Professional Documents

Culture Documents

Transformer Basement

Uploaded by

mohamed elahwal0 ratings0% found this document useful (0 votes)

6 views3 pagesThe document provides a confined space evaluation for painting and touch up work in a transformer basement. It identifies potential hazards such as trip, slip, and fall hazards. It requires controls like providing safe access, cleaning work areas, and using personal protective equipment. The evaluation also identifies hazards from working at heights, with electricity, and from vapors and gases. It requires ventilation, gas monitoring, fire watches, and emergency planning to control risks during the work.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a confined space evaluation for painting and touch up work in a transformer basement. It identifies potential hazards such as trip, slip, and fall hazards. It requires controls like providing safe access, cleaning work areas, and using personal protective equipment. The evaluation also identifies hazards from working at heights, with electricity, and from vapors and gases. It requires ventilation, gas monitoring, fire watches, and emergency planning to control risks during the work.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesTransformer Basement

Uploaded by

mohamed elahwalThe document provides a confined space evaluation for painting and touch up work in a transformer basement. It identifies potential hazards such as trip, slip, and fall hazards. It requires controls like providing safe access, cleaning work areas, and using personal protective equipment. The evaluation also identifies hazards from working at heights, with electricity, and from vapors and gases. It requires ventilation, gas monitoring, fire watches, and emergency planning to control risks during the work.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

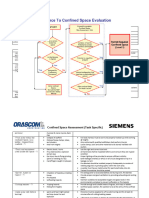

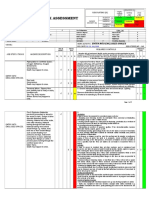

Contractor : Orascom Confined Space Evaluation Ref. No.

Module 4 - Transformer Basement 42

Supervisor : Scope: painting and touch up

Assessment Date : 28-3-2017

Task : Cold work

Name of Assessors : 1.Mohamed Abdel Fattah 3. Kopus

2.Mohamed Bakr 4.Ahmed Khaled

Task Steps Potential Hazards / consequences Controls - Additional Measures

(Access to the trip hazard Safe access, Housekeeping must be conducted daily to assure clean and

entrance?) empty

(Entrance / Entry Slip hazard, restricted access, Provide enough and suitable means of egress,

Into…?) Collapse of Scaffold

(Manner of moving about Slip hazard, trip hazard (walking) Access to be cleaned and empty of obstacles.

inside, e.g. crouching,

crawling, walking…?)

(Ventilation…?) Suffocating hazards Provide proper and good ventilation by providing exhausting and venting

Inhalation of hazardous means (mechanical ventilation)

Contact with paints / solvents Suitable and sufficient fume extraction shall be implemented where there

lead to Dermatitis / Skin could be a build-up of flammable or explosive paint vapours.

disorders. Where possible designers shall ensure that non-flammable paints are

Fire / explosion because of specified.

Flammable vapours in Personnel shall ensure that they wash their hands, arms and face

atmosphere. thoroughly after paint spraying operations to remove any paint or solvent

contaminants off the skin.

(Specific activities ,e.g. Back injuries, Disc injuries, Manual handling in proper and right way

grinding while on his ligament & tendon injuries,

back or other awkward muscular & nerve injuries, Back

position)

Confined Space Assessment (Task Specific)

Pain

(Work area within the Collapse of Scaffold Full body harness must be worn and properly hooked-up while working

confined space, on a Falling of loose clamps, tubes, @ heights.

ladder, slopped floor, and couplers Only authorized & qualified scaffolders shall perform the job.

scaffold…?) Falls from heights Loose clamps, tools and other materials to be stored/ handled with

caution.

(Tools and equipment Electric shock / burns Use the right and correct size tools.

used inside the space…?) Fire, electrocution, explosion All hand tools shall be inspected before use to ensure they are in good

and arc-eye. condition

Eye injury due to flying grinding Proper lighting will be provided to ensure sufficient visibility

sparks or welding arc rays Earth leakage switches (or GFCI) on all circuits designed to trip on a

Hand/fingers caught in between leakage current.

Fire Blankets should be installed properly & adequately to contain all

welding slag and/ or grinding sparks within the work area.

A welder must have a metal bucket for spent electrodes, disc etc.

Trained Fire watcher should be posted.

(Gasses, fumes or Inhalation of hazardous Fire extinguisher to be existed before and during work, fire blanket.

vapors…?) Fire hazards Provide proper and good ventilation by providing exhausting and venting

Suffocating hazards means

Maintain suitable and acceptable Oxygen and gases levels in the

environmental workplace to prevent suffocation or fire hazards

(Exiting manner…?) Tripping hazards Provide enough and suitable means of egress, exit ways or ladders

Falling from heights Confined space watcher, fire watcher to be at the entry of the confined

space

(Make area safe before Cleaning the whole area from Person(s) must be assigned to a fire watch during and for at least 30

leaving) chemical containers remaining minutes after all cutting/welding ceases.

Housekeeping should be applied

A fire alarm pull station or means of contacting the fire department (i.e.

after finishing the work inside

2-way radio or phone) available and accessible to fire watch person(s).

basement

Fire watch person(s) are to be supplied with multi-purpose dry

chemical, portable fire extinguisher and trained in its use.

(In the event of an

emergency, can the

entrant be self-rescued

Confined Space Assessment (Task Specific)

or assisted rescue…?)

(Others…?)

Reference to the NCP Construction Safety Manual 23.3 (1);

‘Confined spaces are identified as any area with a limited means of access / egress and subject to oxygen deficiency, accumulation

of flammable vapors, or any airborne contaminants that exceeds the Permissible Exposure Limits’.

Reference to OSHA 1910.146 Appendix A - refers to 1910.146(b);

“Confined Space”, means a space that;

1. Is large enough and so configured that an employee can bodily enter and perform assigned work; and

2. Has limited or restricted means for entry or exit (For example, tanks, vessels, silos, bins, hoppers, vaults, and pits are spaces

that may have limited means of access & egress.

3. Is not designed for continuous employee occupancy.

“Permit required confined space (permit space)’ means a confined space that has one or more of the following characteristics;

1. Contains or has a potential to contain a hazardous atmosphere;

2. Contains a material that has the potential for engulfing an entrant;

3. Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor

which slopes downward and tapers to a smaller cross-section; or

4. Contains any other recognized serious safety or health hazard.

You might also like

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- Confined Space - Generic - Rescue Plan TemplateDocument10 pagesConfined Space - Generic - Rescue Plan TemplateNick Shelley100% (2)

- Hazard Indentificaction and Risk Assessment: Name of Project:-Documents NoDocument4 pagesHazard Indentificaction and Risk Assessment: Name of Project:-Documents Noaman anand100% (2)

- AEC 2018 Aluminum Extrusion ManualDocument191 pagesAEC 2018 Aluminum Extrusion ManualJuan Andrés Díaz RiveroNo ratings yet

- Safe Work Method Statement Hot Works: OST Constructional Projects LLCDocument8 pagesSafe Work Method Statement Hot Works: OST Constructional Projects LLCIrfan UllahNo ratings yet

- Confined Space Entry Rescue Plan GENERICDocument10 pagesConfined Space Entry Rescue Plan GENERICNii AshiiiNo ratings yet

- NEBOSH PSM Exam 2Document13 pagesNEBOSH PSM Exam 2mohamed elahwal91% (23)

- Fire Drill-Mock Drill KuwaitDocument14 pagesFire Drill-Mock Drill KuwaitBinoy Gopinathan100% (2)

- Aug Toolbox Talks Confined Spaces 0517Document2 pagesAug Toolbox Talks Confined Spaces 0517WaSim AKramNo ratings yet

- Confined Space Entry Rescue Plan 1Document11 pagesConfined Space Entry Rescue Plan 1patrick ruwonaNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce Entrywahyu nugrohoNo ratings yet

- CSP 16 Final Exam Rev007Document7 pagesCSP 16 Final Exam Rev007mohamed elahwal100% (1)

- Ej 2021 q1 IssueDocument82 pagesEj 2021 q1 IssueReab SimanthNo ratings yet

- Confined Space Safety TrainingDocument38 pagesConfined Space Safety TrainingAhmad Bilal100% (1)

- NEOM OPERATIONS - FM - Hot PTWDocument3 pagesNEOM OPERATIONS - FM - Hot PTWHBHJBMNNo ratings yet

- Jsa Working at Height (Maintenance & Cleaning)Document2 pagesJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- Trade Area: Construction Industry-PaintingDocument3 pagesTrade Area: Construction Industry-PaintingRam-tech Jackolito FernandezNo ratings yet

- Atex PresentationDocument37 pagesAtex PresentationPitchaimani KandasamyNo ratings yet

- Manual Bomba KoomeyDocument95 pagesManual Bomba KoomeyDiego De JesusNo ratings yet

- HSW2 Workplace Risk AssessmentDocument3 pagesHSW2 Workplace Risk AssessmentNoel Nico Fernando100% (1)

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDocument2 pagesStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RNo ratings yet

- Fire Safety SimulationDocument10 pagesFire Safety SimulationERICNo ratings yet

- OSHA Long Term Care Worker Protection ProgramDocument50 pagesOSHA Long Term Care Worker Protection ProgramKaiser Angelo G. LadoresNo ratings yet

- Chemistry: Quarter 1 - Module 5: "Recognize Common Isotopes and Their Uses."Document13 pagesChemistry: Quarter 1 - Module 5: "Recognize Common Isotopes and Their Uses."Norman100% (2)

- Recommended Practice For Precast Prestressed Concrete Composite Bridge Deck PanelsDocument43 pagesRecommended Practice For Precast Prestressed Concrete Composite Bridge Deck PanelsAnonymous Gd0PTUQNo ratings yet

- JsaDocument13 pagesJsaArnold Roy Coballes Manalo100% (1)

- Industrial Automation Technologies (Chanchal Dey (Editor) Sunit Kumar Sen (Editor) )Document376 pagesIndustrial Automation Technologies (Chanchal Dey (Editor) Sunit Kumar Sen (Editor) )Ed Carlo Ramis100% (1)

- IG2 Project Risk Assessment RoughDocument21 pagesIG2 Project Risk Assessment RoughRemya83% (6)

- JSA-RHI-ARZ-0-006 ASU - Confined Space Rev00 - ArzewDocument3 pagesJSA-RHI-ARZ-0-006 ASU - Confined Space Rev00 - ArzewUmit KaymakNo ratings yet

- Confined Space SlideDocument65 pagesConfined Space SlideSyahrul AnisNo ratings yet

- Confined Space Entry Training CourseDocument32 pagesConfined Space Entry Training CourseKhizar Hayat100% (2)

- JsaDocument15 pagesJsaZeremia SamosirNo ratings yet

- TanksDocument3 pagesTanksmohamed elahwalNo ratings yet

- Steam DuctDocument3 pagesSteam Ductmohamed elahwalNo ratings yet

- Task Steps Potential Hazards / Consequences Controls - Additional MeasuresDocument3 pagesTask Steps Potential Hazards / Consequences Controls - Additional Measuresmohamed elahwalNo ratings yet

- Lube Oil Skid (Base Module)Document3 pagesLube Oil Skid (Base Module)mohamed elahwalNo ratings yet

- Fire Watcher& Safety WatcherDocument6 pagesFire Watcher& Safety WatcherFarman ShaikhNo ratings yet

- Hot Work PermitDocument2 pagesHot Work PermitSamson SeanNo ratings yet

- Hot Work Permit PDFDocument2 pagesHot Work Permit PDFQuang Tan TruongNo ratings yet

- Confined SpaceDocument26 pagesConfined Spaceengrshahid.awanNo ratings yet

- Chapter Three: Occupational Health & Safety in Construction ProjectsDocument97 pagesChapter Three: Occupational Health & Safety in Construction ProjectsABU BEBEK AhmNo ratings yet

- Fire Watch TrainingDocument20 pagesFire Watch TrainingShovon khanNo ratings yet

- Confined Space Hot Work PermitDocument9 pagesConfined Space Hot Work PermitKhayra MadinaNo ratings yet

- Confined Space Entry Rescue Plan (GENERIC) Template (For Internal Rescue Services Only)Document10 pagesConfined Space Entry Rescue Plan (GENERIC) Template (For Internal Rescue Services Only)Idris AdeniranNo ratings yet

- MS - Plumbing JobDocument13 pagesMS - Plumbing JobrajubiswashseNo ratings yet

- Loams Permit To Work For ExcavationDocument2 pagesLoams Permit To Work For ExcavationmohdthrNo ratings yet

- Hot Work ChecklistDocument2 pagesHot Work ChecklistMd UsamaNo ratings yet

- Emergency Planning and Means of Escape A ZDocument4 pagesEmergency Planning and Means of Escape A ZGodfrey TamaneNo ratings yet

- (JSA) Job Safety AnalysisDocument3 pages(JSA) Job Safety AnalysisnbvillarazoNo ratings yet

- Belt Cold Repair ProcedureDocument1 pageBelt Cold Repair ProcedureAnoopNo ratings yet

- EEEPL - JSA EARTH FLAT LAYING New 123Document7 pagesEEEPL - JSA EARTH FLAT LAYING New 123nishanthNo ratings yet

- Safety - Form-SAF019-HotWorkPermitDocument5 pagesSafety - Form-SAF019-HotWorkPermitEdwin MofokengNo ratings yet

- Confined SpaceDocument16 pagesConfined SpaceAbdul Moeed KalsonNo ratings yet

- JSA 02-Rev.01 - Blinding & DeblindingDocument1 pageJSA 02-Rev.01 - Blinding & DeblindinggolusinghdataNo ratings yet

- Confined Space ChecklistDocument1 pageConfined Space ChecklistIbrahim EsmatNo ratings yet

- Universiti Malaysia Terengganu SESSION I 2021/2022: Individual Assignment Kas 3501: Occupational Safety and HealthDocument4 pagesUniversiti Malaysia Terengganu SESSION I 2021/2022: Individual Assignment Kas 3501: Occupational Safety and HealthAin frhnniiiNo ratings yet

- Sss AssigmentDocument11 pagesSss Assigmentindran SuppiahNo ratings yet

- Risk Assessment No 43 Entry Into Enclosed Spaces Rev 02 20doc PDF FreeDocument3 pagesRisk Assessment No 43 Entry Into Enclosed Spaces Rev 02 20doc PDF FreeLilian IbimarNo ratings yet

- CS Sub Station JsaDocument4 pagesCS Sub Station JsaEHS Unit IINo ratings yet

- Ene Risk AssessmentDocument1 pageEne Risk AssessmentSanjeet SinghNo ratings yet

- Enc SpaceDocument3 pagesEnc SpaceГай Юлий ЦезарьNo ratings yet

- AppB F - ConfinedSpaceSOPs 20161102Document23 pagesAppB F - ConfinedSpaceSOPs 20161102Mohamed GaafarNo ratings yet

- Industrial Health SafetyDocument13 pagesIndustrial Health SafetyAkula NikhilNo ratings yet

- JSA - Civil Compaction WorkDocument4 pagesJSA - Civil Compaction WorkRajuNo ratings yet

- IG2 Report, MUHAMMAD ALI, 00796731, Nbiz Information Consultancy LLC .Document24 pagesIG2 Report, MUHAMMAD ALI, 00796731, Nbiz Information Consultancy LLC .qadeesbhatti09511No ratings yet

- Duties of Hole WatcherDocument3 pagesDuties of Hole WatcherMD SHAHNAWAZNo ratings yet

- GE PTW Confined SpacesDocument2 pagesGE PTW Confined SpacesKural MurugesanNo ratings yet

- WO SA076 0012 WorkOrderDocument1 pageWO SA076 0012 WorkOrdermohamed elahwalNo ratings yet

- Steel FixerDocument1 pageSteel Fixermohamed elahwalNo ratings yet

- WO SA076 0011 WorkOrderDocument2 pagesWO SA076 0011 WorkOrdermohamed elahwalNo ratings yet

- Confined Space 2016 CatDocument56 pagesConfined Space 2016 Catmohamed elahwalNo ratings yet

- CSE Infographic Tank Maintenance Illuph DGT 2297 2020 en MasterDocument1 pageCSE Infographic Tank Maintenance Illuph DGT 2297 2020 en Mastermohamed elahwalNo ratings yet

- PMF-015-HSE-131 v1 Confined Space Entry RecordDocument2 pagesPMF-015-HSE-131 v1 Confined Space Entry Recordmohamed elahwalNo ratings yet

- Fire ExtinguishersDocument1 pageFire Extinguishersmohamed elahwalNo ratings yet

- Con SpaceDocument38 pagesCon Spacemohamed elahwalNo ratings yet

- Continuous Improvement in Incident ReportingDocument21 pagesContinuous Improvement in Incident Reportingmohamed elahwalNo ratings yet

- Xix Paper 05Document12 pagesXix Paper 05mohamed elahwalNo ratings yet

- VPPPA Nationals Final Rev 1Document21 pagesVPPPA Nationals Final Rev 1mohamed elahwalNo ratings yet

- Wescef - Safe Working With Fibreglass - Manual: Applicability TableDocument12 pagesWescef - Safe Working With Fibreglass - Manual: Applicability Tablemohamed elahwalNo ratings yet

- EHS Requisition MOMDocument2 pagesEHS Requisition MOMmohamed elahwalNo ratings yet

- Adding Library Objects To Sbuilder BY Jon Masterson Scruffyduck SceneryDocument17 pagesAdding Library Objects To Sbuilder BY Jon Masterson Scruffyduck SceneryInterim InterimNo ratings yet

- M-VAT 012018 BIR Email Notification (EFiling of Tax Return)Document2 pagesM-VAT 012018 BIR Email Notification (EFiling of Tax Return)Don SumiogNo ratings yet

- Minesweepers 2019 Rule Book v5.4Document48 pagesMinesweepers 2019 Rule Book v5.4JOSE DAVID VALDA PEÑARANDANo ratings yet

- Thesis Defense SlideshareDocument6 pagesThesis Defense Slidesharesprxzfugg100% (2)

- Interview Prep Packet!: Part 1: Talk The Talk!Document8 pagesInterview Prep Packet!: Part 1: Talk The Talk!koti3No ratings yet

- ECE 4316: Digital Signal Processing: Dr. Hany M. ZamelDocument19 pagesECE 4316: Digital Signal Processing: Dr. Hany M. ZamellovelearnNo ratings yet

- Tingkat Konsumsi Energi, Karbohidrat, Protein, Lemak (Azzarah, DKK)Document21 pagesTingkat Konsumsi Energi, Karbohidrat, Protein, Lemak (Azzarah, DKK)dimasNo ratings yet

- Reinforced Concrete Building Design and Analysis: Project: Proposed Two-Storey Residential HouseDocument106 pagesReinforced Concrete Building Design and Analysis: Project: Proposed Two-Storey Residential HouseRonaldo BatlaganNo ratings yet

- DLL - English 6 - Q2 - W2Document3 pagesDLL - English 6 - Q2 - W2Xyrelle Grace Borbon VernaulaNo ratings yet

- Drill HolesDocument304 pagesDrill HolesJorge Luis Zegarra OtoyaNo ratings yet

- Hydrotech Company ProfileDocument46 pagesHydrotech Company ProfileBOBANSO KIOKONo ratings yet

- Research 3 Quarter 3 LESSON-2-HYPOTHESIS-TESTINGDocument29 pagesResearch 3 Quarter 3 LESSON-2-HYPOTHESIS-TESTINGRaven Third-partyAccNo ratings yet

- 191IT623 - Internet of Things - Unit 1 QBDocument3 pages191IT623 - Internet of Things - Unit 1 QBprakash S100% (1)

- Project Report On Business Eco Magazine - Vivek Kumar ShawDocument36 pagesProject Report On Business Eco Magazine - Vivek Kumar ShawAnand shawNo ratings yet

- Lion Air Eticket Itinerary / Receipt: Putra/Wirawan Lohisto MRDocument3 pagesLion Air Eticket Itinerary / Receipt: Putra/Wirawan Lohisto MRNo NameNo ratings yet

- Cambridge IGCSE: BIOLOGY 0610/42Document20 pagesCambridge IGCSE: BIOLOGY 0610/42Ashtav ArunNo ratings yet

- Probability Calculation in MinesweeperDocument2 pagesProbability Calculation in MinesweeperBrayan Perez ContrerasNo ratings yet

- Practice Test 01 Hints & Solutions NEET Ultimate Crash Course 2Document15 pagesPractice Test 01 Hints & Solutions NEET Ultimate Crash Course 2EvolutionNo ratings yet

- Climate Change Scheme of Work For KS2Document13 pagesClimate Change Scheme of Work For KS2Zoe AlsumaitNo ratings yet

- The Steps How To Use Theodolite For SurveyingDocument2 pagesThe Steps How To Use Theodolite For Surveyinglong bottomNo ratings yet

- TvlistDocument6 pagesTvlistMichael CifuentesNo ratings yet

- Skin Friction in CaissonsDocument6 pagesSkin Friction in CaissonsJayakumar VenkataramanNo ratings yet

- Accenture G20 YEA 2015 Open Innovation Executive Summary PDFDocument24 pagesAccenture G20 YEA 2015 Open Innovation Executive Summary PDFJulian Dario Combariza GonzalezNo ratings yet

- Chapter 07 AnsDocument5 pagesChapter 07 AnsDave Manalo100% (1)