Professional Documents

Culture Documents

Gas Cutting Jha

Uploaded by

syed aquib0 ratings0% found this document useful (0 votes)

4 views3 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views3 pagesGas Cutting Jha

Uploaded by

syed aquibCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

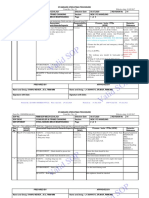

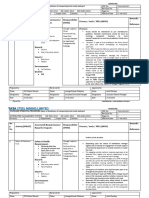

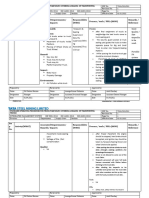

DOC NO- NEX/CSMS-NMD/JHA/1.2.

1/02

REV. NO.-02

JOB HAZARD ANALYSIS

Dept./Section CIVIL JHA No.:

Location of Job TSL,NOAMUNDI

Job Description Fabrication(Gas Cutting)

Team Who has done Safety Supervisor

JHA

Basic sequence of Potential Safe Guards / Controls to be Responsibility

Job Hazards put in place

1.Shifting of Safety: 1. Shoulder pad should be Safety Supervisor

materials by Manually 1) Heavy load used during work ,25 kg

for men & 16 kg for

2) Sharp edges of

women are the maximum

load

lifting capacity to be

3) Bad strictly followed.

housekeeping 2. Safety gloves to be worn

while handling.

Environment: 3. Good housekeeping is to

NA be maintained on

Quality:

worksite.

NA

Ergonomic: 4. Proper supervision for

1.Improper wrong procedural

working posture. working.

2.Continuation Of 5. Small intervals to be

work. provided between work.

Seasonal: 6. Rain coat to be provided

1.Heavy

to workers.

downpour.

2.Lightening 7. Stop the work & reside

3.High inside the room.

Temperature 8. Drinking water facility &

Occupational ORS.

Health Hazard: 9. Adequate PPEs usage.

1.Musculoskeletal 10. Periodic medical check up

disorder

Required PPE Required Tools/ Required Skill/Training Experienced site

Equipment in-charge/supervi

sor

Safety Training before start of job Available

shoe,jacket,helmet,g Training about the following SOP

oggles,nose

mask.gloves

Signature of JHA Team Members

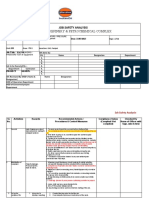

Dept./Section CIVIL JHA No.:

DOC NO- NEX/CSMS-NMD/JHA/1.2.1/02

REV. NO.-02

JOB HAZARD ANALYSIS

Location of Job TSL,NOAMUNDI Date:

Job Description

Team Who has Safety Supervisor

done JHA

Basic sequence Potential Hazards Safe Guards / Controls to be put in Responsibilit

of Job place y

2.Gas Cutting Safety: 1.Oxygen and fuel cylinder to be stored Safety

1.Gas cylinders apart i.e. at least 20 foot away from Supervisor

2.Gas fumes each other. Gas Cutting

3.Fire Cylinders to be checked thoroughly by operator

4. Damaged or leaking hoses. competent person before start of work.

5.Bad housekeeping 2.Work place to be well ventilated and

safety gas cutting goggles , nose mask

6. Splinters

to be worn during work.

7. Backfire/flashback 3. Fire Extinguisher/fire blankets to be

8. Hot rejected metal cut pieces present on work site.

Quality: Gas cutting process to be carried in a

Environmental: safe distance from

NA flammable/combustible materials

Ergonomic: nearby.

4.Pre-inspection of hoses to be carried

1.Wrong posture during performing

out before start of work.

work. Use good quality and approved standard

2.Continuous working hours. hoses.

Seasonal: 5. Good housekeeping to be maintained

at work site.

Summer- Barricade the area.

1.Humidity & high atmospheric 6. Protective clothing such as apron etc

needed along with safety gas cutting

temperature.

goggles.

Rainy- 7.Flashback arrestor to be used during

1. Lightening work.

Winter- 8. The rejected meatal cut pieces to be

NA collected and discarded in designated

Occupational Health Hazard: metal waste bin.

9.Training required for the welders about

1.Longterm exposure to gas cutting

the correct working postures &

process leads to chronic diseases.

supervision.

2. Musculoskeletal disorder. 10.Break to be given to welders during

work.

11. Working area to be shedded properly

with well ventilation.

ORS & drinking water should be

available at work site.

12. Stop the work & take shelter in

designated safe place.

13. Gas cutting process to be done on

rotation wise & by taking mid breaks

during work.

14.Periodic medical check-up.

Required PPE Required Tools/ Equipment Required Skill/Training Experienced

site in-

charge

Safety shoe, safety Gas cutting set with flash back arrestor Standard Operating procedure for gas Available

helmet, safety cutting process training to be provided.

apron, safety Vertigo Test

goggles,leather

gloves, gas cutting

safety goggles ,

Nose mask

Signature of JHA Team Member

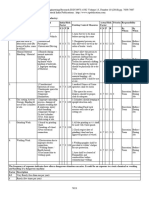

DOC NO- NEX/CSMS-NMD/JHA/1.2.1/02

REV. NO.-02

JOB HAZARD ANALYSIS

Dept./Section CIVIL JHA No.:

Location of Job TSL,NOAMUNDI Date:

Job Description

Team Who has done Safety Supervisor

JHA

Basic sequence of Potential Safe Guards / Controls to be Responsibility

Job Hazards put in place

3. Dumping of debris Safety: 1. Tools checklist before start of Safety Supervisor

1.Faulty Trolley job.

2. Dust 2.Dust mask to be worn.

3. Flying Splinters 3. Proper PPEs to be worn while

Environment: working.

Dust 4. Water to be sprinkled

Quality: throughout the process.

NA 5. Proper supervision during

Ergonomic: work.

1.Wrong body 6. Break to be provided within

posture during work.

work. 7. Raincoat/ umbrella to be

2.Long working provided, if heavy downpour

hour. continues stop the work.

Seasonal: Shelter to be used.

1. Thunderstorm 8. Drinking water facility on work

2. Continuous site.

Rainfall 9. Periodic medical check up.

3.Humidity

Occupational

Health Hazard:

1.Musculoskeletal

disorder

Required PPE Required Required Skill/Training Experienced

Tools/Equipme site in-charge

nt

Safety shoe, safety Trolley Training before start of job Available

helmet , safety Training about the following SOP

googles, safety

gloves. Gum boot,

Fluorescent jacket,

Nose mask

Signature of JHA Team Members

You might also like

- Arc Welding JhaDocument4 pagesArc Welding Jhasyed aquibNo ratings yet

- Garudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Document3 pagesGarudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Dwitikrushna Rout0% (1)

- Scrap Material Cutting, Handling & Loading Jha - 2Document3 pagesScrap Material Cutting, Handling & Loading Jha - 2Dwitikrushna Rout100% (5)

- M/S Arun Kumar Mitra: Job Hazard AnalysisDocument5 pagesM/S Arun Kumar Mitra: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- PCC Safety Supervisor: CivilDocument4 pagesPCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- M/S Kalachand Construction Job Hazard Analysis: JHA No.Document4 pagesM/S Kalachand Construction Job Hazard Analysis: JHA No.Dwitikrushna RoutNo ratings yet

- RCC Safety Supervisor: CivilDocument7 pagesRCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- Brick Work BSM Jha - 1Document3 pagesBrick Work BSM Jha - 1Dwitikrushna RoutNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument3 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument8 pagesR.K Construction: Job Hazard AnalysisDwitikrushna Rout100% (1)

- R.K Construction: Job Hazard AnalysisDocument2 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- 18 - Maintenance of Skip HoistDocument5 pages18 - Maintenance of Skip Hoistgiet11aei010No ratings yet

- Jha JiggingDocument4 pagesJha Jiggingsyed aquibNo ratings yet

- Kapoor Enterprises Jha-1Document3 pagesKapoor Enterprises Jha-1Dwitikrushna RoutNo ratings yet

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument2 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- HIRARC - ReturbingDocument8 pagesHIRARC - ReturbingnursharunNo ratings yet

- 21.removal and Refixing of 02SDV3301C.Document3 pages21.removal and Refixing of 02SDV3301C.Mohammad Fazal KhanNo ratings yet

- 3 RN Sop PDFDocument4 pages3 RN Sop PDFDwitikrushna RoutNo ratings yet

- SOP of Conveyor Belt Re-JointingDocument9 pagesSOP of Conveyor Belt Re-JointingDwitikrushna RoutNo ratings yet

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Procedures in Hazard Analysis in The WorkplaceDocument2 pagesProcedures in Hazard Analysis in The Workplacexbyun40No ratings yet

- JSA - T8420 Tank Cleaning - docFSPDocument3 pagesJSA - T8420 Tank Cleaning - docFSPavinash100% (2)

- 621-CC#09 Idler and Frame ChangingDocument4 pages621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- SOP of Bearing ChangeDocument9 pagesSOP of Bearing ChangeDwitikrushna Rout100% (3)

- SOP of Idler ChangeDocument9 pagesSOP of Idler ChangeDwitikrushna RoutNo ratings yet

- SOP For Maintenance & Testing of 6.6KV BET-CETDocument2 pagesSOP For Maintenance & Testing of 6.6KV BET-CETArbind NathNo ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- SOP of Conveyor ReplacementDocument11 pagesSOP of Conveyor ReplacementDwitikrushna Rout100% (1)

- SOP of Pump Changing JobDocument11 pagesSOP of Pump Changing JobDwitikrushna Rout100% (1)

- Job Activity Hazard Effect Control MeasuresDocument2 pagesJob Activity Hazard Effect Control Measuresperquino oasan100% (1)

- Job Safety Analysis WorksheetDocument3 pagesJob Safety Analysis Worksheetmohammed a hseNo ratings yet

- Job Safety Analysis Worksheet: Tie - in For Power Cable 33 KVDocument3 pagesJob Safety Analysis Worksheet: Tie - in For Power Cable 33 KVmohammed a hseNo ratings yet

- JHA For Shuttring and DeshuttringDocument2 pagesJHA For Shuttring and DeshuttringTigor GurningNo ratings yet

- 1-JHA - ExcavationDocument2 pages1-JHA - ExcavationAnna Marie Filipinas RajilNo ratings yet

- Belt Conveyor Bearing InspectionDocument3 pagesBelt Conveyor Bearing InspectionKarthikeyan MNo ratings yet

- Job Hazard Analysis: Amichand Technological Pvt. LTDDocument6 pagesJob Hazard Analysis: Amichand Technological Pvt. LTDSandeep KumarNo ratings yet

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- Method Statement For MpsDocument14 pagesMethod Statement For MpsAhmed NasserNo ratings yet

- Pre Commissioning Electrical EquipmentDocument4 pagesPre Commissioning Electrical Equipmentmohammed a hseNo ratings yet

- Result & DiscussionDocument4 pagesResult & DiscussionJuliana AzwaNo ratings yet

- Job Safety Analysis Foundation WorkDocument3 pagesJob Safety Analysis Foundation WorkMihirduttaNo ratings yet

- SOP609 - ESP by Pass Launder Knife Gate Valve FixingDocument12 pagesSOP609 - ESP by Pass Launder Knife Gate Valve FixingSunil KumarNo ratings yet

- Ijaerv13n10 56-15Document1 pageIjaerv13n10 56-15nazasraf2012No ratings yet

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoNo ratings yet

- Risk Assessment Sheet - in An Indian IndustryDocument2 pagesRisk Assessment Sheet - in An Indian IndustryAswini AcharyaNo ratings yet

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Job Safety Analysis Sheet:: GOR TestDocument1 pageJob Safety Analysis Sheet:: GOR Testhp9mzbjzsfNo ratings yet

- Hiradc ServicingDocument4 pagesHiradc ServicingAyub Abd RahmanNo ratings yet

- Job Safety Analysis: Gujarat RefineryDocument11 pagesJob Safety Analysis: Gujarat RefineryMICHAEL Rose100% (2)

- CE06 Use of Power SawDocument3 pagesCE06 Use of Power SawTafireyi TeveraNo ratings yet

- CE20 Installation of Crosby ClampsDocument3 pagesCE20 Installation of Crosby ClampsTafireyi TeveraNo ratings yet

- Job Safety Analysis - Work SheetDocument4 pagesJob Safety Analysis - Work Sheetrickie7809No ratings yet

- JSEA Install Grounding & Stick Earth BuildingDocument6 pagesJSEA Install Grounding & Stick Earth BuildingGus PurNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- Siddhivinayak Jsa-004-Work in ShaftDocument5 pagesSiddhivinayak Jsa-004-Work in Shaftyogeshraut1910No ratings yet

- M/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisDocument3 pagesM/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisHARSHADNo ratings yet

- Hiring of D.G JHADocument10 pagesHiring of D.G JHAsyed aquibNo ratings yet

- SOP For Breakdown of Vehicle - 17. Rev-2Document3 pagesSOP For Breakdown of Vehicle - 17. Rev-2syed aquibNo ratings yet

- SOP For PC130 Operation For Load Adjustment at WeighBridge - 055Document7 pagesSOP For PC130 Operation For Load Adjustment at WeighBridge - 055syed aquibNo ratings yet

- SOP For Manual Loading of Ore - 19Document7 pagesSOP For Manual Loading of Ore - 19syed aquibNo ratings yet

- Manual Loading of Chrome Ore Into Trucks - 019Document8 pagesManual Loading of Chrome Ore Into Trucks - 019syed aquibNo ratings yet

- Suggestion FormDocument1 pageSuggestion Formsyed aquibNo ratings yet

- SOP For Tarpaulin Sealing of Transportation Truck - 21Document5 pagesSOP For Tarpaulin Sealing of Transportation Truck - 21syed aquib100% (1)

- Nearmiss 2Document2 pagesNearmiss 2syed aquibNo ratings yet

- Exit Interview FormDocument3 pagesExit Interview FormJohn Nikko InacayNo ratings yet

- HR Complaince Audit Checklist TemplateDocument3 pagesHR Complaince Audit Checklist TemplateOSAMA ABUSKARNo ratings yet

- CR 8.8 Assistant Construction Supervisor TEMPLATEDocument1 pageCR 8.8 Assistant Construction Supervisor TEMPLATELiam Du PiesanieNo ratings yet

- Morbiditet RadnikaDocument15 pagesMorbiditet RadnikaMilivoje GaljakNo ratings yet

- Lmflex LM40 Atbc MSDSDocument10 pagesLmflex LM40 Atbc MSDSMohammed Tanjil Morshed remonNo ratings yet

- Problem 4-1 Method Calculation A. Separation Method Labor Turnover Rate %Document3 pagesProblem 4-1 Method Calculation A. Separation Method Labor Turnover Rate %Regina PhalangeNo ratings yet

- Lesotho Highlands Water Project - Phase II Contract - Method Statement (MS)Document4 pagesLesotho Highlands Water Project - Phase II Contract - Method Statement (MS)RetselisitsoeNo ratings yet

- GE - Work Health and Safety PolicyDocument4 pagesGE - Work Health and Safety Policybodaivai126No ratings yet

- 5 Fundamentals of Fire FightingDocument15 pages5 Fundamentals of Fire FightingCsjdm Bfp BulacanNo ratings yet

- FISPQ - H2S 25 PPM 6812114Document7 pagesFISPQ - H2S 25 PPM 6812114romerov24No ratings yet

- Confined Space Entry Training - PPT BabtainDocument91 pagesConfined Space Entry Training - PPT BabtainKh Mo0% (1)

- Carbon Dioxide Health Hazard Information SheetDocument3 pagesCarbon Dioxide Health Hazard Information SheetEdson BastoNo ratings yet

- Customer Data Management AnalyticsDocument75 pagesCustomer Data Management AnalyticsMaheshBirajdarNo ratings yet

- Msds Backing Ceramico Ne-0224 - e 04-12-2018Document5 pagesMsds Backing Ceramico Ne-0224 - e 04-12-2018manuelNo ratings yet

- 41-Article Text-242-1-10-20200218Document7 pages41-Article Text-242-1-10-20200218Eas DanistianNo ratings yet

- 4uphr - Obe - Owen KhozaDocument20 pages4uphr - Obe - Owen Khozaken khozaNo ratings yet

- Sample JHADocument3 pagesSample JHAprinceNo ratings yet

- MSDS Breathing OxygenDocument6 pagesMSDS Breathing OxygenDinchak RRAHNo ratings yet

- Confined Space ProceduresDocument3 pagesConfined Space ProceduresRich FreerNo ratings yet

- N Propyl Acetate 2 5LTDocument8 pagesN Propyl Acetate 2 5LTAde AsriyatnaNo ratings yet

- IOSH Risk Assessment Example 1Document2 pagesIOSH Risk Assessment Example 1J PpNo ratings yet

- Unit 18 Organization Citizenship Behaviour: ObjectivesDocument9 pagesUnit 18 Organization Citizenship Behaviour: ObjectivesSanjita LenkaNo ratings yet

- SikaTop 121 Comp. BDocument8 pagesSikaTop 121 Comp. BHaris RisdianaNo ratings yet

- OCP 123 Noise ProcedureDocument7 pagesOCP 123 Noise Procedurematam natarajNo ratings yet

- Hindyati RachmahDocument9 pagesHindyati RachmahhindyatiadtNo ratings yet

- 5c SAFETY SIGNSDocument21 pages5c SAFETY SIGNSPark Lin MariNo ratings yet

- HRM MCQDocument65 pagesHRM MCQUmair VirkNo ratings yet

- Working Safely Powerpoint PresentationDocument60 pagesWorking Safely Powerpoint PresentationAISECT PMKK SalemNo ratings yet

- Kidde Fire Systems APC Wet Chemical Safety Data Sheet 10-Feb-2020 ENGLISHDocument9 pagesKidde Fire Systems APC Wet Chemical Safety Data Sheet 10-Feb-2020 ENGLISHMyo Myint AungNo ratings yet

- Job Analysis and EvaluationDocument27 pagesJob Analysis and EvaluationJohn Christlier Rabara100% (2)