Professional Documents

Culture Documents

Juntas Tóricas CPI 9

Juntas Tóricas CPI 9

Uploaded by

xavier castro0 ratings0% found this document useful (0 votes)

5 views1 pageOriginal Title

Juntas-Tóricas-CPI-9

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageJuntas Tóricas CPI 9

Juntas Tóricas CPI 9

Uploaded by

xavier castroCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

ISO 3601-3:2005(E)

Table 1 — Limits of size for surface imperfections for Grade N O-rings

Dimensions in millimetres

Maximum limits of imperfections

Surface Grade N O-rings

Diagrammatic Limiting Cross-section, d2

imperfection

representation dimensions

type

> 0,8b > 2,25 > 3,15 > 4,50 > 6,30

u 2,25 u 3,15 u 4,50 u 6,30 u 8,40b

Off-register,

e 0,08 0,10 0,13 0,15 0,15

mismatch (offset)

x 0,10 0,12 0,14 0,16 0,18

Combined flash

(combination of

offset, flash and y 0,10 0,12 0,14 0,16 0,18

parting line

projection)

When the flash can be differentiated,

a

it shall not exceed 0,07 mm.

g 0,18 0,27 0,36 0,53 0,70

Backrind

u 0,08 0,08 0,10 0,10 0,13

Excessive Trimming is allowed provided the

trimming (radial dimension n is not reduced below the

n

tool marks not minimum diameter d2 for the O-ring.

allowed)

v 1,50a 1,50a 6,50a 6,50a 6,50a

Flow marks

(radial

orientation of

flow marks is not

permissible) k 0,08 0,08 0,08 0,08 0,08

w 0,60 0,80 1,00 1,30 1,70

Non-fills and

indentations

--`,,```,,,,````-`-`,,`,,`,`,,`---

(including parting

line indentations)

t 0,08 0,08 0,10 0,10 0,13

a Or 0,05 times the O-ring’s inside diameter (d1), whichever is greater.

b Limits of imperfections for cross sections < 0,8 mm or > 8,40 mm shall be agreed upon between manufacturer and customer.

c Round edges.

© ISO 2005 – All rights reserved

Copyright International Organization for Standardization 5

Reproduced by IHS under license with ISO

No reproduction or networking permitted without license from IHS

You might also like

- Eaton 9 SpeedDocument214 pagesEaton 9 SpeedFusoTech93% (15)

- Ct02 Ect Extended AsmeDocument1 pageCt02 Ect Extended AsmeVasyaNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Press Tool DesignDocument36 pagesPress Tool DesignAmar Bhopi100% (2)

- Wet and Dry Installation of Natural Stone CladdingDocument12 pagesWet and Dry Installation of Natural Stone CladdinglakshmiNo ratings yet

- Design of Base Plate For BS5950Document2 pagesDesign of Base Plate For BS5950dantevarias89% (19)

- O RingSurface CriteriaDocument1 pageO RingSurface CriteriaBharatNo ratings yet

- Brush and Brush-Holder Tolerances On "T" and "A" Dimensions: Technical Note Sta Be 16-4 GBDocument2 pagesBrush and Brush-Holder Tolerances On "T" and "A" Dimensions: Technical Note Sta Be 16-4 GBloulou_beNo ratings yet

- Sello de Pistón K08-EDocument2 pagesSello de Pistón K08-Epablo zanottiNo ratings yet

- Micro Chip Fuse Erbrd Erbre Erbrg: FeaturesDocument5 pagesMicro Chip Fuse Erbrd Erbre Erbrg: FeaturesshounakroyNo ratings yet

- RuberGuide - 2017 ENGLISHDocument8 pagesRuberGuide - 2017 ENGLISHAndres Byke SepulvedaNo ratings yet

- Technical Fiche Profile H65 Rev 13Document2 pagesTechnical Fiche Profile H65 Rev 13Satendra ThakurNo ratings yet

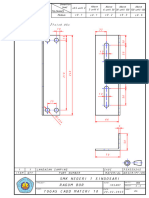

- Released 00011 P0007-000.002: Neosia Training CenterDocument1 pageReleased 00011 P0007-000.002: Neosia Training CenterJubah Syariat Asep SaefudinNo ratings yet

- CORSON (C7025) : Cu-Ni-Si ALLOYDocument2 pagesCORSON (C7025) : Cu-Ni-Si ALLOYstrip1No ratings yet

- Specifications of Raw Materials: Technical Fiche Profile H 65Document3 pagesSpecifications of Raw Materials: Technical Fiche Profile H 65RigoRuizNo ratings yet

- Fittings and TolerancesDocument31 pagesFittings and TolerancesVinay GautamNo ratings yet

- ISO 3302-1:1996 (E) : M-ClassDocument2 pagesISO 3302-1:1996 (E) : M-ClassMarcos Antonio RossiNo ratings yet

- Energoinvest Raop Catalogue Porcelain Insulators PDFDocument36 pagesEnergoinvest Raop Catalogue Porcelain Insulators PDFPetar TuskanNo ratings yet

- Rod Seal TS22PDocument1 pageRod Seal TS22Pfrançois MNo ratings yet

- Ragum BorDocument4 pagesRagum BorwidodoNo ratings yet

- Primera Planta: Comandos A UsarseDocument1 pagePrimera Planta: Comandos A UsarseFreddy Mateo Aragon DelgadoNo ratings yet

- Current Sense Low Value Resistors: Part Number StructureDocument3 pagesCurrent Sense Low Value Resistors: Part Number StructureraveendraNo ratings yet

- ERAW0402 PanasonicDocument4 pagesERAW0402 PanasonicKarthik SANGAPILLAINo ratings yet

- International Standard: Rubber-Tolerances For ProductsDocument6 pagesInternational Standard: Rubber-Tolerances For ProductsvenkatramanNo ratings yet

- Sot26 SC74RDocument6 pagesSot26 SC74RchetanNo ratings yet

- 0607 Carcoseal Un Data SheetDocument2 pages0607 Carcoseal Un Data SheetMarco FranceseNo ratings yet

- Surface Roughness Conversion Chart Tables - Engineers EdgeDocument10 pagesSurface Roughness Conversion Chart Tables - Engineers Edgejames.anitNo ratings yet

- Ballscrew Bearings (E)Document6 pagesBallscrew Bearings (E)Wahyu SulistyoNo ratings yet

- Compress EursDocument11 pagesCompress Eursofon OML102No ratings yet

- DK35-P Piston Seal Datasheet - 16296 EN PDFDocument2 pagesDK35-P Piston Seal Datasheet - 16296 EN PDFSridhar TholasingamNo ratings yet

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesDocument17 pagesMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasNo ratings yet

- DatasheetDocument16 pagesDatasheetErick MauricioNo ratings yet

- PLATE 12in X 12in X 2inDocument1 pagePLATE 12in X 12in X 2inEdwin TacoNo ratings yet

- Eta Engineering Private LimitedDocument2 pagesEta Engineering Private Limitedanon_501928972No ratings yet

- Tugas 1 Cs SoketDocument1 pageTugas 1 Cs Soketilham dwi putraNo ratings yet

- Metal Film Chip Resistors, High Reliability Type 0402, 0603, 0805, 1206 ERA 2A, 3A, 6A, 8ADocument4 pagesMetal Film Chip Resistors, High Reliability Type 0402, 0603, 0805, 1206 ERA 2A, 3A, 6A, 8AaaaaaaaaNo ratings yet

- 2 WRM WheelDocument1 page2 WRM WheelIbnu aslamNo ratings yet

- Tantalum Alloy Rev3 Tds en 3 v1Document1 pageTantalum Alloy Rev3 Tds en 3 v1Симеон АрабовNo ratings yet

- Extracto Norma ASTM A792Document2 pagesExtracto Norma ASTM A792Christian Latorre VielmaNo ratings yet

- Transfer Piece Model1 ModelDocument1 pageTransfer Piece Model1 Modelmochammad sofiNo ratings yet

- Surface Dressing Pavement DesignDocument5 pagesSurface Dressing Pavement DesignSang RawalNo ratings yet

- Seal Datasheet, Piston Seal: Standard Dimensions Maximal Radial Extrusion GapDocument2 pagesSeal Datasheet, Piston Seal: Standard Dimensions Maximal Radial Extrusion Gapclaiberth castillo villanuevaNo ratings yet

- Bosch PDFDocument2 pagesBosch PDFLeonardo AlexNo ratings yet

- BoschDocument2 pagesBoschLeonardo AlexNo ratings yet

- INOMETA Bridge Profile TubesDocument2 pagesINOMETA Bridge Profile Tubeskhame006No ratings yet

- SOD123Document5 pagesSOD123stefano soriceNo ratings yet

- K01 PExDocument2 pagesK01 PExclaiberth castillo villanuevaNo ratings yet

- Klem C PDFDocument3 pagesKlem C PDFYounkPDNo ratings yet

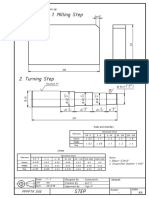

- Milling Step: PPPPTK Boe A4Document3 pagesMilling Step: PPPPTK Boe A4YounkPDNo ratings yet

- Klem C PDFDocument3 pagesKlem C PDFYounkPDNo ratings yet

- Tutorial 5: Slope RoughnessDocument9 pagesTutorial 5: Slope RoughnessAnshi MishraNo ratings yet

- Sem-Safe Water Mist: Total Weight: XX KGDocument1 pageSem-Safe Water Mist: Total Weight: XX KGRaluca OlaruNo ratings yet

- Seal Datasheet, Piston Seal: Standard Dimensions Maximal Radial Extrusion GapDocument2 pagesSeal Datasheet, Piston Seal: Standard Dimensions Maximal Radial Extrusion Gapclaiberth castillo villanuevaNo ratings yet

- Re20380 (Ke)Document10 pagesRe20380 (Ke)Ânderson Silva BrasilNo ratings yet

- Tabela 1 NP EN 61008-12018Document1 pageTabela 1 NP EN 61008-12018Paulo BrituNo ratings yet

- Carcoseal AP / WT. The Lip Is Designed So That TheDocument2 pagesCarcoseal AP / WT. The Lip Is Designed So That ThemattiaNo ratings yet

- Value Part-4 Elongation Part-1 Absorption Part-3 Aggregate Part-1 LL, Pl&Pi 5 OMC lS2720Part8Document2 pagesValue Part-4 Elongation Part-1 Absorption Part-3 Aggregate Part-1 LL, Pl&Pi 5 OMC lS2720Part8vishal gupta0% (1)

- BRUSH and BRUSH-HOLDER TOLERANCES On T and A DIMENSIONS - Carbone Lorraine - INGDocument2 pagesBRUSH and BRUSH-HOLDER TOLERANCES On T and A DIMENSIONS - Carbone Lorraine - INGClaylson Figueiredo JúlioNo ratings yet

- Panasonic - Micro Chip FuseDocument5 pagesPanasonic - Micro Chip FuseJuan HernándezNo ratings yet

- Ceramic Capacitor Landing PatternDocument1 pageCeramic Capacitor Landing PatternmuasaobangcnNo ratings yet

- 6 Interference FitsDocument42 pages6 Interference FitsMadhu Mitha50% (2)

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- Regular Machining Dimension ToleranceDocument1 pageRegular Machining Dimension ToleranceSIVA 1010No ratings yet

- Main LT Panel With PfiDocument4 pagesMain LT Panel With Pfishoaib ehsanNo ratings yet

- Lecture 3 Handout - Edited PDFDocument16 pagesLecture 3 Handout - Edited PDFTTTNo ratings yet

- O-2 8.5in RSS 18032021 MR 2021.03.18.22.24.539Document1 pageO-2 8.5in RSS 18032021 MR 2021.03.18.22.24.539Mostafa ElghifaryNo ratings yet

- Benson BoilerDocument4 pagesBenson Boilershivrant shivrantNo ratings yet

- X-Ray Infeed Conveyor Spare Parts ManualDocument83 pagesX-Ray Infeed Conveyor Spare Parts ManualJames CoffeyNo ratings yet

- Kitchen Unit SizesDocument5 pagesKitchen Unit SizesGraemeNichollsNo ratings yet

- Quick-Opening Closures SurveyDocument13 pagesQuick-Opening Closures SurveyAjmi HmidaNo ratings yet

- Takeuchi Compact Excavator Tb80frcl4e000 Workshop ManualDocument20 pagesTakeuchi Compact Excavator Tb80frcl4e000 Workshop ManualJune100% (52)

- N5 Mechanotechnics April 2023 MemorandumDocument8 pagesN5 Mechanotechnics April 2023 MemorandumNyiko DaveNo ratings yet

- Potain MC 115B Strut InstallationDocument1 pagePotain MC 115B Strut InstallationPraveen KumarNo ratings yet

- MEC411 2011 - 09 Test 1Document2 pagesMEC411 2011 - 09 Test 1AmirulHanif AlyahyaNo ratings yet

- Tuesday September 5, 2023 Morning Exam Schedule AAiT Campus 5 KilloDocument21 pagesTuesday September 5, 2023 Morning Exam Schedule AAiT Campus 5 KilloSelemon BezaNo ratings yet

- Operating Data Specification: Faixa de AplicaçãoDocument1 pageOperating Data Specification: Faixa de AplicaçãoScaramouche SualkNo ratings yet

- Datasheet Pompa PDFDocument2 pagesDatasheet Pompa PDFadrian bargasNo ratings yet

- W555H Spares ManualDocument58 pagesW555H Spares ManualAriee ArieNo ratings yet

- Replacement Parts List: Fairhurst Single-Handle Pull-Down Sprayer Kitchen FaucetDocument1 pageReplacement Parts List: Fairhurst Single-Handle Pull-Down Sprayer Kitchen FaucetKilty ONealNo ratings yet

- Inauguration of SRB Substation and LP/HP Compressor System by MD, CPCL at BS-VI Auto Fuels Project (OBE), CPCL Manali Refinery, ChennaiDocument7 pagesInauguration of SRB Substation and LP/HP Compressor System by MD, CPCL at BS-VI Auto Fuels Project (OBE), CPCL Manali Refinery, ChennaiSree Arvind Harish SomasundaramNo ratings yet

- Unit 1 Introduction To WorkholdingDocument31 pagesUnit 1 Introduction To WorkholdingRamiro Acosta CepedaNo ratings yet

- EB Range Door HandlesDocument42 pagesEB Range Door HandlesOwenNo ratings yet

- My House SpecificationDocument50 pagesMy House SpecificationmurugeshwaranNo ratings yet

- TOTAL SP-TCS-146 Bolts For Piping 1993Document7 pagesTOTAL SP-TCS-146 Bolts For Piping 1993Dedy WindiyantoNo ratings yet

- محمد 1Document10 pagesمحمد 1Osama EL-AbdNo ratings yet

- Lecture 4 5 Workholding PrinciplesDocument99 pagesLecture 4 5 Workholding PrinciplesSolidworks Mania100% (1)

- Abrasive Grinding Wheels-HSE GuidelinesDocument8 pagesAbrasive Grinding Wheels-HSE Guidelinescanadiangrizzer1No ratings yet

- Technical Rescue Riggers Guide 0Document194 pagesTechnical Rescue Riggers Guide 0Patrik lativovicNo ratings yet

- Spears Butterfly Check ValvesDocument2 pagesSpears Butterfly Check ValvesDaniel FloresNo ratings yet