Professional Documents

Culture Documents

Arc Welding Jha

Uploaded by

syed aquib0 ratings0% found this document useful (0 votes)

3 views4 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views4 pagesArc Welding Jha

Uploaded by

syed aquibCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

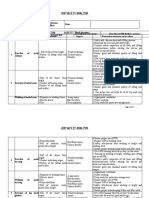

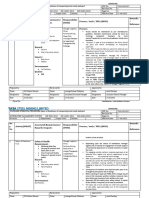

DOC NO- NEX/CSMS-NMD/JHA/1.2.

1/02

REV. NO.-02

JOB HAZARD ANALYSIS

Dept./Section CIVIL JHA No.:

Location of Job TSL,NOAMUNDI

Job Description Fabrication(Arc Welding)

Team Who has done Safety Supervisor

JHA

Basic sequence of Potential Safe Guards / Controls to be Responsibility

Job Hazards put in place

1.Shifting of Safety: 1. Shoulder pad should be Safety Supervisor

materials by 1)Heavy load used during work ,25 kg

Manually for men & 16 kg for

2)Sharp edges of

women are the maximum

load

lifting capacity to be

3)Bad strictly followed.

housekeeping 2. Safety gloves to be worn

while handling.

Environment: 3. Good housekeeping is to

NA be maintained on

Quality:

worksite.

NA

Ergonomic: 4. Proper supervision for

1.Improper wrong procedural

working posture. working.

2.Continuation Of 5. Small intervals to be

work. provided between work.

Seasonal: 6. Rain coat to be provided

1.Heavy

to workers.

downpour.

2.Lightening 7. Stop the work & reside

3.High inside the room.

Temperature 8. Drinking water facility &

Occupational ORS.

Health Hazard: 9. Adequate PPEs usage.

1.Musculoskeletal 10. Periodic medical check up

disorder

Required PPE Required Required Skill/Training Experienced site

Tools/Equipments in-charge/supervi

sor

Safety shoe, jacket, Training before start of job Available

helmet, Training about the following SOP

goggles ,nose mask.

gloves

Signature of JHA Team Members

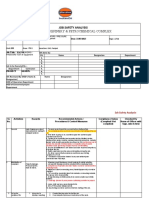

DOC NO- NEX/CSMS-NMD/JHA/1.2.1/02

REV. NO.-02

JOB HAZARD ANALYSIS

Dept./Section CIVIL JHA No.:

Location of Job Date:

Job Description Fabrication

Team Who has Safety Supervisor

done JHA

Basic Potential Hazards Safe Guards / Controls to be put Responsib

sequence of in place ility

Job

2.Arc Welding Safety: 1.Pre-inspection before start of work Safety

1.Faulty wire & loose & good quality wire to be used. Supervisor

connection. ELCB/MCCB to be present in every Welder

2.Welding fumes machine.

3.Fire 2. Good ventilation & proper method

4.Hot Rejected electrode during work.

stubs 3.Fire Extinguisher/fire blankets to

be present on work site.

5.Bad housekeeping

Welding process to be carried in a

6. Welding sparks & safe distance from

splinters flammable/combustible materials

7. UV Radiations nearby.

Quality: 4.The rejected stubs to be collected

1.Low grade welding and discarded in designated metal

electrodes. waste bin.

5.Good housekeeping to be

Environmental:

maintained at work site.

NA 6.Usage of adequate PPEs (in this

Ergonomic: case protective clothing, apron etc )

1.Wrong posture during 7. Welding face shield, welding

performing work. safety goggles usage during welding.

2.Continuous working 8.Only approved standard electrodes

hours. with IS standard to be used during

work.

Seasonal:

9. Training required for the welders

Summer- about the correct working postures

1.Humidity & high &Proper supervision.

atmospheric temperature. 10.Break to be given to welders

Rainy- during work.

1. Heavy Downpour 11. Working area to be shedded

2. Lightening properly with well ventilation.

ORS & drinking water should be

Winter-

available at work site.

NA 12. Welding to be carried on non-

Occupational Health conductive & non-flammable sheet

Hazard: underneath.

1.High exposure to welding 13.Stop the work & take shelter in

process leads to chronic designated safe place.

14. Welding process to be done on

diseases.

rotation wise & by taking mid breaks

2. Musculoskeletal during work.

disorder. 15.Periodic medical check-up.

Required PPE Required Tools/ Required Skill/Training Experienc

Equipment ed site in-

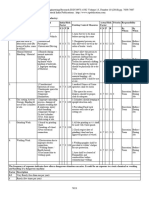

DOC NO- NEX/CSMS-NMD/JHA/1.2.1/02

REV. NO.-02

JOB HAZARD ANALYSIS

charge

Safety shoe, Arc Welding Machine Set Standard Operating procedure for Available

safety helmet, arc welding process training to be

safety apron, provided.

safety goggles,

ear

plug,leather

gloves,gas

cutting safety

goggles , Nose

mask

Signature of JHA Team Member

DOC NO- NEX/CSMS-NMD/JHA/1.2.1/02

REV. NO.-02

JOB HAZARD ANALYSIS

Dept./Section CIVIL JHA No.:

Location of Job Date:

Job Description

Team Who has done Safety Supervisor

JHA

Basic sequence of Potential Safe Guards / Controls to be Responsibility

Job Hazards put in place

3. Dumping of debris Safety: 1. Tool checklist before start of Safety Supervisor

1.Faulty Trolley job.

2. Dust 2.Dust mask to be worn.

3. Flying Splinters 3. Proper PPEs to be worn while

Environment: working.

Dust 4. Proper supervision during

Quality: work.

NA 5. Water to be sprinkled

Ergonomic: throughout the process.

1.Wrong body 6. Break to be provided within

posture during work.

work. 7. Raincoat/ umbrella to be

2.Long working provided, if heavy downpour

hour. continues stop the work.

Seasonal: Shelter to be used.

1. Thunderstorm 8. Drinking water facility on work

2.Continuous site.

Rainfall 9. Periodic medical check up.

3.Humidity

Occupational

Health Hazard:

1.Musculoskeletal

disorder

Required PPE Required Required Skill/Training Experienced

Tools/Equipme site in-charge

nt

Safety shoe, safety Trolley Training before start of job Available

helmet , safety Training about the following SOP

googles, safety

gloves. Gum boot,

Fluorescent jacket,

Nose mask

Signature of JHA Team Members

You might also like

- Performance Management Systems and Strategies by Dipak Kumar BhattacharyyaDocument385 pagesPerformance Management Systems and Strategies by Dipak Kumar Bhattacharyyasayal96amrit100% (3)

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat67% (3)

- Scrap Material Cutting, Handling & Loading Jha - 2Document3 pagesScrap Material Cutting, Handling & Loading Jha - 2Dwitikrushna Rout100% (5)

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- Job Safety Analysis Foundation WorkDocument3 pagesJob Safety Analysis Foundation WorkMihirdutta75% (4)

- JSA - T8420 Tank Cleaning - docFSPDocument3 pagesJSA - T8420 Tank Cleaning - docFSPavinash100% (2)

- Manual Loading of Chrome Ore Into Trucks - 019Document8 pagesManual Loading of Chrome Ore Into Trucks - 019syed aquibNo ratings yet

- Manufacturing Finance With SAP ERP Financials: Subbu RamakrishnanDocument33 pagesManufacturing Finance With SAP ERP Financials: Subbu RamakrishnanKhalifa Hassan100% (1)

- TTC 1000Document2 pagesTTC 1000svismaelNo ratings yet

- Garudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Document3 pagesGarudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Dwitikrushna Rout0% (1)

- PCC Safety Supervisor: CivilDocument4 pagesPCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- Gas Cutting JhaDocument3 pagesGas Cutting Jhasyed aquibNo ratings yet

- M/S Arun Kumar Mitra: Job Hazard AnalysisDocument5 pagesM/S Arun Kumar Mitra: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Brick Work BSM Jha - 1Document3 pagesBrick Work BSM Jha - 1Dwitikrushna RoutNo ratings yet

- M/S Kalachand Construction Job Hazard Analysis: JHA No.Document4 pagesM/S Kalachand Construction Job Hazard Analysis: JHA No.Dwitikrushna RoutNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- RCC Safety Supervisor: CivilDocument7 pagesRCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- R.K Construction: Job Hazard AnalysisDocument8 pagesR.K Construction: Job Hazard AnalysisDwitikrushna Rout100% (1)

- R.K Construction: Job Hazard AnalysisDocument3 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument2 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Jha JiggingDocument4 pagesJha Jiggingsyed aquibNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument2 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- 3 RN Sop PDFDocument4 pages3 RN Sop PDFDwitikrushna RoutNo ratings yet

- Kapoor Enterprises Jha-1Document3 pagesKapoor Enterprises Jha-1Dwitikrushna RoutNo ratings yet

- Job Safety Analysis Foundation WorkDocument3 pagesJob Safety Analysis Foundation WorkMihirduttaNo ratings yet

- Pre Commissioning Electrical EquipmentDocument4 pagesPre Commissioning Electrical Equipmentmohammed a hseNo ratings yet

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoNo ratings yet

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- Siddhivinayak Jsa-004-Work in ShaftDocument5 pagesSiddhivinayak Jsa-004-Work in Shaftyogeshraut1910No ratings yet

- Job Safety Analysis Worksheet: Tie - in For Power Cable 33 KVDocument3 pagesJob Safety Analysis Worksheet: Tie - in For Power Cable 33 KVmohammed a hseNo ratings yet

- JHA For Shuttring and DeshuttringDocument2 pagesJHA For Shuttring and DeshuttringTigor GurningNo ratings yet

- Carpentry Works 20.09.2020Document11 pagesCarpentry Works 20.09.2020Amit BhattNo ratings yet

- Job Safety Analysis (JSA) - HVAC Ducting DateDocument1 pageJob Safety Analysis (JSA) - HVAC Ducting DatenabeelNo ratings yet

- Power Tools JsaDocument1 pagePower Tools JsanabeelNo ratings yet

- Safety Officer Project SODocument2 pagesSafety Officer Project SODarwin De ChavezNo ratings yet

- 18 - Maintenance of Skip HoistDocument5 pages18 - Maintenance of Skip Hoistgiet11aei010No ratings yet

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- Job Safety Analysis (JSA) - Night Work DateDocument2 pagesJob Safety Analysis (JSA) - Night Work Datenabeel100% (2)

- M/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisDocument3 pagesM/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisHARSHADNo ratings yet

- OH Crane OverhaulingDocument2 pagesOH Crane OverhaulingSharjeel AhmedNo ratings yet

- Procedures in Hazard Analysis in The WorkplaceDocument2 pagesProcedures in Hazard Analysis in The Workplacexbyun40No ratings yet

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- JSA Rebar Cutting & BendingDocument2 pagesJSA Rebar Cutting & BendingGunjan Sinha AdityaNo ratings yet

- Job Hazard Analysis: Amichand Technological Pvt. LTDDocument6 pagesJob Hazard Analysis: Amichand Technological Pvt. LTDSandeep KumarNo ratings yet

- HIRARC - ReturbingDocument8 pagesHIRARC - ReturbingnursharunNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisBrain Dee Tech LtdNo ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- Job Activity Hazard Effect Control MeasuresDocument2 pagesJob Activity Hazard Effect Control Measuresperquino oasan100% (1)

- Ijaerv13n10 56-15Document1 pageIjaerv13n10 56-15nazasraf2012No ratings yet

- 1-JHA - ExcavationDocument2 pages1-JHA - ExcavationAnna Marie Filipinas RajilNo ratings yet

- Risk Assessment Sheet - in An Indian IndustryDocument2 pagesRisk Assessment Sheet - in An Indian IndustryAswini AcharyaNo ratings yet

- Cable Laying &termination HIRADocument66 pagesCable Laying &termination HIRAPRIYESH . K. PRIYANNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Job Safety Analysis (JSA) - Using Power Tools DateDocument1 pageJob Safety Analysis (JSA) - Using Power Tools DatenabeelNo ratings yet

- Hot Work JSA - SAFETYMGMTSTUDY PDFDocument1 pageHot Work JSA - SAFETYMGMTSTUDY PDFMohammed AlshehhiNo ratings yet

- Safety N/A Ergonomics N/A Environment 1. Dust Prone Zone. Positive Isolation & Work Permit Special Climatic ConditionsDocument8 pagesSafety N/A Ergonomics N/A Environment 1. Dust Prone Zone. Positive Isolation & Work Permit Special Climatic ConditionsAnjanav RoyNo ratings yet

- Omn01ard - Jsa-Electric WeldingDocument4 pagesOmn01ard - Jsa-Electric Weldinghechame TamerhouletNo ratings yet

- Job Hazard Analysis (JHA) Hot Water Gyeser InstallationDocument2 pagesJob Hazard Analysis (JHA) Hot Water Gyeser Installationwaqar naeemNo ratings yet

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- Hiring of D.G JHADocument10 pagesHiring of D.G JHAsyed aquibNo ratings yet

- SOP For Breakdown of Vehicle - 17. Rev-2Document3 pagesSOP For Breakdown of Vehicle - 17. Rev-2syed aquibNo ratings yet

- SOP For PC130 Operation For Load Adjustment at WeighBridge - 055Document7 pagesSOP For PC130 Operation For Load Adjustment at WeighBridge - 055syed aquibNo ratings yet

- SOP For Manual Loading of Ore - 19Document7 pagesSOP For Manual Loading of Ore - 19syed aquibNo ratings yet

- Suggestion FormDocument1 pageSuggestion Formsyed aquibNo ratings yet

- Nearmiss 2Document2 pagesNearmiss 2syed aquibNo ratings yet

- SOP For Tarpaulin Sealing of Transportation Truck - 21Document5 pagesSOP For Tarpaulin Sealing of Transportation Truck - 21syed aquib100% (1)

- Plastics Library 2016 enDocument32 pagesPlastics Library 2016 enjoantanamal tanamaNo ratings yet

- Lesson 3 - Practical ResearchDocument17 pagesLesson 3 - Practical ResearchBenNo ratings yet

- Seinfelt - The CheesecakeDocument31 pagesSeinfelt - The Cheesecakeseinfelt100% (2)

- Exercise On Coordination and ResponseDocument8 pagesExercise On Coordination and ResponseNorliyana AliNo ratings yet

- Internal Audit, Compliance& Ethics and Risk Management: Section 1) 1.1)Document6 pagesInternal Audit, Compliance& Ethics and Risk Management: Section 1) 1.1)Noora Al ShehhiNo ratings yet

- Lesson Plan 2 BasketballDocument3 pagesLesson Plan 2 Basketballapi-313716520100% (1)

- Capital BudgetingDocument24 pagesCapital BudgetingHassaan NasirNo ratings yet

- Block 7Document62 pagesBlock 7Poco ChanNo ratings yet

- Javascript PrefiDocument66 pagesJavascript Prefiguendelyn omegaNo ratings yet

- Business ProblemsDocument5 pagesBusiness ProblemsMaureen GarridoNo ratings yet

- RCD - SEF (Liquidating)Document40 pagesRCD - SEF (Liquidating)Chie NemzNo ratings yet

- TODO Data Sheet PDFDocument70 pagesTODO Data Sheet PDFJake ZyrusNo ratings yet

- The Complete Guide To Installing The 44 Split Defense PDFDocument171 pagesThe Complete Guide To Installing The 44 Split Defense PDFsaid100% (1)

- Essentials of Repertorization Tiwari Link PageDocument11 pagesEssentials of Repertorization Tiwari Link PageBibin TSNo ratings yet

- Ponce vs. Court of AppealsDocument7 pagesPonce vs. Court of AppealsMp CasNo ratings yet

- Ssg-Ng01012401-Gen-Aa-5880-00012 - C01 - Ssags Nigerian Content PlanDocument24 pagesSsg-Ng01012401-Gen-Aa-5880-00012 - C01 - Ssags Nigerian Content PlanStroom Limited100% (2)

- Learning Activity Sheet Pre-Calculus: Science Technology Engineering and Mathematics (STEM) Specialized SubjectDocument26 pagesLearning Activity Sheet Pre-Calculus: Science Technology Engineering and Mathematics (STEM) Specialized SubjectJanet ComandanteNo ratings yet

- Seminar ReportDocument15 pagesSeminar ReportNipesh MAHARJANNo ratings yet

- Manual de Caja Eaton Fuller ET20113Document22 pagesManual de Caja Eaton Fuller ET20113Juan Gomez100% (3)

- LoRa TechnologyDocument10 pagesLoRa TechnologyAnonymous CGk2roNo ratings yet

- Lab5.ipynb - ColaboratoryDocument8 pagesLab5.ipynb - ColaboratoryMin YNo ratings yet

- Subject-Verb AgreementDocument10 pagesSubject-Verb AgreementLouie Jay Cañada AbarquezNo ratings yet

- Essay Writing TipsDocument4 pagesEssay Writing TipsSubhasish MitraNo ratings yet

- Department of Mechanical Engineering: Er. Nipesh RegmiDocument30 pagesDepartment of Mechanical Engineering: Er. Nipesh RegmiRosina AdhikariNo ratings yet

- Kajima's Three PolicyDocument2 pagesKajima's Three PolicyBe Seang SeNo ratings yet

- Small Scale IndustriesDocument6 pagesSmall Scale IndustriesMangesh KadamNo ratings yet