Professional Documents

Culture Documents

SOP For Breakdown of Vehicle - 17. Rev-2

Uploaded by

syed aquibOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP For Breakdown of Vehicle - 17. Rev-2

Uploaded by

syed aquibCopyright:

Available Formats

2 ANNEXURE:

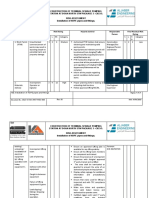

STANDARD OPERATING PROCEDURE: Repair of Breakdown of transporting trucks inside stackyard SOP No. TSML/SCH/017

Revision No. 1

INTEGRATED MANAGEMENT SYSTEM ISO 9001 2015 ISO 14001 2015 ISO 45001 2018 Page No. 2

Division: Department: Supply Chain Section: Effective Date: 27 -06-2023

Ste Remarks

Associated Requirements/ Responsibility

p Activity(WHAT) Process / tools / PPEs (HOW) /

Hazards/ Impacts (WHO)

No. Reference

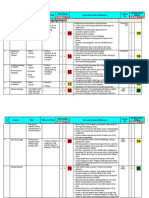

1 Communication and Safety & Health Manager Logistics / Process:

Barrication of Mines Trucks should be maintained as per manufactures

Breakdown Trucks. Requirement: Foreman/Mining guideline. Schedule maintenance should be done by

Communication to Mate( Shift involving competent mechanic by truck

Transporter. Incharge)/Transpor owner/Transporter to avoid any breakdown inside mine

Barrication of breakdown ter supervisor/ boundary.

truck. However, in case of truck breakdown the driver should

Transporter Site

not panic and inform immediately to Transporter

Incharge. supervisor.

Hazard:

Slip trip. If any TSML Supervisor/Security personnel observes any

breakdown case of truck, he forthwith inform the fact to

May hit by other vehicle

Transporter Side in-charge.

After receiving breakdown message the Transport

Impact : Supervisor/Transporter Side in-charge report at site for

Body Injury accessing the exact reason of breakdown and after

Fatality. discussion with truck driver he should provide proper

barrication around the truck. The truck ignition key to be

Environment: taken over by Transport Supervisor from truck driver.

Soil Pollution. For barrication safety cone and caution tape to be used.

Wheel choke to be provided for ensuring positive

Quality: isolation of breakdown truck. To be ensured by Shift In-

NA Charge TSML.

The transport supervisor shall inform the breakdown

case to TSML Supervisor. It is the duty of TSML

supervisor to inspect the site and verify the action taken

so far and inform the matter to Manger Logistics for

Prepared by Reviewed by Approved by

Name Md Matinul Hassan Name Ananga Kumar Mahanna Name Amit Choubey

Designation Manager Designation Assistant Divisional Manager Designation Assistant General Manager

Date 27.06.2023 Date 27.06.2023 Date 27.06.2023

Form No: CONFIDENTIAL – FOR INTERNAL USE ONLY

2 ANNEXURE:

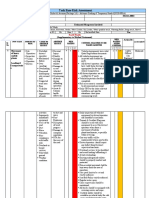

STANDARD OPERATING PROCEDURE: Repair of Breakdown of transporting trucks inside stackyard SOP No. TSML/SCH/017

Revision No. 1

INTEGRATED MANAGEMENT SYSTEM ISO 9001 2015 ISO 14001 2015 ISO 45001 2018 Page No. 2

Division: Department: Supply Chain Section: Effective Date: 27 -06-2023

Ste Remarks

Associated Requirements/ Responsibility

p Activity(WHAT) Process / tools / PPEs (HOW) /

Hazards/ Impacts (WHO)

No. Reference

further course of action

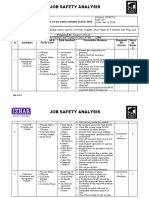

2 Repair of Breakdown Safety & Health Manager Logistics /

truck Requirement: Mines Depending upon the nature of breakdown manager

Obtaining Gate Pass Foreman/Mining logistics has to decide for engagement of inside support

Carrying of mechanic and of mechanical department or outside mechanic to repair

Mate( Shift in-

Spare parts to site the truck.

charge)/Transporte

Use of tools and Tackles For engaging outside mechanic necessary gate pass to be

r supervisor/ obtained from logistic and security department as per

Dispose of rejected oil and

Transporter Site in- format no - by transporter site in-charge.

spares

charge After due permission from manager (L/Y) /Shift In-charge

Hazard:

and Security control the mechanic/electrician to be given

Slip trip

safety orientation training (validity 3 months) before

May hit by other vehicle engaging in repair job. To be ensured by shift in-charge of

Fall of material TSML.

Conveyance of mechanic and required spare part to be

Impact : arranged by transporter site in-charge .

Body Injury Before starting of repair job TSML shift in-charge should

Fatality. ensure that necessary positive isolation measures have

been taken and necessary tools ,tackles to be used.

Environment: Necessary PPE like safety shoe, safety helmet, FL jacket

Soil Pollution & face shield ( if required ) to be used by mechanic.

The repair job is to be carried out under the supervision

of site safety supervisor/safety pro of the transporter

representative.

Prepared by Reviewed by Approved by

Name Md Matinul Hassan Name Ananga Kumar Mahanna Name Amit Choubey

Designation Manager Designation Assistant Divisional Manager Designation Assistant General Manager

Date 27.06.2023 Date 27.06.2023 Date 27.06.2023

Form No: CONFIDENTIAL – FOR INTERNAL USE ONLY

2 ANNEXURE:

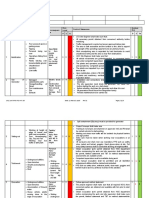

STANDARD OPERATING PROCEDURE: Repair of Breakdown of transporting trucks inside stackyard SOP No. TSML/SCH/017

Revision No. 1

INTEGRATED MANAGEMENT SYSTEM ISO 9001 2015 ISO 14001 2015 ISO 45001 2018 Page No. 2

Division: Department: Supply Chain Section: Effective Date: 27 -06-2023

Ste Remarks

Associated Requirements/ Responsibility

p Activity(WHAT) Process / tools / PPEs (HOW) /

Hazards/ Impacts (WHO)

No. Reference

After repairing of the truck and removal of safety

barricading material the ignition key to be handed over to

truck driver by transporter supervisor and the truck

moves out of the breakdown spot.

The mechanic with tools & tackles to be disposed from

site by transporter site in-charge and gate pass to be

handed over to security while exit at gate.

The rejected spare parts to be disposed as per TSML

standard by transporter site in-charge

No repair job to be undertaken after sunset till morning

hours.

If breakdown truck is not cleared in the same day

intimation to be given to mine manager & Safety officer

of TSML regarding the reason of the same.

Prepared by Reviewed by Approved by

Name Md Matinul Hassan Name Ananga Kumar Mahanna Name Amit Choubey

Designation Manager Designation Assistant Divisional Manager Designation Assistant General Manager

Date 27.06.2023 Date 27.06.2023 Date 27.06.2023

Form No: CONFIDENTIAL – FOR INTERNAL USE ONLY

You might also like

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentPajserchina100% (4)

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Standard Three-Storey SCHL BLDG DUPADocument139 pagesStandard Three-Storey SCHL BLDG DUPAKaren Balisacan Segundo Ruiz100% (3)

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- Risk Assessment For EquipmentDocument6 pagesRisk Assessment For Equipmentabou bakar100% (5)

- RA Erection of Pre-Engineered Steel Buildings (Structural Steel)Document8 pagesRA Erection of Pre-Engineered Steel Buildings (Structural Steel)kumar100% (1)

- Identification & Evaluation of HSE Aspects & Hazards Risk Assessment & Control FormDocument30 pagesIdentification & Evaluation of HSE Aspects & Hazards Risk Assessment & Control FormImam AliNo ratings yet

- RISK ASSESSMENT For Installation of HDPE Pipes and Fittings...Document21 pagesRISK ASSESSMENT For Installation of HDPE Pipes and Fittings...721917114 4757% (7)

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentNii Ashiii100% (2)

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- 2 RA 1410 Earth WorksDocument5 pages2 RA 1410 Earth WorksMuhammad Shahid Iqbal50% (2)

- Risk Assessment For General ActivitiesDocument25 pagesRisk Assessment For General Activitiesabou bakar67% (3)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- AURTTK102 Student Assessment - TheoryDocument9 pagesAURTTK102 Student Assessment - TheoryDeymon Alejandro Pinzon NaranjoNo ratings yet

- Method Statement For Staircase HandrailDocument18 pagesMethod Statement For Staircase HandrailEnviron Support50% (2)

- 1 Earth WorksDocument5 pages1 Earth WorksMuhammad Shahid Iqbal100% (1)

- Method StatementDocument63 pagesMethod StatementMikku Katta67% (3)

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment For Generator EquipmentDocument6 pagesRisk Assessment For Generator Equipmentabou bakar0% (1)

- k3 Bore Pile DenganBIMDocument6 pagesk3 Bore Pile DenganBIMrhoewiebNo ratings yet

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- Generic RiskDocument15 pagesGeneric RiskSujith B100% (2)

- Installation of Fahu's and Ahu'sDocument7 pagesInstallation of Fahu's and Ahu'sAnandu AshokanNo ratings yet

- Hazard Identification Plan (Schedule XX Jobs) Test - NewDocument20 pagesHazard Identification Plan (Schedule XX Jobs) Test - Newprince100% (1)

- Risk Assessment Form - KingGroveDocument12 pagesRisk Assessment Form - KingGroveeric chenNo ratings yet

- Risk Assessment 2A1Document10 pagesRisk Assessment 2A1Illias ShaikNo ratings yet

- Annexure A Subcontractor PrequalificationDocument11 pagesAnnexure A Subcontractor Prequalificationshazeb aliNo ratings yet

- Msds Clare 601Document7 pagesMsds Clare 601Abu Wildan100% (1)

- Emergency Response Drill Scenario - Collision & Damage Control (MBTC - Abaja)Document3 pagesEmergency Response Drill Scenario - Collision & Damage Control (MBTC - Abaja)Alok SinghNo ratings yet

- Basic Manual Metal Arc Welding (MMAW) : Learning Resource Metals and EngineeringDocument108 pagesBasic Manual Metal Arc Welding (MMAW) : Learning Resource Metals and EngineeringKiwi YhunNo ratings yet

- WSHi - Vehicular Safety at Work in SingaporeDocument17 pagesWSHi - Vehicular Safety at Work in SingaporeThupten Gedun Kelvin Ong100% (1)

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- JMS For MroDocument9 pagesJMS For Mroalexius lucasNo ratings yet

- JSA - Non-Destructive Testing (NDT) - Magnetic Particle TestDocument7 pagesJSA - Non-Destructive Testing (NDT) - Magnetic Particle TestRajuNo ratings yet

- Generic TPL JsaDocument83 pagesGeneric TPL JsaSanjay Kumar GhadaiNo ratings yet

- Hiradc Bore PileDocument10 pagesHiradc Bore PileDon McleanNo ratings yet

- Hazard Identification, Risk Assessment and Risk Control (Hirarc)Document7 pagesHazard Identification, Risk Assessment and Risk Control (Hirarc)Nate James100% (5)

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- 2016 Victory Gunner 70482Document106 pages2016 Victory Gunner 70482John WinchesterNo ratings yet

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- Laboratory Biosafety and Biosecurity Standards ManualDocument68 pagesLaboratory Biosafety and Biosecurity Standards ManualFloyd balansag100% (1)

- SOP For Machine Loading of Ore - 18Document7 pagesSOP For Machine Loading of Ore - 18syed aquibNo ratings yet

- SOP For Manual Loading of Ore - 19Document7 pagesSOP For Manual Loading of Ore - 19syed aquibNo ratings yet

- Safety Alert - AIS Fatal IncidentDocument1 pageSafety Alert - AIS Fatal Incidentshashank chawdharyNo ratings yet

- Standard Operating Procedure: Activity (What) Detail Process (How) Associated Hazards/Impacts ResponsibilityDocument12 pagesStandard Operating Procedure: Activity (What) Detail Process (How) Associated Hazards/Impacts ResponsibilityDwitikrushna RoutNo ratings yet

- Truck Movement Inside Stack Yard - 14Document9 pagesTruck Movement Inside Stack Yard - 14syed aquibNo ratings yet

- 15 (1) HIRA - Shifting of Const MaterialDocument3 pages15 (1) HIRA - Shifting of Const MaterialSk younusNo ratings yet

- Risk AssessmentsDocument7 pagesRisk Assessmentstareqawad95.taNo ratings yet

- Bypass SOPDocument4 pagesBypass SOPtayibouNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Emergency Plan For LiftDocument8 pagesEmergency Plan For LiftScribdTranslationsNo ratings yet

- SOP For Tarpaulin Sealing of Transportation Truck - 21Document5 pagesSOP For Tarpaulin Sealing of Transportation Truck - 21syed aquib100% (1)

- Risk Assessment Form: Page 1 of 5Document5 pagesRisk Assessment Form: Page 1 of 5RadhaKrishnan RNo ratings yet

- 11.1 TBOMO311 Crane Operation - Rev 0Document5 pages11.1 TBOMO311 Crane Operation - Rev 0quangNo ratings yet

- Concrete Pumping Risk AssessmentDocument5 pagesConcrete Pumping Risk AssessmentlenindraNo ratings yet

- TB-18U-C-TOA-2040-R1 - Working Plan - Temporary Sheet Pile Driving Works (Onshore) Turbine House - Part4Document32 pagesTB-18U-C-TOA-2040-R1 - Working Plan - Temporary Sheet Pile Driving Works (Onshore) Turbine House - Part4anh leNo ratings yet

- Emergency Response Drill Scenario - Collision & Damage Control (Cat - Abaja)Document3 pagesEmergency Response Drill Scenario - Collision & Damage Control (Cat - Abaja)Alok SinghNo ratings yet

- 20230319-WDN-HIRA-HRO-01 Haul Road Operation-Rev 01Document6 pages20230319-WDN-HIRA-HRO-01 Haul Road Operation-Rev 01Yuniar DultanNo ratings yet

- SMS-RMM 11.6.6 Fire: Sistem Manajemen Keselamatan Pedoman Manajemen Resiko KebakaranDocument4 pagesSMS-RMM 11.6.6 Fire: Sistem Manajemen Keselamatan Pedoman Manajemen Resiko KebakarandonnyNo ratings yet

- PPR Installation & Pressure Testing RADocument19 pagesPPR Installation & Pressure Testing RAJomy JohnyNo ratings yet

- JSA - 008 - Hydraulic Rig and Mobile Crane MarchingDocument2 pagesJSA - 008 - Hydraulic Rig and Mobile Crane MarchingAhmed AlderbiNo ratings yet

- Control Valves and Relief Valves Removal and InstallationDocument9 pagesControl Valves and Relief Valves Removal and InstallationELDIABLO 24KNo ratings yet

- Earth Work Using Dumper LoaderDocument4 pagesEarth Work Using Dumper LoaderBen Hammadi RymNo ratings yet

- 17 (1) HIRA - Sub Grade GSB & WMMDocument2 pages17 (1) HIRA - Sub Grade GSB & WMMSk younusNo ratings yet

- Fatality - Crane AccidentDocument1 pageFatality - Crane AccidentMohammedNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- 3263 - Transfer of Diesel JSA-R76!02!202-01Document1 page3263 - Transfer of Diesel JSA-R76!02!202-01cmrig74No ratings yet

- GMC Hse Procedure For Offloading MaterialsDocument7 pagesGMC Hse Procedure For Offloading MaterialsKwame GeeNo ratings yet

- Lifting Operations - Risk AssessmentDocument3 pagesLifting Operations - Risk AssessmentkhanalNo ratings yet

- Hiring of D.G JHADocument10 pagesHiring of D.G JHAsyed aquibNo ratings yet

- SOP For PC130 Operation For Load Adjustment at WeighBridge - 055Document7 pagesSOP For PC130 Operation For Load Adjustment at WeighBridge - 055syed aquibNo ratings yet

- Gas Cutting JhaDocument3 pagesGas Cutting Jhasyed aquibNo ratings yet

- Manual Loading of Chrome Ore Into Trucks - 019Document8 pagesManual Loading of Chrome Ore Into Trucks - 019syed aquibNo ratings yet

- Suggestion FormDocument1 pageSuggestion Formsyed aquibNo ratings yet

- Nearmiss 2Document2 pagesNearmiss 2syed aquibNo ratings yet

- SOP For Tarpaulin Sealing of Transportation Truck - 21Document5 pagesSOP For Tarpaulin Sealing of Transportation Truck - 21syed aquib100% (1)

- Waterproofing JhaDocument5 pagesWaterproofing Jhaprince olanNo ratings yet

- MSDS - Citric AcidDocument4 pagesMSDS - Citric AcidJose Luis Lucas ParedesNo ratings yet

- Method Statement Glass WorksDocument4 pagesMethod Statement Glass WorksAmal SaNo ratings yet

- Tinolux BBSDocument9 pagesTinolux BBSMoises Samuel PomaNo ratings yet

- Hand Hygiene: Alcohol Based Hand RubDocument2 pagesHand Hygiene: Alcohol Based Hand RubKIERSTINE MARIE BARCELONo ratings yet

- I So Propanol TreatDocument4 pagesI So Propanol Treatdinesh ghodkeNo ratings yet

- 安川sk16手册 PDFDocument232 pages安川sk16手册 PDFTrisno NgagorolonkNo ratings yet

- WHO - TRS - 996 - annex06-GTDP For Starting MaterialDocument16 pagesWHO - TRS - 996 - annex06-GTDP For Starting MaterialSilver KwongNo ratings yet

- SDS 1109 Pilot II AV Aluminium HR Eng CADocument8 pagesSDS 1109 Pilot II AV Aluminium HR Eng CAArya Suganda100% (1)

- Safety Data Sheet: Nipagin MDocument17 pagesSafety Data Sheet: Nipagin MwulandariNo ratings yet

- Site Id Site Address Regio N Area Longitude Latitude Tech NameDocument5 pagesSite Id Site Address Regio N Area Longitude Latitude Tech NameMJ D studioNo ratings yet

- Oil Gas CatalogDocument21 pagesOil Gas CatalogOws AnishNo ratings yet

- School Transport Arrangements From September 2020 FINALv2.1 PDFDocument7 pagesSchool Transport Arrangements From September 2020 FINALv2.1 PDFAlistair TelfordNo ratings yet

- Lawson Products, Inc - Non-Flammable Penetrating OilDocument4 pagesLawson Products, Inc - Non-Flammable Penetrating Oiljaredf@jfelectric.comNo ratings yet

- Engerix-B Pres Free Sds 2018-05-24Document7 pagesEngerix-B Pres Free Sds 2018-05-24anipratiwiNo ratings yet

- Work at Height - Health and Safety AuthorityDocument8 pagesWork at Height - Health and Safety AuthorityMurugan RaNo ratings yet

- OLYMPUS User Manual GabineteDocument55 pagesOLYMPUS User Manual Gabineteandres2013bioNo ratings yet

- Methanol: Safety Data SheetDocument16 pagesMethanol: Safety Data SheetNaveen CNo ratings yet