Professional Documents

Culture Documents

Clamp Unit

Uploaded by

khalil alhatab0 ratings0% found this document useful (0 votes)

25 views25 pagesOriginal Title

6. Clamp Unit

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views25 pagesClamp Unit

Uploaded by

khalil alhatabCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 25

Plastic Injection Technology

BMM 4843

Clamp unit

Wan Sharuzi Wan Harun

Faculty of Mechanical Engineering

Universiti Malaysia Pahang

sharuzi@ump.edu.my

jihad_ku@yahoo.com

019 959 0039

09 424 6339

INTRODUCTION

Figure 6.1 Schematic of an IMM clamp unit

• The clamp unit performs the following

functions;

1. Holds the mold;

2. Closes the mold;

3. Keep the mold closed under pressure during

injection;

4. Opens the mold to allow the parts to be ejected;

and

5. Accommodates the ejector system which ejects

the part out of the mold.

• The clamp unit is illustrated in Figure 6.1

showing the mold in the open position with

the moving platen as far to the left as possible.

• The clamping mechanism provides the force

to keep the mold closed during the injection

and holding-pressure stages of the machine

cycle.

• Two types of clamping mechanisms;

– Hydraulic

– Hydro-mechanical

Hydraulic Clamp System

• Uses direct acting hydraulic cylinders to

achieve the closing and clamping of the mold.

Figure 6.2 IMM hydraulic clamp unit

• Figure 6.2 is typical design of this type of system

with the mold in the open position.

• The hydraulic oil reservoir is mounted in a

position (some on top and some below the

main cylinder) that allows the oil to flow by

gravity or by pumping pressure into the main

cylinder.

• The high-speed cylinder is smaller in diameter

and permits the rapid movement on the moving

platen to a point where mold is nearly closed.

• During this movement, the prefill valve is open,

allowing the oil to flow into the hydraulic main

cylinder behind the main ram.

• When the mold is nearly closed, the prefill valve

closes.

• The hydraulic pressure, developed by hydraulic

pumps, develops a force on the main ram of about 21

MPa. This force is used to achieve the final clamping

of the mold, typically a relatively short stroke.

• Depending upon the size of the main ram, the 21 MPa

can translate into a clamp tonnage of considerable

magnitude.

Example Calculati on

Hydro-Mechanical System

• Uses lever arms, toggles or other mechanical devices

to multiply the force exerted by the hydraulic system

to achieve desired clamping force.

Figure 6.3 IMM

toggle clamp unit

• Also referred to as a toggle clamp system.

• Figure 6.3 illustrates the functioning of a double

toggle clamping unit. Its referred as double toggle

because of the 2 sets of toggle links bringing force to

the moving platen, one set at the top sets and

another set at the bottom.

• On smaller machines (<50tons), a single toggle clamp

unit is often used.

• Because the mechanical force enabled by the toggle

links, the hydraulic cylinder that provides the force to

the toggle links can be much smaller than hydraulic

clamp unit.

• The mechanical advantage in the toggle system

can range from 25:1 to 50:1.

• This mechanical advantage reduces the diameter

of the hydraulic cylinder required to achieve clamp

force.

• It also permit the use of lower hydraulic pressures

and hydraulic oil requirements.

Figure 6.4 Toggle

clamp unit in a

closed position

• The toggle clamp unit in the closed position in shown in

Figure 6.4.

• IMMs in use today offer clam tonnage from less than 30 tons

to 5000 tons.

• The force generated by these systems is to clamp and hold the

mold closed.

• For example, 200 ton machine means that the clamp

unit can develop 200tons of force to hold the closed

mold during injection and holding stages.

• The clamp force is needed to withstand the opposing

force of injection pressure as the screw comes

forward.

• Typical injection pressure is 110 to 152 MPa.

• Does this mean that a clamp force of about 150MPa

(10 tons/in2) is required to offset the force?

• NO!!, greater tonnage capacities would be required

to achieve successfully molding.

Clamp Unit Specifi cati ons

• Mold Height Maximum/Minimum – Defines the

max & min total thickness of a mold that can be

used in that particular clamp unit.

• Maximum daylight – The max amount of space

that is available between the movable and

stationary platens. Approx. equal to the max mold

height plus the clamp stroke.

• Clamp Stroke – the distance that the movable

platen is able to move (open). This spec., combined

with the max. mold height, can serve to limit the

height of a product that you can mold.

Clamp Unit Specifi cati ons

• Platen Size – the horizontal and vertical

measurement of the platens can be a determinant

in the maximum size of the mold that can be

mounted in that particular clamp unit.

• Distance Between Tie Bars – most clamp units

have 2 upper and 2 lower tie bars. Horizontal

measurement is more critical than the vertical

because most molds are mounted from the top.

This spec., combined with platen size and the max

mold height, serves to limit the overall size of

mold that can placed in the clamp unit.

Figure 6.5

Illustration of the

stroke of a clamp

unit

• Some IMM are considered “tie bar-less” machines which

facilitate the mounting of and access to the mold.

• Most of this machines are small clamp tonnage

(<500tons).

Ejector System

• The process of ejecting parts out of the mold involves

both the clamp unit and the mold itself.

• Hydraulic ejection is a standard feature of all

machines.

• The clamp unit includes the hydraulic mechanism

that provides the force to push the part out of the

mold.

• The mechanism referred to as a knock-out (K.O.)

system.

• There are standardized hole patterns on both

movable and stationary platens

• The patterns consists of;

– Mounting holes (for mounting the mold on the platen)

– Knock-out holes (for ejector system)

• The pattern of holes was standardized by the

Society of the Plastics Industry (S.P.I)

Figure 6.6 Platen

hole patterns for

500 ton IMM

Ejecti on

• Ejector bars (ejector rods) are inserted through the

movable platen and threaded into the ejector housing

(ejector box) that is mounter on the back side of the

movable platen.

• The ejector housing is typically a steel plate that rides

on guide rods.

• The hydraulic cylinder(s) that locates behind the

ejector housing actuates the housing to move forward

which, in turn, causes the ejector bars to move

forward.

• The ejector bar enters the back side of the mold and

contacts the ejector plate in the mold, causing it to

move forward.

• The mold ejector plate is in contact with one of

several possible devices; ejector pins, a stripper

plate, or another ejection mechanism that, when

pushed forward, contacts the molded part and

ejects it out of the mold.

• Springs, mounted between the mold and the ejector

plate, return the ejector plate to its normal position.

• The important point to understand about the

ejector system in the clamp unit is how the

hydraulic force causes a forward action against the

mold ejector plate.

Figure 6.7 Hydraulic ejector system

• Other types of ejection systems are;

1. A single hydraulic cylinder

2. A push-pull action with the ejector bars bolted to

ejector plate, and

3. Floating ejection bars.

• However, the principles involved in their

operation are similar to those illustrated.

Case Study

• On many occasions, molders have experienced

flash on the parts being produced yet a careful

review of the mold and processing parameters

fails to disclose a cause.

• Finally, a check of the squareness of the

platens, one to the other, revealed the source

of the problem. In similar instances, the mold

halves have been found to not be square,

one to the other. Although these maintenance

checks seem so fundamental and obvious, such

problems do occur.

Case Study

On several occasions during the past few years, we have

read of cases where a machine operator has lost fingers

and hands as a result of not paying heed to the safety rules

involving the clamp unit. In some more violent accidents

that have been described in trade journals, men have been

crushed to death when the clamp unit accidentally closed

on their bodies.

All injection molding machines are equipped with safeties

that prevent the accidental closing of the clamp unit.

Discuss your opinion on why accident related to IMM clap

unit still occurs regardless all well-quipped machine

safeties.

Case Study-answer

Yet there have been and will no doubt be many

operators or maintenance men in the future that

disable the safeties to theoretically facilitate

their work on the clamp unit or the mold while

it is in the machine. The results can be fatal!

Do NOT disable machine safeties that affect the

operation of the clamp unit. While working

around this unit and/or the mold, turn the power

off and proceed according to the safety rules

that the machine manufacturer supplies.

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Injection Moulding April 2023Document50 pagesInjection Moulding April 2023AmniNo ratings yet

- Chapter 1-2Document70 pagesChapter 1-2Shivpoojan SinghNo ratings yet

- ControlDocument49 pagesControlkhalil alhatabNo ratings yet

- Frank Fischer - Injection MoldingDocument12 pagesFrank Fischer - Injection MoldingStarchyLittleOleMeNo ratings yet

- Report Literture ReviewDocument11 pagesReport Literture Reviewosama hasanNo ratings yet

- Sheet Metal Stamping Presses: Training ObjectiveDocument6 pagesSheet Metal Stamping Presses: Training ObjectiveSileno DiasNo ratings yet

- Injection Moulding MachineDocument35 pagesInjection Moulding MachineRajesh Kumar88% (8)

- 22 Understanding Clamping Force PDFDocument2 pages22 Understanding Clamping Force PDFAlexNo ratings yet

- QMC001 01 GBDocument16 pagesQMC001 01 GBsansagithNo ratings yet

- Cone CrusherDocument3 pagesCone Crusherchand_yelNo ratings yet

- 2 IM Parameters, Cycle Time N Machine Selection 2023Document62 pages2 IM Parameters, Cycle Time N Machine Selection 2023AmniNo ratings yet

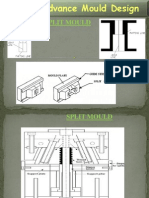

- Advance Mould DesignDocument35 pagesAdvance Mould DesignKamal Krishna Kashyap100% (6)

- Injection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarsDocument37 pagesInjection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarslakhancipetNo ratings yet

- Injection Muolding MachineDocument26 pagesInjection Muolding MachineSidharth Shankar singhNo ratings yet

- Practical Guide To Rubber Injection MouldingDocument10 pagesPractical Guide To Rubber Injection Mouldingسعید اینانلوNo ratings yet

- Projectile LoomDocument30 pagesProjectile Loomyuganshu_soni89% (9)

- Proto Copy Finale DraeteDocument60 pagesProto Copy Finale DraeteAjinkya MoreNo ratings yet

- Plastic Mould DesignDocument6 pagesPlastic Mould Designyes1nthNo ratings yet

- Chapter 1-5Document54 pagesChapter 1-5Abah FarisNo ratings yet

- Liner Hanger & Setting ToolDocument58 pagesLiner Hanger & Setting ToolRobert Koch100% (1)

- Injection Molding BasicsDocument26 pagesInjection Molding BasicsVIGNESH100% (1)

- دورة تشغيل ماكينات البلاستيكDocument28 pagesدورة تشغيل ماكينات البلاستيكfadyNo ratings yet

- Plastic Injection TechnologyDocument4 pagesPlastic Injection TechnologyRima ChinnasamyNo ratings yet

- A) Describe The Injection Molding Process. An Injection-Molding Machine Is Divided Into Two Principal Components, Name ThemDocument9 pagesA) Describe The Injection Molding Process. An Injection-Molding Machine Is Divided Into Two Principal Components, Name ThemAsad kkNo ratings yet

- Different Types of Blow MoldingDocument11 pagesDifferent Types of Blow MoldingParvateshNo ratings yet

- Advance Injection Mould DesignDocument175 pagesAdvance Injection Mould DesignŠetkić SemirNo ratings yet

- Hydraulic Press Brake MachineDocument7 pagesHydraulic Press Brake MachineWahyu SiwastanaNo ratings yet

- INTRODUCTIONDocument13 pagesINTRODUCTIONPrabhav KulkarniNo ratings yet

- Computer Controlled Machine Maintenance (Mechanical) FailuresDocument23 pagesComputer Controlled Machine Maintenance (Mechanical) Failuressank_knasNo ratings yet

- Injection Molding FinalDocument49 pagesInjection Molding FinalShoaib RathoreNo ratings yet

- Coal Cutting MachineDocument62 pagesCoal Cutting MachineSaiNo ratings yet

- Ejemplo de Variables de InstrumentacionDocument16 pagesEjemplo de Variables de InstrumentacionEduardo JiménezNo ratings yet

- Pumps Course MaterialDocument222 pagesPumps Course Materialarkan1976No ratings yet

- Manual Book ZS 265Document8 pagesManual Book ZS 265Yulissa Paola Galeana RamosNo ratings yet

- Power Point 1111122222Document17 pagesPower Point 1111122222Gadisa AbrahimNo ratings yet

- Engine Top BracingDocument14 pagesEngine Top Bracingcall_manishNo ratings yet

- Alba C-52L User ManualDocument12 pagesAlba C-52L User ManualdrmassterNo ratings yet

- Ass. 2Document18 pagesAss. 2Ramez RaymonNo ratings yet

- Catalog - Hot Rolled MillsDocument18 pagesCatalog - Hot Rolled MillsAlex LevinNo ratings yet

- Machine MaintenanceDocument39 pagesMachine MaintenanceTariku HabteselassieNo ratings yet

- (IJET-V1I2P4) Authors :mrs - Rita S. Pimpalkar, Rutuja U. Joshi, Rakesh R. Khandare, Rounak R. Agarwal, Bhushan S. BendaleDocument8 pages(IJET-V1I2P4) Authors :mrs - Rita S. Pimpalkar, Rutuja U. Joshi, Rakesh R. Khandare, Rounak R. Agarwal, Bhushan S. BendaleInternational Journal of Engineering and TechniquesNo ratings yet

- Ymt 2 ManualDocument32 pagesYmt 2 ManualRahul Patel100% (1)

- Injection Moulding: Dharmendra Kumar Yadav Mtech, Rubber Technology IIT KharagpurDocument30 pagesInjection Moulding: Dharmendra Kumar Yadav Mtech, Rubber Technology IIT KharagpurlawrenziNo ratings yet

- Aluminium Extrusion ProcessDocument14 pagesAluminium Extrusion ProcessJalim YadavNo ratings yet

- Injection Moulding PPT Presentation F16me11Document24 pagesInjection Moulding PPT Presentation F16me11AbdulRehman Ahmed SoomroNo ratings yet

- April May 2014 Design of Jigs and Fixtures Anwer KeyDocument17 pagesApril May 2014 Design of Jigs and Fixtures Anwer Keybalaguru78No ratings yet

- Unit I Locating and Clamping PrinciplesDocument15 pagesUnit I Locating and Clamping PrinciplesMECHANICAL DESIGNSNo ratings yet

- How To Overhaul Centrifugal PumpDocument19 pagesHow To Overhaul Centrifugal Pumpanil thakurNo ratings yet

- Cone Crusher Busing Burn OutDocument1 pageCone Crusher Busing Burn Outatul.deshmukhNo ratings yet

- Industrial Report (PSG)Document21 pagesIndustrial Report (PSG)Ratna PadaviNo ratings yet

- Friction GuidewaysDocument13 pagesFriction Guidewaysyummit100% (1)

- Fine BlankingDocument9 pagesFine BlankingElaine JohnsonNo ratings yet

- Injection UnitDocument27 pagesInjection Unitkhalil alhatabNo ratings yet

- Catlog of QMCS and QDC For Injection Molding Machine From Mico, Korea by Semyung India, ChennaiDocument19 pagesCatlog of QMCS and QDC For Injection Molding Machine From Mico, Korea by Semyung India, ChennaiMuthu KumaranNo ratings yet

- Maintenance and Troubleshooting of Centrifugal PumpsDocument21 pagesMaintenance and Troubleshooting of Centrifugal PumpsMichael HailuNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Wet EtchDocument28 pagesWet Etchkhalil alhatabNo ratings yet

- Final Exam Stress Analysis 2016 AnswersDocument7 pagesFinal Exam Stress Analysis 2016 Answerskhalil alhatabNo ratings yet

- 1 Introduction 학생용Document16 pages1 Introduction 학생용khalil alhatabNo ratings yet

- Design and Development of Tilting Rotary Furnace: IOP Conference Series: Materials Science and EngineeringDocument8 pagesDesign and Development of Tilting Rotary Furnace: IOP Conference Series: Materials Science and EngineeringaliNo ratings yet

- Course Overveiw 1Document14 pagesCourse Overveiw 1khalil alhatabNo ratings yet

- Chem 470/me 497Document1 pageChem 470/me 497khalil alhatabNo ratings yet

- Depostion and Liftoff - Lab2Document10 pagesDepostion and Liftoff - Lab2khalil alhatabNo ratings yet

- 27 11 2022 2dMidtermExamMT308-Industrial AutomationDocument2 pages27 11 2022 2dMidtermExamMT308-Industrial Automationkhalil alhatabNo ratings yet

- UNIT 2 HELICAL & BEVEL GEAR Handwritten NotesDocument47 pagesUNIT 2 HELICAL & BEVEL GEAR Handwritten Noteskhalil alhatabNo ratings yet

- Lecture 3 Introduction To Machine Tool Drives and MechanismsDocument59 pagesLecture 3 Introduction To Machine Tool Drives and Mechanismskhalil alhatab100% (1)

- Drives in Mechatronics1Document14 pagesDrives in Mechatronics1Durga PrasadNo ratings yet

- Chapter 2Document6 pagesChapter 2khalil alhatabNo ratings yet

- 23 Control of Machine ToolsDocument7 pages23 Control of Machine Toolskhalil alhatabNo ratings yet

- PlasticsDocument27 pagesPlasticskhalil alhatabNo ratings yet

- Design Injection Molds PDFDocument76 pagesDesign Injection Molds PDFJose Luis MendozaNo ratings yet

- Midterm P2800 2008 SolutionsDocument6 pagesMidterm P2800 2008 Solutionskhalil alhatabNo ratings yet

- MTExam ME 101 31 11 2022Document6 pagesMTExam ME 101 31 11 2022khalil alhatabNo ratings yet

- Designandfabricatonofsoapploddingmachineinresponsetohighdemandofsoapanddetergentduringthecovid 19eraDocument12 pagesDesignandfabricatonofsoapploddingmachineinresponsetohighdemandofsoapanddetergentduringthecovid 19erakhalil alhatabNo ratings yet

- CHAP1 - Product Design Theory and MethodologyDocument34 pagesCHAP1 - Product Design Theory and Methodologykhalil alhatabNo ratings yet

- Chap2 - Product Development ProcessDocument47 pagesChap2 - Product Development ProcessSeng SoonNo ratings yet

- Chap2 - Product Development ProcessDocument47 pagesChap2 - Product Development ProcessSeng SoonNo ratings yet

- MTExam ME 101 31 11 2022Document6 pagesMTExam ME 101 31 11 2022khalil alhatabNo ratings yet

- Cad Cam Mtexam 2Document3 pagesCad Cam Mtexam 2khalil alhatabNo ratings yet

- Final ExamMDFinal 2023Document2 pagesFinal ExamMDFinal 2023khalil alhatabNo ratings yet

- Properties & Strength of MaterialsDocument1 pageProperties & Strength of Materialskhalil alhatabNo ratings yet

- MidTermExam CADCAM2019 AnswerDocument6 pagesMidTermExam CADCAM2019 Answerkhalil alhatabNo ratings yet

- Which of The Following Modelling 3D Model Representation Is Also Called As Building Block ApproachDocument8 pagesWhich of The Following Modelling 3D Model Representation Is Also Called As Building Block Approachkhalil alhatabNo ratings yet

- MTExam3 Strength of Materials 2022 2023Document4 pagesMTExam3 Strength of Materials 2022 2023khalil alhatabNo ratings yet

- Distress Manual PDFDocument51 pagesDistress Manual PDFEIRINI ZIGKIRIADOUNo ratings yet

- Pump Foundation Design PDFDocument18 pagesPump Foundation Design PDFArchana ArchuNo ratings yet

- Directorate of Pension, Provident Fund & Group Insurance: WWW - Wbepension.gov - inDocument37 pagesDirectorate of Pension, Provident Fund & Group Insurance: WWW - Wbepension.gov - inSandipan RoyNo ratings yet

- DX-790-960-65-17.5i-M: Electrical PropertiesDocument2 pagesDX-790-960-65-17.5i-M: Electrical PropertiesАлександрNo ratings yet

- UCLA-Career Preparation ToolkitDocument61 pagesUCLA-Career Preparation ToolkitCaelulalaNo ratings yet

- ToRs ESIA Maputo Sewerage System FinalDocument36 pagesToRs ESIA Maputo Sewerage System FinalVirgilio MuandoNo ratings yet

- Harper's Illustrated Biochemistry - Hormonal Control in Signal TransductionDocument18 pagesHarper's Illustrated Biochemistry - Hormonal Control in Signal TransductionDr Sanjeeb Kumar Dey BaidyaNo ratings yet

- Punch Fear in The Face Escape AverageDocument12 pagesPunch Fear in The Face Escape AverageRezaBachtiarNo ratings yet

- Case Analysis: The Kimpton ExperienceDocument1 pageCase Analysis: The Kimpton ExperienceMaricel Ann BaccayNo ratings yet

- The Baldur's Gate Series 1 - Baldur GateDocument125 pagesThe Baldur's Gate Series 1 - Baldur GateJustin MooreNo ratings yet

- CBSE Sample Paper For Class 9 Maths 2021 Set 1Document6 pagesCBSE Sample Paper For Class 9 Maths 2021 Set 1Aryaman TiwariNo ratings yet

- Competency Based Learning Materials: Housekeeping NciiDocument54 pagesCompetency Based Learning Materials: Housekeeping NciiNickolodian AsuncionNo ratings yet

- 3.3 Cell MembraneDocument19 pages3.3 Cell MembraneHanaa WazzanNo ratings yet

- Server Preparation Details LinuxDocument9 pagesServer Preparation Details Linuxbharatreddy9No ratings yet

- Pashchimanchal Campus: Set ADocument1 pagePashchimanchal Campus: Set AAnonymous uTC8baNo ratings yet

- Kompilasi Soal Paket BDocument10 pagesKompilasi Soal Paket Babdul wahidNo ratings yet

- RCB Dealers PHDocument3 pagesRCB Dealers PHJing AbionNo ratings yet

- NSDADocument1 pageNSDAShallu ManchandaNo ratings yet

- CN Mod1 Ppt-FinalDocument56 pagesCN Mod1 Ppt-FinalkkNo ratings yet

- Case Study 6Document6 pagesCase Study 6Shaikh BilalNo ratings yet

- SAP On ASE Development UpdateDocument16 pagesSAP On ASE Development Updatebetoy castroNo ratings yet

- CH 121: Organic Chemistry IDocument13 pagesCH 121: Organic Chemistry IJohn HeriniNo ratings yet

- Catalogue For TubingDocument1 pageCatalogue For Tubingprabhakaran.cNo ratings yet

- Jeff Nippard's Workout Routine & Diet (2022) - Jacked GorillaDocument11 pagesJeff Nippard's Workout Routine & Diet (2022) - Jacked Gorillaticoninx100% (1)

- UNA010F-0-V2: Electrical SpecificationsDocument2 pagesUNA010F-0-V2: Electrical SpecificationsNiko ZabalaNo ratings yet

- BT JOE Quiz 4 MasonryDocument1 pageBT JOE Quiz 4 Masonrycorazon phil100% (1)

- Afternoon Quiz Set 4Document66 pagesAfternoon Quiz Set 4pchakkrapani100% (1)

- Gas Pressure Reduction StationDocument2 pagesGas Pressure Reduction StationMathias OnosemuodeNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- VISTA LAND AND LIFESCAPES INC FinalDocument9 pagesVISTA LAND AND LIFESCAPES INC Finalmarie crisNo ratings yet