Professional Documents

Culture Documents

Job Safety Analysis Sheet:: GOR Test

Uploaded by

hp9mzbjzsfOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis Sheet:: GOR Test

Uploaded by

hp9mzbjzsfCopyright:

Available Formats

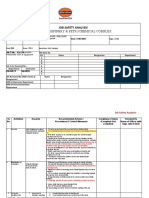

Job Safety Analysis Sheet

Job Description: GOR Test JSA Ref. No. 01/Test

Facility: Work Area / Equipment: Work Permit No:

Date:

PERSONAL PROTECTIVE EQUIPMENT & TOOLS NEEDED FOR WORK ACTIVITIES: Hard Hat, Safety Shoes,

Safety Goggles, Hand Gloves ,Chemical gloves, Ear plugs, Safety harness,H2S Monitor, H2S Escape Unit/ SCBA set

SEQUENCE OF BASIC JOB POTENTIAL YES/

PRECAUTIONS

STEPS HAZARDS NO

a) Performing job by 1- Performing the job only by authorized operator

unauthorized operator

2- Conduct pre-job briefing with all involved personnel in the job

b) Equipment

selection , Equipment 3- Ensure all the equipment, fittings, hoses, to be of the correct pressure rating

1.Job Preparation and pressure rating &

planning equipment condition 4- Use right tool for the right job

5- Make sure all personnel are trained involved in the job

6- Valid equipment certifications

7- Valid fire extinguisher and breathing apparatus certification

8- Minimum HSE Trainings

9- All Crew must be wear personnel H2S monitor

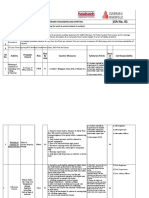

1- Equipment should be parked in suitable distance from wellhead area

a) Hitting the fence

2. Equipment spotting b) Hitting/ Crushing/ 2- use the ground guide while backing the vehicle

injury to people 3- Spot the unit in upwind direction as possible

4- Position all the safety equipment , Fire extinguisher, SCBA set after equipment is spotted

a) Lifting and twisting 1- Pre job safety meeting to be conducted prior to rig up

injury from handling

2- Follow the safety working procedures and techniques

loads

3. Rig up / rig down testing b) Trapped hands and 3- Observe correct manual handling techniques

equipment

fingers 4- Proper use of PPE

c) Stepping handling 5 - Avoid the pinch points

d) Hammering 6- Use brass hammer

a) Equipment failure 1- Safety briefing & proper use of PPE

b) Pressure 2- Valid pressure equipment certificates

C) Personnel injury 3- Beware of pressure rating, Never exceed W.P

4- Use suitable gasket to avoid the flange leak

4. Pressure testing

5- Never try to tight the leak joint under pressure

6- Inform to all crew prior to pressure testing

7- Smoking is not allowed at site

8- Provide barriers and warning signs to be used

a) Pressure 1- Safety briefing before open the well

b) Failure in equipment 1- Safety briefing before open the well

2- Emergency phone

c) Fire numbers posted in all

vehicles

5- Start the operation & flow d) H2S 3- Equipment grounding

the well

e) Leakage in the line &

4- Spill kit available

spill

f) Slips / Trips

g) Electrostatic

1- Ensure use of PPE

a) Cold/Sand storm /

6- Working in open area Heat stroke . 2- Ensure availability of drinking water if required follow the work cycle

Dehydration

1- Effective supervision

a) Trapped gas & oil in

2- Purge & flush piping prior rig down

lines & separator

7- After completion of job

3- Drain the line & separator to G.C and close WH and G.C line & the depressurize the unit to atmosphere tank ( For

rigless operation )

4- Keep the site clean & tidy

Additional Hazards ( Other

than indicated above )

Name:

Designation:

ID. No.

JSA Done By Signature:

Company:

Contract No.(If Applicable):

You might also like

- Operation and Mantenance Manual Perkins 1103 and 1104c Engines SystemsDocument92 pagesOperation and Mantenance Manual Perkins 1103 and 1104c Engines SystemsDiego Barbas83% (6)

- Jsa For Welding, Grinding, Gas CuttingDocument2 pagesJsa For Welding, Grinding, Gas Cuttingwahyu nugroho50% (2)

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- Hazard Identification and Risk Assessment For Grit Blasting & CoatingDocument4 pagesHazard Identification and Risk Assessment For Grit Blasting & CoatingAchalere Shekhar KashinathNo ratings yet

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- Denim Business PlanDocument10 pagesDenim Business PlanAushru Hasan100% (1)

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- JsaDocument5 pagesJsaMohd AzrinNo ratings yet

- Risk Assessment of Confined Space (CS) Entry:: Job Safety Analysis Worksheet DOC: CS/RA-01 Revision 1Document2 pagesRisk Assessment of Confined Space (CS) Entry:: Job Safety Analysis Worksheet DOC: CS/RA-01 Revision 1Dheeraj Kapoor /QOGIL/QuippoworldNo ratings yet

- JSA - For Trays ErectionDocument1 pageJSA - For Trays ErectionAvinash RaiNo ratings yet

- Machineh: SadcoersDocument92 pagesMachineh: SadcoersHerbert Hillary Booker 2ndNo ratings yet

- Job Safety Analysis WorksheetDocument1 pageJob Safety Analysis Worksheetsrinivasa raoNo ratings yet

- 48 Structural Steel Erection WorkDocument5 pages48 Structural Steel Erection WorkvasudevanmNo ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat67% (3)

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Fabric Rendering TechniquesDocument32 pagesFabric Rendering Techniquesbushra noor100% (4)

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (4)

- Method of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryDocument5 pagesMethod of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryKarpana Devi LetchumananNo ratings yet

- Job Safety Procedure - TSEILDocument13 pagesJob Safety Procedure - TSEILRavi thokalNo ratings yet

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Pre Commissioning Electrical EquipmentDocument4 pagesPre Commissioning Electrical Equipmentmohammed a hseNo ratings yet

- JSA FOR HT LT Panel - Transformer InstallationDocument2 pagesJSA FOR HT LT Panel - Transformer Installationwahyu nugroho83% (6)

- Alcpt 22R (Script)Document18 pagesAlcpt 22R (Script)Matt Dahiam RinconNo ratings yet

- List of Parts Singer 31-15 and 31-20Document296 pagesList of Parts Singer 31-15 and 31-20Just4Him89% (9)

- Nike Global FactoriesDocument98 pagesNike Global FactoriesSanjay Sethia100% (1)

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- SWP 05 - Installation of PipesDocument5 pagesSWP 05 - Installation of PipesGerald Wong NttNo ratings yet

- SAF Commando CourseDocument18 pagesSAF Commando CourseMcNavy PA100% (1)

- Volume 1 Focus PDFDocument47 pagesVolume 1 Focus PDFAjay Kumar GuptaNo ratings yet

- 05 WMS - CHWP InstallationDocument15 pages05 WMS - CHWP InstallationHimanshu Niveriya100% (1)

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- ARTS 8 Summative TestDocument1 pageARTS 8 Summative TestRonnel Andres Hernandez100% (2)

- Monthly Safety Inspection 2.3Document6 pagesMonthly Safety Inspection 2.3makaranthNo ratings yet

- JSA Pressure TestingDocument1 pageJSA Pressure TestingScott Mills100% (1)

- Job Safety Analysis - Doc With Penumatic TestingDocument5 pagesJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- Where Is Sam Fun Activities VideoDocument1 pageWhere Is Sam Fun Activities VideoKilver Silvester100% (1)

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- 712-Lubrcation Pipe Checking and Changing of CSR#2Document5 pages712-Lubrcation Pipe Checking and Changing of CSR#2Buddy HartNo ratings yet

- Inspection Format For Health and Safety Conditions at Work FIELDDocument3 pagesInspection Format For Health and Safety Conditions at Work FIELDScribdTranslationsNo ratings yet

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisBrain Dee Tech LtdNo ratings yet

- Kapoor Enterprises Jha-1Document3 pagesKapoor Enterprises Jha-1Dwitikrushna RoutNo ratings yet

- Height Work SOPDocument2 pagesHeight Work SOPMeghanath LalemmaNo ratings yet

- Job Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Document7 pagesJob Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Ranadheer Reddy KanthalaNo ratings yet

- Method Statement - FOC - FYSH - 031010Document2 pagesMethod Statement - FOC - FYSH - 031010DilxazNo ratings yet

- 49 Switch Board - Panel ErectionDocument4 pages49 Switch Board - Panel ErectionvasudevanmNo ratings yet

- SOP-12-Installation and Disconnection of Live Head of Drilliing LineDocument6 pagesSOP-12-Installation and Disconnection of Live Head of Drilliing LineDQE040 HSSENo ratings yet

- JSA For Hydrotesting of 24 Production HeaderDocument4 pagesJSA For Hydrotesting of 24 Production HeaderjavithNo ratings yet

- Compact Notes OSHDocument4 pagesCompact Notes OSHWaizMuqrieNo ratings yet

- SOP-15-Installation and Disassembly of BOP Hydraulic Control LineDocument6 pagesSOP-15-Installation and Disassembly of BOP Hydraulic Control LineDQE040 HSSENo ratings yet

- HCCP Jsa Wo5992032Document2 pagesHCCP Jsa Wo5992032Forida EasminNo ratings yet

- JSA 004 Sand Blasting of Exposed RebarDocument1 pageJSA 004 Sand Blasting of Exposed RebarRyanNo ratings yet

- 01 Job Hazard Analysis For Piling Works (JHA)Document3 pages01 Job Hazard Analysis For Piling Works (JHA)AmanNo ratings yet

- Siddhivinayak Jsa-004-Work in ShaftDocument5 pagesSiddhivinayak Jsa-004-Work in Shaftyogeshraut1910No ratings yet

- DQE SOP-183-Upper Substructure DisassemblyDocument8 pagesDQE SOP-183-Upper Substructure DisassemblyDQE040 HSSENo ratings yet

- Standard Operating Procedure SOP - NO.-01 Joda Date:-19.09.2020Document6 pagesStandard Operating Procedure SOP - NO.-01 Joda Date:-19.09.2020Dwitikrushna Rout50% (2)

- HCCP Jsa Wo5988583Document2 pagesHCCP Jsa Wo5988583Forida EasminNo ratings yet

- SOP For Safety WalkthroughDocument5 pagesSOP For Safety WalkthroughNeshar AhmadNo ratings yet

- Job Hazard Analysis: Amichand Technological Pvt. LTDDocument6 pagesJob Hazard Analysis: Amichand Technological Pvt. LTDSandeep KumarNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- M-45 Remove & Install Mud Tank AgitatorDocument3 pagesM-45 Remove & Install Mud Tank AgitatorMohamed AnwarNo ratings yet

- JSA-009a Drilling and Mon Well Construction-Sonic - 2Document4 pagesJSA-009a Drilling and Mon Well Construction-Sonic - 2sudarmanNo ratings yet

- Assessment BT01 BT03Document3 pagesAssessment BT01 BT03Syed IqmalNo ratings yet

- Work Method Statement: BNPP-HSE-JHA-2014-210 6Document8 pagesWork Method Statement: BNPP-HSE-JHA-2014-210 6Karthik babuNo ratings yet

- Engineering Problem Solving With C 4th Edition Etter Solutions ManualDocument26 pagesEngineering Problem Solving With C 4th Edition Etter Solutions ManualKevinBensongjykx100% (68)

- Malawi Customs and Excise Tariff 2017-2018Document432 pagesMalawi Customs and Excise Tariff 2017-2018Stephen Amachi ChisatiNo ratings yet

- Tutorial Chapter 1 (Semester March - August 2023)Document3 pagesTutorial Chapter 1 (Semester March - August 2023)Hasif IrfanNo ratings yet

- Ropa Interior RomanaDocument11 pagesRopa Interior RomanaRaquel5394No ratings yet

- She Enjoys Being A Girl: An Interview With PhrancDocument1 pageShe Enjoys Being A Girl: An Interview With PhranclarrybobsfNo ratings yet

- Federal Police: Federal Police Force Germany Federal Ministry of The InteriorDocument11 pagesFederal Police: Federal Police Force Germany Federal Ministry of The InteriorNormalyn Andres MacaysaNo ratings yet

- Running To Raise Awareness: Former Chiefs Receive AwardDocument20 pagesRunning To Raise Awareness: Former Chiefs Receive AwardelauwitNo ratings yet

- The Unamericans: My Grandmother Tells Me This StoryDocument26 pagesThe Unamericans: My Grandmother Tells Me This Story4th Estate BooksNo ratings yet

- Vdovenko Ss English For Junior PupilsDocument173 pagesVdovenko Ss English For Junior PupilsSarancha YelenaNo ratings yet

- How To Establish An Aseptic Gowning Qualification ProgramDocument3 pagesHow To Establish An Aseptic Gowning Qualification Programprakash deshmukhNo ratings yet

- Capstone ProjectDocument35 pagesCapstone Projectapi-312851684No ratings yet

- Islcollective House Riddles 2 Medium 258974cfee784f25ad6 06917405Document3 pagesIslcollective House Riddles 2 Medium 258974cfee784f25ad6 06917405littlefbitchNo ratings yet

- BÀI TẬP VỀ SỰ HÒA HỢP GIỮA S-V EdittedDocument2 pagesBÀI TẬP VỀ SỰ HÒA HỢP GIỮA S-V EdittedPham Thuy DuongNo ratings yet

- IpsDocument19 pagesIpsCj ZuluetaNo ratings yet

- Exposants 2013Document3 pagesExposants 2013pranubNo ratings yet

- White Water Rafting Bali Ubud Adventure and Experience TheDocument2 pagesWhite Water Rafting Bali Ubud Adventure and Experience Therafting bali ubudNo ratings yet

- ZARADocument11 pagesZARAAthul George100% (3)

- Children ShoesDocument8 pagesChildren Shoespradip_kumarNo ratings yet

- Concrete Road Risks AssessmentDocument18 pagesConcrete Road Risks AssessmentCynthia ChuaNo ratings yet

- Evidence Describing Outfits and LikesDocument8 pagesEvidence Describing Outfits and LikesLina Mojica RubianoNo ratings yet