Professional Documents

Culture Documents

20230319-WDN-HIRA-HRO-01 Haul Road Operation-Rev 01

20230319-WDN-HIRA-HRO-01 Haul Road Operation-Rev 01

Uploaded by

Yuniar DultanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20230319-WDN-HIRA-HRO-01 Haul Road Operation-Rev 01

20230319-WDN-HIRA-HRO-01 Haul Road Operation-Rev 01

Uploaded by

Yuniar DultanCopyright:

Available Formats

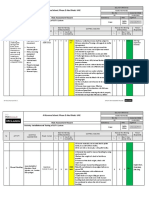

2 Vehicle Inspection Operating/Driving Accident/incident Commissioning check and sticker commisioning to be fitted into the truck/light Random check

ng to be fitted into the truck/light Random check by Safety Team on

Driver pre-start preparation to without completing the vehicle for the new hire truck/light vehicle hauling road

operate vehicle Pre Start Check/risk

assessment

Pre Start Check list must be completed.

3 3 9 M 1 3 3 L Driver

Truck/light vehicle must be checked and monitored before, during and after operation

truck/light vehicle

Driver & Supervisor must sign Pre start check list

Operating truck/light Incident/accident/ SOP Pre start check Random check by Safety Team on

vehicle with “ No Go” injury If the items under ‘NO GO’ are faulty, the truck/ light vehicle must not be operated hauling road

hazard until the problems are rectified. Supervisor must be notified. Supervisor must

check and sign the pre start check list before truck/light vehicle running Driver/

3 4 12 H 1 4 4 L

Supervisor

No preventive or periodic Injury/Property SOP Preventive Maintenance

maintenance carried out damage Preventive and periodic maintenance to be carried out as per the schedule and

Supervisor/

3 3 9 M manufacturer recommendations and truck must not be operated where there is a 1 3 3 L

Maint. Dept

"No Go" hazard.

No strobe light fitted in Incident due to poor Strobe light must be fitted on all trucks/light vehicles operating inside the mine Random check by Safety Team on

Driver/

the truck / light vehicle visibility 3 3 9 M premises/hauling road 1 3 3 L hauling road

Supervisor

Electrical fault/fire Property damage/ Regular preventative maintenance must be performed.

injury Fire extinguisher must be placed in haul truck/ light vehicle and inspected daily to Driver/

3 4 12 H 1 3 3 L

ensure that the gauge is in the green zone Supervisor

Damaged lights and Incident/Accidents All lights must be in working condition and truck/light vehicle must not be opertaed Random check by Safety Team on

warning lights/ with a “No Go” hazard hauling road

Driver/

indicators 2 3 6 M 1 3 3 L

Supervisor

Damaged handholds and Falling from Handholds and footsteps must be well maintained and three points of contact used

footsteps defective steps or at all times

2 4 8 M 1 3 3 L Driver

handholds resulting

in Injury

Damaged tyre Incident/accident due Good maintenance routine must be followed to avoid using truck/light vehicle with

condition/excessive wear to tyre blow out tyres in bad condition, innspect tires before starting each shift, and register it in the

check-list. Inform supervisor about any fault found on the truck/ light vehicle tires.

3 5 15 H 1 3 3 L Driver

Do not operate truck/light vehicle, if the condition of the tyre is not safe

Faulty horn/reverse Incident/property Make sure that the horn and reverse alarm are working properly.

alarm damage/injury

3 5 15 H 2 2 4 L Driver

Driver must ensure If horn is not working – do not operate the truck light vehicle

Dirty/unclean windshield Incident/accident Windshield must be cleaned with water and operator must ensure that the wiper is

working to improve visibility

2 5 10 M 1 5 5 L Driver

If the wind shield wiper is not working, do not operate the truck/light vehicle until it

is rectified. Report to the supervisors

Poor housekeeping Fire/smoke and Drivers must ensure that inside the truck/light vehicle is clean at all times before

inside the truck/light health issues 2 4 8 M and after operation. 1 4 4 L Driver

vehicle

Warning lights/ Incident/Accident/ Do not operate any truck/light vehicle with warning light appearing on the dash board.

symbols on truck/light injury

vehicle dash board

appearing/damaged

2 4 8 M Warning light must be reported to maintenance /supervisor immediately. 1 4 4 L Driver

If the dash board is not functioning, do not the operate the truck/light vehicles and

report it to the supervisor

Faulty service and Incident/Accident/ Brakes must be tested to make sure of the effectiveness before operating. Any

engine brakes injury fault observed on brakes must be reported

2 5 10 M 1 5 5 L Driver

If brake is not working – Do not operate the truck/light vehicle

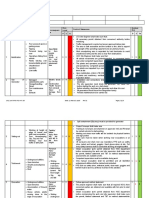

3 Vehicle Operations Operating vehicle Incident/property Make sure backup alarm, horns and all indicators work before operating haul truck

Driving DT truck/light vehicle without warnings/ damage/injury light vehicle Driver/

3 4 12 H 1 4 4 L

indicators Supervisor

Operating without head Incident/accident/ Never drive with no or single head light before and after sun set Random check by Safety Team

Driver/

lights/single head light injury 2 4 8 M 1 4 4 L on hauling road

Supervisor

Driving without wearing Incident/Injury Seat belt must be worn at all times unless it not safe as per HIRA Random check by Safety Team

seat belts If the truck/light vehicle did not have seat belt or seatbelt is not working, the on hauling road

truck/light vehicle must not be operated Driver/

3 5 15 H 1 5 5 L

Supervisor

Taking unauthorised Single or multiple Only authorized personnel (person checking time and safety checks) can ride on

passenger in the injury, in case of an the truck/ light vehicle. Driver/

3 5 15 H 1 5 5 L

vehicle accident Supervisor

Talking, texting or Incident/accident/ No texting and communication while driving the truck/light vehicles

answering cell phones injury In case of emergency, the Driver pull off the truck/light vehicle to a safe location

Driver/

and Bluetooth 3 5 15 H and attend the call/ ommunicate 1 5 5 L

Supervisor

Driving vehicle while Incident/accident/ OSPAT Asssesment prior starting shift

fatigued/dizzy/sick injury Report to your supervisor/Stop and take rest/ refreshment before going further.

Break at the assigned time during shift and follow fatigue management SOP, Rest

area available, Driver/

3 5 15 H 1 5 5 L

Fatigue buzzer installed in the truck Supervisor

Truck/light vehicle hit Injury/Property People on the ground wearing uniform with reflector safety

people or other truck/ damage Follow the Traffic direction dividing sign (Loaded lane and Empty lane) Driver

light vehicle/ equipment must make sure horn and reverse alarm is in working condition at all times

Positive communication using hauling Radio

communication channel. Driver/

3 3 9 M 1 3 3 L

Safe distance min. 50 meter on the flat road, 100 meter on the uphill or downhill Supervisor

road

Haul Road Maintenance traffic sign in place when HRM in progress

Truck/light vehicle tip Injury/Property Seat belt must be worn at all times while the truck/light vehicle is in motion Safe

over/roller over on the Damage distance min. 50 meter on the flat road, 100 meter on the ascent or descent road

hauling road Do not change gears on an downhill. Ensure correct gear selection before

approaching an downhill and never shifting the gear along the downhill.

In order to reduce the pressure on the service brake, use the engine brake when

going downhill.

Avoid driving at the edge of the road. This could cause the truck / light vehicle to

slip / slide off the road.

Prohibited to take passenger inside the cabin, except designated for Orientation Driver/

3 5 15 H 1 5 5 L

with permit letter Supervisor

Install ROPS for truck.

LV Overtaking on active Incident/accident/ SOP Traffic Management Plan Safety Patrol

hauling road injury There is sufficient visibility with a minimum distance of 60 m ahead, Vehicle is

not within curve area or blind spot area,

Overtaking can be done only when conditions are safe and there is no traffic from

the opposite direction,

Light vehicles (LV) can overtake in the uphill/downhill area on the hauling road that

already have 4 lanes with dividers,

driver who will overtaking keep contacts the vehicle in front, Driver/

3 4 12 H 1 4 4 L

Driver of the vehicle in front has reduced speed / gave way by activating the left Supervisor

indicator and not over speeding on that area,

Maintain safe distance with the vehicle /truck in the front,

Slow-moving vehicles on a 4-lane hauling road with dividers installed, if the speed

only 60% from maximum speed limit must be driving on the left side of the road,

Regular Haul Road Maintenance, water spray when dusty and road

maintenance sign in place

Dump truck Overtaking Incident/accident/ Full implementation of SOP for Traffic Management Plan. Overtaking must only DTs are equipped with ROPs

on active hauling road injury be done when there is sufficient visibility with a minimum distance of 60 m ahead. as a standard requirement.

Dump trucks are forbiden to overtake on downhill and when vehicle is within Implementation of anti- fatigue

curve area or blind spot area. and anti-collision systems and

Overtaking can be done only when conditions are safe and there is no traffic from program

the opposite direction,

Loaded/empty trucks can overtake in the uphill area on the hauling road that

already has 4 lanes with dividers,

Signs allowing or forbidding overtaking are installed along the road. Driver

who will be overtaking must keep radio communication with the driver of the

vehicle in front, Driver of overtaking vehicle must wait until Driver/

4 4 16 H Driver of the vehicle in front has reduced speed and given way by activating the 1 4 4 L Supervisor,

left indicator. Driver of vehicle in front must not increase speed, Safety Team

Slow-moving vehicles on a 4-lane hauling road driving at speed of 60% or less of

the maximum speed limit must be driving on the left side of the road. Dividers are

installed to manage risk of collision. Drivers must maintain a safe distance

between their units and others

Regular Haul Road Maintenance, water spray when dusty and road maintenance

sign in place

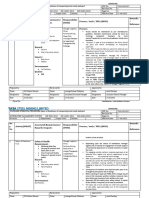

Driver over speed Injury/Property Speed Sign installed, visible and maintained, Speed ROPs, Fleet Management

along hauling road on Damage bump installed and maintained system, real time speed

downhill hauling road Speed max downhill (loaded lane) 20 km/h for Dump Truck and 30 km/h for control, CCTV and speed

section KM 36-34 Light Vehicle radar monitoring

Gear Selection along downhill this section ; Hino & Continuous Safety Patrol

4 4 16 H Shacman : Gear 3rd 2 4 8 M monitoring

Volvo : Gear 5th Renault : Safety Personel in the post

Gear 5th Scania : Gear 5th

Speed signs are updated

Driver over speed Injury/Property Speed Sign installed, visible and maintained, Speed ROPs, Fleet Management

along hauling road on Damage bump installed and maintained system, real time speed

uphill hauling road Speed max uphill (empty lane) 30 km/h for Dump Truck and 40 km/h for Light control, CCTV and speed

section KM 34-36 Vehicle radar monitoring

4 4 16 H Speed signs are updated 2 4 8 M

Continuous Safety Patrol

monitoring

Safety Personel in the post

Driver over speed Injury/Property Speed Sign installed, visible and maintained, ROPs, Fleet Management

along hauling road on Damage Speed bump installed and maintained Speed system, real time speed

hauling road section max 40 km/h for Dump Truck Speed max 50 control, CCTV and speed

KM 14-KM 17 (Loaded 4 4 16 H km/h for Light Vehicle Speed signs are updated 2 4 8 M radar monitoring

& Empty) Continuous Safety Patrol

monitoring

Safety Personel in the post

Driver over speed Injury/Property Speed Sign installed, visible and maintained, Speed ROPs, Fleet Management

along hauling road on Damage bump installed and maintained system, real time speed

hauling road section Speed max 30 km/h for Dump truck loaded and 40 km/h for dump truck empty control, CCTV and speed

KM 18 (Loaded & 4 4 16 H Speed max 50 km/h for Light Vehicle 2 4 8 M radar monitoring

Empty) Speed signs are updated Continuous Safety Patrol

monitoring

Safety Personel in the post

Driver over speed Injury/Property Speed Sign installed, visible and maintained, Speed ROPs, Fleet Management

along hauling road on Damage bump installed and maintained system, real time speed

hauling road section Speed max 30 km/h for Dump truck loaded and 40 km/h for dump truck empty control, CCTV and speed

KM 21 (Loaded & 4 4 16 H Speed max 50 km/h for Light Vehicle 2 4 8 M radar monitoring

Empty) Speed signs are updated Continuous Safety Patrol

monitoring

Safety Personel in the post

Driver over speed Injury/Property Speed Sign installed, visible and maintained, ROPs, Fleet Management

along hauling road Damage Speed signs are updated and Speed limit Map Update (see attach) system, real time speed

Follow speed sign along the road, control, CCTV and speed

Drive within specified speed limit and drive with extreme caution using correct gear radar monitoring

selection and overtaking only in areas and under conditions permissible in Continuous Safety Patrol

this risk assessment. monitoring Driver/

4 4 16 H Socialization of change in speed limit to ensure that drivers are aware of 2 4 8 M Supervisor,

sections of road that this is permissible. Safety Team

Speed monitoring each shift, Speed

buzzer installed

Unsafe road condition Injury/Property Lights must be in working condition. Both head lights must be on during the

(slippery, dusty, bumpy damage/ operation both day & night,

road, boulder spillage) Air Polution In poor visibility or wet road conditions, truck/ light vehicle speed must be reduced

to suit the road condition,

Driver/

4 2 8 M Water truck watering road when dusty condition with spraying method 20 meter 2 2 4 L

Supervisor

wet 30 meter dry

Regular road maintenance each shift. DT

Installed tail gate for hauling boulders

4 Handling Truck/Light Vehicle Repair break down Incident/Accident/ TAKE 5 Implementation

breakdown on the active hauling vehicle/truck/light vehicle Land Contamination Clear & reflective traffic cone 2 pcs (50 meters in the front and behind) of LOTO Audit

road on hauling road due to oil leaking or vehicle/equipment and wheel chock for vehicle type wheel

spill

Pre start check must be done before start operating any break down vehicle cleared

by maintenance crew

Driver/

2 3 6 M 1 3 3 L Mechanic,

Parking in the edge of the road, evacuate vehicle/equipment in the safe area if Supervisor

possible or immediate towing to the worskshop

LOTO Implementation

Spill kit, secondary containment available

You might also like

- Risk Assessment For General ActivitiesDocument25 pagesRisk Assessment For General Activitiesabou bakar67% (3)

- Risk Assessment For Installation and Testing of CCTVDocument11 pagesRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (5)

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Vehicular Movement Job Safety Analysis (JSA)Document2 pagesVehicular Movement Job Safety Analysis (JSA)sudam kumar raut100% (2)

- JSA - Non-Destructive Testing (NDT) - Magnetic Particle TestDocument7 pagesJSA - Non-Destructive Testing (NDT) - Magnetic Particle TestRajuNo ratings yet

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentPajserchina100% (4)

- Defensive Driver Safety Training PDFDocument38 pagesDefensive Driver Safety Training PDFAdeeb MalikNo ratings yet

- 2 RA 1410 Earth WorksDocument5 pages2 RA 1410 Earth WorksMuhammad Shahid Iqbal50% (2)

- 1 Earth WorksDocument5 pages1 Earth WorksMuhammad Shahid Iqbal100% (1)

- Risk Assessment For EquipmentDocument6 pagesRisk Assessment For Equipmentabou bakar100% (5)

- Omm DP50N CT28CDocument48 pagesOmm DP50N CT28Casri novhandi100% (2)

- Generic RiskDocument15 pagesGeneric RiskSujith B100% (2)

- Precast Concrete BarriersDocument142 pagesPrecast Concrete BarriersPaulo César Queiroz100% (1)

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Functions of Safety CommitteeDocument2 pagesFunctions of Safety CommitteenayakyaNo ratings yet

- Risk Assessment For Generator EquipmentDocument6 pagesRisk Assessment For Generator Equipmentabou bakar0% (1)

- Family Auto Policy ContractDocument16 pagesFamily Auto Policy ContractchickenalfredoNo ratings yet

- Highway Safety and Accident AnalysisDocument3 pagesHighway Safety and Accident Analysisdash199167% (3)

- Risk Assessment Form - KingGroveDocument12 pagesRisk Assessment Form - KingGroveeric chenNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument7 pagesRisk Assessment For Installation of Automatic Revolving Door InstallationTECHCOM100% (1)

- JHA For Transportation of Equipments, MaterialsDocument4 pagesJHA For Transportation of Equipments, MaterialsHolly Smith100% (1)

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- Pushback and Towing of Aircraft IttDocument5 pagesPushback and Towing of Aircraft IttfpcaeroinsNo ratings yet

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentNii Ashiii100% (2)

- Operation Manual SigmaDocument76 pagesOperation Manual Sigmalee82% (22)

- Traffic Engineering Road Safety - A Practitioner's Guide Kw. Ogden Department of Civil Engineefung Monash UniversityDocument108 pagesTraffic Engineering Road Safety - A Practitioner's Guide Kw. Ogden Department of Civil Engineefung Monash UniversityEman AgiusNo ratings yet

- Case Studies On Accidents Involving Lorry CraneDocument27 pagesCase Studies On Accidents Involving Lorry CraneThupten Gedun Kelvin OngNo ratings yet

- Manual de Operacion FD-160-230 Seria 2Document158 pagesManual de Operacion FD-160-230 Seria 2christian vergaray gonzales100% (1)

- Sample Safety ProgramDocument35 pagesSample Safety ProgramNeal LesterNo ratings yet

- High Risk Job Safety Analysis: Contractor ArgonneDocument13 pagesHigh Risk Job Safety Analysis: Contractor ArgonneVwoke OyibogareNo ratings yet

- ExcavationDocument73 pagesExcavationZien Mahmoud Ahmad0% (1)

- Swem-Systematic Work Environment ManagementDocument19 pagesSwem-Systematic Work Environment ManagementNicolaeDanPopNo ratings yet

- Hiradc Bore PileDocument10 pagesHiradc Bore PileDon McleanNo ratings yet

- Another Iosh 3 PDFDocument3 pagesAnother Iosh 3 PDFAviects Avie JaroNo ratings yet

- Reaction Paper For Safety ManagementDocument2 pagesReaction Paper For Safety ManagementAchara100% (4)

- 15 (1) HIRA - Shifting of Const MaterialDocument3 pages15 (1) HIRA - Shifting of Const MaterialSk younusNo ratings yet

- Control Valves and Relief Valves Removal and InstallationDocument9 pagesControl Valves and Relief Valves Removal and InstallationELDIABLO 24KNo ratings yet

- SOP For Breakdown of Vehicle - 17. Rev-2Document3 pagesSOP For Breakdown of Vehicle - 17. Rev-2syed aquibNo ratings yet

- Drum CrushingDocument3 pagesDrum CrushingShannon MooreNo ratings yet

- 04 - Guidance - Loading and Unloading VehiclesDocument21 pages04 - Guidance - Loading and Unloading VehiclesAmjad Wael Yahia FayedNo ratings yet

- Freight Wings (P) LTD.: Contingency PlanDocument8 pagesFreight Wings (P) LTD.: Contingency PlanRUBEN BARTOLOME GARCIANo ratings yet

- Carpentry WorkDocument10 pagesCarpentry WorkNisanth ThulasidasNo ratings yet

- Straddle Lift Truck: Operator'S ManualDocument28 pagesStraddle Lift Truck: Operator'S ManualDmitryNo ratings yet

- Brakes: MaintenanceDocument14 pagesBrakes: MaintenanceZoltán RozinkaNo ratings yet

- F.03-09 Job Safety Analysis - Oil, Grease and Lubricant ChangeDocument3 pagesF.03-09 Job Safety Analysis - Oil, Grease and Lubricant Changeaqeel ahmedNo ratings yet

- Manual Material HandlingDocument9 pagesManual Material HandlingNisanth ThulasidasNo ratings yet

- Forklift Operator Daily ChecklistDocument2 pagesForklift Operator Daily ChecklistazozinlcNo ratings yet

- Risk Assessment For All Activities - 9Document42 pagesRisk Assessment For All Activities - 9Sonu KrishnaNo ratings yet

- Utm Dredging Limited: Health & Safety Management SystemDocument2 pagesUtm Dredging Limited: Health & Safety Management SystemVICTORNo ratings yet

- 17 (1) HIRA - Sub Grade GSB & WMMDocument2 pages17 (1) HIRA - Sub Grade GSB & WMMSk younusNo ratings yet

- PDS Straddle Lift Truck: Operator'S ManualDocument24 pagesPDS Straddle Lift Truck: Operator'S ManualDmitryNo ratings yet

- Adr Jsa 1711 002Document7 pagesAdr Jsa 1711 002Dada KhalandarNo ratings yet

- Operator Skill Assessmentn (Light Vehicle) FormulaDocument3 pagesOperator Skill Assessmentn (Light Vehicle) Formulaberto hutamaNo ratings yet

- Brake Lock Test KOMATSU 830Document4 pagesBrake Lock Test KOMATSU 830Shaylove SchultzNo ratings yet

- Vehicle DrivingDocument4 pagesVehicle Drivingwahyu nugrohoNo ratings yet

- Ept20 20wa Operation-ManualDocument36 pagesEpt20 20wa Operation-Manualניקולאי איןNo ratings yet

- 34.HIRA CompressorDocument2 pages34.HIRA CompressorMMRDACA07 SAFETYNo ratings yet

- Risk Assessment: Unilever ProjectDocument2 pagesRisk Assessment: Unilever ProjectmuradNo ratings yet

- Clark c500 355 Planned Maintenance Adjustment ProceduresDocument20 pagesClark c500 355 Planned Maintenance Adjustment Proceduresenid100% (56)

- 901346b Powered Pallet Truckbig JoeDocument28 pages901346b Powered Pallet Truckbig JoeMarioNo ratings yet

- JSA For Coating and PaintingDocument7 pagesJSA For Coating and PaintingMuthu AlaguRajNo ratings yet

- ID 204-JSEA-WS-092 Replace Track Roller Excavator Komatsu PC1250-7Document4 pagesID 204-JSEA-WS-092 Replace Track Roller Excavator Komatsu PC1250-7leoNo ratings yet

- Check Sheet Improved MT Inspection Procedure Report For C-0659Document3 pagesCheck Sheet Improved MT Inspection Procedure Report For C-0659Himanyu RafiqNo ratings yet

- Risk Assessment Form: Page 1 of 5Document5 pagesRisk Assessment Form: Page 1 of 5RadhaKrishnan RNo ratings yet

- Ab6 Type Rating Training Guide Session C3: IndexDocument2 pagesAb6 Type Rating Training Guide Session C3: IndexPunthep PunnotokNo ratings yet

- PRS 3431 Summative Accident Case Study AssignmentDocument9 pagesPRS 3431 Summative Accident Case Study AssignmentStanley LoNo ratings yet

- 6076-Article Text-10968-1-10-20230326Document9 pages6076-Article Text-10968-1-10-20230326Yuniar DultanNo ratings yet

- 20230409-WDN-BLRA-PK-01 Parking - Rev 0Document19 pages20230409-WDN-BLRA-PK-01 Parking - Rev 0Yuniar DultanNo ratings yet

- 20230425-WDN-HIRA-RTD-01 Road Construction-Rev 2Document3 pages20230425-WDN-HIRA-RTD-01 Road Construction-Rev 2Yuniar DultanNo ratings yet

- Kontrol Pemenuhan Tanggung Jawab Pengawas Di Bidang K3LH PDFDocument1 pageKontrol Pemenuhan Tanggung Jawab Pengawas Di Bidang K3LH PDFYuniar DultanNo ratings yet

- Logical Reasoning QuestionsDocument18 pagesLogical Reasoning QuestionsChirag ChaudharyNo ratings yet

- Second Division Government Service Insurance System, G.R. No. 166863Document12 pagesSecond Division Government Service Insurance System, G.R. No. 166863Alyssa Alee Angeles JacintoNo ratings yet

- Traffic Accident Investigation - JIBC LibraryDocument3 pagesTraffic Accident Investigation - JIBC LibraryJosé sergio M costaNo ratings yet

- Mohamed Boudiaf Secondary Schoo1Document2 pagesMohamed Boudiaf Secondary Schoo1imanbenkaakaa100% (1)

- Organization Portfolio A Mission Core Values:: Auto Company ,,ferrari''Document6 pagesOrganization Portfolio A Mission Core Values:: Auto Company ,,ferrari''Almedin CuricNo ratings yet

- Transportation in Canada 2011 PDFDocument155 pagesTransportation in Canada 2011 PDFmenagesNo ratings yet

- Managing Safety and Health in ConstructionDocument33 pagesManaging Safety and Health in ConstructiontuNo ratings yet

- Road Accidents in KeralaDocument3 pagesRoad Accidents in KeralaShyjan PooncholaNo ratings yet

- A Letter To God, Summary: CBSE Class 10 ENGLISH, First Flight - MeritnationDocument19 pagesA Letter To God, Summary: CBSE Class 10 ENGLISH, First Flight - MeritnationRatul RanjanNo ratings yet

- 2021 Road Safety in India Draft1Document75 pages2021 Road Safety in India Draft1amit raviNo ratings yet

- A Vehicle Control System Using A Time Synchronized Hybrid VANET To Reduce Road Accidents Caused by Human ErrorDocument31 pagesA Vehicle Control System Using A Time Synchronized Hybrid VANET To Reduce Road Accidents Caused by Human ErrorAKASH HASMUKHBHAI SAVALIYA SVNITNo ratings yet

- Pedestrian Fatality Risk As A Function of Car Impact SpeedDocument7 pagesPedestrian Fatality Risk As A Function of Car Impact SpeedCristian NaizaqueNo ratings yet

- Safety Performance HelicopterDocument76 pagesSafety Performance HelicopterFatih D. PrasetioNo ratings yet

- Driver Disciplinary Program: Written RulesDocument5 pagesDriver Disciplinary Program: Written RulesQHSE ManagerNo ratings yet

- 02-1. Risk Assessment Guide LineDocument67 pages02-1. Risk Assessment Guide LinePEng. Tech. Alvince KoreroNo ratings yet

- Teen Driving Safety GuideDocument13 pagesTeen Driving Safety GuideMrs. LibbyNo ratings yet

- CPD Traffic Crash Investigations Policy StatementsDocument10 pagesCPD Traffic Crash Investigations Policy StatementsWSYX/WTTENo ratings yet

- Office of The Chief Coroner of Ontario - Pedestrian Death ReviewDocument66 pagesOffice of The Chief Coroner of Ontario - Pedestrian Death ReviewWilliam Wolfe-WylieNo ratings yet

- Tyre An Analysis: Forensic ExaminationsDocument8 pagesTyre An Analysis: Forensic ExaminationsDanar Tri YurindatamaNo ratings yet

- Ethics Corsework 2.0Document16 pagesEthics Corsework 2.0Ramendra ShukhonNo ratings yet