can be found in most crude oils around the

world. First, we have paraffins or alkanes and they make up 25% of crude oil. These are

saturated hydrocarbons and the simplest example of alkanes is methane. As the number of carbon

atoms in the alkanes increases so does their boiling temperature. Next we have napthenes and

they make up 45% of crude oil. Napthenes have a higher boiling temperature than paraffins.

Aromatics make up about 20% of crude oil. All aromatics contain a benzene ring . Some

examples are Tolueneтолуйн and зайлин Xylene. If they contain at least one benzene ring, they

are called aromatic. If they contain at least one cycloparaffin ring (the saturated ring), they are

called naphthenic. And if they have neither, they are called paraffinic.

There are 5 primary types of solid which can form and these fluids are flowing through a

pipeline and they all present flow assurance challenges now today we consider about one that is

wax (paraffins).

3rd slide: So what is a wax? Waxes are paraffins for a general name for a group of

hydrocarbons , its very chain like so roughly between six and sixty carbons long and they are

mostly linear waxes. They can have low or high molecular weight. The problem with these

waxes particularly as they get to longer and longer chains . Whats really happening here so there

are three key steps . These yellow circles represents a wax molecule. If I want to form a nucleus I

need to get two or more of these wax molecules to come together , so they stick totogether and

after this they can aggregate and grow. They precipitate out they can crystallize and they cant

continue to grow

4th slide: What issues do these waxes cause, there is two issues, so the first one is wax

precipitation causes increases fluid viscosity. If you imagine putting something solid into a

liquid, it gradually becomes more viscous does not flow very well, this is a nice simple example

and same thing happens with oil.

Wax can deposit on the wells of pipeline and this decreases the internal diameter . we ve got

some excellent pictures. These are pictures of different pipelines where wax has deposited. And

you see how big a decrease the of the internal diameter. So wax deposition is a big issue.

One more example where the precipitation and deposition is so bad , you essentially block up the

pipeline, in yhis case you might have to pig, that is the technical term for mechanical scraping of

your pipeline so you push all of that blockage out, and you end up with this fantastic looking

image here.

5th slide: When things go wrong, if I blocked on my pipeline I ve got various options. First of

these is a thermal treatment, we know wax deposits and precipitates because temperature

decreases, I could increase temperature I can do that by adding in a hot fluid that would be a

good way.

A common method used to remove paraffin and asphaltene is hot fluid treatment. This treatment

removes these deposits by using hot oil/diesel, hot water or steam. If it happens that heat thatis

generated might e sufficient to reduce all some of the wax.

I ve also got some options to use chemical trearments. I could try dissolve some of the wax that

has precipitated and deposited so perhaps having in some kind of solvent.

Lastly, you ve got the option to have some kind of physical remediation treatment so if you

remember this the image of about pigging on the previous slide mechanical scripping of a

pipekine .

6th slide:

Tanks for oil products and

gas

must

be sealed - this is one of

the main tasks facing

specialized enterprises.

In order for the operated equipment

to be less exposed to breakdowns and

accidents, each container must

be protected. This is done with the help

of various

means

of anti-corrosion protection.

To understand how to protect

an oil tank from corrosion, you need to know

what

causes it.

This

is a natural phenomenon, the reasons for its

formation

can

be

very

different:

• humidity in combination with

temperature changes,

• the aggressiveness of the products that

are •

stored in containers,

the painting technology that

is applied to them.

To protect the underground tank,

two types of events are held.

Such

a tank

needs

an anticorrosive layer from two types

of damage - soil (also

electrochemical)

corrosion

and

stray currents. For

this

purpose, three types of protection are used:

•tread;

•drainage;

•

soil.

The outer surfaces are protected

by applying anticorrosive coatings on them

.This

is a very

effective

method

that

requires

pre

-treatment

of the surface of the container.

You might also like

- The Complete Book of EcstacyDocument56 pagesThe Complete Book of EcstacyMagikFungus86% (7)

- Bright Star's MDMA Synthesis For The First Time Chemist - (WWWDocument7 pagesBright Star's MDMA Synthesis For The First Time Chemist - (WWWSCRUPEUSSNo ratings yet

- Film Interpretation and Reference RadiographsDocument7 pagesFilm Interpretation and Reference RadiographsEnrique Tavira67% (3)

- Crude OilDocument25 pagesCrude OilBipin AryaNo ratings yet

- 0801871441Document398 pages0801871441xLeelahx50% (2)

- Risk Response PlanDocument8 pagesRisk Response Planapi-639207174No ratings yet

- Reaction Paper GattacaDocument1 pageReaction Paper GattacaJoasan PutongNo ratings yet

- How Oil Refining WorksDocument13 pagesHow Oil Refining WorksHerman_ms2000No ratings yet

- Chemical Engineering Interview Questions and AnswersDocument38 pagesChemical Engineering Interview Questions and Answerspradipsai100% (2)

- This File Is A Part of The Rhodium Site ArchiveDocument7 pagesThis File Is A Part of The Rhodium Site Archiveimharsh1992No ratings yet

- Procedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowDocument8 pagesProcedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowMarjorie Dulay Dumol80% (5)

- Crude Petroleum analysis handbook: Crude oil Quality control, #1From EverandCrude Petroleum analysis handbook: Crude oil Quality control, #1Rating: 4 out of 5 stars4/5 (1)

- Oil Treatment (Dehydration) PDFDocument66 pagesOil Treatment (Dehydration) PDFMahathir Che Ap86% (7)

- "I Want Some Methylamine!": Chapter FourteenDocument5 pages"I Want Some Methylamine!": Chapter FourteenkomanieckizakapiorNo ratings yet

- Hydraulic Excavator: Engine WeightsDocument28 pagesHydraulic Excavator: Engine WeightsFelipe Pisklevits LaubeNo ratings yet

- Crude Oil Refining Process 15.12.2010Document9 pagesCrude Oil Refining Process 15.12.2010Sheheryar MirzaNo ratings yet

- Basics of Refinery1Document15 pagesBasics of Refinery1Sunil PatanwadiyaNo ratings yet

- Specific Instuctions To BiddersDocument37 pagesSpecific Instuctions To BiddersShahed Hussain100% (1)

- Wax RemediationDocument3 pagesWax RemediationDonna GrayNo ratings yet

- Wax in Crude Oil ProjectDocument4 pagesWax in Crude Oil ProjectHuda Alkhouri100% (1)

- Natural Gas Petroleum IndustriesDocument55 pagesNatural Gas Petroleum IndustriesBalqis yasinNo ratings yet

- How Oil Refining WorksDocument6 pagesHow Oil Refining WorksAnonymous NyvKBWNo ratings yet

- Petroleum Fractional DistillationDocument8 pagesPetroleum Fractional Distillationrosemariegalindo70No ratings yet

- Industrial Paper FinalDocument10 pagesIndustrial Paper FinalM Javed RamzanNo ratings yet

- How Oil Refining WorksDocument12 pagesHow Oil Refining WorkssubashNo ratings yet

- 1 Stockmann GermanyDocument20 pages1 Stockmann GermanyVadimNo ratings yet

- Advanced Ship Building Materials Lesson 12 - Mixing of ChemicalsDocument17 pagesAdvanced Ship Building Materials Lesson 12 - Mixing of ChemicalsChanaka DilshanNo ratings yet

- Petroleum WebquestDocument3 pagesPetroleum Webquestapi-334885441No ratings yet

- Section 12.4 PaintDocument13 pagesSection 12.4 PaintwmuhannyNo ratings yet

- Oil OxidationDocument36 pagesOil OxidationdaudiNo ratings yet

- Lecturer: Dr. Charles Topic: Physio-Chemical Properties of Engine OilDocument3 pagesLecturer: Dr. Charles Topic: Physio-Chemical Properties of Engine OilVictorNo ratings yet

- About GasolineDocument5 pagesAbout GasolineAngel Anne AlcantaraNo ratings yet

- Oil Spill Clean-Up: An Engineering Challenge: TH THDocument4 pagesOil Spill Clean-Up: An Engineering Challenge: TH THBala GopalNo ratings yet

- Refining of Petroleum: Back To TopDocument11 pagesRefining of Petroleum: Back To TopMazhar AliNo ratings yet

- Teaching 922 18783 1613332733 1Document39 pagesTeaching 922 18783 1613332733 1Stark JohnNo ratings yet

- My Organic ChemDocument134 pagesMy Organic ChemFatima Gul FarazNo ratings yet

- Lecture Notes 34 - Crude Oil IndustryDocument4 pagesLecture Notes 34 - Crude Oil IndustrySurendra RamkissoonNo ratings yet

- GasolineDocument7 pagesGasolinewanieduffNo ratings yet

- 17.1 To 17.4 Organic Chemistry NotesDocument5 pages17.1 To 17.4 Organic Chemistry NotesahmedNo ratings yet

- Project Crude OilDocument21 pagesProject Crude OilNishant RandevNo ratings yet

- Hydrocarbon Production Engineering: Presented By: Manish Kumar (18PE10006)Document14 pagesHydrocarbon Production Engineering: Presented By: Manish Kumar (18PE10006)Manish KumarNo ratings yet

- Emerging Problem of Lubricant Varnish MAM 201007 PDFDocument5 pagesEmerging Problem of Lubricant Varnish MAM 201007 PDFCeciliagorraNo ratings yet

- Novel Solution To Oil Spill Recovery: Using Thermodegradable Polyole Fin Oil Superabsorbent Polymer (Oil SAP)Document7 pagesNovel Solution To Oil Spill Recovery: Using Thermodegradable Polyole Fin Oil Superabsorbent Polymer (Oil SAP)Grinder Hernan Rojas UrcohuarangaNo ratings yet

- Crude OilDocument11 pagesCrude OildamochkaNo ratings yet

- Cracking AlkanesDocument2 pagesCracking Alkaneskadek_windyNo ratings yet

- HowStuffWorks - How Oil Refining WorksDocument3 pagesHowStuffWorks - How Oil Refining Worksnishant361No ratings yet

- Downstream Team1Document11 pagesDownstream Team1Priyanka PanigrahiNo ratings yet

- Instrumentation Part1omkarDocument173 pagesInstrumentation Part1omkaromkarvadlooriNo ratings yet

- Crude Oil RefiningDocument28 pagesCrude Oil RefiningtswNo ratings yet

- Fire HazardsDocument7 pagesFire HazardsJl VicNo ratings yet

- ASSIGNMENT 3 - Cindi Noviani - 1C D4-TKI - 06Document4 pagesASSIGNMENT 3 - Cindi Noviani - 1C D4-TKI - 06Cindi NovianiNo ratings yet

- Refining of PetroleumDocument10 pagesRefining of PetroleumHanyszShalNo ratings yet

- Unit 1 Petrochemistry: Reading 1Document23 pagesUnit 1 Petrochemistry: Reading 1TRINHTHANHPHUHD7No ratings yet

- Man-Made Fibres GLDocument5 pagesMan-Made Fibres GLLinh NguyenNo ratings yet

- Chemistry Project: By: Ouail BalahDocument9 pagesChemistry Project: By: Ouail BalahOuail BalahNo ratings yet

- List of Petroleum ProductsDocument21 pagesList of Petroleum ProductsYasir ButtNo ratings yet

- EthyleneDocument7 pagesEthyleneHassam UlhaqNo ratings yet

- Fossil FuelDocument7 pagesFossil FuelJerome BalatbatNo ratings yet

- Topic 7 Products From Crude OilDocument13 pagesTopic 7 Products From Crude OilCollins JimNo ratings yet

- RefiningDocument3 pagesRefiningMariela RuizNo ratings yet

- Topic 9 Crude Oil JCAFDocument12 pagesTopic 9 Crude Oil JCAFEllson LinNo ratings yet

- Mitigation of Wax in Oil PipelinesDocument9 pagesMitigation of Wax in Oil PipelinesIsaac MuñozNo ratings yet

- Selfheating and Spontaneous Ignition Spontaneous CombustionDocument2 pagesSelfheating and Spontaneous Ignition Spontaneous CombustionKhoirul WaladNo ratings yet

- Petroleum ProcessingDocument22 pagesPetroleum ProcessingMark Anthony FauneNo ratings yet

- Chemistry NotesDocument14 pagesChemistry NotesMina TadrosNo ratings yet

- Spe 113673 MsDocument7 pagesSpe 113673 MsБатырхан ИзбасарNo ratings yet

- Spe 102026 MsDocument10 pagesSpe 102026 MsБатырхан ИзбасарNo ratings yet

- Effect of O2 On Corrosion of SteelDocument89 pagesEffect of O2 On Corrosion of SteelAnand GuptaNo ratings yet

- Drill Stem TestingDocument16 pagesDrill Stem TestingpothirajkalyanNo ratings yet

- Hydraulics Sheet 5 Energy ADocument19 pagesHydraulics Sheet 5 Energy AMohamed H AliNo ratings yet

- LC 67002000 B Hr-Jumbo enDocument2 pagesLC 67002000 B Hr-Jumbo enJulio OrtegaNo ratings yet

- Summer Internship Project Report ANALYSIDocument60 pagesSummer Internship Project Report ANALYSIKshitija KudacheNo ratings yet

- 06.21.2010 - Historic Treasure of Jewish Life and Culture Gifted To UC BerkeleyDocument2 pages06.21.2010 - Historic Treasure of Jewish Life and Culture Gifted To UC BerkeleymagnesmuseumNo ratings yet

- Splash25 Winner InstructionsDocument8 pagesSplash25 Winner InstructionsRamkrishna PaulNo ratings yet

- University Grading System - VTUDocument3 pagesUniversity Grading System - VTUmithilesh8144No ratings yet

- Decolonization DBQDocument3 pagesDecolonization DBQapi-493862773No ratings yet

- Abbott 2021 ApJL 915 L5Document24 pagesAbbott 2021 ApJL 915 L5Manju SanthakumariNo ratings yet

- Btech CertificatesDocument6 pagesBtech CertificatesSuresh VadlamudiNo ratings yet

- JurnalDocument12 pagesJurnalSandy Ronny PurbaNo ratings yet

- PNP Loan Application Form February 2021 16Document6 pagesPNP Loan Application Form February 2021 16Wilhelm RegaladoNo ratings yet

- Activity 4 - Energy Flow and Food WebDocument4 pagesActivity 4 - Energy Flow and Food WebMohamidin MamalapatNo ratings yet

- JSSC JDLCCE 2021 (Civil Engineering) Official Pape 230615 233342Document39 pagesJSSC JDLCCE 2021 (Civil Engineering) Official Pape 230615 233342Bhuban KumbhakarNo ratings yet

- Richard IIIDocument36 pagesRichard IIIXuan Mai Nguyen ThiNo ratings yet

- The Politics of GenreDocument21 pagesThe Politics of GenreArunabha ChaudhuriNo ratings yet

- Viking 062293Document8 pagesViking 062293Lukman ZakariyahNo ratings yet

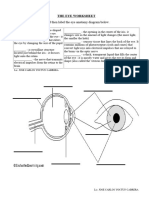

- The Eye WorksheetDocument3 pagesThe Eye WorksheetCally ChewNo ratings yet

- Maharashtra State Board of Technical Education. Academic Monitoring Department ProfileDocument14 pagesMaharashtra State Board of Technical Education. Academic Monitoring Department Profilevspd2010No ratings yet

- LANY Lyrics: "Thru These Tears" LyricsDocument2 pagesLANY Lyrics: "Thru These Tears" LyricsAnneNo ratings yet

- Classroom Activty Rubrics Classroom Activty Rubrics: Total TotalDocument1 pageClassroom Activty Rubrics Classroom Activty Rubrics: Total TotalMay Almerez- WongNo ratings yet

- Jmac TempDocument5 pagesJmac TempDan GerNo ratings yet

- Baumer Tdp02 Tdpz02 Ds enDocument4 pagesBaumer Tdp02 Tdpz02 Ds enQamar ZiaNo ratings yet