Professional Documents

Culture Documents

Designof Power Driven Dough Mixing Machine

Designof Power Driven Dough Mixing Machine

Uploaded by

qwztjiorxsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designof Power Driven Dough Mixing Machine

Designof Power Driven Dough Mixing Machine

Uploaded by

qwztjiorxsCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/330760598

Design of Power Driven Dough Mixing Machine

Article · February 2015

CITATIONS READS

5 12,031

1 author:

Basil Okafor

Federal University of Technology Owerri

31 PUBLICATIONS 94 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Design Chips View project

hydro-cyclone separation View project

All content following this page was uploaded by Basil Okafor on 31 January 2019.

The user has requested enhancement of the downloaded file.

International Journal of Engineering and Technology Volume 5 No. 2, February, 2015

Design of Power Driven Dough Mixing Machine

Basil E. Okafor

Department of Mechanical Engineering, Federal University of Tech., Owerri – Imo State, Nigeria.

ABSTRACT

There is still need for improvement on design of dough mixers despite the availability of a number of them in the market. It is required

that the constituents be mixed efficiently at a shorter time. The cost of the machine should also be affordable. A dough mixer has been

designed for this purpose. Whilst the mixing basin rotates in anti-clockwise direction, the stirrer (suspended on the mixing basin)

rotates in clockwise direction. Detailed design of the machine was done. Performance test result shows that proper dough mixing is

achieved in a comparatively shorter time and the cost is quite affordable with 86 per cent process efficiency.

Keywords: Mixing, Rotation, Improvement, dough, affordable.

1. INTRODUCTION

In food industries, mixing of flour to form dough has been a 3

major operation in their production process. Even in many

homes, mixing of flour for baked foods has become necessary; 5

hence the need for an affordable flour mixing machine is on 6

the increase. Despite so many dough mixers in the market, 7

2

many small and medium scale productions in developing

economies still use the traditional method of hand mixing of 1 8

9

dough for economic reasons. The challenge of producing low 4

11 10

cost mixers had led to the development of mega dough-mixing 12

machines which gained popularity in highly intensive bakeries Fig. 1.0 Assembly Drawing of Dough Mixing Machine

(Vincent, 1966). However, the cost of dough mixing still

remained uneconomically affordable for the small and

medium scale bakeries (Godwin, 1961). The primary

objective of solid mixing requires intimate intermingling of

the materials to be mixed. To meet this requirement, the flour

is placed in a vessel of some type which allows the material to

be moved and stirred in a desired pattern. This is not so simple,

as there is no one mixer design that universally satisfies all

mixing requirements (Vincent, 1966).

830

630

2. DESIGN CONCEPT

720 Side View

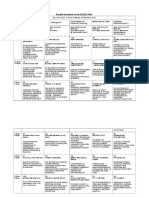

Figures 1.0 and 2.0 show the assembly drawing and Front View

orthographic views of the dough mixing machine respectively.

Table 1.0 gives the component parts of the machine 430

Plan

Fig. 2.0 Orthographic View of the Dough Mixer

ISSN: 2049-3444 © 2015 – IJET Publications UK. All rights reserved. 76

International Journal of Engineering and Technology (IJET) – Volume 5 No. 2, February, 2015

Designing for a mixer capable of mixing 10kg of flour per

batch;

Volume of mixing basin, V=10/ 11.5 =0.86m3

Table 1.0 Parts List of Mixing Machine

Let, vol. of water + vol. of air space + other ingredients = 12%

V

S/N Item No. S/N Item No. Thus, V = 0.86 + (0.12 x 0.86) = 0.96m3

Off Off But, V= r2h; let h = 0.85m; r = (V/h)1/2 = 0.59;

1 Mixing 1 7 Gear Box 1 Thus, d = 0.59x2 =1.18m

Basin Bracket

2 Stirrer 1 8 Pulley 1 3.2 Thickness of Mixing Basin, t

3 Reduction 1 9 Bushing 2

Gear Circumferential or hoop stress on mixing basin (Khurmi,

2003);

4 Drive Shaft 1 10 Sprocket 1

∆t = Pix s/2t; since the mixing basin is open, longitudinal stress

5 Pinion 1 11 Worm 1 is negligible.

pulley Gear

6 Drive Bolt 2 12 Base 1 Where Pi is the intensity of internal pressure; d is the internal

diameter of mixing basin, and t is wall thickness of the basin,

3. DESIGN ANALYSIS ∆t ≤ 5 Mpa

Capacity of the machine 70kg/Hr

Relative density of dough 11.5kg/m3 (perry, 1998) But Pi = pressure due to (centrifugal force + weight of

mixture); Pi =Pi + Pw

3.1 Volume of Mixing Basin Centrifugal Force on Mixture, Fc = mrT2; where m= mass

of mixture, kg

d = 2N/60 where r is radius of basin, m; ω is the angular

d velocity, rad/s; and N=750 rev/min

= (2 x 750)/60 = 78.44 rad/sec.; Fc 11 x 0.59 x (78.44)2

=39931.9 N

d

h P = gh; is density of mixture, h is height of mixture, and

P = pressure

P= 11.5 x 9.818 x 0.75 = 84.6 N/m2

Since Fc is acting on the circumference of the mixing basin;

Area on which Fc acts; Ac = 2rh = 2 x 0.59 x 0.85 = 3.15m

Pc = Fc /Ac = 39931.9/3.15 = 12672.7 N/m2; Pi = 12672.7 + 84.6

= 12577.3 N/m2

t = Pi d / 2∆t = (1275.3 x 1.18) / 2x 5 x 10 6 = 0.0015m; Use

2mm thick plate.

3.3 Drive Shaft

ISSN: 2049-3444 © 2015 – IJET Publications UK. All rights reserved. 77

International Journal of Engineering and Technology (IJET) – Volume 5 No. 2, February, 2015

DATA Vertical Bending Moment at C: MCV = RBV X 0.28=605.5

Coefficient of friction between drive and pulley = 0.3; Angle N-m

of wrap = 1800 Vertical Bending Moment at D: MDV = RAV x 0.3 = 2025 x

Speed = 180 rev/min; Power = Hp (3.3kw) 0.3 = 607.5 N-m

Torque transmitted is given by (Hall, 1980); T = (9550 x (i.e. from eqn,3; RAV = 4187.5 – 2162.5 = 2025 N)

kW)/RPM For Horizontal Loading; RAH + RBH = 796.19 + 1944.94 =

T = (9550 x 3.3)/180 = 175N-m; T=(T1 – T2)R 2741.13 N

where R is radius of pulley, 90mm; Taking moment at A; RBH x 0.5 = 1944.94 (0.3) +

T1 and T2 are tensions on the tight and slack sides of drive 796.19(0.22); RBH = 1519.20 N; RAH = 1223.84 N

belt respectively. Horizontal Bending Moment at C; M CH = RBH x 0.28 =

T1 = (175/0.09) /= T2 = 1944.44 + T2 (1) 1517.28 x 0.28 = 424.84 N-m

Also, T1 = T2 e:v = T2e 0.3B = 2.57 T2 (2) Horizontal Bending Moment at D; M DH = RAH X 0.3 =

From equations 1 and 2; T1 = 3182.94 N; T2 = 1238N 1223.84 X 0.3 = 367.15 N-m

Tangential force acting on spur gear, C; Ftc =T/Rc = 175/0.08 Resultant Horizontal Bending Moment;

= 2187.5N RH = [(MDH)2 + (MCH)2]1/2 = [(367.15)2 + (424.84)2]1/2 =

Normal load acting on foot of gear C (Khurmi, 2003); W c = 561.51 N-m N-m

Ftc/cos200 = 2187.5/cos20 = 2327.89N Resultant Vertical Bending Moment;

Vertical component of Wc; Wcv = Wc cos 20 = 2327.89 cos 20 Rv = [(MDV)2 + (MCV)2]1/2 = [(607.5)2 + (605.5)2]1/2 =

= 2187.5 N 857.72 N-m

Horizontal component; Wch = Wc sin 20 = 796.19 N Resultant Bending Moment; MR = (RH2 + RV2)1/2 =

Horizontal load on shaft at D; Wdh = T1 – T2 = 19.44.94N [(561.51)2 + (857.72)2]1/2 = 1025.17 N-m

Vertical Load acting on shaft at D; Wdv = 2000 N = Weight of Size of drive shaft; d3 = 16/Bss [(Kb Mb)2 + (Kt T)2]1/2

pulley (Robert, 1985)

For vertical bending moment; RAV + RBV = 2187.5 + 2000 = Where d is diameter of shaft, m; Ss is shear stress, 8 MN/m2;

4187.5 (3) and Kb = Kt = shock factors =1.2

Taking moment at A; RBV x 0.5 =2000 (0.3) + 2187.5 (0.22); d3 1= (16/B x 8 x 106 [(1.2 x 1025.17)2 + (1.2 x 175)2+]1/2 =

RBV =2162.5 N 7.95x10-6; d= 0.02m ; Use26mm shaft.

4. CONCLUSION

The mixer was fabricated and tested and the Performance was

very satisfactory. Also the cost was found quite affordable

(Appendix).

ISSN: 2049-3444 © 2015 – IJET Publications UK. All rights reserved. 78

International Journal of Engineering and Technology (IJET) – Volume 5 No. 2, February, 2015

Design capacity = 70 kg/hr REFERENCES

Capacity per batch = 10 kg [1] Erick, O. et al (1979). Mechinery's Handbook.

Industrial Press Inc. New York.

But thorough mixing of dough was achieved in approximately

[2] Godwin, J.O. et al (1961). Mixing Theory. Jerrold

10 minutes per batch. printing press. England.

Time for mixing 70 kg of dough = 7 x 10 = 70 mins [3] Hall, H.L. (1980). Machine Design. Schaum's Series.

McGraw-Hill Book Company, New York.

Efficiency = (60mins/70mins) x 100 = 86% [4] Khurmi, R.S. (2003). Machine Design. S. Chard

Company Ltd., India.

[5] Perry, R.H. (1998). Chemical Engineers Handbook.

McGraw-Hill Book Company, Singapore.

[6] Robert, O.P. (1985). Mechanical Component

Handbook. McGraw-Hill Book Company. New York.

[7] Vincent, W. (1966). Mixing Theory and Practice.

Academic Press Inc. London.

APPENDIX: MATERIALS, PROCESSES AND COST ANALYSIS OF THE DOUGH MIXER

S/N Components Qty Materials Process Machines Used United Cost N Cost N

1 Mixing 1 Stainless Steel Sheet Rolling Doming, Rolling m/c Doming m/c 4, 000 4,000

1.5 Thick Welding Are welding m/c

2 Stirring Rod 1 Stainless Steel Turning Lathe 1,600 1,600

3 Reduction Gear 1 Hard Steel Turning, Milling Lathe, Milling m/c 5,000 5,000

4 Pulley 1 Mild Steel Turning Lathe 600 600

5 Bushings 4 Bronze Turning, Boring Lathe 200 200

6 Drive Shafts 2 Mild Steel Cutting Hack Saw 800 800

7 Ball Bearings 4 200 200

8 Bevel Gear 1 Hard Steel Turning, Milling Lathe, Milling m/c 3,000 3,000

9 Skid (Base) Lump Mild Steel Cutting, Welding Saw, Welding m/c 1,800 1,800

10 V-Belt and Sprocket Mild Steel Cutting, Welding Hack Saw Arc Welding 1,500 1,500

Guards Lump m/c

11 Bolts and Nuts Lump 400 400

12 Spraying Lump 1,000 1,000

13 Labour Lump 6,000 6,000

14 Miscellaneous 2,000 2,000

TOTAL N 30,100

(Thirty Thousand, One Hundred Naira Only or One Hundred and Twenty US Dollars)

ISSN: 2049-3444 © 2015 – IJET Publications UK. All rights reserved. 79

View publication stats

You might also like

- Dark Heresy 1E A1.2 Core Alternate Character BackgroundDocument3 pagesDark Heresy 1E A1.2 Core Alternate Character Backgroundjim contrerasNo ratings yet

- S7 U1 WorksheetsDocument19 pagesS7 U1 WorksheetsDr Ahmed Reyad100% (4)

- Clamp UnitDocument25 pagesClamp Unitkhalil alhatabNo ratings yet

- Method Statement For Tank Jack Lifting 2Document19 pagesMethod Statement For Tank Jack Lifting 2tomj910492% (37)

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- How To Set Up MDS in PDMSDocument17 pagesHow To Set Up MDS in PDMSAmri Rsylna100% (2)

- Chapter IDocument74 pagesChapter Ihoney mae100% (1)

- 08 CH-6, Fluid Motion Within Combustion ChamberDocument24 pages08 CH-6, Fluid Motion Within Combustion ChamberAhsan AliNo ratings yet

- 215 Sample ChapterDocument23 pages215 Sample ChapterSreekumar RajendrababuNo ratings yet

- Design and Performance Evaluation of A Screw Press Separator For Separating Dairy Cattle ManureDocument10 pagesDesign and Performance Evaluation of A Screw Press Separator For Separating Dairy Cattle ManureDaniel SouzaNo ratings yet

- Fabrication of Portable Noodle Making Ma Fd82a2eeDocument4 pagesFabrication of Portable Noodle Making Ma Fd82a2eeankush belkarNo ratings yet

- 05 OS 08 GE Rapid Design Solutions For Automotive Bumper EnergyDocument6 pages05 OS 08 GE Rapid Design Solutions For Automotive Bumper EnergyatulhandeNo ratings yet

- Design and Fabrication of Groundnut ShellerDocument7 pagesDesign and Fabrication of Groundnut ShellerIJRASETPublications100% (1)

- Stress Analysis in Crankshaft Through FEMDocument3 pagesStress Analysis in Crankshaft Through FEMEditor IJRITCCNo ratings yet

- Design Plastic Bottle CrusherDocument4 pagesDesign Plastic Bottle CrusheragungNo ratings yet

- Design and Fabrication of Can CrusherDocument5 pagesDesign and Fabrication of Can CrusherBrightchip TechnologiesNo ratings yet

- Pneumatic Bike: A Step To Future: V. Lohit A. Imran MohideenDocument3 pagesPneumatic Bike: A Step To Future: V. Lohit A. Imran MohideenTanviNo ratings yet

- DEBRE BERHAN UNIVERSITY ThesisDocument27 pagesDEBRE BERHAN UNIVERSITY Thesishayliyesus100% (1)

- TE - Mech - RAC - Chapter 4 - VCC Cycles-1Document98 pagesTE - Mech - RAC - Chapter 4 - VCC Cycles-1Aniket MandalNo ratings yet

- Roller Conveyor Chain AttachmentsDocument19 pagesRoller Conveyor Chain AttachmentsRichard VachonNo ratings yet

- Coconut Dehusking MachineDocument16 pagesCoconut Dehusking MachineArjuncv100% (4)

- Design and Fabrication of Plastic Bottle and Can Crusher For Recycling PurposeDocument3 pagesDesign and Fabrication of Plastic Bottle and Can Crusher For Recycling PurposeInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Bullock Cart: Aarushree KhobragadeDocument13 pagesBullock Cart: Aarushree KhobragadeAzure MidoriyaNo ratings yet

- Mais Thresher PDFDocument6 pagesMais Thresher PDFHenry DatangelNo ratings yet

- Automatic Plaster MachineDocument4 pagesAutomatic Plaster MachineIJMTST-Online JournalNo ratings yet

- Fabrication of Low-Cost Manualcrop Harvesting MachineDocument9 pagesFabrication of Low-Cost Manualcrop Harvesting Machinepratik g100% (1)

- 1st Assignment of MMCDocument9 pages1st Assignment of MMCAwais Asghar KhanNo ratings yet

- Auto CadDocument21 pagesAuto CadMohammed AminNo ratings yet

- Pnumatic Ramming and Punching Machine ReportDocument28 pagesPnumatic Ramming and Punching Machine ReportSun SriNo ratings yet

- Test Code & Procedure of Power ThresherDocument8 pagesTest Code & Procedure of Power ThresherAnonymous fB9ZzVzV100% (1)

- Analysis of Tool Geometry For Screw Extrusion MachinesDocument12 pagesAnalysis of Tool Geometry For Screw Extrusion MachinesdjklikaNo ratings yet

- Block Brakes Design ProcedureDocument3 pagesBlock Brakes Design ProcedureChristian Breth BurgosNo ratings yet

- Design of Automated Hammering Machine ReportDocument55 pagesDesign of Automated Hammering Machine ReportBiruk Damtew Ze MerhabeteNo ratings yet

- Jimma UniversityDocument99 pagesJimma UniversityBekan NegesaNo ratings yet

- Design and Fabrication of Motorised Scotch Yoke MechanismDocument16 pagesDesign and Fabrication of Motorised Scotch Yoke Mechanismlost wolfNo ratings yet

- ME308 Second Project PDFDocument13 pagesME308 Second Project PDFOzan OzgenNo ratings yet

- 6 Design of Gear BoxDocument2 pages6 Design of Gear BoxRutvikLathia100% (1)

- Flange Coupling Lab PDFDocument25 pagesFlange Coupling Lab PDFAli Raza MalikNo ratings yet

- Unit 6: Stability of Linear Control SystemDocument14 pagesUnit 6: Stability of Linear Control SystemNasrullah YusupNo ratings yet

- Design and Fabrication of Groundnut Thresher MachineDocument5 pagesDesign and Fabrication of Groundnut Thresher MachineBhanu Hi100% (1)

- Project On Hydraulic Telescopic Transmission JackDocument69 pagesProject On Hydraulic Telescopic Transmission JackbirukNo ratings yet

- VHJJJKDocument17 pagesVHJJJKKhanna Dhinesh100% (1)

- Introduction of The Dough Making Mixing Machine VDocument8 pagesIntroduction of The Dough Making Mixing Machine VMyster Reilous100% (1)

- Can Crusher ReportDocument12 pagesCan Crusher ReportHarkirat SinghNo ratings yet

- ENGINE FINS Final Report - Phase 1Document44 pagesENGINE FINS Final Report - Phase 1Boopathi KalaiNo ratings yet

- Design and Fabrication of Pedal Powered Lawn Mower CycleDocument2 pagesDesign and Fabrication of Pedal Powered Lawn Mower CycleVinayaga ProjectinstituteNo ratings yet

- Belt and Drive Analysis of Flour MillDocument16 pagesBelt and Drive Analysis of Flour Milllikhith saiNo ratings yet

- Chapter 10Document78 pagesChapter 10Si Thu AungNo ratings yet

- Archimedys Technical Data - Metric - GB 11264 PDFDocument43 pagesArchimedys Technical Data - Metric - GB 11264 PDFAnonymous Cxriyx9HIXNo ratings yet

- Series Hybrid Car Doc - 3Document137 pagesSeries Hybrid Car Doc - 3mekkararameshNo ratings yet

- MD E-Note 22092018 125841PM PDFDocument175 pagesMD E-Note 22092018 125841PM PDFPramod DhaigudeNo ratings yet

- MM 321 Field ReportDocument15 pagesMM 321 Field ReportSiddhant Vishal Chand0% (1)

- Design of Clutch Plate For Light Motor Vehicle NewDocument14 pagesDesign of Clutch Plate For Light Motor Vehicle NewKedar BardeNo ratings yet

- Pan Mixer-1 PDFDocument6 pagesPan Mixer-1 PDFBhupatiNo ratings yet

- Albatur 7036 - M03 Sliding Door System PDFDocument2 pagesAlbatur 7036 - M03 Sliding Door System PDFБорис БиджевNo ratings yet

- BOE CertificatesDocument2 pagesBOE CertificatesMahadev KovalliNo ratings yet

- Mechanical HandbookDocument11 pagesMechanical HandbookPradeep PushparajNo ratings yet

- Stress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894Document7 pagesStress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894anil sajjanarNo ratings yet

- Road Performance PDFDocument8 pagesRoad Performance PDFwanawNo ratings yet

- Automatic Coconut Cutting MachineDocument3 pagesAutomatic Coconut Cutting Machinesidhant samalNo ratings yet

- Vishal 35426455tyre Changer Machine NEWDocument22 pagesVishal 35426455tyre Changer Machine NEWSushant ManeNo ratings yet

- AT6501 (R-13) Notes PDFDocument131 pagesAT6501 (R-13) Notes PDFAashiq NawinNo ratings yet

- 5.2 Flanged Bolt CouplingDocument11 pages5.2 Flanged Bolt CouplingShayneBumatay0% (1)

- 1618-Article Text-4285-1-10-20200603Document6 pages1618-Article Text-4285-1-10-20200603seyrie_icNo ratings yet

- Edo Bro Coe Cor Int XXX 013 038 039 Rev A Aluminium AnodesDocument7 pagesEdo Bro Coe Cor Int XXX 013 038 039 Rev A Aluminium AnodesErol DAĞNo ratings yet

- Membership Application Form: Picqs Philippine Institute of Certified Quantity Surveyors, IncDocument2 pagesMembership Application Form: Picqs Philippine Institute of Certified Quantity Surveyors, IncfreannNo ratings yet

- Capacitor PYQDocument8 pagesCapacitor PYQbinitamuzNo ratings yet

- 966H and 972H Wheel Loader TA2 Technical InspectionDocument8 pages966H and 972H Wheel Loader TA2 Technical InspectionLaouini GhaithNo ratings yet

- CMINDS AdmissionTest - SYLLABUS Apr22Document4 pagesCMINDS AdmissionTest - SYLLABUS Apr22Soham DattaNo ratings yet

- Using Fastcgi To Host PHP Applications On Iis 7Document24 pagesUsing Fastcgi To Host PHP Applications On Iis 7sebacruzarNo ratings yet

- Dna Replication Lesson PlanDocument14 pagesDna Replication Lesson PlanKatsunori TolentinoNo ratings yet

- Technical Support Engineer Interview Questions 2Document2 pagesTechnical Support Engineer Interview Questions 2Rajesh BabuNo ratings yet

- 1999-Application of Subset Autoregressive Integrated Moving Average Model For Short-Term Freeway Traffic Volume ForecastingDocument10 pages1999-Application of Subset Autoregressive Integrated Moving Average Model For Short-Term Freeway Traffic Volume Forecastingsantiago montenegroNo ratings yet

- Efficient Computation of The DFTDocument35 pagesEfficient Computation of The DFTNikita ShakyaNo ratings yet

- The Challenges Oracle Forms Migration To ADFDocument18 pagesThe Challenges Oracle Forms Migration To ADFMrinmoy AicchNo ratings yet

- UPSC Public Administration Previous Year Topic Wise Segregated OptionalDocument87 pagesUPSC Public Administration Previous Year Topic Wise Segregated OptionalengineernarayanNo ratings yet

- eMAX LP1502 ManualDocument20 pageseMAX LP1502 Manualtp.segarNo ratings yet

- 7.7 Gantt Chart. Milestones, Tasks, Critical PathDocument5 pages7.7 Gantt Chart. Milestones, Tasks, Critical PathnikitaybhavsarNo ratings yet

- AMREF - AWiM19 Sponsorship ProposalDocument29 pagesAMREF - AWiM19 Sponsorship ProposalPower to Youth KenyaNo ratings yet

- Ecofeminism - WikipediaDocument24 pagesEcofeminism - WikipediaSaumyabrata GaunyaNo ratings yet

- Teka2013 - Sinks and TapesDocument63 pagesTeka2013 - Sinks and Tapesignaciogarciasanz84No ratings yet

- Thesis Fahmi 28072021Document54 pagesThesis Fahmi 28072021faqih editNo ratings yet

- Zforce Touch FINAL REPORTDocument20 pagesZforce Touch FINAL REPORTSWAPNILJUMALE75% (4)

- Electricity MCQ'SDocument131 pagesElectricity MCQ'SSalik SalikNo ratings yet

- DCTech IRMA Roof Design GuideDocument16 pagesDCTech IRMA Roof Design GuideGayan WeerasekeraNo ratings yet

- Parallel Sessions of 1st ICGBEC2016 - V6Document8 pagesParallel Sessions of 1st ICGBEC2016 - V6Shona TahseenNo ratings yet

- Waoo Wet 1 AutoDocument2 pagesWaoo Wet 1 AutoMuharrahmansyahNo ratings yet

- The Titration of Clay MineralsDocument10 pagesThe Titration of Clay MineralsroyamohamadyNo ratings yet

- Quick Start Guide Leica 1203Document14 pagesQuick Start Guide Leica 1203turlututu123No ratings yet