Professional Documents

Culture Documents

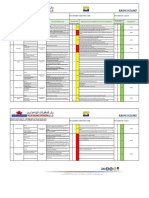

Risk Assessment For Modification of Phase 1 Existing Building GPR Tank

Uploaded by

Anandu AshokanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment For Modification of Phase 1 Existing Building GPR Tank

Uploaded by

Anandu AshokanCopyright:

Available Formats

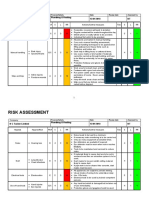

Document Reference

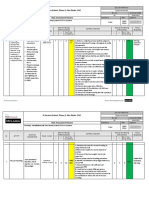

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

1

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

2

1

1 Delivering, Plant and Traffic Plumber 3 4 12 Medium 1. Delivery/ collection drivers shall be 1 4 4 Low Site Eng.

unloading and movement Supervisor subject to McLaren induction/Training Supervisor

storing of UPVC Foreman with regards to traffic management. Foreman

Flanges and

Run over by 2. Ensure exclusion zone is set up around

plumbing

vehicles/plants the preparation work area and all plant

materials using

pickup and Hit by reversing movement and checked by supervisor

unloading by equipment 3. Always use the pedestrian access

manual handling Overhead provided

obstructions 4. Traffic light batons shall be provided for

Vehicle break banks man at night

down 5. All plant to have a fully trained banks man

Property damage present all times.

Collision with 6. No plant to reverse without banks man.

other vehicles 7. Ensure access route are sufficient and

Personal injury safe to use.

8. Do not take rest in or under vehicles

9. Proper barricade and safety signboard

provided on open excavation

10.All vehicles must be fitted with reverse

alarm / Flashing light.

11.The work place and all access to be well

illuminated.

12.Enforce Speed limit

13.Ensure all vehicles entering the site is

properly maintained and reported if

found any defect

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

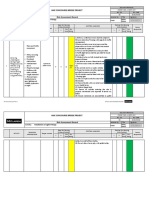

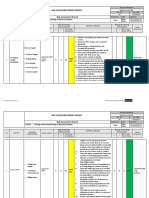

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

3

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

4

14.Ensure materials are secured/tied in

pallet trolley to avoid fall from trolley.

1. Work briefing must be conduct before

starting the activity.

2. Eliminate the need for manual handling by

1 Improper Manual using mechanical aid.

Handling technique 3. Operatives must be trained for safe

2 Wrong Posture manual handling

3 Poor visibility Operatives

4. If unsure of the load weight, check with

4 Lack of access & involved in

supervisor.

egress work Supervisor,

Manual Handling 5. Ensure proper manual handling procedure

2 Med Low Foreman,

5 Back aches 3 4 12 6. Ensure adherence with sufficient and 1 4 4

6 Slippery surfaces appropriate PPE.

7. Limit load carrying to 20kg per person

8. Supervisor must make sure while manual

handling loads individual task and

environment to be considered to reduce

the risk of manual handling.

Manual Handling assessment will be carried

by SAF 68

3 Material storing 1 Loose & Operatives 3 4 12 Med 1. Ensure accesses are kept clear at all times. 1 4 4 Low Supervisor,

unsecured material Staff/storekeeper 2. Housekeeping to be carried out regularly Foreman,

2 smoking at throughout the day when required

storage area 3. Supervisor to ensure operatives are

3 Incorrect storage stacking material neatly and stacks are

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

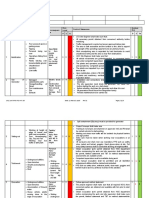

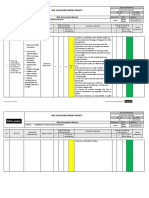

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

5

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

6

stable and in a safe condition

4. Provide adequate lighting especially during

night hours

5. Appropriate space is allowed around

storage areas for employees to move

around safely without the risk being

&improper trapped between stacked materials.

materials stacking 6. No smoking signage must be displayed in

4 Fire storage area and strictly to be followed

5 Slip, Trip & Fall smoking policy

7. Fire extinguisher must be available in

storage area in fore point.

8. Emergency number must display in storage

area

.

4 Use of Ladder Falling from height Operatives/ 3 4 12 Medium Ladder is not to use daily basis but in certain 1 4 4 Low

Staff/ cases where there is very narrow place and even Supervisor

Working on Uneven podium ladder not possible to fix in that cases Foreman

ground Ladder can use if permission granted from

McLaren Safety

Falling objects 1) Only light work, off short duration and work in

which the operative can maintain secure hand and

foot hold can be undertaken form a ladder

2) Never try to overreach with any ladders

3) Check the ladder is of suitable quality for

industrial use and is in good condition

4) Maintain a minimum of 3 points of contact with

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

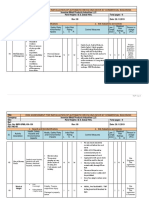

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

7

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

8

stepladders at all times (feet/thighs/hands)

If possible avoid the use of stepladders at a

working height of 2 meters and more.

5) Check the ladder legs (and stays) are fully

deployed or locked (depending on type) to

maintain maximum base dimensions and the step

ladder is orientated to provide maximum stability.

6) Stepladders/ladders has to be used on leveled

ground/firm base

7) Ensure that during using ladder from the top 2

steps is blocked to avoid climb on that.

8) The ladder securely fixed to prevent slipping

outwards or sideways or securely footed at all

times.

9) Person must hold the ladder while another

operative working on it

8) Materials should not be placed above the

thread of ladders/step ladders

9) Do not carry any materials in one hand while

climbing or getting down from ladder

10) Ensure the area under the ladder is barricaded

especially if it is being used in a public area.

11) Ensure the ladder is electrical insulated

podium type if working in live services

Work at height 1. STARRT card briefing must before start

Operatives/Staff/

Climbing to GRP the activity

Visitors Mediu Supervisors,

5 Tank access from

Others

3 4 12 2. Ensure that work at height permit 1 4 4 Low

m Foreman

tank roof Fall form height obtained by Supervisor

3. Ensure proper access with complete fall

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

9

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

10

protection

4. Ensure Full body harness and 100% Tie off

5. Ensured that below 4 mtr height

operatives will bypass the Shock absorber

from safety harness.

6. Ensure the scaffold platform is properly

erected with "Safe to use" tag.

7. Hand tools must be secured/tethered

8. Work materials strictly not allowed to be

Falling objects stored on platform except for working

tools

Over loading 9. Ensure avoid over reaching and climb on

handrail.

Protruding objects 10. Ensure unauthorised person not allowed

to modify the scaffolding and if needed to

Access & egress any changes then must be modified by

trained and certified scaffolder.

11. Ensure safe access to the working

platform

12. Scaffold access must be free from

obstruction

13. Ensure sufficient illumination in work

area.

14 Must clean the debris after completion the

job and maintain good housekeeping.

6 Plumbing work Confined Space Operatives 4 4 16 High 1 All the operatives entering in confined 1 4 4 Low Site

in side Existing entry entering in space they must have trained & awareness of engineer

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

11

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

12

hazard of confined space and certified by 3rd

party.

2 Permit must be obtained for confined

space entry

3 STARRT card briefing must be done by

supervisor and operatives signature must be

there in STARRT card

4 Need to ensure that you pay attention to

the atmosphere. Get an instrument

Explosion, to monitor your environment for things like

asphyxiation, hazardous gases that can’t be detected by

toxicity your nose.

Water tank Supervisor

Drowning in confined space 5 Make sure that the area is well-ventilated. Foreman

liquids Try to using forced-air ventilation in confined

Loss of spaces.

consciousness

6 Make sure use of PPE and strictly to be

wearing full body harness for emergency

rescue

7 Before entering in confined space

supervisor must maintain a register for name

of the person entering and time in and out

8 An emergency rescue. There should be a

stand by person on top the entry point for

clear method of communication with

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

13

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

14

mechanical aids such as an emergency tripod

attached to an operative’s safety harness and

sign in/out logs for commencement and

completion of work.

9 Make sure proper illumination in side tank.

10 Operatives must attend confined space

rescue training by 3rd party.

11 Plumber should not use regular safety

shoes in side tank and use only un used

Gumboot.

7 Spillage/ soil Operatives 3 4 12 Medium 1 Ensure that all chemical substances have a 1 4 4 Low Supervisor

contamination using solvent COSHH assessment Foreman

2 Refer SDS prior to any handling of

Burns hazardous substances and ensure SDS is

Contact with skin easily accessible at site while working with

Use of GRP chemicals.

Lamination Acute/Chronic 3 Ensure chemicals are properly stacked.

materials and adverse heath 4 Ensure all chemical containers are properly

Glue/Solvent, effect. labeled.

(Hazardous Fire 5 Spill kits to be available at site.

Substance) 6 Ensured all COSHH waste must be dispose

in designated waste bin.

7 Competent person to oversee the storage,

use and disposal of hazardous materials.

8 Ensure that correct welfare/first aid

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

15

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

16

facilities are available in the area i.e. washing

facility/eye wash.

9 Proper and adequate PPE to be used always

10 Ensure all chemical containers are

properly labeled.

11 Adjust work schedules so that workers are

not overexposed to a hazardous chemical.

12 Ensure proper and adequate PPE to be

used always.

13 Ensure smoking is prohibited

14 Ensure appropriate Firefighting

equipment’s are in place and easily accessible

8 Use of power Damaged Operatives and 3 4 12 Med 1. All portable electrical equipment must be 1 4 4 Low Supervisor

tools such as Sockets & cable Foreman PAT tested and color coded. Make sure Foreman

Drill machine for insulation. the test dates are visible on the

Coring activity Electrocution equipment.

using hole saw Electric shock 2. Ensure all disk shall be appropriate and

cutter Short circuit & expiry date is over.

Burns 3. Ensure all power tools are in good

Trip/Fall condition and appropriately maintained

Noise 4. PTW to be obtained, prior to commencing

Hearing loss the task

Vibration 5. Damaged Cable and sockets must be

Dust removed.

Entanglement 6. Ensure cables from power tools shall be

organized so as not to present a tripping

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

17

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

18

hazard

7. Only trained competent operatives to

operate the power tools.

8. Ensure proper and regular maintenance

of equipment that takes account of noise

9. Ensure proper hearing protection always.

10.Make sure people use the right tool for

the job and are trained to use it correctly

11.Ensure defective tools that require

maintenance is reported for repair or

replacement.

12.Ensure proper earth leakage protection is

provided.

13.Operatives must awareness of rotating

object of whole saw cutter and safety use

14.Avoid loose clothing and jewellery item

during using rotating tools.

15 Power tools must be 110V to be

ensured.

16 Use PPE and in side tank use un used

Gumboot

9 Use of Hand tools Improper selection of 3 3 9 Medium 1) Hand tools should be visually inspected for 1 3 3 Low .

hand tools. Operatives/Staff defects, prior to use Supervisor

Damaged and 2) Select right tools for right Job Foreman

Defective Hand tools 3) Ensure no Homemade or makeshift tools to be

Hand injuries used at site

Pinch point 6) Ensure Hand tools are Stored in accordance with

Ergonomics the manufacturer’s instructions.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

19

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

20

Repetitive strain injury 4) Ensure hands are not in direct line of fire while

working with hand tools.

5) Ensure appropriate PPE always.

1) Ensure proper night work permit is obtained

2) Proper lighting system should be in place

3) Ensure proper Communication / Coordination

Operatives/staff and close supervision

Poor visibility due to

4) Industrial safe torches to be available for Site Engr

Working at night darkness / poor

emergency situations Supervisor

10 time illumination 3 4 12 Medium 1 4 4 Low

5) High visibility Traffic Vest for personnel’s in Foreman

Lone worker

night shift

136) Avoid lone working and always ensure buddy

system while working at night

7) Employees to be trained and understand

McLaren Crises plan.

1 Make sure there is no water leakage and

flooding nearby area.

2 make sure all people using ear plug for noise

Flooding protection

People nearby Plumber

Dewatering Noise 3 Make sure there is no naked cable or electrical

11 area 3 4 12 1 4 4 Low Foreman

activity Electrocution DB nearby Dewatering activity.

Operatives Supervisor

Slip, trip fall 4 Make sure there is no slippery floor and if water

fall immediately use wiper to make the floor is

dried

12 Covid 19 Cough All employees 4 5 20 High 1. Avoid close contact with anyone showing 1 5 5 Low Every

Sneezing symptoms of respiratory illness. individual

Fever (fever as body 2. Wash hands often with soap and water

temperature higher

for at least 20 seconds or use an alcohol-

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

21

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

22

based hand rub if your hands are not

visibly dirty.

3. Use hand sanitizer if soap and water are

not available.

4. Cover coughs and sneezes with tissues.

5. Maintain at least 1 meter (3 feet)

distance between yourself and other

people, particularly those who are

coughing, sneezing and have a fever.

6. Avoid touching eyes, nose and mouth: It

than 38°C

Headache transfer the virus from the surface to

Nasal Discharge yourself through hands

7. If you're the one feeling sick, cover your

mouth and nose when you cough or

sneeze, and disinfect the objects and

surfaces you touch, seek medical care

early

8. Do not travel if you develop any illness

symptoms

9. Strictly to be followed wearing face mask

13 Adverse weather Rain, All employee, 4 4 16 High 1 Weather report must be monitored and 1 4 4 Low Site Eng.

condition Sand Storm visitors working informed to work force. Supervisor

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

23

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

24

2 No activity shall be allowed during adverse

weather condition on site

3 Protect the Power tools/DB from rain water

to avoid short circuit.

4 Ensure during adverse weather or Foggy

weather no lifting operation and no vehicle

movement.

5 After clear the weather make sure all power

tools are safe to use.

Fog

6 No work at height during high wind and rain

Slippery surface

7 In case of emergency, call

Risk of electrocution

McLaren/Emergency number

Flying debris,

8 No activity in direct sunlight 12.30 to 3 pm

Slip, Tripping and outside and Foreman

9 Drink more water and rehydration drink

fall inside HSE team

10 in case of anybody feel sick immediately

Direct Sunlight

contact site clinic

Humidity

11 Arrange sufficient Fan/Blower to inside

Heat stress

building.

Heat stroke

12 Give frequent rest if more humidity.

13 Do not ignore if dizziness or headache and

immediate contact in site emergency

number.

14 Operatives must follow the Flag(Green,

Orange & Red )fixed on the roof and

accordingly act

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karamah School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-081

Rev. No. Assessment Date

00 15/07/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Modification of Phase 1 Existing Building GRP Tank Safety

Prabir

Officer

25

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

26

2

3

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21 Approved By: Name Vishnu Mohan Position _PM________ Signature _ ________ ___________

22

23

24

25

26

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

27

28 RISK ASSESSMENT & CONTROL GUIDELINES

29

30 1. Executing Steps:

31 1.1. Planning

32 a) Construction and HSE team must ensure that hazard identification is complete.

33 b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks

34 have well established legal requirements, potentially high risks).

35 c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these

36 potential high risks.

37 1.2. Risk Assessment

38 Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The

39 hazard is the potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an

40 event occurring, but also the outcome will be in terms of injury, loss, damage or harm.

41 1.3. Risk Assessment Process

42 The process of carrying out a risk assessment should be as follows.

43 1. Identify the hazards.

44 2. Identify who might be harmed and how.

45 3. Evaluate the risk and implement the control measures.

46 4. Record the significant findings.

47 5. Review the assessment and update if necessary.

48 1.4. Examination of the Hazards and Risk Associated

49 Competent staff must be used in examining the risk associated with the identified hazard.

50 Competent staff should examine following aspect to determine the risk involved:

51 o Examine the existing control measures in place.

52 o Identify employees at risk.

53 o Likelihood of risk.

54 o Severity

55 o Risk level and their tolerability.

56 1.5. Evaluating the risk:

57 Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to

58 access the risks.

59 1.5.1. Risk Rating Score

60 Risk rating score is a combination of two factors.

61 The severity of the risk that could injure persons or cause damage to plant.

62 The likelihood of the risk that it could happen (Probability).

63

64 RISK RATING = LIKELIHOOD X SEVERITY

65 NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in

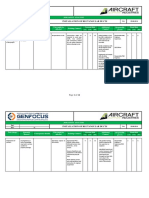

66 the table below. SEVERITY

67

No Injury Minor Moderate Major Catastrophic

68

(1) Injury (2) Injury (3) Injury (4) (5)

69 LIK

70 ELI 1 2 3 4 5

Rarely (1)

71 HO

72 OD Unlikely (2) 2 4 6 8 10

73 Possible (3) 3 6 9 12 15

74

75 Likely (4) 4 8 12 16 20

76 Almost

77 Certain (5)

5 10 15 20 25

78 RISK LEVEL:

Low Medium High

79

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

80

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

You might also like

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Document12 pagesRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- RISK ASSESSMENT Installation and Testing of Access Control SystemDocument11 pagesRISK ASSESSMENT Installation and Testing of Access Control SystemAnandu Ashokan100% (3)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For Installation of SMDB DBDocument12 pagesRisk Assessment For Installation of SMDB DBRAMA100% (1)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Sanitary Fixtures Risk AssessmentDocument12 pagesSanitary Fixtures Risk AssessmentAnandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 pagesRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Installation of Fire Fighting Pipes Risk AssessmentDocument15 pagesInstallation of Fire Fighting Pipes Risk AssessmentAnandu Ashokan80% (5)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasNo ratings yet

- MS For Installation of Light FittingsDocument11 pagesMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Risk Assessment For Installation and Testing of CCTVDocument11 pagesRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (4)

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 pagesRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan94% (17)

- Risk Assessment For MEP Services in P6 Existing ParkingDocument16 pagesRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Risk Assessment For Installation of Fire Fighting SystemDocument14 pagesRisk Assessment For Installation of Fire Fighting SystemMohamed Elhadad100% (5)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- RA For Installation of Air Colled ChillersDocument8 pagesRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- RISK ASSESSMENTDocument8 pagesRISK ASSESSMENTEm Niax100% (1)

- Risk Assessment For Dismantling of Temporary ServicesDocument17 pagesRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNo ratings yet

- Risk Assessment For .Testing and Commissioning of Fire Rated Bus DuctDocument13 pagesRisk Assessment For .Testing and Commissioning of Fire Rated Bus Ductarun kurlanNo ratings yet

- Risk Assessment for Lifting OperationsDocument2 pagesRisk Assessment for Lifting OperationsPrem Shiva100% (1)

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- Installation of Earthing SystemDocument9 pagesInstallation of Earthing SystemamalNo ratings yet

- Risk Assessment For Testing and Commissioning of Water Supply Pipes Including ChlorinationDocument3 pagesRisk Assessment For Testing and Commissioning of Water Supply Pipes Including Chlorinationfidgety100% (4)

- Risk Assessment (Installation of Cables & Wires)Document6 pagesRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- Generic RiskDocument15 pagesGeneric RiskSujith B100% (2)

- Risk Assessment For General ActivitiesDocument25 pagesRisk Assessment For General Activitiesabou bakar67% (3)

- Risk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Document12 pagesRisk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Anandu Ashokan100% (1)

- Risk Assessment For Cable TrayDocument11 pagesRisk Assessment For Cable Traynellaika puspa dewiNo ratings yet

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 pagesRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Plant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingDocument11 pagesPlant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingRAMANo ratings yet

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- Risk Assessment - FM 200Document5 pagesRisk Assessment - FM 200Nangyal KhanNo ratings yet

- 14 Risk Assessment of CleaningDocument12 pages14 Risk Assessment of Cleaningطارق رضوان100% (1)

- Risk assessment for automatic revolving doorsDocument8 pagesRisk assessment for automatic revolving doorssabirbdk100% (1)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- RA For Plumbing and HeatingDocument8 pagesRA For Plumbing and HeatingAngela DaveyNo ratings yet

- Building System Risk AssessmentDocument42 pagesBuilding System Risk Assessmentمحمد عمر حسين100% (4)

- Risk Assessment For Installation of Air Handling UnitsDocument19 pagesRisk Assessment For Installation of Air Handling UnitsAnandu Ashokan100% (8)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 pagesRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 pagesRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (2)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- Risk Assessment For MEP Isolation WorksDocument8 pagesRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (5)

- Installation of Rectangular DuctsDocument14 pagesInstallation of Rectangular DuctsAnandu AshokanNo ratings yet

- Risk Assessment For .TESTING AND COMMISSIONING OF LV CABLEDocument19 pagesRisk Assessment For .TESTING AND COMMISSIONING OF LV CABLEarun kurlan100% (3)

- Risk Assessment For Chilled Water CladdingDocument2 pagesRisk Assessment For Chilled Water CladdingHAMIDULLAH MNo ratings yet

- RA For Installation of FanDocument8 pagesRA For Installation of FanAnandu AshokanNo ratings yet

- Risk Assessment For Installation of Drainage Pipes and FittingsDocument8 pagesRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (1)

- Risk Assessment for Overhead Line Relocation ProjectDocument5 pagesRisk Assessment for Overhead Line Relocation Projectghada gattouchNo ratings yet

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsAnandu Ashokan88% (8)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsHerdhiska Pradhiarta AjiprayogaNo ratings yet

- Ara-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Document15 pagesAra-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Anandu AshokanNo ratings yet

- SAT of Final Small Power & Lighting Circuits (GEN)Document13 pagesSAT of Final Small Power & Lighting Circuits (GEN)Anandu AshokanNo ratings yet

- ETIHAD SOUTHSIDE CATERING ELECTRICAL TESTINGDocument81 pagesETIHAD SOUTHSIDE CATERING ELECTRICAL TESTINGAnandu AshokanNo ratings yet

- SAT of Earthing & Lightning Protection System (GEN)Document15 pagesSAT of Earthing & Lightning Protection System (GEN)Anandu AshokanNo ratings yet

- SAT of MV Cables (GEN)Document18 pagesSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- Master Log - LOGDocument15 pagesMaster Log - LOGAnandu AshokanNo ratings yet

- DCPRO Submittal Response Sheet ReviewDocument1 pageDCPRO Submittal Response Sheet ReviewAnandu AshokanNo ratings yet

- M1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BDocument72 pagesM1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningDocument27 pagesm1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningAnandu AshokanNo ratings yet

- Etihad Southside Catering Facility Lockout Tagout Method StatementDocument24 pagesEtihad Southside Catering Facility Lockout Tagout Method StatementAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- Harmonic Measurement Risk AssessmentDocument41 pagesHarmonic Measurement Risk AssessmentAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- M1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityDocument24 pagesM1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityAnandu AshokanNo ratings yet

- Water Filtration System - Method StatementDocument7 pagesWater Filtration System - Method Statementsunil_v575% (4)

- Testing Commissioning Fire Fighting SystemsDocument47 pagesTesting Commissioning Fire Fighting SystemsAnandu AshokanNo ratings yet

- M1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerDocument63 pagesM1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerAnandu AshokanNo ratings yet

- Risk Assessment for Fire Alarm IntegrationDocument49 pagesRisk Assessment for Fire Alarm IntegrationAnandu AshokanNo ratings yet

- Rerouting of Existing MEP Services in New SubstationDocument52 pagesRerouting of Existing MEP Services in New SubstationAnandu AshokanNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- Installation of Sanitary Fixtures MixersDocument44 pagesInstallation of Sanitary Fixtures MixersAnandu AshokanNo ratings yet

- Installation of Toilet Exhaust FansDocument51 pagesInstallation of Toilet Exhaust FansAnandu AshokanNo ratings yet

- Testing Commissioning of HVAC SystemDocument53 pagesTesting Commissioning of HVAC SystemAnandu Ashokan100% (4)

- Installation and Testing Commissioning of PumpsDocument60 pagesInstallation and Testing Commissioning of PumpsAnandu Ashokan100% (1)

- Installation of Grill Diffuser LouversDocument51 pagesInstallation of Grill Diffuser LouversAnandu AshokanNo ratings yet

- MSS Approvals Required for HVAC InstallationDocument102 pagesMSS Approvals Required for HVAC InstallationAnandu AshokanNo ratings yet

- Installation of Underground Electrical-ELV DuctDocument41 pagesInstallation of Underground Electrical-ELV DuctAnandu AshokanNo ratings yet

- (ART.) VEKEMANS, Charlotte SEGERS, Yves (2020) Settler Farming, Agricultural Colonisation and Development in Katanga (Belgian Congo), 1910-1920Document32 pages(ART.) VEKEMANS, Charlotte SEGERS, Yves (2020) Settler Farming, Agricultural Colonisation and Development in Katanga (Belgian Congo), 1910-1920Vitor RodriguesNo ratings yet

- англійська 11 final altered PDFDocument192 pagesанглійська 11 final altered PDFАнна НазаренкоNo ratings yet

- 10 INSIGHT - 2023 - D SouzaDocument7 pages10 INSIGHT - 2023 - D SouzazhaobingNo ratings yet

- Insurance Dispute Over Mortgaged PropertyDocument2 pagesInsurance Dispute Over Mortgaged PropertyBetson CajayonNo ratings yet

- 15 Aluminium Packaging PDFDocument4 pages15 Aluminium Packaging PDFAchmadda FebiyonoNo ratings yet

- Notes of Meetings MergedDocument8 pagesNotes of Meetings MergedKreeshnee OreeNo ratings yet

- ch-1 Phy MEASUREMENT AND MOTIONDocument2 pagesch-1 Phy MEASUREMENT AND MOTIONRakesh GuptaNo ratings yet

- Stratigrapghy Mineral Potential of BalochistanDocument45 pagesStratigrapghy Mineral Potential of BalochistanMohsin Ali KhuhawarNo ratings yet

- JVC Mini DV and S-VHS Deck Instruction Sheet: I. Capturing FootageDocument3 pagesJVC Mini DV and S-VHS Deck Instruction Sheet: I. Capturing Footagecabonedu0340No ratings yet

- CVDocument7 pagesCVRedemptah Mutheu MutuaNo ratings yet

- M-Commerce Seminar ReportDocument13 pagesM-Commerce Seminar ReportMahar KumarNo ratings yet

- Bcom MADocument21 pagesBcom MAAbl SasankNo ratings yet

- ICT in Education ComponentsDocument2 pagesICT in Education ComponentsLeah RualesNo ratings yet

- Vasitars PVT Limited - Pipeline RepairsDocument12 pagesVasitars PVT Limited - Pipeline RepairsPavan_yoyo100% (1)

- Latex Rubber Fetishcmmwv PDFDocument5 pagesLatex Rubber Fetishcmmwv PDFFetishLeggings57No ratings yet

- Exam StructuralDocument1 pageExam StructuralJoyce DueroNo ratings yet

- OBE-Syllabus Photography 2015Document8 pagesOBE-Syllabus Photography 2015Frederick Eboña100% (1)

- Water and Sanitation CrisisDocument4 pagesWater and Sanitation CrisisKarl EstenzoNo ratings yet

- The Next Form of DemocracyDocument313 pagesThe Next Form of DemocracyVanderbilt University Press100% (2)

- Artificial VisionDocument16 pagesArtificial VisionPriya PanyamNo ratings yet

- MPT Training CentreDocument11 pagesMPT Training CentreGrace PMNo ratings yet

- How Plant and Animal Adapt To Aquatic HabitatDocument16 pagesHow Plant and Animal Adapt To Aquatic HabitatCharles Amaechi100% (2)

- Criminal Law Tutorial RapeDocument7 pagesCriminal Law Tutorial RapeJosephine TappNo ratings yet

- Divya Shree: ObjectiveDocument2 pagesDivya Shree: Objectivekids montessoriNo ratings yet

- Rigging & Slinging For Engineers - Purchasers PDFDocument2 pagesRigging & Slinging For Engineers - Purchasers PDFΈνκινουαν Κόγκ ΑδάμουNo ratings yet

- Topic 1 Being A 21st Century LearnerDocument17 pagesTopic 1 Being A 21st Century LearnerNAZATUL EZETY BINTI AHMAD STUDENTNo ratings yet

- Full Download Law and Economics 6th Edition Cooter Solutions ManualDocument35 pagesFull Download Law and Economics 6th Edition Cooter Solutions Manualscraperletternh21o100% (37)

- NajeebRehman 1505 14145 1/AFN ExamplesDocument47 pagesNajeebRehman 1505 14145 1/AFN ExamplesQazi JunaidNo ratings yet

- Norman ConquestDocument35 pagesNorman Conquestapi-463690129No ratings yet

- Storyboard: Video Script and Storyboard On Evaluating Functions LessonDocument2 pagesStoryboard: Video Script and Storyboard On Evaluating Functions LessonIvanhoe BalaroteNo ratings yet