0% found this document useful (0 votes)

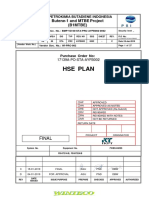

323 views8 pagesHydro Pressure Testing Safety Guide

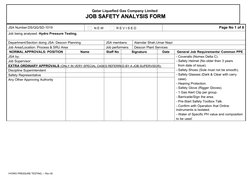

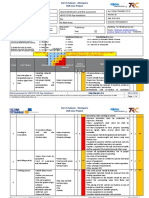

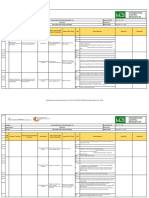

1. The document is a Job Safety Analysis form for hydro pressure testing at Qatar Liquefied Gas Company. It was prepared by Descon Planning and identifies hazards and control measures for the job.

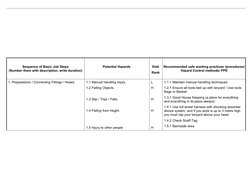

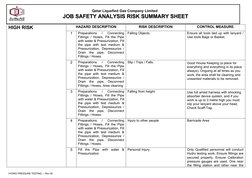

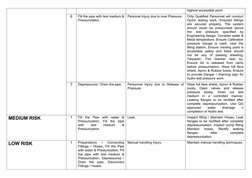

2. The hydro pressure testing process involves preparing fittings and hoses, filling pipes with water or test medium and pressurizing. Potential hazards identified include falls, slips, manual handling injuries, falling objects, and over pressurization.

3. Recommended safety practices to control hazards include using fall protection, maintaining housekeeping, inspecting equipment, restricting work to qualified personnel, not exceeding test pressures, using proper PPE, and implementing signage and barricades.

Uploaded by

Mohammad Fazal KhanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

323 views8 pagesHydro Pressure Testing Safety Guide

1. The document is a Job Safety Analysis form for hydro pressure testing at Qatar Liquefied Gas Company. It was prepared by Descon Planning and identifies hazards and control measures for the job.

2. The hydro pressure testing process involves preparing fittings and hoses, filling pipes with water or test medium and pressurizing. Potential hazards identified include falls, slips, manual handling injuries, falling objects, and over pressurization.

3. Recommended safety practices to control hazards include using fall protection, maintaining housekeeping, inspecting equipment, restricting work to qualified personnel, not exceeding test pressures, using proper PPE, and implementing signage and barricades.

Uploaded by

Mohammad Fazal KhanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

- Job Safety Analysis Form

- Basic Job Steps and Hazards

- Job Safety Analysis Risk Summary