Professional Documents

Culture Documents

Belt Cold Repair Procedure

Uploaded by

Anoop0 ratings0% found this document useful (0 votes)

15 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageBelt Cold Repair Procedure

Uploaded by

AnoopCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

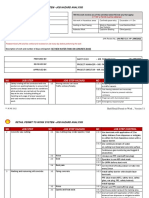

CONVEYOR BELT REPIR PROCEDURE: (Cold Repair)

Individual Activities To Identified Hazard(s) Persons Precautions and Plan of actions To

Complete Work. List In Associated With Exposed To Be Taken To Remove / Control

Sequence of Activity Activity Hazard Hazards

Inspect the Conveyor Belt and identify 1. Isolation, &

- Technicians

mark the repair areas. 2. Use proper PPE

1. Isolation, &

Clean the Repair area - Technicians

2. Use proper PPE

Buff (Grind) the Conveyor belt on the 1. Isolation, &

Buffing Tool operation Technicians

repair area and the Repair strip. 2. Use proper PPE

1. Use proper safety mask, PPE & Gloves

2. Display Safety Sign Boards in work Area

Clean the surface with the solvent. ( NO SMOKING …) &

Irritant, Flammable Technicians 3. Isolation

Toluene (Long sleeved coverall, Rubber Gloves,

Leather Gloves, Chemical Resistance gas

Filter mask)

1. Use proper safety mask, PPE, & Gloves

2. Display Safety Sign Boards in work Area

Apply the Rubber Cement

( NO SMOKING …) &

(Rubber cement SC2000 with Irritant, Flammable Technicians 3. Isolation

hardener) (Long sleeved coverall, Rubber Gloves,

Leather Gloves, Chemical Resistance gas

Filter mask)

1. Use proper safety mask,

2. Display Safety Sign Boards in work Area

Apply the Rubber Cement 2 times on ( NO SMOKING …) &

The Buffed area (Rubber cement Irritant, Flammable Technicians 3. Isolation

SC2000 with hardener) (Long sleeved coverall, Rubber Gloves,

Leather Gloves, Chemical Resistance gas Filter

mask)

Apply the Cover strip rubber on the

- - - - - ---

buffed area and stitch it with the hand Technicians Isolation

roller.

Give minimum setting time of 8 hours - - - - - ---

- - - - - -- Isolation

before running the conveyor belt.

You might also like

- Cooling Tower HiracDocument4 pagesCooling Tower HiracblackyNo ratings yet

- JsaDocument15 pagesJsaZeremia SamosirNo ratings yet

- Hazard Identification & Risk Analysis for Civil ReworksDocument3 pagesHazard Identification & Risk Analysis for Civil ReworksHARSHADNo ratings yet

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Qatar Liquefied Gas Company Limited JSA for Cutting, Grinding and WeldingDocument5 pagesQatar Liquefied Gas Company Limited JSA for Cutting, Grinding and WeldingMohammad Fazal KhanNo ratings yet

- 11.pneumatic Pressure Testing.Document7 pages11.pneumatic Pressure Testing.Mohammad Fazal KhanNo ratings yet

- Jsa Removal Fixing InsulationDocument2 pagesJsa Removal Fixing InsulationAprilia Rizki Ardila63% (8)

- Jsa PaintingDocument1 pageJsa Paintingclynne despiNo ratings yet

- Hiradc ServicingDocument4 pagesHiradc ServicingAyub Abd RahmanNo ratings yet

- General Requirements For Protective Clothing Against Heat and FlameDocument2 pagesGeneral Requirements For Protective Clothing Against Heat and FlameIbeth MuñozNo ratings yet

- JSA New Line Installation 2012Document2 pagesJSA New Line Installation 2012Deshbandhu Aman PandeyNo ratings yet

- Job Safety Analysis (JSA) Risk AssessmentDocument3 pagesJob Safety Analysis (JSA) Risk AssessmentnbvillarazoNo ratings yet

- HIRARC of Branches, Prune, Cutting Tree ActivityDocument4 pagesHIRARC of Branches, Prune, Cutting Tree ActivityAmirudin Hashim100% (1)

- Job Safety Analysis: Kalco Alu System (P) LTDDocument2 pagesJob Safety Analysis: Kalco Alu System (P) LTDShekh BabulNo ratings yet

- Switchyard Energizing: Personal Protective EquipmentDocument5 pagesSwitchyard Energizing: Personal Protective EquipmentPatut Tua Parulian ButarbutarNo ratings yet

- 18.hot Tapping Preparation & Work.Document11 pages18.hot Tapping Preparation & Work.Zubair Ahmed KhaskheliNo ratings yet

- JSA - Bar BendingDocument6 pagesJSA - Bar BendingRajuNo ratings yet

- SHED-000 SHED Process (During Construction Work) 09.08.2021 (Pratusda) .....Document50 pagesSHED-000 SHED Process (During Construction Work) 09.08.2021 (Pratusda) .....Debraj SenNo ratings yet

- MUARA TAWAR COMBINED CYCLE POWER PLANT OIL DRAINAGE WORK JSADocument8 pagesMUARA TAWAR COMBINED CYCLE POWER PLANT OIL DRAINAGE WORK JSAJuantoro Puspo WiryolukitoNo ratings yet

- HIRADCDocument56 pagesHIRADCAli Rizki Budiman100% (1)

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- Step-by-step Instrument ServicingDocument1 pageStep-by-step Instrument Servicingsaji kumarNo ratings yet

- 19.hydro Pressure Testing.Document8 pages19.hydro Pressure Testing.Mohammad Fazal KhanNo ratings yet

- List of PPEDocument4 pagesList of PPEBinayNo ratings yet

- JSA - EDDY CURRENRT - AmendedDocument1 pageJSA - EDDY CURRENRT - AmendedMahmoud Abdel DayemNo ratings yet

- HIRADC FormDocument2 pagesHIRADC Formdeborahjiva23No ratings yet

- Technical Datasheet XTRADocument1 pageTechnical Datasheet XTRAMacdonald FuniNo ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Exemple Analyse de RisqueDocument2 pagesExemple Analyse de RisquechaimaaNo ratings yet

- Jha - SW - 22 - Spandex Wall ReplacementDocument5 pagesJha - SW - 22 - Spandex Wall ReplacementFikri HidayatNo ratings yet

- JHA For Test WT ShiftingDocument1 pageJHA For Test WT ShiftingShahid RazaNo ratings yet

- JSA Hot WorkDocument2 pagesJSA Hot WorkHARTO TRI HADI YUWONO 53119041No ratings yet

- JSA For DPTDocument3 pagesJSA For DPTMohammed Minhaj100% (1)

- Soil CompactionDocument1 pageSoil CompactionLebohang ChakaNo ratings yet

- Soil Compaction With Plate Compactor JSA HSE ProfessionalsDocument1 pageSoil Compaction With Plate Compactor JSA HSE ProfessionalsSamadov 13No ratings yet

- Rohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkDocument3 pagesRohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkAbhaySngh100% (1)

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- Hirarc ProjectDocument2 pagesHirarc Projecttashadzureen100% (4)

- 8.PM of MCR SCADA PanelDocument1 page8.PM of MCR SCADA PanelVivek SinghNo ratings yet

- PPE Selection and Use GuidelinesDocument3 pagesPPE Selection and Use GuidelinesSynergene EHSNo ratings yet

- HIRA - Copper Pipe Brazing WorkDocument2 pagesHIRA - Copper Pipe Brazing Workyogeshraut1910No ratings yet

- Stand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Document3 pagesStand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Dwitikrushna Rout100% (1)

- CE06 Use of Power SawDocument3 pagesCE06 Use of Power SawTafireyi TeveraNo ratings yet

- Gas Cutting JhaDocument3 pagesGas Cutting Jhasyed aquibNo ratings yet

- Transformer BasementDocument3 pagesTransformer Basementmohamed elahwalNo ratings yet

- Files Uploaded: Date CreatedDocument5 pagesFiles Uploaded: Date CreatedCaptatulpandeyNo ratings yet

- Work Method Statement - Soil ProtectionDocument2 pagesWork Method Statement - Soil ProtectionAugust Caezar LagatNo ratings yet

- 2.blinding & De-Blinding..Document5 pages2.blinding & De-Blinding..Zubair Ahmed KhaskheliNo ratings yet

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- Jsa Dekade KineDocument21 pagesJsa Dekade Kineramaiksan038No ratings yet

- HCIA-Data Center Facility V1.0 Training MaterialDocument422 pagesHCIA-Data Center Facility V1.0 Training MaterialShamsuzzaman FaridNo ratings yet

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- 130 Metal-Inert Gas (MIG) WeldingDocument2 pages130 Metal-Inert Gas (MIG) Weldinglara cross100% (1)

- UST Degassing Prior Breaking and Removing Concrete - 2000266Document4 pagesUST Degassing Prior Breaking and Removing Concrete - 2000266Reina SantiagoNo ratings yet

- Jha - SWT - 22 - Set New Water Tank On Concrete BaseDocument4 pagesJha - SWT - 22 - Set New Water Tank On Concrete BaseFikri HidayatNo ratings yet

- CDOT Job Safety Analysis for Measuring Concrete Unit Weight and Air ContentDocument1 pageCDOT Job Safety Analysis for Measuring Concrete Unit Weight and Air ContentHalima Irianti Puspita SariNo ratings yet

- BASF MasterSeal CR 125 - Ficha Técnica PDFDocument3 pagesBASF MasterSeal CR 125 - Ficha Técnica PDFOsmar Amadeo Bejarano JimenezNo ratings yet

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- Upc - Dic Factory - Semi Gantry Survey Observations: Bay 02 - Grid KDocument6 pagesUpc - Dic Factory - Semi Gantry Survey Observations: Bay 02 - Grid KAnoopNo ratings yet

- Upc - Dic Factory - Semi Gantry Survey Observations: Bay 01 - Grid MDocument4 pagesUpc - Dic Factory - Semi Gantry Survey Observations: Bay 01 - Grid MAnoopNo ratings yet

- Bay 04 Grid J & Grid IDocument4 pagesBay 04 Grid J & Grid IAnoopNo ratings yet

- Daily work plan progressDocument2 pagesDaily work plan progressAnoopNo ratings yet

- Client: Upc / Dic DATE: 19 AUG 2017 Shift: NightDocument2 pagesClient: Upc / Dic DATE: 19 AUG 2017 Shift: NightAnoopNo ratings yet

- DAILY PROGRESS REPORTDocument2 pagesDAILY PROGRESS REPORTAnoopNo ratings yet

- Al Nimr Tech Booklet PDFDocument52 pagesAl Nimr Tech Booklet PDFarnab mandalNo ratings yet

- Schedule Assessment Guide - Best Practices For Project Schedules Dic15Document240 pagesSchedule Assessment Guide - Best Practices For Project Schedules Dic15José Nolasco100% (1)

- Brochure FX951Document3 pagesBrochure FX951Claudiu NistorescuNo ratings yet

- TI Oxydur PTB 206 - en PDFDocument5 pagesTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- H2SO4Document24 pagesH2SO4Karina Sutanto SilvanNo ratings yet

- Series 3000 Cooling Tower SpecificationsDocument9 pagesSeries 3000 Cooling Tower SpecificationsTahseenNo ratings yet

- KS4 Chemistry: 1 of 20 1 of 68Document25 pagesKS4 Chemistry: 1 of 20 1 of 68Maurice Kim CamillonNo ratings yet

- Interaction Between Active Sites and Sorbents During TheDocument9 pagesInteraction Between Active Sites and Sorbents During TheJulian De BedoutNo ratings yet

- Casein PlasticDocument6 pagesCasein Plasticpiepie2No ratings yet

- Biokemistri Volume 32, Number 1Document95 pagesBiokemistri Volume 32, Number 1Clement BewajiNo ratings yet

- In-Line Coagulation With Low-Pressure Membrane Filtration: Kevin Young-June Choi, Brian A. DempseyDocument11 pagesIn-Line Coagulation With Low-Pressure Membrane Filtration: Kevin Young-June Choi, Brian A. DempseyM TNo ratings yet

- Advanced IC Engines: Prof. R. Devaraj Dr. S. Ramachandran Dr. A. AndersonDocument61 pagesAdvanced IC Engines: Prof. R. Devaraj Dr. S. Ramachandran Dr. A. AndersonGopi KrishnanNo ratings yet

- Flexible Dentures 2Document28 pagesFlexible Dentures 2jquin3100% (1)

- Hydrogen Fuel of The FutureDocument184 pagesHydrogen Fuel of The FutureDefEntNo ratings yet

- Lu Et Al., 2021Document14 pagesLu Et Al., 2021Srija sagiNo ratings yet

- Material Safety Data Sheet Material Safety Data Sheet Material Safety Data Sheet Material Safety Data SheetDocument7 pagesMaterial Safety Data Sheet Material Safety Data Sheet Material Safety Data Sheet Material Safety Data Sheetmiketyson11No ratings yet

- Cutting Tool Materials History and TypesDocument58 pagesCutting Tool Materials History and TypesBikram Panthee100% (1)

- Chemical Bonding I The Covalent Bond Copyright © The McGraw-Hill CompaniesDocument87 pagesChemical Bonding I The Covalent Bond Copyright © The McGraw-Hill CompaniesRoll OutNo ratings yet

- Applied Soil Mechanics With ABAQUS Applications by Sam HelwanyDocument398 pagesApplied Soil Mechanics With ABAQUS Applications by Sam HelwanyMarcelo HottaNo ratings yet

- Recent Mineral Processing Publications PDFDocument8 pagesRecent Mineral Processing Publications PDFMonica Ulloa LamasNo ratings yet

- Simulation of Wax Deposition Model for Various FieldsDocument53 pagesSimulation of Wax Deposition Model for Various FieldsAyauwu LovedayNo ratings yet

- Microbial Fuel Cell: A Source of BioelectricityDocument13 pagesMicrobial Fuel Cell: A Source of BioelectricityKim ChuaNo ratings yet

- @ TocoferolDocument4 pages@ TocoferolsindromfallNo ratings yet

- Waste Tyre Crumb Rubber Particle As A Partial Replacement To Fine Aggregate in Concrete IJERTV3IS061161Document4 pagesWaste Tyre Crumb Rubber Particle As A Partial Replacement To Fine Aggregate in Concrete IJERTV3IS061161220Ranjeet PatilNo ratings yet

- Insam - Recycling of Biomass Ashes PDFDocument173 pagesInsam - Recycling of Biomass Ashes PDFingjorgeveraNo ratings yet

- Day 29: Mechanical Behavior of PolymersDocument24 pagesDay 29: Mechanical Behavior of Polymersmailnewaz9677No ratings yet

- Bhopal Gas TragedyDocument14 pagesBhopal Gas Tragedyhriday kumarNo ratings yet

- 818 IC Pump: ManualDocument56 pages818 IC Pump: ManualKhalid Zghear100% (1)

- M13 Jacketed High-Pressure Fuel Pipe of Diesel EngineDocument10 pagesM13 Jacketed High-Pressure Fuel Pipe of Diesel EngineMaxwellNo ratings yet

- Tutorial 2 CHMT 4006-4008 2019Document4 pagesTutorial 2 CHMT 4006-4008 2019Da Saint0% (1)

- Frick Oil No 3 MSDS PDFDocument8 pagesFrick Oil No 3 MSDS PDFMahmoud Mohamed50% (2)