Professional Documents

Culture Documents

Lube Oil Skid (Base Module)

Lube Oil Skid (Base Module)

Uploaded by

mohamed elahwal0 ratings0% found this document useful (0 votes)

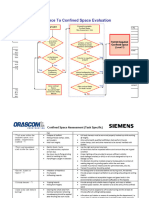

6 views3 pagesThis document summarizes a confined space evaluation for erecting small parts inside the base module of a lube oil skid. It identifies potential hazards such as trip, slip, and fall hazards. It also notes hazards from restricted movement, poor ventilation, and tools. Controls are provided such as housekeeping, signage, ventilation, fall protection, lighting, communication, and rescue procedures. The evaluation references definitions of confined spaces from the NCP Construction Safety Manual and OSHA standards.

Original Description:

Original Title

Lube oil skid (base module)

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes a confined space evaluation for erecting small parts inside the base module of a lube oil skid. It identifies potential hazards such as trip, slip, and fall hazards. It also notes hazards from restricted movement, poor ventilation, and tools. Controls are provided such as housekeeping, signage, ventilation, fall protection, lighting, communication, and rescue procedures. The evaluation references definitions of confined spaces from the NCP Construction Safety Manual and OSHA standards.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesLube Oil Skid (Base Module)

Lube Oil Skid (Base Module)

Uploaded by

mohamed elahwalThis document summarizes a confined space evaluation for erecting small parts inside the base module of a lube oil skid. It identifies potential hazards such as trip, slip, and fall hazards. It also notes hazards from restricted movement, poor ventilation, and tools. Controls are provided such as housekeeping, signage, ventilation, fall protection, lighting, communication, and rescue procedures. The evaluation references definitions of confined spaces from the NCP Construction Safety Manual and OSHA standards.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

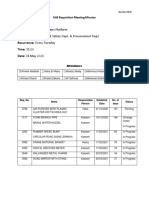

Contractor : Orascom Confined Space Evaluation Ref. No.

Module 4 – Base Module (Lube oil

skid) 41,42

Supervisor : Scope: checking and inspection

Assessment Date : 28-3-2017

Task : Erection of small parts

Name of Assessors : 1.Mohamed Abdel Fattah 3. Kopus

2.Mohamed Bakr 4.Ahmed Khaled

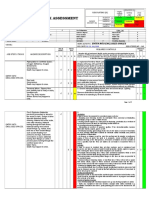

Task Steps Potential Hazards / consequences Controls - Additional Measures

(Access to the trip hazard Safe access, Housekeeping must be conducted daily to assure clean and

entrance?) empty

(Entrance / Entry Slip hazard, restricted access, Provide enough and suitable means of egress,

Into…?) Collapse of Scaffold

(Manner of moving about crawling through the open to Signs to indicate low height through access

inside, e.g. crouching, enter inside the base module

crawling, walking…?) may lead to Back injuries, Disc

injuries and Back Pain

(Ventilation…?) Suffocating hazards Provide proper and good ventilation by providing exhausting and venting

means (mechanical ventilation)

(Specific activities ,e.g. Back injuries, Disc injuries, Manual handling in proper and right way

grinding while on his ligament & tendon injuries,

back or other awkward muscular & nerve injuries, Back

position) Pain

(Work area within the Slips Be careful of slipping

confined space, on a Confined space watcher to be at the entry of the confined space

ladder, slopped floor,

Using a rope to get guys out in case of emergency

scaffold…?)

proper communication way between the watcher and guys inside

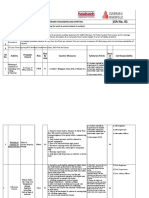

Confined Space Assessment (Task Specific)

confined space

(Tools and equipment Hand injuries. Use the right and correct size tools.

used inside the space…?) Hand/fingers caught in between All hand tools shall be inspected before use to ensure they are in good

condition

Proper lighting will be provided to ensure sufficient visibility

Trained Fire watcher should be posted.

(Gasses, fumes or Suffocating hazards Fire extinguisher to be existed before and during work outside the

vapors…?) fire hazards confined space

Provide proper and good ventilation by providing exhausting and venting

means

Maintain suitable and acceptable Oxygen and gases levels in the

environmental workplace to prevent suffocation or fire hazards

(Exiting manner…?) Tripping hazards Provide enough and suitable means of egress, exit ways or ladders

Confined space watcher, fire watcher to be at the entry of the confined

space

(Make area safe before Damage of base module

Removing all hand tools inside the base module

leaving)

(In the event of an

emergency, can the

entrant be self-rescued

or assisted rescue…?)

(Others…?)

Reference to the NCP Construction Safety Manual 23.3 (1);

‘Confined spaces are identified as any area with a limited means of access / egress and subject to oxygen deficiency, accumulation

of flammable vapors, or any airborne contaminants that exceeds the Permissible Exposure Limits’.

Confined Space Assessment (Task Specific)

Reference to OSHA 1910.146 Appendix A - refers to 1910.146(b);

“Confined Space”, means a space that;

1. Is large enough and so configured that an employee can bodily enter and perform assigned work; and

2. Has limited or restricted means for entry or exit (For example, tanks, vessels, silos, bins, hoppers, vaults, and pits are spaces

that may have limited means of access & egress.

3. Is not designed for continuous employee occupancy.

“Permit required confined space (permit space)’ means a confined space that has one or more of the following characteristics;

1. Contains or has a potential to contain a hazardous atmosphere;

2. Contains a material that has the potential for engulfing an entrant;

3. Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor

which slopes downward and tapers to a smaller cross-section; or

4. Contains any other recognized serious safety or health hazard.

You might also like

- NEBOSH PSM Exam 2Document13 pagesNEBOSH PSM Exam 2mohamed elahwal91% (23)

- Senr5664 11 01 AllDocument156 pagesSenr5664 11 01 AllThemba Tonga89% (9)

- IG2 Project Risk Assessment RoughDocument21 pagesIG2 Project Risk Assessment RoughRemya83% (6)

- Confined Spaces: Job Safety AnalysisDocument2 pagesConfined Spaces: Job Safety Analysismalimsaidi_160040895No ratings yet

- Caterpillar Wheel Loader Service ManualDocument11 pagesCaterpillar Wheel Loader Service ManualالمهندسوليدالطويلNo ratings yet

- CSP 16 Final Exam Rev007Document7 pagesCSP 16 Final Exam Rev007mohamed elahwal100% (1)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- Excavation Job Safety AnalysisDocument1 pageExcavation Job Safety AnalysisVishal Upadhyay100% (3)

- Jsa Working at Height (Maintenance & Cleaning)Document2 pagesJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- NWC Corporate Projects Risk Assessment Forms: Confined SpaceDocument4 pagesNWC Corporate Projects Risk Assessment Forms: Confined SpaceNowfal Habeeb50% (2)

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDocument3 pagesJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (4)

- Unofficial TranscriptDocument3 pagesUnofficial Transcriptapi-516350014No ratings yet

- Task Steps Potential Hazards / Consequences Controls - Additional MeasuresDocument3 pagesTask Steps Potential Hazards / Consequences Controls - Additional Measuresmohamed elahwalNo ratings yet

- Steam DuctDocument3 pagesSteam Ductmohamed elahwalNo ratings yet

- Transformer BasementDocument3 pagesTransformer Basementmohamed elahwalNo ratings yet

- TanksDocument3 pagesTanksmohamed elahwalNo ratings yet

- Confined Space Entry PlansDocument6 pagesConfined Space Entry Plansrichard100% (1)

- JSA-RHI-ARZ-0-006 ASU - Confined Space Rev00 - ArzewDocument3 pagesJSA-RHI-ARZ-0-006 ASU - Confined Space Rev00 - ArzewUmit KaymakNo ratings yet

- Risk Assessment No 43 Entry Into Enclosed Spaces Rev 02 20doc PDF FreeDocument3 pagesRisk Assessment No 43 Entry Into Enclosed Spaces Rev 02 20doc PDF FreeLilian IbimarNo ratings yet

- GE PTW Confined SpacesDocument2 pagesGE PTW Confined SpacesKural MurugesanNo ratings yet

- Aug Toolbox Talks Confined Spaces 0517Document2 pagesAug Toolbox Talks Confined Spaces 0517WaSim AKramNo ratings yet

- JsaDocument15 pagesJsaZeremia SamosirNo ratings yet

- Confined SpaceDocument26 pagesConfined Spaceengrshahid.awanNo ratings yet

- EEEPL - JSA EARTH FLAT LAYING New 123Document7 pagesEEEPL - JSA EARTH FLAT LAYING New 123nishanthNo ratings yet

- Risk Assessment & Risk ManagementDocument5 pagesRisk Assessment & Risk ManagementJeric MonroidNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce Entrywahyu nugrohoNo ratings yet

- Risk Assessment ProjectfinalDocument16 pagesRisk Assessment ProjectfinalHawkar TahaNo ratings yet

- Confined Space Construction 1 Short VersionDocument91 pagesConfined Space Construction 1 Short Versionreda mesbahNo ratings yet

- Jsa Cable LayingDocument2 pagesJsa Cable LayingAbcd efgh100% (1)

- JOB HAZARD ANALYSIS Deep Excavation-2Document9 pagesJOB HAZARD ANALYSIS Deep Excavation-2jay RNo ratings yet

- Job Safety Analysis: JSA Reference #: DateDocument3 pagesJob Safety Analysis: JSA Reference #: DateLi QiNo ratings yet

- Jsa For Unloading - Shifting of Heavy Materials (Panels, Transformers, Cable Drums Etc.)Document1 pageJsa For Unloading - Shifting of Heavy Materials (Panels, Transformers, Cable Drums Etc.)noahlungu96No ratings yet

- Enc SpaceDocument3 pagesEnc SpaceГай Юлий ЦезарьNo ratings yet

- Proca: Risk Assessment For Bio Mass Wood Pellet BoilerDocument8 pagesProca: Risk Assessment For Bio Mass Wood Pellet BoilerNaveenkumar KuppanNo ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- Confined Space SlideDocument65 pagesConfined Space SlideSyahrul AnisNo ratings yet

- Entry To Enclosed Spaces Checklist: Maritime Register IncDocument1 pageEntry To Enclosed Spaces Checklist: Maritime Register Incwaleed yehiaNo ratings yet

- WBOP Hazards For Horizontal JumpsDocument2 pagesWBOP Hazards For Horizontal JumpsayuNo ratings yet

- Jsa of ConstructionDocument9 pagesJsa of ConstructionSabari VtNo ratings yet

- Confined Space Entry Rescue Plan (GENERIC) Template (For Internal Rescue Services Only)Document10 pagesConfined Space Entry Rescue Plan (GENERIC) Template (For Internal Rescue Services Only)Idris AdeniranNo ratings yet

- Toolbox Talks Confined Space Entry Proceedures English 0Document1 pageToolbox Talks Confined Space Entry Proceedures English 0arockiajijinsNo ratings yet

- Confined Space ChecklistDocument1 pageConfined Space ChecklistIbrahim EsmatNo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisAris RNNo ratings yet

- Permit Required Confined Space Checklist: CompletedDocument2 pagesPermit Required Confined Space Checklist: CompletedHarold Fernando Guavita ReyesNo ratings yet

- Per 01 - Enclosed Space Entry PermitDocument3 pagesPer 01 - Enclosed Space Entry PermitRajesh NairNo ratings yet

- Gripsholm Shipping S.A.: Maritime Safety CardDocument2 pagesGripsholm Shipping S.A.: Maritime Safety Cardjgonzalez1980No ratings yet

- Duties of Hole WatcherDocument3 pagesDuties of Hole WatcherMD SHAHNAWAZNo ratings yet

- JSA For The Confined SpaceDocument2 pagesJSA For The Confined SpaceMIAN MATEENNo ratings yet

- Confined Space: Mona Lestari, S.K.M., M.K.K.K. Keselamatan Dan Kesehatan Kerja, FKM UnsriDocument20 pagesConfined Space: Mona Lestari, S.K.M., M.K.K.K. Keselamatan Dan Kesehatan Kerja, FKM UnsriAprilia Nur HanisaNo ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- Hole Watcher Trainin GDocument21 pagesHole Watcher Trainin GbabjihanumanthuNo ratings yet

- SWP CHECKLISTS - ExcavationDocument4 pagesSWP CHECKLISTS - ExcavationSrinivas Dumpala HSENo ratings yet

- Confined Space ManagementDocument19 pagesConfined Space ManagementFajar RiyadiNo ratings yet

- Jsa For Cold Box in Process AreaDocument5 pagesJsa For Cold Box in Process AreaMohammed MinhajNo ratings yet

- Confined Space Entry Rescue Plan GENERICDocument10 pagesConfined Space Entry Rescue Plan GENERICNii AshiiiNo ratings yet

- Risk Assessment For Above Ground Drainage SystemDocument2 pagesRisk Assessment For Above Ground Drainage Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Confined Space Entry Rescue Plan 1Document11 pagesConfined Space Entry Rescue Plan 1patrick ruwonaNo ratings yet

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- TA-Replacing Floor TilesDocument8 pagesTA-Replacing Floor TilesShannon MooreNo ratings yet

- InfoSheet10 PDFDocument6 pagesInfoSheet10 PDFKlemens Bonggo SuhartonoNo ratings yet

- Appendix of Confine SpaceDocument6 pagesAppendix of Confine SpacearjunkoiralaNo ratings yet

- JSA-Installation of Electronic Access Control & Physical Security Devices at Main Entrance Gate-1 HADEEDDocument8 pagesJSA-Installation of Electronic Access Control & Physical Security Devices at Main Entrance Gate-1 HADEEDMuhammad Umar GondalNo ratings yet

- Confined Space Pre-Entry Checklist: Mark The Appropriate Column: X Yes, X No, or X N/A Not ApplicableDocument4 pagesConfined Space Pre-Entry Checklist: Mark The Appropriate Column: X Yes, X No, or X N/A Not Applicablereda mesbahNo ratings yet

- TA - Converting Office SpacesDocument8 pagesTA - Converting Office SpacesShannon MooreNo ratings yet

- WO SA076 0011 WorkOrderDocument2 pagesWO SA076 0011 WorkOrdermohamed elahwalNo ratings yet

- Steel FixerDocument1 pageSteel Fixermohamed elahwalNo ratings yet

- WO SA076 0012 WorkOrderDocument1 pageWO SA076 0012 WorkOrdermohamed elahwalNo ratings yet

- Confined Space 2016 CatDocument56 pagesConfined Space 2016 Catmohamed elahwalNo ratings yet

- Continuous Improvement in Incident ReportingDocument21 pagesContinuous Improvement in Incident Reportingmohamed elahwalNo ratings yet

- PMF-015-HSE-131 v1 Confined Space Entry RecordDocument2 pagesPMF-015-HSE-131 v1 Confined Space Entry Recordmohamed elahwalNo ratings yet

- Con SpaceDocument38 pagesCon Spacemohamed elahwalNo ratings yet

- CSE Infographic Tank Maintenance Illuph DGT 2297 2020 en MasterDocument1 pageCSE Infographic Tank Maintenance Illuph DGT 2297 2020 en Mastermohamed elahwalNo ratings yet

- Fire ExtinguishersDocument1 pageFire Extinguishersmohamed elahwalNo ratings yet

- Xix Paper 05Document12 pagesXix Paper 05mohamed elahwalNo ratings yet

- VPPPA Nationals Final Rev 1Document21 pagesVPPPA Nationals Final Rev 1mohamed elahwalNo ratings yet

- EHS Requisition MOMDocument2 pagesEHS Requisition MOMmohamed elahwalNo ratings yet

- Wescef - Safe Working With Fibreglass - Manual: Applicability TableDocument12 pagesWescef - Safe Working With Fibreglass - Manual: Applicability Tablemohamed elahwalNo ratings yet

- Spektrofotometri UV-VIS AriDocument44 pagesSpektrofotometri UV-VIS AriMiqdad Abdul MuizNo ratings yet

- Visual Weight Cheat Sheet NewDocument1 pageVisual Weight Cheat Sheet NewRicardo W. BrandNo ratings yet

- Salary Formula: Gross Salary Received and The Net Salary ReceivedDocument9 pagesSalary Formula: Gross Salary Received and The Net Salary ReceivedFarhang PrintingNo ratings yet

- Mukesh Abap Sapui5 HanaDocument10 pagesMukesh Abap Sapui5 HanaLearn EnglishNo ratings yet

- Simatic HMI Option+Document121 pagesSimatic HMI Option+hdswt_mNo ratings yet

- Milk BookDocument20 pagesMilk BookwyattmwattsNo ratings yet

- What Is The Most Famous Vehicle in Desert - Google SearchDocument1 pageWhat Is The Most Famous Vehicle in Desert - Google SearchRandima bandaraNo ratings yet

- Week 7 AUDIT PreTestDocument19 pagesWeek 7 AUDIT PreTestCale HenituseNo ratings yet

- A885 PDFDocument164 pagesA885 PDFLadaru Daniel100% (1)

- 125d WBA1T32040P926318: Generated On Http://bimmer - WorkDocument5 pages125d WBA1T32040P926318: Generated On Http://bimmer - WorkStevan AritonovicNo ratings yet

- Lighting Stryker Bacnet™ Clb6438S Configurable Lighting ControllerDocument24 pagesLighting Stryker Bacnet™ Clb6438S Configurable Lighting ControllerErmiasNo ratings yet

- Emergency traumaEMQ34Document34 pagesEmergency traumaEMQ34assssadfNo ratings yet

- RC1 Process Modification Case Study Process SafetyDocument2 pagesRC1 Process Modification Case Study Process SafetyGustavo AgudeloNo ratings yet

- Antifibrinolytic Therapy and Perioperative ConsiderationsDocument14 pagesAntifibrinolytic Therapy and Perioperative Considerationsandrey wahyudiNo ratings yet

- Myocardial Infarction and Heart Failure Practice Quiz (70 Questions)Document44 pagesMyocardial Infarction and Heart Failure Practice Quiz (70 Questions)Melodia Turqueza GandezaNo ratings yet

- IPC-TM-650 Test Methods ManualDocument3 pagesIPC-TM-650 Test Methods ManualBushra ShaukatNo ratings yet

- Mathematical Analysis of ILI MFL Data: January 2003Document13 pagesMathematical Analysis of ILI MFL Data: January 2003santiago cruzNo ratings yet

- Lesson 1Document16 pagesLesson 1Alexandra Blasco100% (1)

- Earthing Philosophy 161012H - 34 Pag - 6.11 MB PDFDocument34 pagesEarthing Philosophy 161012H - 34 Pag - 6.11 MB PDFconstantinNo ratings yet

- 2016 03 31 Basa Pilipinas Quarter 1 Grade 1 Ilokano Teacher's Guide (Third Edition)Document213 pages2016 03 31 Basa Pilipinas Quarter 1 Grade 1 Ilokano Teacher's Guide (Third Edition)Renato Luna100% (2)

- NAT BCA 10-06 Waterproofing Requirements For Wet AreasDocument4 pagesNAT BCA 10-06 Waterproofing Requirements For Wet AreasGayan IndunilNo ratings yet

- 7020 Commerce and FinanceDocument13 pages7020 Commerce and FinanceMhiz MercyNo ratings yet

- Kapustin Publication Schedule As at 5 September 2006Document8 pagesKapustin Publication Schedule As at 5 September 2006Gaspard de la NuitNo ratings yet

- ASR 2020 J2Prelim H2Chem P4 QP PDFDocument20 pagesASR 2020 J2Prelim H2Chem P4 QP PDFchuasioklengNo ratings yet

- SikaBit W-15 Page 1 - 39Document52 pagesSikaBit W-15 Page 1 - 39Keesh RonoloNo ratings yet

- Junk Food 10aDocument3 pagesJunk Food 10aManastirea ContNo ratings yet

- Class 9 Maths Ws 06 PDFDocument9 pagesClass 9 Maths Ws 06 PDFPoorv KantNo ratings yet