Professional Documents

Culture Documents

Risk Assessment For Installation of Drainage Pipes and Fittings

Uploaded by

faizan khanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment For Installation of Drainage Pipes and Fittings

Uploaded by

faizan khanCopyright:

Available Formats

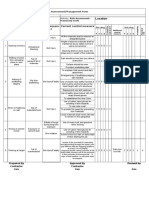

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Contract Name: Construction of Bird Breeding Building and VIP Majlis Contract No: P-001819000

Risk Assessment for ☒ Routine Activity ☐ Non-Routine Activity Assessment Date: 18-02-2020

Activity: Installation of Drainage Pipes and Fittings Rev Date: 17-08-2020

Degree of Residual Risk

Risk Person

Sub-Activity Hazard Who is at Risk Consequence (s) Control Measure (s)

Responsible

L S R L S R

Entering to 1.Without All project 1.Minor or major 3 3 9 1. All the project personnel must be holding a 2 3 6 Site Engineer

the project safety involved injury valid Visa, and emirates ID. EHS Inspector

site Induction personnel 2. All the operatives shall be wearing suitable

2.Entering the PPE, s hand glove, safety helmet, high

reflective safety jacket, and safety goggles.

site without

3. The operative must be undergone client

PPE’s /internal HSE induction training prior to

3.Unaware of starting the task at the site.

the site 4. All the operatives must stay inside the

condition project premises.

4. Entering to 5.Ensure no operatives will enter restricted

the restricted area bird/dog and other pet cages

area. 6. The site supervisor must be delivered the

5.Snake & specific TBT to all involved operatives Do, s

and don’ts, emergency preparedness, snake

venomous

bit etc.

7. Specific safety signage’s must be placed for

project personnel awareness.

8. All the visitors must be reported to the

project security gate.

9. Photography strictly prohibited inside the

project premises.

10. Treat all snakes as if they are venomous,

report immediately concern supervisor.

11. Don’t killed or injured snake or any

venomous.

12. The responsible person must be

undergone snake bit training and full time

available on site, required first aid treatment

resources must be available on site

IMSP-17 Page 1 of 8 IMS 08/2019

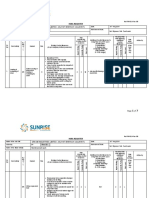

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

13. Project emergency contact numbers must

be displayed at the site.

14. Ensure nearby assembly point.

Delivering, Plant and Operatives 1.Minor or major 3 3 9 1. Delivery/ collection drivers shall be 2 3 6 Site supervisor

unloading and Traffic Staff/visitors injury subject to project induction/Training

storing of PVC movement 2.Property with regards to traffic management.

Pipe & fittings damage 2. Ensure exclusion zone is set up

using pickup Run over by 3Musculoskeletal around the preparation work area

and unloading vehicles/pla disorders and all plant movement and

by manual nts 4Hand injuries, monitored by certified Banksman

handling Hit by 5. Cut, bruises 3. Always use the pedestrian access

reversing provided

equipment 4. Traffic light batons shall be provided

Overhead for banks man at night

obstructions 5. All plant to have a fully trained &

Vehicle certified banks man present all times.

break down 6. No plant to reverse without banks

Property man.

damage 7. Ensure access route are sufficient and

Collision safe to use.

with other 8. Use Pallet Trolley for PVC Pipes

vehicles shifting.

Personal 9. All vehicles must be fitted with

injury reverse alarm / Flashing light.

10. The work place and all access to be

well illuminated.

11. Identify and eliminate sharp edges

before any manual lift

12.Enforce Speed limit as per site rules.

13. Supervisor must make sure while

manual handling loads individual task and

environment to be considered to reduce

the risk of manual handling

14. Ensure all vehicles entering the site is

properly maintained and reported if

found any defect

15. The load allowed for a worker does

IMSP-17 Page 2 of 8 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

not exceed more than 20 kg.

16. PPE in use full time.

Material Slips, Trips and Head Injury due 3 3 9 1.Ensure accesses are kept clear always. 1 3 3 Site Supervisor

storing fall Operatives to tripping 2.Housekeeping to be carried out Store Keeper

Poor Staff/storekeeper Hazard regularly throughout the day when

housekeeping/n Property Damage required

arrow access

3.Supervisor to ensure operatives are

stacking material neatly and stacks are

stable and in a safe condition

4.Provide adequate lighting especially

during night hours

5. Appropriate space is allowed around

storage areas for employees to move

around safely without the risk being

trapped between stacked materials.

6. Maintain good housekeeping.

7.Fire Extinguisher in place and do not

obstruct with materials

8. No smoking and no loose connection in

storage area

9. Make sure PVC pipes should not

scatted with other materials and properly

stacked to avoid rolling.

IMSP-17 Page 3 of 8 IMS 08/2019

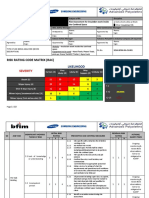

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Installation of 1. Fall from Electrician 1Eye injury Cuts. 3 4 12 1.Only trained and authorised personnel 1 4 4 Site Engineer,

PVC Pipes and height Helpers Broken Limbs. to carry out the task. Supervisor,

accessories 2. Over loading All Personnel 2Fingers, Arms 2. Ensure the PTW in place. Foreman

fittings using 3 Slip, trip/Fall involved and hand in the 3. Ensure proper working platform with

mobile 4 Protruding long term to complete fall protection

Tower/Ladder disability cuts of 4. Ensure safe access to the working

body parts. platform.

Cuts. Broken 5. Ensure Full body harness and 100% Tie

Limbs, off

3Injuries/ Property 6. Ensure the scaffold platform is

damage properly erected with "Safe to use" tag.

4Deep 7. Ensure castor wheels are locked and

lacerations, cuts. out rigger in place

8. Work materials strictly not allowed to

be stored on work plat form except for

working tools

9. Tools must be secured while working

on height

10. Maintain 3point contact while

accessing A Type ladder.

11. Use PPE and use Gumboots if

underground work in water

12. Maintain good housekeeping to

avoid Slip, Trip and Fall

13. Ensure that not to injured in finger

during using hit gun for joint in PVC Pipe.

14. Ensure hot work permit obtained for

using Hit Gun and fire extinguisher in

place

15. Ensure while fittings the GI clamp

and brackets operatives must safely use

drill machine to avoid finger injury .

16.Ensure underground drainage pipe

should proper backfill and should not

leakage /flooding

IMSP-17 Page 4 of 8 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Spillage/ soil Operatives using Skin allergy 3 4 12 1. Ensure that all chemical substances 1 4 4 Supervisor

Use of Glue contaminatio solvent/Supervis Inhalation have a COSHH assessment Foreman

Solvent, n or/visitor Injection 2. Refer SDS prior to any handling of

(Hazardous Environment hazardous substances and ensure

Substance Burns contamination SDS is easily accessible at site while

Contact with working with chemicals.

skin 3. Ensure chemicals are properly

stacked.

Acute/ 4. Ensure all chemical containers are

Chronic properly labeled.

adverse 5. Spill kits to be available at site.

heath effect. 6. Ensure operatives use the correct

PPE

7. Competent person to oversee the

storage, use and disposal of

hazardous materials.

8. Ensure that correct welfare/first aid

facilities are available in the area i.e.

washing facility/eye wash.

9. Ensured drip tray in use for solvent

storing.

10 Ensure all chemical containers are

properly labeled.

11.Adjust work schedules so that

workers are not overexposed to a

hazardous chemical.

12 Wear respiratory protection

13 Ensure smoking only in designated

area

14. Ensure appropriate Firefighting

equipment’s are in place and easily

accessible

IMSP-17 Page 5 of 8 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Use of power 1. Unsafe use All 1.Minor or major 3 4 12 1. All portable electrical equipment must 1 4 4 Site supervisor

tools such as of hand tools. operatives/supe injuries be PAT tested and color coded. Make

Grinder/Drill/ 2. Dust / flying rvisor/visitors 2.Property sure the test dates are visible on the

Hit Gun particles. Damage equipment

3. Fall of 2. PTW shall be obtained prior to

materials commencing the task.

4.Electric shock 3. Ensure operatives use suitable PPE, s

Head protection, hand protection,

respiratory protection, and eye

protection.

4. Ensure enough fire extinguishers shall

be available at the site.

5. Effective supervision in place to guide

the team members.

6. Ensure Proper insulation/shockproof

of power tools.

7. Ensure proper conditions of electrical

cables, switchboards and electrical

connections.

8. Ensure power tools have safety guards

in place especially for grinding machines.

9. Ensure all the power tools are safe to

use.

10. Grinder must have safety guard and

auxiliary handle.

11. Fire extinguisher in place with fire

watcher

12. Ensure that electrical supply must be

taken from certified DB.

13. Use face shield while using abrasive

wheel.

14. Power tools must be check by store

keeper before issuing to site.

15. Ensure color coding for the power

tools are maintained and maintaining

monthly inspection checklist.

IMSP-17 Page 6 of 8 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

External work 1.Minor or major 4 4 16 1)Ensure adequate PPE’s 2 4 8 Site supervisor

Adverse High wind, Operatives injury 2) Provision for availability of drinking

weather sand storm, involved in work 2. Property water at work location.

condition fog damaged. 3) Take rest in frequent intervals

Direct Sunlight 3.Heat stress 4) In case High wind stop the activity

4.Heat Stroke until stop the storm.

5) Sufficient shaded rest area with

adequate ventilation available at work

location

6) Heat stress awareness training

conducted.

7) Site Emergency contact number

Should have displayed and ensuring all

employees are aware of it.

8) Avoid working on direct heat.

9) All operatives must have aware First

Aid location.

IMSP-17 Page 7 of 8 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Use of Hand Improper All Operatives Hand injuries 3 3 9 1. Hand tools should be visually 1 3 3 Supervisor

tools selection of Pinch point inspected for defects, prior to use. Foreman

hand tools. Ergonomics 2. Never use damaged, blunt or broken

Damaged and tools to avoid injury.

Defective Hand 3. Select right tools for right Job

tools 4.Ensure no Homemade or makeshift

Improper use tools to be used at site

of hand tools 5. Remove from service any tool that

shows signs of damage or defect

6. Ensure Hand tools are Stored in

accordance with the manufacturer’s

instructions.

7. Ensure hands are not in direct line of

fire while working

PREPARED BY (QC Engr)

REVIEWED BY (HSE Engr)-Genfocus REVIEWED BY LBS APPROVED BY (Engineering Office)

Genfocus

Name: Anandu Name: Prabir Kumar Name: Name:

Designation Designation: Designation: Designation:

:Signature: Signature: Signature: Signature:

IMSP-17 Page 8 of 8 IMS 08/2019

You might also like

- Risk Assessment For Water Heaters InstallationDocument6 pagesRisk Assessment For Water Heaters Installationfidgety100% (1)

- Risk Assessment of Block Works and Plastering WorksDocument7 pagesRisk Assessment of Block Works and Plastering Worksfaizan khanNo ratings yet

- Project HS Risk AssessmentDocument8 pagesProject HS Risk AssessmentParasNo ratings yet

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 pagesRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanNo ratings yet

- Risk Assessment Sheet For Installation of Wooden DoorsDocument3 pagesRisk Assessment Sheet For Installation of Wooden Doorsrajat100% (1)

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- Brick WorkDocument1 pageBrick WorkGyanendra Narayan NayakNo ratings yet

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDocument2 pagesJob Safety Analysis (JSA) - CONCRETE WORKS - DatenabeelNo ratings yet

- Shuttering WorksDocument3 pagesShuttering WorksAbdul GhaffarNo ratings yet

- Hira For Pipe Coating Monsher Fire Protectioin System P. L.Document31 pagesHira For Pipe Coating Monsher Fire Protectioin System P. L.Nikhil ManjrekarNo ratings yet

- SWMS - HVAC ShiftingDocument6 pagesSWMS - HVAC ShiftingParas100% (1)

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- Risk Assessment of Concrete PouringDocument13 pagesRisk Assessment of Concrete PouringAbdul MujeebNo ratings yet

- Job Hazard Analysis PermitDocument1 pageJob Hazard Analysis PermitKhorchnoi Abaja CalimlimNo ratings yet

- RA - Plumbing Works Rev. BDocument8 pagesRA - Plumbing Works Rev. BResearcherNo ratings yet

- Insulation of Ducting and PipingDocument1 pageInsulation of Ducting and PipingKrishna Patil100% (1)

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal PattanayakNo ratings yet

- 10 - Example Risk Assement Cladding InstallationDocument3 pages10 - Example Risk Assement Cladding InstallationAhmed Tarek67% (3)

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadNo ratings yet

- Installation of Diesel GeneratorDocument12 pagesInstallation of Diesel Generatoramal100% (1)

- Risk Assessment For Use of Power ToolsDocument2 pagesRisk Assessment For Use of Power ToolsRicardo DalisayNo ratings yet

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- 005 Risk Assessment T&C Fire Suppression SystemDocument10 pages005 Risk Assessment T&C Fire Suppression SystemJohn RazaNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- RA 002 - Mechanical ExcavationDocument2 pagesRA 002 - Mechanical ExcavationZaki Abdullah ALQweaenNo ratings yet

- Hira Plastering Finishing WorkDocument2 pagesHira Plastering Finishing WorkDwitikrushna Rout0% (1)

- JSA PlumberDocument2 pagesJSA PlumberSyed Yousuf AliNo ratings yet

- Risk Assessment - Installation of Exhaust FansDocument4 pagesRisk Assessment - Installation of Exhaust FansehteshamNo ratings yet

- Risk Assessment Construction of Lighting Pole at Site OfficeDocument9 pagesRisk Assessment Construction of Lighting Pole at Site OfficeSinaNo ratings yet

- Risk Assessment For Earthing Work-R1Document3 pagesRisk Assessment For Earthing Work-R1Azhar Mushtaq75% (4)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument7 pagesRisk Assessment For Installation of Automatic Revolving Door InstallationTECHCOM100% (1)

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (1)

- Safe Work Method Statement: (See Below)Document7 pagesSafe Work Method Statement: (See Below)Siddharth P100% (2)

- Construction Safety: Page 1 of 4Document4 pagesConstruction Safety: Page 1 of 4ryan.aniceteNo ratings yet

- HIRA - Height WorkDocument3 pagesHIRA - Height WorkHiralal Pattanayak100% (2)

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- Insignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicDocument6 pagesInsignificant (2) Minor (3) Moderate (4) Major (5) Catastrophicabhinav dj50% (2)

- 04 HIRA For Reinforcement WorkDocument7 pages04 HIRA For Reinforcement WorkMithlesh Singh100% (1)

- RA For Man Lift OperationDocument6 pagesRA For Man Lift Operationalla malikNo ratings yet

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDocument8 pagesInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu67% (3)

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- 007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationDocument5 pages007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationJahan Zaib50% (2)

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- Risk Assessment For Excavation and BackfillingDocument4 pagesRisk Assessment For Excavation and BackfillingShazayn Khan100% (1)

- Confined Space Entry - SH&E Risk Assessment: Middle EastDocument5 pagesConfined Space Entry - SH&E Risk Assessment: Middle EastyahiyaNo ratings yet

- Deshuttering WorkDocument1 pageDeshuttering WorkAhmed AbdulfatahNo ratings yet

- JSA - Civil Compaction WorkDocument4 pagesJSA - Civil Compaction WorkRajuNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildanNo ratings yet

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayNo ratings yet

- Risk Assesment Form ScaffoldDocument10 pagesRisk Assesment Form ScaffoldRejin PradeepNo ratings yet

- Risk Assessment For Installation of Cable Tray & TrunkingDocument7 pagesRisk Assessment For Installation of Cable Tray & Trunkingfaizan khanNo ratings yet

- Method Statement (2) - 14-11-2020Document21 pagesMethod Statement (2) - 14-11-2020faizan khanNo ratings yet

- Risk Assessment For Working On Mobile TowerDocument5 pagesRisk Assessment For Working On Mobile Towerfaizan khanNo ratings yet

- Blockwork and Plastering WorksDocument12 pagesBlockwork and Plastering Worksfaizan khanNo ratings yet

- Method Statement For Painting Works: ProjectDocument9 pagesMethod Statement For Painting Works: Projectfaizan khan100% (1)

- Risk Assessment For Installation of Cable Tray & TrunkingDocument7 pagesRisk Assessment For Installation of Cable Tray & Trunkingfaizan khanNo ratings yet

- Risk Assessment For Installation of Air OutletsDocument8 pagesRisk Assessment For Installation of Air Outletsfaizan khanNo ratings yet

- Risk AssessmentDocument16 pagesRisk Assessmentfaizan khan50% (2)

- Carefour RA-For Tile & Granite WorksDocument10 pagesCarefour RA-For Tile & Granite Worksfaizan khan100% (3)

- Carefour RA-For Suspended Gypsummetallic Tiles Celling WorksDocument8 pagesCarefour RA-For Suspended Gypsummetallic Tiles Celling Worksfaizan khanNo ratings yet

- Carefour RA-For Block Works and Plastering WorksDocument17 pagesCarefour RA-For Block Works and Plastering Worksfaizan khanNo ratings yet

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- LBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)Document10 pagesLBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)faizan khanNo ratings yet

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- Risk Assessment For Installation of Ventilation FansDocument5 pagesRisk Assessment For Installation of Ventilation Fansfaizan khanNo ratings yet

- Risk Assessment For Temporary ServicesDocument15 pagesRisk Assessment For Temporary Servicesfaizan khan100% (2)

- Method Statement For Installation of Temporary ServicesDocument22 pagesMethod Statement For Installation of Temporary Servicesfaizan khanNo ratings yet

- Instrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Document88 pagesInstrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Raj ChavanNo ratings yet

- Excess Saving Statement 09.03.2023Document242 pagesExcess Saving Statement 09.03.2023RASCON BUILDNo ratings yet

- Basic Principles of Sanitary DesignDocument16 pagesBasic Principles of Sanitary DesignDeniell Kahlil Kyro Gabon100% (2)

- List of Registered Plastic Recycling UnitsDocument22 pagesList of Registered Plastic Recycling UnitsEaswari PrabhuNo ratings yet

- Process For The Polymerization of Vinyl ChlorideDocument32 pagesProcess For The Polymerization of Vinyl ChlorideThu TongNo ratings yet

- TES P 119 19 r0Document43 pagesTES P 119 19 r0omar100% (1)

- Sika®-Waterstop GDocument4 pagesSika®-Waterstop Gvertigo100% (1)

- Sikaplan 14.6 - Flexible PVC For TunnelsDocument2 pagesSikaplan 14.6 - Flexible PVC For TunnelsmystrophanNo ratings yet

- Packaging of Fresh and Processed MeatDocument20 pagesPackaging of Fresh and Processed MeatShriraj ThatteNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument11 pagesSafety Data Sheet: 1. IdentificationZamriNo ratings yet

- 570-C35 P&C Potable Water Pump Station in MutrafiahDocument226 pages570-C35 P&C Potable Water Pump Station in MutrafiahMMFAWZYNo ratings yet

- 2014 - 008 Domestic Cold Water Supply SystemDocument94 pages2014 - 008 Domestic Cold Water Supply SystemPrinceEnopiaNo ratings yet

- Der 332Document9 pagesDer 332bd1972No ratings yet

- CPRI ReportDocument104 pagesCPRI ReportPavan KhetrapalNo ratings yet

- PT PLN (Persero) : 1 Based On Konsinyering Dated 11 Oct 2021 0 Original IssueDocument18 pagesPT PLN (Persero) : 1 Based On Konsinyering Dated 11 Oct 2021 0 Original IssueFaizal SetiawanNo ratings yet

- Plastic ManufacturingDocument31 pagesPlastic ManufacturingDipika KumariNo ratings yet

- Sterrad 50 Users GuiseDocument78 pagesSterrad 50 Users GuiseJose MorenoNo ratings yet

- Belden 8723 DatasheetDocument3 pagesBelden 8723 DatasheetBibiana LealNo ratings yet

- Iplex PVC U Pressure Series 1 Pipe DimensionsDocument1 pageIplex PVC U Pressure Series 1 Pipe Dimensions许爱文No ratings yet

- Project Introduction PipeDocument3 pagesProject Introduction Pipepankaj24x7No ratings yet

- Price ListDocument22 pagesPrice ListNeil Ang75% (4)

- CH 13Document102 pagesCH 13Alex BjNo ratings yet

- GTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5Document3 pagesGTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5santhoshNo ratings yet

- PVC ValveDocument28 pagesPVC ValveVincent Ferrer NironNo ratings yet

- Comparisons Between GRP Pipes With Various Metallic by NadeemDocument16 pagesComparisons Between GRP Pipes With Various Metallic by NadeemAli ZarehNo ratings yet

- CableDocument13 pagesCablejugnudubeyNo ratings yet

- Vinh An - Building Applicaton-EnDocument13 pagesVinh An - Building Applicaton-EnCuong Pham HuyNo ratings yet

- A200cos BDocument2 pagesA200cos BClaudia LopezNo ratings yet

- Argus DeWitt PolymersDocument9 pagesArgus DeWitt Polymersdrmohamed120No ratings yet

- Upvc Doors and Windows MakingDocument39 pagesUpvc Doors and Windows MakingVivekanandaSharmaLanka80% (15)