Professional Documents

Culture Documents

Risk Assessment For Installation of MDBSMDB DB (Modified)

Uploaded by

Anandu AshokanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment For Installation of MDBSMDB DB (Modified)

Uploaded by

Anandu AshokanCopyright:

Available Formats

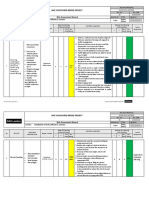

Document Reference

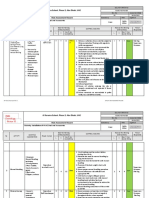

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

1

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

2

1

1 Delivering, Plant and Operatives 3 4 12 Med 1. Delivery/ collection drivers shall be 1 4 4 Low Site Eng.

unloading and Traffic Staff/visitors subject to McLaren induction/Training Supervisor,

storing of MDB, movement with regards to traffic management. Foreman,

SMDB & DB cubical 2. Ensure exclusion zone is set up around

using pickup and

unloading by using

Run over by the preparation work area and all plant

Forklift/Mobile vehicles/plants movement and checked by supervisor

crane & manual Hit by reversing 3. Traffic light batons shall be provided for

handling equipment banks man at night

Overhead 4. All plant to have a fully trained banks

obstructions man present all times.

Vehicle break 5. No plant to reverse without banks man.

down 6. Ensure access route are sufficient and

Property safe to use.

damage 7. Do not take rest in or under vehicles

Collision with 8. Proper barricade and safety signboard

other vehicles provided on open excavation

Falling objects 9. All vehicles must be fitted with reverse

Over turning of alarm / Flashing light.

Mobile 10. The work place and all access to be well

Crane/Forklift illuminated.

11. Enforce Speed limit

12. Ensure all vehicles entering the site is

properly maintained and reported if

found any defect

13. Ensure materials are secured/tied in

pallet trolley to avoid fall from trolley.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

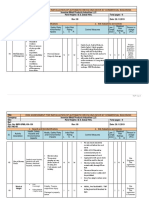

Document Reference

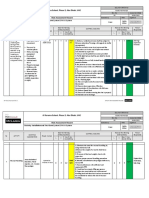

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

3

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

4

14. STARRT Card must be briefed to the

operatives

15. Mobile Crane/Forklift must be tested

and certified by 3rd party.

16. Daily Checklist to be maintained by

operator.

17. Operator must check the soil condition

before fixing mobile crane/forklift to

avoid overturning.

18. No unloading activity will carry if high

wind, rain or poor visibility.

19. Mobile Crane/ Forklift operator, rigger

and banksman’s must be competent

and certified by Abudhabi municipality

approved 3rd party.

20. Ensure that after unloading

MDB/SMDB/DB materials secured/tied

in pallet trolley to avoid fall from trolley.

21. strictly to be followed SWL during lifting

operation.

Equipment failure

Defective lifting 1) Lifting permit issued and signed off by appointed

Appointed

gears person.

Person, Lifting

Lifting of MDB Slips, trips and falls Operatives 2) Crane must be certified as fit for use within the last

2 4 4 16 High 1 4 4 Low Supervisor,

cubical Crushed between Staff/visitor 12 months by OSHAD approved third party.

Foreman,

Pinch point, 3) All lifting accessories must be certified as fit for use

Engineer

trapped body parts within 6 months by OSHAD approved third party.

Adverse weather 4) STARRT card briefing to be conducted to all

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

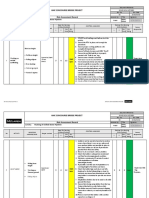

Document Reference

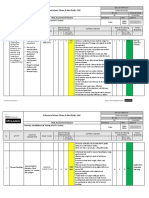

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

5

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

6

conditions workers prior to commencement of works.

Toppling of lifting 5) Before starting work, check the work area for the

equipment presence of aerial hazards (if any) and other

Falling materials obstructions.

Falling objects 6) Check the ground conditions prior to any erection

Failure of of crane

communication 7) The tail swing area must be cordoned off to avoid

Uncertified collision/crushing.

operator/Riggers 8) Install exclusion zone around lifting activity.

and lifting gears 9) Ensure that the area is being barricaded with

Overloading adequate signage

Damage to existing 10)Always ensure banksman to be present

facilities 11)The capacity of crane should be propionate with

Improper rigging the weight of the Load

and lifting practice 12)Check the load before lifting.

Uneven Ground 13)Check the lifting point and ensure that the lifting

level points are in good condition as per requirements.

Mechanical failure 14)Ensure safe rigging practices are followed under

Wear and tear of competent lifting supervisor.

lifting accessories 15)Lifting supervisor to check and verify the load

Property damaged chart.

Environment 16)Ensure that rigger and operator are aware about

contamination the signals

Serious injuries 17)Adequate padding must be provided for outriggers

including cut, as per rig configurations calculations

bruises, strain, 18)The crane should have its outriggers fully extended

sprain and fracture and be so positioned that the operator has a clear

Fatality view of the operations and rigger.

19)Lifting operations should be suspended if adverse

conditions persists and wind speed more than

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

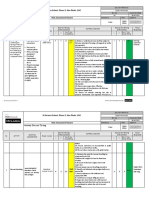

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

7

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

8

38kmph.

20)Crane inspection to be carried out prior to operate

the crane and fill the check list.

21)Pre-lift inspection to be completed for the crane

and lifting gear prior to use.

22)Rigger and operator to ensure load airway is clear

23)Ensure ground level firm, compact and free from

any impediments

24)Follow equipment’s load chart capacity

25)Never attempt to move a load greater than SWL

26)Check advance weather report.

27)Only trained and competent Operator and rigger to

appoint for task with valid third-party certificate.

28)Conduct TBT prior to start of work, discuss hazards,

risk and control measures

29)Ensure only authorized personnel within lifting

area.

30)Use tag lines to maneuver the load.

31)Ensure operatives are not moving under the

suspended load.

32)Spider beam shall be inspected and certified by

approved third party consultancy.

33)Equipment should be well maintained and out of

defect.

34)Ensure all belts unlashed prior to lift the load.

35)Do not leave the load suspended and never

stand/walk under the lifting load.

36)Initial lift of 50cm to be completed to ensure

center of gravity achieved and no loose loads

before hoisting.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

9

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

10

37)Use site mandatory PPE’s all the time.

38)Ensure all lifting gears are inspected and color

coded.

39)All lifting gears to be properly stored.

40)Ensure warning light installed on the highest point

of the crane for extended hours lifting operations.

41)Use sleeves at sharp edges to prevent damage to

the lifting gears.

42)Ensure anemometer is installed and working.

44) Ensure operator cabin is not covered with

handmade curtains.

3 Manual Handling 1 Improper Operatives Med 1. Work briefing must be conduct before Low Supervisor,

Manual Handling involved in work 3 4 12 starting the activity. 1 4 4 Foreman,

technique 2. Eliminate the need for manual handling by Site Eng.

2 Wrong Posture using mechanical aid.

3 Poor visibility 3. Operatives must be trained for safe manual

4 Lack of access & handling

egress 4. If unsure of the load weight, check with

5 Back aches supervisor.

6 Slippery surfaces 5. Ensure proper manual handling procedure

6. Ensure adherence with sufficient and

appropriate PPE.

7. Limit load carrying to 20kg per person

8. Supervisor must make sure while manual

handling loads individual task and

environment to be considered to reduce the

risk of manual handling.

9. Manual Handling assessment will be carried

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

11

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

12

by SAF 68

1. Ensure accesses are kept clear at all times.

2. Housekeeping to be carried out regularly

throughout the day when required

3. Supervisor to ensure operatives are stacking

material neatly and stacks are stable and in a

safe condition

1 Loose &

4. Provide adequate lighting especially during

unsecured Med night hours

material

5. Appropriate space is allowed around storage

2 smoking at Operatives Supervisor,

areas for employees to move around safely

storage area Staff/storekeeper Foreman,

4 Material storing 3 4 12 without the risk being trapped between 1 4 4 Low

3 Incorrect storage Site Eng.

stacked materials.

&improper

6. No smoking signage must be displayed in

materials stacking

storage area and strictly to be followed

4 Fire

smoking policy

5 Slip, Trip & Fall

7. Fire extinguisher must be available in storage

area in fore point.

8. Emergency number must display in storage

area

.

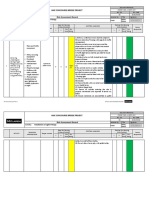

5 MDB, SMDB & DB Involved all 3 4 12 Med 1 4 4 Low Site Eng.

shifting & fixing by musculoskeletal operatives 1 Ensure that During shifting of MDB/SMDB Supervisor

using Palate Trolley/ disorders, Hand materials secured/tied in pallet trolley to avoid

manual handling Foreman

injuries, cut, fall from trolley

bruises

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

13

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

14

2 Eliminate the need for manual handling by

using mechanical aid.

3 Reduce the weight of a load to limit force

exertion

4 If unsure of the load weight, check with

supervisor.

5 Ensure sufficient illumination in work place

6 Identify and eliminate shape/sizes and weight

Sharp edges before any manual lift

Tripping hazard 7Ensure adherence with sufficient and

Fall from hand by appropriate PPE.

human error 8 Limit loads carrying to 20kg per person

9 Supervisor must make sure while manual

handling loads individual task and environment

to be considered to reduce the risk of manual

handling.

10 Ensure good house keeping

11 Ensure while manually rolling the MED cubical

there should not be any obstruction to avoid tripping

hazard.

12 make sure power cables are not trailing during

manually moving the MDB/SMDB

Falling from height Operatives/ Ladder is not to use daily basis but in certain Site Engr

Use of Ladder

6 Staff/ 3 4 12 Med cases where there is very narrow place and 1 4 4 Low Sup

Working on even podium ladder not possible to fix in that Foreman

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

15

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

16

Uneven ground cases Ladder can use if permission granted from

McLaren Safety

Falling objects 1) Only light work, off short duration and work in

which the operative can maintain secure hand

and foot hold can be undertaken form a ladder

2) Never try to overreach with any ladders

3) Check the ladder is of suitable quality for

industrial use and is in good condition

4) Maintain a minimum of 3 points of contact

with stepladders at all times (feet/thighs/hands)

If possible avoid the use of stepladders at a

working height of 2 meters and more.

5) Check the ladder legs (and stays) are fully

deployed or locked (depending on type) to

maintain maximum base dimensions and the

step ladder is orientated to provide maximum

stability.

6) Stepladders/ladders has to be used on leveled

ground/firm base

7) Ensure that during using ladder from the top 2

steps is blocked to avoid climb on that.

8) The ladder securely fixed to prevent slipping

outwards or sideways or securely footed at all

times.

9) Person must hold the ladder while another

operative working on it

8) Materials should not be placed above the

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

17

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

18

thread of ladders/step ladders

9) Do not carry any materials in one hand while

climbing or getting down from ladder

10) Ensure the area under the ladder is

barricaded especially if it is being used in a public

area.

11) Ensure the ladder is electrical insulated

podium type if working in live services

1. All portable electrical equipment must be

Damaged

PAT tested and color coded. Make sure the

Sockets & cable

test dates are visible on the equipment.

insulation.

2. Ensure all disk shall be appropriate and

Electrocution

expiry date is over.

Electric shock

3. Ensure all power tools are in good condition

Short circuit &

and appropriately maintained

Use of power Burns Supervisor

Operatives and 4. Damaged industrial sockets and power

7 tools such as Drill Trip/Fall 3 4 12 Med 1 4 4 Low Foreman

staff cables must be removed.

machine/Grinder Noise Site Eng.

Hearing loss 5. Ensure the electrical cable is not damaged

Vibration and has not been repaired with insulating

Dust tape or unsuitable connectors.

6. Ensure cables from power tools shall be

organized so as not to present a tripping

hazard

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

19

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

20

7. Only trained competent operatives to

operate the power tools.

8. Ensure proper and regular maintenance of

equipment that takes account of noise

9. Ensure proper hearing protection always.

10.Make sure Face shield in use while using

rotating tools.

11.Ensure defective tools that require

maintenance is reported for repair or

replacement.

12.Instruct workers to keep their hands warm

and dry, and to not grip a vibrating tool too

tightly.

13. Hot work permit should have obtained if

using Hole saw cutter for Glanding hole.

14.Fire extinguisher/Fire blanket must be in

place

15.Fire watcher must monitor the hot work area

and he will not move until there is any smoke

or heat.

16.Ensure proper earth leakage protection is

provided

17. Power tools must be 110V and if use above

110 volts need to obtained Elec Permit.

8 Adverse weather Rain, All employee, 4 4 16 High 1 Weather report must be updated and informed 1 4 4 Low Site Eng.

condition Sand Storm visitors to work force if there is any prediction about Sup

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

21

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

22

adverse weather.

2 No activity shall be allowed during adverse

weather condition on site

3 Protect the Power tools/DB from rain water to

Fog

avoid short circuit.

Slippery surface

4 Ensure during adverse weather or Foggy

Risk of

weather no lifting operation and no vehicle

electrocution

movement. Foreman

Flying debris,

5 After clear the weather make sure all power

Slip, Tripping and

tools are safe to use.

fall

6 No work at height during high wind and rain

7 In case of emergency, call McLaren/Emergency

number

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

23

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

24

1. Ensure proper night work permit is obtained

2. Proper lighting system should be in place

3. Ensure proper Communication / Coordination

and close supervision

Poor visibility Operatives/staff

4. Industrial safe torches to be available for

due to darkness emergency situations

Working at night 5. High visibility Traffic Vest for personnel’s in

/ poor Supervisor

9 time 3 4 12 Med night shift 1 4 4 Low

illumination Foreman

Lone worker 6. Avoid lone working and always ensure buddy

system while working at night

7.Employees to be trained and understand

McLaren Crises plan.

9 Use of Hand tools Improper 3 3 9 Med 1 Hand tools should be visually inspected for 1 3 3 Low

selection of defects, prior to use.

hand tools. 2 Never use damaged, blunt or broken tools to

Damaged and avoid injury.

Defective Hand 3Select right tools for right Job Site Engr

tools. 4 Ensure no Homemade or makeshift tools to be Supervisor

Hand injuries Operatives/Staff used at site Foreman

Pinch point 5Remove from service any tool that shows signs

Ergonomics of damage or defect

Repetitive 6Ensure Hand tools are Stored in accordance

strain injury with the manufacturer’s instructions.

7Ensure hands are not in direct line of fire while

working with hand tools

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2 Abu Dhabi, UAE M1492-HSE-RA-026

Rev. No. Assessment Date

00 30/03/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Installation of MDB, SMDB & DB Safety

Prabir

Officer

25

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

26

8Ensure appropriate PPE at all times.

4

5 Approved By: Name Vishnu Mohan Position PM _________ Signature _________ ___________

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

6

7 RISK ASSESSMENT & CONTROL GUIDELINES

8

9 1. Executing Steps:

10 1.1. Planning

11 a) Construction and HSE team must ensure that hazard identification is complete.

12 b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks

13 have well established legal requirements, potentially high risks).

14 c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these

15 potential high risks.

16 1.2. Risk Assessment

17 Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The

18 hazard is the potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an

19 event occurring, but also the outcome will be in terms of injury, loss, damage or harm.

20 1.3. Risk Assessment Process

21 The process of carrying out a risk assessment should be as follows.

22 1. Identify the hazards.

23 2. Identify who might be harmed and how.

24 3. Evaluate the risk and implement the control measures.

25 4. Record the significant findings.

26 5. Review the assessment and update if necessary.

27 1.4. Examination of the Hazards and Risk Associated

28 Competent staff must be used in examining the risk associated with the identified hazard.

29 Competent staff should examine following aspect to determine the risk involved:

30 o Examine the existing control measures in place.

31 o Identify employees at risk.

32 o Likelihood of risk.

33 o Severity

34 o Risk level and their tolerability.

35 1.5. Evaluating the risk:

36 Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to

37 access the risks.

38 1.5.1. Risk Rating Score

39 Risk rating score is a combination of two factors.

40 The severity of the risk that could injure persons or cause damage to plant.

41 The likelihood of the risk that it could happen (Probability).

42

43 RISK RATING = LIKELIHOOD X SEVERITY

44 NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in

45 the table below. SEVERITY

46

No Injury Minor Moderate Major Catastrophic

47

(1) Injury (2) Injury (3) Injury (4) (5)

48 LIK

49 ELI 1 2 3 4 5

Rarely (1)

50 HO

51 OD Unlikely (2) 2 4 6 8 10

52 Possible (3) 3 6 9 12 15

53

54 Likely (4) 4 8 12 16 20

55 Almost

56 Certain (5)

5 10 15 20 25

57 RISK LEVEL:

Low Medium High

58

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

59

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

You might also like

- RISK ASSESSMENT Installation and Testing of Access Control SystemDocument11 pagesRISK ASSESSMENT Installation and Testing of Access Control SystemAnandu Ashokan100% (3)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Sanitary Fixtures Risk AssessmentDocument12 pagesSanitary Fixtures Risk AssessmentAnandu Ashokan100% (1)

- Risk Assessment For Installation of SMDB DBDocument12 pagesRisk Assessment For Installation of SMDB DBRAMA100% (1)

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Document12 pagesRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Installation of Fire Fighting Pipes Risk AssessmentDocument15 pagesInstallation of Fire Fighting Pipes Risk AssessmentAnandu Ashokan80% (5)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 pagesRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan94% (17)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 pagesRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsAnandu Ashokan88% (8)

- Pump Installation Risk AssessmentDocument17 pagesPump Installation Risk AssessmentAnandu Ashokan75% (8)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Risk Assessment For Installation and Testing of CCTVDocument11 pagesRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (4)

- Risk Assessment For Installation of Fire Fighting SystemDocument14 pagesRisk Assessment For Installation of Fire Fighting SystemMohamed Elhadad100% (5)

- Risk Assessment For Pressure TestingDocument13 pagesRisk Assessment For Pressure TestingAnandu Ashokan80% (5)

- Risk Assessment For CABLE TRAYDocument11 pagesRisk Assessment For CABLE TRAYAnandu Ashokan86% (14)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 pagesRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 pagesRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Risk Assessment For Testing & Commissioning of Fire Fighting SystemDocument17 pagesRisk Assessment For Testing & Commissioning of Fire Fighting SystemAnandu Ashokan92% (12)

- Risk assessment for automatic revolving doorsDocument8 pagesRisk assessment for automatic revolving doorssabirbdk100% (1)

- Risk Assessment For MEP Services in P6 Existing ParkingDocument16 pagesRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasNo ratings yet

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument8 pagesRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (8)

- Risk Assessment For Flushing of Chilled Water PipingDocument9 pagesRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanNo ratings yet

- Risk Assessment For Dismantling of Temporary ServicesDocument17 pagesRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNo ratings yet

- RISK ASSESSMENTDocument8 pagesRISK ASSESSMENTEm Niax100% (1)

- RA For Installation of Air Colled ChillersDocument8 pagesRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 pagesRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- MS For Installation of Light FittingsDocument11 pagesMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Risk Assessment - FM 200Document5 pagesRisk Assessment - FM 200Nangyal KhanNo ratings yet

- Health and Safety Risk AssessmentDocument7 pagesHealth and Safety Risk Assessmentamal100% (3)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- Risk assessment for conduit pipe installationDocument17 pagesRisk assessment for conduit pipe installationJayson Escamillan75% (4)

- Risk Assessment For MEP Isolation WorksDocument8 pagesRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (5)

- Risk Assessment For Installation of Drainage Pipes and FittingsDocument8 pagesRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (1)

- Risk Assessment For Installation of SMDB&DBDocument15 pagesRisk Assessment For Installation of SMDB&DBAnandu Ashokan78% (9)

- Installation of Earthing SystemDocument9 pagesInstallation of Earthing SystemamalNo ratings yet

- Risk Assessment for Lifting OperationsDocument2 pagesRisk Assessment for Lifting OperationsPrem Shiva100% (1)

- Risk Assessment For Cable TrayDocument11 pagesRisk Assessment For Cable Traynellaika puspa dewiNo ratings yet

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- RA For Hvac Duct InstallationDocument10 pagesRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- Ra - Water Tank CleaningDocument3 pagesRa - Water Tank CleaningYousaf Richu50% (2)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 pagesRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (2)

- Risk Assessment For Installation of Air Handling UnitsDocument19 pagesRisk Assessment For Installation of Air Handling UnitsAnandu Ashokan100% (8)

- Risk Assessment (Installation of Cables & Wires)Document6 pagesRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- Risk Assessment For Water Heaters InstallationDocument6 pagesRisk Assessment For Water Heaters Installationfidgety100% (1)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsHerdhiska Pradhiarta AjiprayogaNo ratings yet

- Risk Assessment For Temporary ServicesDocument15 pagesRisk Assessment For Temporary Servicesfaizan khan100% (2)

- ETIHAD SOUTHSIDE CATERING ELECTRICAL TESTINGDocument81 pagesETIHAD SOUTHSIDE CATERING ELECTRICAL TESTINGAnandu AshokanNo ratings yet

- SAT of MV Cables (GEN)Document18 pagesSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- SAT of Earthing & Lightning Protection System (GEN)Document15 pagesSAT of Earthing & Lightning Protection System (GEN)Anandu AshokanNo ratings yet

- Ara-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Document15 pagesAra-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Anandu AshokanNo ratings yet

- SAT of Final Small Power & Lighting Circuits (GEN)Document13 pagesSAT of Final Small Power & Lighting Circuits (GEN)Anandu AshokanNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- DCPRO Submittal Response Sheet ReviewDocument1 pageDCPRO Submittal Response Sheet ReviewAnandu AshokanNo ratings yet

- Master Log - LOGDocument15 pagesMaster Log - LOGAnandu AshokanNo ratings yet

- M1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerDocument63 pagesM1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerAnandu AshokanNo ratings yet

- M1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BDocument72 pagesM1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BAnandu AshokanNo ratings yet

- M1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityDocument24 pagesM1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityAnandu AshokanNo ratings yet

- Etihad Southside Catering Facility Lockout Tagout Method StatementDocument24 pagesEtihad Southside Catering Facility Lockout Tagout Method StatementAnandu AshokanNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningDocument27 pagesm1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- Installation of Sanitary Fixtures MixersDocument44 pagesInstallation of Sanitary Fixtures MixersAnandu AshokanNo ratings yet

- Water Filtration System - Method StatementDocument7 pagesWater Filtration System - Method Statementsunil_v575% (4)

- Testing Commissioning Fire Fighting SystemsDocument47 pagesTesting Commissioning Fire Fighting SystemsAnandu AshokanNo ratings yet

- Risk Assessment for Fire Alarm IntegrationDocument49 pagesRisk Assessment for Fire Alarm IntegrationAnandu AshokanNo ratings yet

- Harmonic Measurement Risk AssessmentDocument41 pagesHarmonic Measurement Risk AssessmentAnandu AshokanNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- Installation and Testing Commissioning of PumpsDocument60 pagesInstallation and Testing Commissioning of PumpsAnandu Ashokan100% (1)

- Testing Commissioning of HVAC SystemDocument53 pagesTesting Commissioning of HVAC SystemAnandu Ashokan100% (4)

- Installation of Toilet Exhaust FansDocument51 pagesInstallation of Toilet Exhaust FansAnandu AshokanNo ratings yet

- Rerouting of Existing MEP Services in New SubstationDocument52 pagesRerouting of Existing MEP Services in New SubstationAnandu AshokanNo ratings yet

- Installation of Grill Diffuser LouversDocument51 pagesInstallation of Grill Diffuser LouversAnandu AshokanNo ratings yet

- MSS Approvals Required for HVAC InstallationDocument102 pagesMSS Approvals Required for HVAC InstallationAnandu AshokanNo ratings yet

- Installation of Underground Electrical-ELV DuctDocument41 pagesInstallation of Underground Electrical-ELV DuctAnandu AshokanNo ratings yet

- On of Smart Crab Water Monitoring System Using ArduinoDocument46 pagesOn of Smart Crab Water Monitoring System Using ArduinoLayla GarciaNo ratings yet

- Acromegaly: Excess Growth Hormone SecretionDocument4 pagesAcromegaly: Excess Growth Hormone SecretionKavita PathakNo ratings yet

- The Morning Calm Korea Weekly - Oct. 14, 2005Document26 pagesThe Morning Calm Korea Weekly - Oct. 14, 2005Morning Calm Weekly NewspaperNo ratings yet

- Piston Water MeterDocument2 pagesPiston Water MeterMark PamularNo ratings yet

- SCR10-20PM Compressor ManualDocument36 pagesSCR10-20PM Compressor ManualTrinnatee Chotimongkol100% (2)

- Convey 1996Document8 pagesConvey 1996Moises Tinte100% (1)

- Which Statement On Physical Development of Infants and Toddlers Is TRUEDocument9 pagesWhich Statement On Physical Development of Infants and Toddlers Is TRUEKristylle Renz100% (1)

- Optimized Die Steel Reference GuideDocument16 pagesOptimized Die Steel Reference GuideKeattikhun ChaichanaNo ratings yet

- 可汗语法48篇(明志教育推荐) PDFDocument163 pages可汗语法48篇(明志教育推荐) PDFtellmewhour100% (2)

- There Came A Gypsy RidingDocument45 pagesThere Came A Gypsy RidingMartin McNelisNo ratings yet

- Sheath CurrentsDocument5 pagesSheath Currentsscribdkkk100% (1)

- HANDOUT - Cell Transport Review WorksheetDocument4 pagesHANDOUT - Cell Transport Review WorksheetDenis Martinez100% (1)

- RA 6541 National Building Code of The PH StandPipeDocument5 pagesRA 6541 National Building Code of The PH StandPipejungzki jungzkiNo ratings yet

- Model Analysis: Presented By: Nikhil V Jose Dept. of OrthodonticsDocument103 pagesModel Analysis: Presented By: Nikhil V Jose Dept. of OrthodonticsDr Nikhil jose100% (1)

- Subsea Cable Floats: Rising To Your Undersea ChallengesDocument1 pageSubsea Cable Floats: Rising To Your Undersea ChallengesMAURICIO DE LOS SANTOS HERNANDEZNo ratings yet

- Pds - Sunshades Instrument CoverDocument2 pagesPds - Sunshades Instrument CoverAntonio LantiguaNo ratings yet

- Specification for Child MUAC Tape Quality ChecksDocument4 pagesSpecification for Child MUAC Tape Quality ChecksM HussainNo ratings yet

- Periodontal DiseaseDocument4 pagesPeriodontal Diseasemojako_badboysNo ratings yet

- Awwa-C302 (1995)Document28 pagesAwwa-C302 (1995)masoudNo ratings yet

- The Pediatric Mandible I. A Primer On Growth and DevelopmentDocument10 pagesThe Pediatric Mandible I. A Primer On Growth and DevelopmentJulián David Ríos ZuluagaNo ratings yet

- APA Style Guide for Student PapersDocument24 pagesAPA Style Guide for Student PapersHeureuse MamanNo ratings yet

- 7Document40 pages7Felipe RichardiosNo ratings yet

- Microwave TubesDocument36 pagesMicrowave TubesHINDUSTAN KNOW 1No ratings yet

- 8.1 - Production and Diagnostic Use of UltrasoundDocument3 pages8.1 - Production and Diagnostic Use of UltrasoundTakudzwa Antony MasendekeNo ratings yet

- Ujian Sains Tingkatan 2Document10 pagesUjian Sains Tingkatan 2SITI ZAIDAH AHMAD50% (6)

- Aminacid MetabolismDocument84 pagesAminacid MetabolismAaronJose100% (1)

- Global Leader: in Glass IonomerDocument2 pagesGlobal Leader: in Glass IonomerAnggini ZakiyahNo ratings yet

- Importance of Fish in Our Daily LifeDocument3 pagesImportance of Fish in Our Daily Lifekamei321No ratings yet

- Case Study in Competency Appraisal II - ABC and EDNDocument5 pagesCase Study in Competency Appraisal II - ABC and EDNRogelio Saupan Jr100% (1)

- Premium detergent market insights and Nirma case studyDocument32 pagesPremium detergent market insights and Nirma case studyBhavya ShahNo ratings yet