Professional Documents

Culture Documents

Risk Assessment For Installation of Cable Tray & Trunking

Uploaded by

faizan khan0 ratings0% found this document useful (0 votes)

146 views7 pagesOriginal Title

Risk assessment for Installation of Cable Tray & Trunking

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

146 views7 pagesRisk Assessment For Installation of Cable Tray & Trunking

Uploaded by

faizan khanCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 7

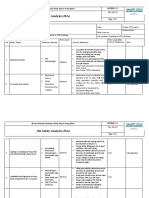

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Contract Name: Construction of Bird Breeding Building and VIP Majlis Contract No: P-001819000

Risk Assessment for ☒ Routine Activity ☐ Non-Routine Activity Assessment Date: 16-02-2020

Activity: Installation of Cable Tray and Trunking Rev Date: 15-08-2020

Degree of Residual Risk

Risk Person

Sub-Activity Hazard Who is at Risk Consequence (s) Control Measure (s)

Responsible

L S R L S R

Entering to 1.Without All project 1.Minor or major 3 3 9 1. All the project personnel must be holding a 2 3 6 Site Engineer

the project safety involved injury valid Visa, and emirates ID. EHS Inspector

site Induction personnel 2. All the operatives shall be wearing suitable

2.Entering the PPE, s hand glove, safety helmet, high

reflective safety jacket, and safety goggles.

site without

3. The operative must be undergone client

PPE’s /internal HSE induction training prior to

3.Unaware of starting the task at the site.

the site 4. All the operatives must stay inside the

condition project premises.

4. Entering to 5.Ensure no operatives will enter restricted

the restricted area bird/dog and other pet cages

area. 6. The site supervisor must be delivered the

5.Snake & specific TBT to all involved operatives Do, s

and don’ts, emergency preparedness, snake

venomous

bit etc.

7. Specific safety signage’s must be placed for

project personnel awareness.

8. All the visitors must be reported to the

project security gate.

9. Photography strictly prohibited inside the

project premises.

10. Treat all snakes as if they are venomous,

report immediately concern supervisor.

11. Don’t killed or injured snake or any

venomous.

12. The responsible person must be

undergone snake bit training and full time

available on site, required first aid treatment

resources must be available on site

IMSP-17 Page 1 of 7 IMS 08/2019

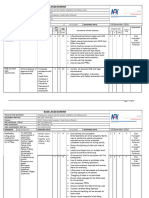

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

13. Project emergency contact numbers must

be displayed at the site.

14. Ensure nearby assembly point.

Delivering, Plant and Operatives 1.Minor or major 3 3 9 1. Delivery/ collection drivers shall be 2 3 6 Site supervisor

unloading and Traffic Staff/visitors injury subject to project induction/Training

storing of movement 2.Property with regards to traffic management.

Cable Tray damage 2. Ensure exclusion zone is set up

&Trunking Run over by 3Musculoskeletal around the preparation of work area

using pickup vehicles/pla disorders and all plant movement and

and unloading nts 4Hand injuries, monitored by Trained banksman.

by manual Hit by 5. Cut, bruises 3. Always use the pedestrian access

handling reversing provided

equipment 4. Traffic light batons shall be provided

Overhead for banks man at night

obstructions 5. Ensured PPE in use all times

Vehicle 6. No plant to reverse without banks

break down man.

Property 7. Ensure access route are sufficient and

damage safe to use.

Collision 8. Use Pallet Trolley for shifting of

with other Tray/Trunking.

vehicles 9. All vehicles must be fitted with

Personal reverse alarm / Flashing light.

injury 10. The work place and all access to be

well illuminated.

11. Identify and eliminate sharp edges

before any manual lift

12.Enforce Speed limit as per site rules.

13.. Supervisor must make sure while

manual handling loads individual task and

environment to be considered to reduce

the risk of manual handling

14 Ensure not to carry more than 20 KG

per individual.

Tray / Sharp edge Head Injury due 3 4 12 1) Ensure accesses are kept clear at all 1 4 4 Site Supervisor

Trunking items Operatives to tripping times. Store Keeper

Material Poor house Staff/storekeeper Hazard 2)Housekeeping to be carried out

IMSP-17 Page 2 of 7 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

storing keeping Property Damage regularly throughout the day when

required

3)Supervisor to ensure operatives are

stacking material neatly and stacks are

stable and in a safe condition

4)Provide adequate lighting especially

during night hours

5) Appropriate space is allowed around

storage areas for employees to move

around safely without the risk being

trapped between stacked materials.

6) Maintain good housekeeping.

7) Fire Extinguisher in place and do not

obstruct with materials

8) No smoking and no loose connection

in storage area

9) Make sure Tray/trunking should not

scatted with other materials and properly

stacked to avoid injury by sharp edge of

materials.

IMSP-17 Page 3 of 7 IMS 08/2019

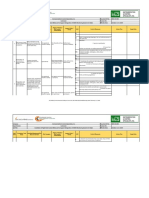

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Installation of 1. Fall from Electrician 1Eye injury Cuts. 3 3 9 1)Only trained and authorised personnel 1 3 3 Site Engineer,

Cable Tray & height Helpers Broken Limbs. to carry out the task. Supervisor,

Trunking for 2. Over loading All Personnel 2Fingers, Arms 2) Ensure the PTW in place. Foreman

wall and 3 Slip, trip/Fall involved and hand in the 3) Ensure proper working platform with

overhead 4 Protruding long term to complete fall protection

using Mobile 5 Angle Grinder disability cuts of 4) Ensure safe access to the working

Tower and for GI Tray body parts. platform.

Ladder cutting Cuts. Broken 5) Ensure Full body harness and 100%

Hot work

Limbs, Fatality. Tie off

Entanglement

3Injuries/ Property 6) Ensure the scaffold platform is

Dust

damage properly erected with "Safe to use" tag.

Electrocution

4Deep 7) Ensure castor wheels are locked and

lacerations, cuts. out rigger in place

8) Work materials strictly not allowed to

be stored on work plat form except for

working tools

9) Tools must be secured while working

on height

10) Maintain 3point contact while

accessing A Type ladder.

11) Use of gloves to protect hand

12) Maintain good housekeeping to

avoid Slip, Trip and Fall

13) Ensure that People protruding

injured during installing of tray &

trunking in concrete wall.

14) Debris to be dispose designated

place.

IMSP-17 Page 4 of 7 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Use of power 1. Unsafe use Plumbers 1.Minor or major 4 4 16 1. Ensure conduct the TBT to all involved 2 4 8 Site supervisor

tools such as of hand tools. Helpers injuries personnel.

Grinder/Drill 2. Dust / flying 2.Property 2. PTW shall be obtained prior to

particles. Damage commencing the task.

3. Fall of 3. Ensure operatives use suitable PPE, s

materials Head protection, hand protection,

4.Electric shock respiratory protection, and eye

protection.

4. Ensure enough fire extinguishers shall

be available at the site.

5. Effective supervision in place to guide

the team members.

6. Ensure Proper insulation/shockproof

of power tools.

7. Ensure proper conditions of electrical

cables, switchboards and electrical

connections.

8. Ensure power tools have safety guards

in place especially for grinding machines.

9. Ensure color coding for the power

tools to be followed.

10. Grinder must have safety guard and

auxiliary handle.

11.Ensure hot work permit obtained if

using abrasive wheel for GI

Tray/Trunking cutting

12. Fire extinguisher in place with fire

watcher

13. Ensure that electrical supply must be

taken from certified DB.

14. Use face shield while using abrasive

wheel.

IMSP-17 Page 5 of 7 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

External work 1.Minor or major 4 4 16 1)Ensure adequate PPE’s 2 4 8 Site supervisor

Adverse High wind, Operatives injury 2) Provision for availability of drinking

weather sand storm, involved in work 2. Property water at work location.

condition fog damaged. 3) Take rest in frequent intervals

Direct Sunlight 3.Heat stress 4) In case High wind stop the activity

4.Heat Stroke until stop the storm.

5) Sufficient shaded rest area with

adequate ventilation available at work

location

6) Heat stress awareness training

conducted.

7) Site Emergency contact number

Should have displayed and ensuring all

employees are aware of it.

8) Avoid working on direct heat.

9) All operatives must have aware First

Aid location.

IMSP-17 Page 6 of 7 IMS 08/2019

HAZARD IDENTIFICATION AND RISK ASSESSMENT

L65

Use of Hand Improper All Operatives Hand injuries 3 3 9 1) Hand tools should be visually 1 3 3 Supervisor

tools selection of Pinch point inspected for defects, prior to use. Foreman

hand tools. Ergonomics 2) Never use damaged, blunt or broken

Damaged and tools to avoid injury.

Defective Hand 3) Select right tools for right Job

tools 4) Ensure no Homemade or makeshift

Improper use tools to be used at site

of hand tools 5) Remove from service any tool that

shows signs of damage or defect

6) Ensure Hand tools are Stored in

accordance with the manufacturer’s

instructions.

7) Ensure hands are not in direct line of

fire while working

PREPARED BY (QC Engr)

REVIEWED BY (HSE Engr)-Genfocus REVIEWED BY LBS APPROVED BY (Engineering Office)

Genfocus

Name: Anandu Name: Prabir Kumar Name: Name:

Designation Designation: Designation: Designation:

:Signature: Signature: Signature: Signature:

IMSP-17 Page 7 of 7 IMS 08/2019

You might also like

- Risk Assessment For Installation of Air OutletsDocument8 pagesRisk Assessment For Installation of Air Outletsfaizan khanNo ratings yet

- HIRADC - 001 - Installation of Earthing SystemDocument3 pagesHIRADC - 001 - Installation of Earthing SystemZhafri SyazwiNo ratings yet

- Jsa - Duck Bank InstallationDocument10 pagesJsa - Duck Bank InstallationAmadeo Sabanal100% (1)

- Busways Installation Risk AssessmentDocument38 pagesBusways Installation Risk AssessmentAjith Deva PrashanthNo ratings yet

- Important Risk Assessment of Wind FarmDocument3 pagesImportant Risk Assessment of Wind FarmRaza Muhammad SoomroNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- Method Statement - Underground Cable Laying Rev04Document26 pagesMethod Statement - Underground Cable Laying Rev04Ahamed UmarNo ratings yet

- Daily JSA - Fence Post InstallationDocument5 pagesDaily JSA - Fence Post Installationshoaib akhtarNo ratings yet

- Electric Risk AssessmentDocument10 pagesElectric Risk AssessmentThandabantu MagengeleleNo ratings yet

- RA - Electrical WorksDocument9 pagesRA - Electrical WorksShezi Bhatti0% (1)

- Risk Assessment For Installation of Telemetry SystemDocument5 pagesRisk Assessment For Installation of Telemetry SystemvictorNo ratings yet

- Risk Assessment For Trial Pit Excavation-RevDocument15 pagesRisk Assessment For Trial Pit Excavation-RevRawoofuddin ChandNo ratings yet

- Jsa Cable LayingDocument2 pagesJsa Cable LayingAbcd efgh100% (1)

- Temporary Electrical Safety ProcedureDocument9 pagesTemporary Electrical Safety ProcedurejaimonjoyNo ratings yet

- Precast Erection JSWDocument6 pagesPrecast Erection JSWPrabhakaran GurunathanNo ratings yet

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- Cable Pulling / Laying, Glanding and Termination SopDocument12 pagesCable Pulling / Laying, Glanding and Termination SopStansilous Tatenda Nyagomo0% (1)

- Risk Generator Risk AssessmentDocument2 pagesRisk Generator Risk AssessmentBaher MohamedNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- Job Hazards AnalysisDocument3 pagesJob Hazards AnalysismohamedNo ratings yet

- Light FittingsDocument35 pagesLight FittingsAnandu AshokanNo ratings yet

- RA 002 - Mechanical ExcavationDocument2 pagesRA 002 - Mechanical ExcavationZaki Abdullah ALQweaenNo ratings yet

- TRA 003-010 (1) - RemovedDocument7 pagesTRA 003-010 (1) - RemovedrashidNo ratings yet

- Risk Assessment Plan For - Site-Clearing-EarthworksDocument2 pagesRisk Assessment Plan For - Site-Clearing-EarthworksYe YintNo ratings yet

- Risk Assessment Switchgear Testing & CommissioningDocument7 pagesRisk Assessment Switchgear Testing & CommissioningguspriyNo ratings yet

- RA Ug Fire Pipe Installation and Hyrant SystemDocument17 pagesRA Ug Fire Pipe Installation and Hyrant SystemvinayNo ratings yet

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 pagesRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleNo ratings yet

- JsaDocument7 pagesJsaAnees TNo ratings yet

- RAMS For Installation of Light FittingsDocument22 pagesRAMS For Installation of Light FittingsAnandu AshokanNo ratings yet

- BMR - Safety PPT Apr-2023Document17 pagesBMR - Safety PPT Apr-2023shamshad ahamedNo ratings yet

- Risk Assessment - Mounting Equipment and Installing Network Devices - SYBYLDocument2 pagesRisk Assessment - Mounting Equipment and Installing Network Devices - SYBYLJOHN IGA100% (1)

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- Installation of GlassDocument6 pagesInstallation of GlassVilky VargheseNo ratings yet

- Appendix A Risk AssessmentDocument16 pagesAppendix A Risk Assessmentamal100% (1)

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- DHG Pharma Distribution Board InstallationDocument21 pagesDHG Pharma Distribution Board InstallationthancvNo ratings yet

- Risk Assesment For Lighting Protection SystemDocument2 pagesRisk Assesment For Lighting Protection SystemAsfand AyazNo ratings yet

- Risk Assessment For Installation of Drainage Pipes PDF FreeDocument17 pagesRisk Assessment For Installation of Drainage Pipes PDF FreeMalik RizwanNo ratings yet

- RAMS For Modification of Phase 1 Existing Water TankDocument22 pagesRAMS For Modification of Phase 1 Existing Water TankAnandu AshokanNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENTDocument31 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENTNikhil ManjrekarNo ratings yet

- 2 - Pulling CablesDocument5 pages2 - Pulling CablesAhmed KhaledNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk assessment for 300MW Masinloc coal-fired power plant plumbing worksDocument8 pagesRisk assessment for 300MW Masinloc coal-fired power plant plumbing worksResearcherNo ratings yet

- Risk Assessment For UPS & Accessories InstallationDocument9 pagesRisk Assessment For UPS & Accessories Installationguspriy100% (1)

- SL No Activity Personnel Involved Hazard Risk Control Measures Responsible Residual RiskDocument4 pagesSL No Activity Personnel Involved Hazard Risk Control Measures Responsible Residual Riskshaikh abdul100% (1)

- Tools / Equipment:: Job Safety Analysis (Jsa)Document5 pagesTools / Equipment:: Job Safety Analysis (Jsa)Sameer AlmahboubNo ratings yet

- J718 SCX1800a RA 220322 Rev02Document13 pagesJ718 SCX1800a RA 220322 Rev02Ion Domnari100% (1)

- 4-Cable Laying PDFDocument6 pages4-Cable Laying PDFAhmed ZaiNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- Risk Assessment - Electrical WorksDocument1 pageRisk Assessment - Electrical WorksGenerdheil Dela CruzNo ratings yet

- F KG HSE RA Steel Doors Installation 2Document3 pagesF KG HSE RA Steel Doors Installation 2Alvin Badz50% (2)

- 19-JMS - Installation Cable Tray or Cable Ladder and Support Installatio...Document10 pages19-JMS - Installation Cable Tray or Cable Ladder and Support Installatio...Mohd KhaidirNo ratings yet

- Installation Risk AssessmentDocument5 pagesInstallation Risk AssessmentIbrahim Esmat100% (1)

- Hazard identification and risk assessment for installation of DX split unitDocument8 pagesHazard identification and risk assessment for installation of DX split unitfaizan khanNo ratings yet

- Risk Assessment For Installation of Drainage Pipes and FittingsDocument8 pagesRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (1)

- Risk Assessment For Water Heaters InstallationDocument6 pagesRisk Assessment For Water Heaters Installationfidgety100% (1)

- Risk Assessment of Testing and Commissioning of Fire Alarm SystemDocument4 pagesRisk Assessment of Testing and Commissioning of Fire Alarm Systemfidgety67% (3)

- Project Falcon Earthing Risk AssessmentDocument16 pagesProject Falcon Earthing Risk Assessmentfaizan khan50% (2)

- Installation of Earthing and Lightning Protection Risk AssessmentDocument21 pagesInstallation of Earthing and Lightning Protection Risk Assessmentfaizan khanNo ratings yet

- Carefour RA-For Tile & Granite WorksDocument10 pagesCarefour RA-For Tile & Granite Worksfaizan khan100% (3)

- Risk Assessment For Working On Mobile TowerDocument5 pagesRisk Assessment For Working On Mobile Towerfaizan khanNo ratings yet

- HAZARD ID AND RISK ASSESSMENTDocument17 pagesHAZARD ID AND RISK ASSESSMENTfaizan khanNo ratings yet

- Blockwork and Plastering WorksDocument12 pagesBlockwork and Plastering Worksfaizan khanNo ratings yet

- Risk Assessment For Installation of Drainage Pipes and FittingsDocument8 pagesRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (1)

- Risk Assessment of Block Works and Plastering WorksDocument7 pagesRisk Assessment of Block Works and Plastering Worksfaizan khanNo ratings yet

- Method Statement For Painting Works: ProjectDocument9 pagesMethod Statement For Painting Works: Projectfaizan khan100% (1)

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- Carefour RA-For Suspended Gypsummetallic Tiles Celling WorksDocument8 pagesCarefour RA-For Suspended Gypsummetallic Tiles Celling Worksfaizan khanNo ratings yet

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- Risk Assessment of Block Works and Plastering WorksDocument7 pagesRisk Assessment of Block Works and Plastering Worksfaizan khanNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- Risk Assessment For Temporary ServicesDocument15 pagesRisk Assessment For Temporary Servicesfaizan khan100% (2)

- LBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)Document10 pagesLBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)faizan khanNo ratings yet

- Risk Assessment of Block Works and Plastering WorksDocument7 pagesRisk Assessment of Block Works and Plastering Worksfaizan khanNo ratings yet

- Risk Assessment For Installation of Ventilation FansDocument5 pagesRisk Assessment For Installation of Ventilation Fansfaizan khanNo ratings yet

- Method Statement For Installation of Temporary ServicesDocument22 pagesMethod Statement For Installation of Temporary Servicesfaizan khanNo ratings yet

- Introduction To Patient SafetyDocument54 pagesIntroduction To Patient Safetyrejoicedear2020No ratings yet

- Bundy Et. Al, 2017Document265 pagesBundy Et. Al, 2017MathiasNo ratings yet

- Presentation Datin PH WongDocument38 pagesPresentation Datin PH WongFakhriyahNur IbrahimNo ratings yet

- PDEV2111 Lesson 5 Challengers of Middle and Late AdolescenceDocument5 pagesPDEV2111 Lesson 5 Challengers of Middle and Late AdolescenceJohn RoasaNo ratings yet

- Forecast Reguler TGL 18 Juni Yg Di Kirim Ke PemasokDocument669 pagesForecast Reguler TGL 18 Juni Yg Di Kirim Ke PemasokKFA SENGKANGNo ratings yet

- Activities of Daily Living in Patients With Dementia - Clinical Relevance, Methods of Assessment and Effects of TreatmentDocument23 pagesActivities of Daily Living in Patients With Dementia - Clinical Relevance, Methods of Assessment and Effects of TreatmentMelisa CastilloNo ratings yet

- Health Writing Task 2Document5 pagesHealth Writing Task 2Pooja SainiNo ratings yet

- Method of Statement For: Hot WorksDocument9 pagesMethod of Statement For: Hot WorksHussam WaleedNo ratings yet

- Subclavian Steal SyndromeDocument14 pagesSubclavian Steal SyndromeCelineNo ratings yet

- Analysis of Classification Techniques For Medical Data: April 2018Document6 pagesAnalysis of Classification Techniques For Medical Data: April 2018Ahmed MostafaNo ratings yet

- Retinal Drawing A Lost Art of MedicineDocument3 pagesRetinal Drawing A Lost Art of MedicinekavyaNo ratings yet

- Hand HygieneDocument11 pagesHand HygieneAllan M Murray-doNo ratings yet

- JCM 11 00011Document11 pagesJCM 11 00011Lal NandaniNo ratings yet

- Application of Drugs Acting On Autonomic Nervous System in HospitalsDocument58 pagesApplication of Drugs Acting On Autonomic Nervous System in HospitalsTama Fara ChiNo ratings yet

- STD Risk Assessment QuestionnaireDocument1 pageSTD Risk Assessment QuestionnaireTine GuibaoNo ratings yet

- Government's Role in Public HealthDocument2 pagesGovernment's Role in Public Healthmrskiller patchNo ratings yet

- Plant Inspection Checklist: Faculty / Other Area (Foa) Information DateDocument2 pagesPlant Inspection Checklist: Faculty / Other Area (Foa) Information Datemj santosNo ratings yet

- S C I e N C e SDocument7 pagesS C I e N C e Scolosseum_emNo ratings yet

- Original Article: Genetic Inheritance Pattern in Prurigo HebraDocument6 pagesOriginal Article: Genetic Inheritance Pattern in Prurigo HebraTaufiq AkbarNo ratings yet

- Minutes 1ST Spta Gen. MeetingDocument3 pagesMinutes 1ST Spta Gen. MeetingMarco Alfonzo100% (1)

- Manalo-John, EssayDocument11 pagesManalo-John, EssayJohn ManaloNo ratings yet

- Color PsychologyDocument10 pagesColor PsychologyRemya100% (1)

- ACFrOgA8Wr6yi7FYY4jC6qYdMj86L225Chgo2d G IA93LyTlqzSvhwFKSNqF61OaWxP3w9EULJvRjQb3oNc5 YaEr 21n-4c0MdfvCp85bfDDtw5zQefV2SHbOfDZQDocument8 pagesACFrOgA8Wr6yi7FYY4jC6qYdMj86L225Chgo2d G IA93LyTlqzSvhwFKSNqF61OaWxP3w9EULJvRjQb3oNc5 YaEr 21n-4c0MdfvCp85bfDDtw5zQefV2SHbOfDZQShaina MabborangNo ratings yet

- Patton, C. Sanchez-Eppler, B. (Editors) (2000) - Queer DiasporasDocument317 pagesPatton, C. Sanchez-Eppler, B. (Editors) (2000) - Queer Diasporastutkjhf0% (1)

- Plagiarism - Paraphrase and Summary HandoutDocument10 pagesPlagiarism - Paraphrase and Summary HandoutTika VirginiyaNo ratings yet

- Fire Resistance of Rolling Stock Elements - 45545-3 Standard and Special Case of TunnelsDocument34 pagesFire Resistance of Rolling Stock Elements - 45545-3 Standard and Special Case of TunnelspnagarajjNo ratings yet

- SusmpDocument669 pagesSusmpSarmad FarhanNo ratings yet

- To Study The Prevalence of Anaemia in Indoor Patients of Tertiary Care CentreDocument3 pagesTo Study The Prevalence of Anaemia in Indoor Patients of Tertiary Care CentreIJAR JOURNALNo ratings yet

- Journal 3 Personal Nutrition AssessmentDocument2 pagesJournal 3 Personal Nutrition Assessmentapi-456566589No ratings yet

- Point FormDocument19 pagesPoint FormEric TalaidNo ratings yet