Professional Documents

Culture Documents

Hyd01 e I 154 0 - Qap

Uploaded by

sureshrajquality.siemensOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hyd01 e I 154 0 - Qap

Uploaded by

sureshrajquality.siemensCopyright:

Available Formats

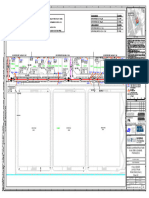

0 24.05.

2023 FIRST SUBMISSION WD WD RKG

Rev. Rev. Date Category of Document Drawn By Reviewed By Approved By

Client Document No. : HYD01-E-I-154-0

Client : Adani Transmission Ltd Location : Hyderabad, Telangana

Substation Type : GIS

Project : HYD01-220 kV EHV Substation Voltage Level : 220kV/33kV

Document Title : GIS SAS - Quality Assurance Plan (QAP)

1 2 3 4 5 6 7 8

A A

SI-DG-EA

Quality Assurance Plan

B B

End Customer

C MICROSOFT C

Consultant

AECOM

Client

ADANI

EPC/Contractor

D D

SIEMENS LIMITED

Project

HYD01-220kV GIS SUBSTATION, HYDRABAD

Ref No

HYD01-E-I-154-0

Substation

E 220kV GIS SUBSTATION E

Title

Quality Assurance Plan

Drawing No.

(3)-G719EA-PG9133-00-Q500

F DATE 24.05.2023 220KV GIS SUBSTATION K 1mm : 1mm. F

HYD01-220kV GIS SUBSTATION, HYDERABAD

DRAWN BY SPR ADANI TRANSMISSION LTD. COVER SHEET K500

0 FIRST SUBMISSION 24.05.2023 DWL CHKD. BY DWL SIEMENS LIMITED SHT. 00 OF --

62OP-91249.P.02 DWG. REF.: (3)-G719EA-PG9133-00-Q500

REVISION REMARKS DATE NAME APPR. BHS <- 01>

1 2 3 4 5 6 7 8

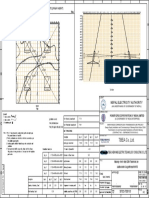

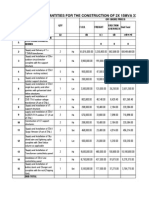

STANDARD QUALITY PLAN

SQP NO:

ITEM : CONTROL & RELAY PANEL REV. NO.:01

SIEMENS DATE:

PAGE:

Approved by QA

1 of 3

INSPECTION

CATEGORY OF TYPE OF QUANTUM OF CHECK REFERENCE ACCEPTANCE

SL. NO COMPONENT/OPERATION CHARACTERISTICS FORMAT OF RECORD AGENCY

CHECK CHECK DOCUMENT NORMS

M C/A M C A REMARKS

1 2 3 4 5 6 7 8 9 *D **10 11

1. RAW MATERIAL/ BOUGHT OUT ITEMS

Visual check, Dimension,Surface finish & Chemical Verification of MTC, 1 Sample /

1.1 Sheet steel (CRCA) Major 1 Sample / Heat App. Drg / IS 513 App. Drg / IS 513 MTC √ P V V

& Mechanical Properties Visual check Heat

Visual/ 1 Sample /

1.2 Cu Busbar Visual check, Dimension, Mechanical Properties Major 1 Sample / Heat App. Drg / IS 613/ 1897 App. Drg / IS 613/ 1897 MTC √ P V V

Physical Heat

Visual/

1.3 PVC Wires Routine Test Report Major 100% 100% App. Drgs/ IS694 App. Drgs/ IS694 MTC P V V

Electrical

Switches, MCB, Contactor, Space Heater, ITR/ Product

Make, Rating & Type,Functional check / Continuity Visual/

1.4 Push Button, Major 100% 100% App. Drgs/ Datasheet App. Drgs/ Datasheet Certificate/ Data P V V

test Electrical

Sockets & Indicating Lamp sheet

Remote Terminal Unit (Including Central MTR/ Product

1.5 processing unit, I/O Cards, Interface Visual check,Functional Check Major Visual/Electrical 100% 100% App. Drgs/ Datasheet App. Drgs/ Datasheet Catalogue/ Data P V V

Modules, Power supply modules) sheet

MTC/Product

1.6 Network Switch, GPS, Industrial Computer Visual check,Functional Check Major Visual/Electrical 100% 100% App. Drgs/ Datasheet App. Drgs/ Datasheet Catalogue/ Data √ P V V

sheet/MTR

1.7 Terminal Blocks Type/Rating Major Visual check 100% 100% App. Drgs/Data Sheet. App. Drgs/Data Sheet. MTC P V V

Visual MTC / Product

Type/ Size Dimension, App. Drgs/Data Sheet/IS App. Drgs/Data Sheet/IS

1.8 Gasket Major check,Verification 100% 100% Certificate/ Data P V V

Material 11149/ASTM Std. 11149/ASTM Std.

of MTC sheet

2. IN PROCESS

Dimension,

2.1 Fabrication of Cubical & Section Major Visual check 100% 100% App. Drg. App. Drg. Checklist √ P V V

Orientation

2.2 Pre Treatment and Painting Surface Preparation,Final paint, Finish Major Physical 100% 100% App. Drgs/Data Sheet. App. Drgs/Data Sheet. ITR/Checklist P V V

Dimension, Assembly of MCB,ELCB,Switch Bus-

2.3 Assembly and Wiring Major Physical 100% 100% App. Drgs App. Drgs Checklist P V V

bars, MCCB, Wires & Terminal Blocks etc.

App. Drgs/

2.4 Lugs, Ferulling,Gasketing and Labeling Fitment & Alignment Major Visual check 100% 100% App. Drgs/Data Sheet. Checklist P V V

Data Sheet.

Functional App. Drgs/ App. Drgs/

2.5 Functional checks Major Electric Check 100% 100% ITR √ P V V

Check of Panel Data Sheet. Data Sheet.

3. FINISHED PRODUCT

3.1 Final Acceptence Test Dimensional Verification Measurement 10% 10% √ P H H

BOM Verification Physical 10% 10% √ P H H

Verification of Wiring

Ferruling/Continuity/ Electrical 10% 10% √ P H H

Colour Coading & Earthing

Operation & Scheme Check Electrical 10% 10% √ P H H

Operational test (Electrical App. Drgs App. Drgs

Control Interlock & Electrical 10% 10% √ P H H

Seq.Operation)

Secondary Current Injection test on Relay Major Electrical 10% 10% IR √ P H H

Functional Checks Time

Syncronization, PC, Electrical 10% 10% √ P H H

& Gateway ( if applicable)

Continuity check for

10% 10%

Earthing Electrical App. Drgs App. Drgs √ P H H

Door Alignment Physical 10% 10% √ P H H

Painting Inspection for

10% 10% App. Drgs/Data Sheet. App. Drgs/Data Sheet.

Shade/DFT Measurement √ P H H

LEGEND:- D* Records identified with tick (√) shall be essentially included by supplier & manufacturer in Quality Documentation package.

** M: Manufacturer / Sub-Supplier, C: Main Supplier , A: Adani or their authorized representative.

Use the following term as appropriate in columns 10. P: Perform, V: verification and H: Customer Hold Point to be witnessed and work shall not proceeded till it is witnessed and cleared in writing.

Format of Record: MTC: Manufacturer/Sub-supplier Test Certificate, ITR: Inprocess Test Report/Record, IR: Inspection Report, MTC: Manufacturer Test Reports

You might also like

- Fast Bus Transfer Panel - Revd - 02072019Document37 pagesFast Bus Transfer Panel - Revd - 02072019manjuat1234211No ratings yet

- DWG-14-041 LUECO Wiring Diagram As Built 5 23 15 PDFDocument25 pagesDWG-14-041 LUECO Wiring Diagram As Built 5 23 15 PDFArmelita Tadifa DucusinNo ratings yet

- 4.6. Schematic - Bus Riser-J1.10 - RDocument13 pages4.6. Schematic - Bus Riser-J1.10 - RMèo Mập Ú NuNo ratings yet

- Stock Aco Lbs and CB - PLN Disjaya: Panel Note QTY 150 SETDocument7 pagesStock Aco Lbs and CB - PLN Disjaya: Panel Note QTY 150 SETRioNo ratings yet

- 5.6. Schematic - Bus Coupler-J2.10Document32 pages5.6. Schematic - Bus Coupler-J2.10Mèo Mập Ú NuNo ratings yet

- 132/30Kv Almochuel Substation Auxiliary Services AC PL-IG-ESPPEE0018-AT-CP-312 Schematics DiagramsDocument21 pages132/30Kv Almochuel Substation Auxiliary Services AC PL-IG-ESPPEE0018-AT-CP-312 Schematics DiagramsMFOBLLLLLLLNo ratings yet

- Minera Spence SGO Project DCS Graphic Displays DrawingsDocument12 pagesMinera Spence SGO Project DCS Graphic Displays Drawingsrodrigo betancurNo ratings yet

- 132 - 33kV Trafo C&R PanelDocument55 pages132 - 33kV Trafo C&R PanelPrashant SoniNo ratings yet

- 132/30Kv Almochuel Substation Auxiliary Services DC PL-IG-ESPPEE0018-AT-CP-311 Schematics DiagramsDocument10 pages132/30Kv Almochuel Substation Auxiliary Services DC PL-IG-ESPPEE0018-AT-CP-311 Schematics DiagramsMFOBLLLLLLLNo ratings yet

- 1VCE015876T0001Document14 pages1VCE015876T0001TESLA IngenieriaNo ratings yet

- A3 e LV 220041 001 405 Profinet Communication LoopDocument9 pagesA3 e LV 220041 001 405 Profinet Communication LoopArif RahmanNo ratings yet

- 1Document7 pages1MostafaElrakhawyNo ratings yet

- GA 33 KV VCB HT Panel - Siddharth Nagar Project. UPDocument17 pagesGA 33 KV VCB HT Panel - Siddharth Nagar Project. UPaayushNo ratings yet

- 11 KV Megawin KioskDocument15 pages11 KV Megawin Kioskveera chaitanyaNo ratings yet

- Project Inverter 130kW Schematic DiagramDocument5 pagesProject Inverter 130kW Schematic DiagramBasadi ZtmNo ratings yet

- Reference Documents:: 100 KBPD Topping Refinery, EbedDocument1 pageReference Documents:: 100 KBPD Topping Refinery, EbedGokulprabhuNo ratings yet

- (E542-PART2 & 3-PLAN) DN099-P02-QBC-SH-FS-1342_00Document1 page(E542-PART2 & 3-PLAN) DN099-P02-QBC-SH-FS-1342_00ahmed yaqoobNo ratings yet

- 220kv Mokokchung (PG) Gis Extn. Ss CFC LogicDocument10 pages220kv Mokokchung (PG) Gis Extn. Ss CFC LogicDundi Kumar BevaraNo ratings yet

- Prefabricated Substation Wiring DrawingDocument2 pagesPrefabricated Substation Wiring DrawingJoed Garzon MontalbanNo ratings yet

- Approved LCS DrawingsDocument2 pagesApproved LCS DrawingsGopikrishnan ThangarajNo ratings yet

- As Built Drawing: Cilegon Sag LineDocument1 pageAs Built Drawing: Cilegon Sag LineYosses Sang NahkodaNo ratings yet

- Universal Robots Work Area Assembly DrawingDocument1 pageUniversal Robots Work Area Assembly DrawingVickocorp SlpNo ratings yet

- Cubicle Pix GH PLTD Kairatu: Pt. Schneider IndonesiaDocument7 pagesCubicle Pix GH PLTD Kairatu: Pt. Schneider IndonesiaMUH ILHAM MARZUKINo ratings yet

- Surface Water Canopy Drainage Connection DetailsDocument1 pageSurface Water Canopy Drainage Connection DetailsShiyamraj ThamodharanNo ratings yet

- Deck Crane Truck M-CT-390Document2 pagesDeck Crane Truck M-CT-390Susi AndraNo ratings yet

- Checklist LGF Zone01Document9 pagesChecklist LGF Zone01minjutNo ratings yet

- AP15ADocument1 pageAP15AHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- 10 53045.01.1727.01 - 110kV CABLE FEEDER C&R PANEL - 3.4.2018 PDFDocument52 pages10 53045.01.1727.01 - 110kV CABLE FEEDER C&R PANEL - 3.4.2018 PDFNassar AbdulrahimanNo ratings yet

- SLD 230KV LAOAG 1 SUBSTATIONDocument1 pageSLD 230KV LAOAG 1 SUBSTATIONrenz canlasNo ratings yet

- DG Synchronizing PanelDocument33 pagesDG Synchronizing PanelArvind KumarNo ratings yet

- Piping and Instrumentation DiagramDocument3 pagesPiping and Instrumentation DiagramRakesh RanjanNo ratings yet

- Sample DrawingDocument1 pageSample DrawingCassy AbulenciaNo ratings yet

- X4029960-301 - Bus Riser+UTX - R01Document15 pagesX4029960-301 - Bus Riser+UTX - R01MUH ILHAM MARZUKINo ratings yet

- 1HID1-3-1057-P025 - INTERLOCKING CONCEPT - GI 70kV TALISE EXT - RADocument10 pages1HID1-3-1057-P025 - INTERLOCKING CONCEPT - GI 70kV TALISE EXT - RABoby SajaNo ratings yet

- Etp20-21nt-Vo1-Bwet-132-Ssp-208 EdDocument83 pagesEtp20-21nt-Vo1-Bwet-132-Ssp-208 Edاحمد العبيديNo ratings yet

- Third Angle Projection Azimuth Assembly DrawingDocument3 pagesThird Angle Projection Azimuth Assembly Drawingsime58No ratings yet

- 220kV Thaltej Substation 220 132 33kV, 250MVA ICT-3 HV (BAY-206) 206Document134 pages220kV Thaltej Substation 220 132 33kV, 250MVA ICT-3 HV (BAY-206) 206Ragul VNo ratings yet

- 132kv Line-1 Protection Panel (Bay-B102)Document85 pages132kv Line-1 Protection Panel (Bay-B102)AshishKumar100% (1)

- Remote Tap Changer Control Panel DetailsDocument1 pageRemote Tap Changer Control Panel DetailsDevi Prasad100% (2)

- X4020126-401 - Buswire Interconnection PDFDocument5 pagesX4020126-401 - Buswire Interconnection PDFazizardniptraNo ratings yet

- Architecture DrawingDocument3 pagesArchitecture DrawingDwiki SetiabudiNo ratings yet

- Electrical Wiring DigramDocument15 pagesElectrical Wiring DigramSunilMurkikarNo ratings yet

- Sa09c2 Jve 04 XX DR Ce 00002Document15 pagesSa09c2 Jve 04 XX DR Ce 00002ghazi4uNo ratings yet

- JHR01-03-DRG-ELE-3-ZZ-SW-6007-SP01-SG Shop DrawingDocument107 pagesJHR01-03-DRG-ELE-3-ZZ-SW-6007-SP01-SG Shop DrawingLoo KlNo ratings yet

- 13-URP Amritsar Connectivity Road-Package-1-CH-24+000 To 40+900-Electric PoleDocument12 pages13-URP Amritsar Connectivity Road-Package-1-CH-24+000 To 40+900-Electric PolepanikarickyNo ratings yet

- 002 Dm1a - Update 2017-11-29Document28 pages002 Dm1a - Update 2017-11-29yohanes akimas2No ratings yet

- Biotech 5m3Document7 pagesBiotech 5m3Jhennery AgeNo ratings yet

- 51ton Loaded Truck: Section A-A'Document1 page51ton Loaded Truck: Section A-A'Mahmudul Alam kanakNo ratings yet

- Dukhan GA MV SwitchgearDocument24 pagesDukhan GA MV SwitchgearRussal MullappallyNo ratings yet

- ROAD LAYOUT PLAN UPDATEDocument1 pageROAD LAYOUT PLAN UPDATEcantikritNo ratings yet

- AutoCAD Drawing TemplateDocument1 pageAutoCAD Drawing TemplatedipenstarNo ratings yet

- Eafd Acc Heavy MetalDocument29 pagesEafd Acc Heavy Metalahmed omarNo ratings yet

- NEA Nepal Manang-Khudi-Udipur 220kV Transmission Line Location Contour & Leg Profile Report AP20Document1 pageNEA Nepal Manang-Khudi-Udipur 220kV Transmission Line Location Contour & Leg Profile Report AP20Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- J3B-AM-17-D-00001-1-Chemical Area 2Document8 pagesJ3B-AM-17-D-00001-1-Chemical Area 2Naheed AkhtarNo ratings yet

- 220kV Thaltej Substation 220 132 33kV, 250MVA ICT-2 HV (BAY-203) 203Document133 pages220kV Thaltej Substation 220 132 33kV, 250MVA ICT-2 HV (BAY-203) 203Ragul VNo ratings yet

- DB-08-7-G-2-L Isolator Load DetailsDocument11 pagesDB-08-7-G-2-L Isolator Load DetailsminjutNo ratings yet

- Alarm and Monitoring System for GOA ShipyardDocument696 pagesAlarm and Monitoring System for GOA Shipyardbipinsarkar88No ratings yet

- AP19Document1 pageAP19Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- F2176030 SAA - Circuit Diagram REV00Document45 pagesF2176030 SAA - Circuit Diagram REV00Kalayanaraman RamakrishnanNo ratings yet

- Installation of IsolatorsDocument12 pagesInstallation of IsolatorsBandaru Ananth NaiduNo ratings yet

- ELK-04 C 145 2GHV008915 0315enDocument20 pagesELK-04 C 145 2GHV008915 0315enmuraliNo ratings yet

- Dry-Type Transformers For Railways Brochure A4 - vFINALDocument18 pagesDry-Type Transformers For Railways Brochure A4 - vFINALYusuke Okudaira100% (1)

- Design of EHV SubstationDocument66 pagesDesign of EHV SubstationMadanasekhar Tadimarri100% (1)

- SM6 2017Document156 pagesSM6 2017Alfredo ApNo ratings yet

- Desta TegegneDocument100 pagesDesta TegegneabadiNo ratings yet

- SP El Ee 001Document30 pagesSP El Ee 001rebabb17No ratings yet

- S T S E W: Tandard Echnical Pecifications FOR Lectric OrksDocument30 pagesS T S E W: Tandard Echnical Pecifications FOR Lectric Orksqais bakrNo ratings yet

- 2018 Aperc 10Document127 pages2018 Aperc 10manojkumar3021No ratings yet

- Catalogue Stationclass Surge Arresters enDocument76 pagesCatalogue Stationclass Surge Arresters enkra_amNo ratings yet

- QP PSS Q0102 Distribution LinemanDocument45 pagesQP PSS Q0102 Distribution LinemanArun JyothiNo ratings yet

- Media Tension 09 PDFDocument12 pagesMedia Tension 09 PDFDaniel GaitanNo ratings yet

- BabyDocument103 pagesBabySahira ChatterjeeNo ratings yet

- Generator & Transformer ProtectionDocument27 pagesGenerator & Transformer ProtectionfriendbceNo ratings yet

- Aboitiz EyesDocument64 pagesAboitiz EyesGerald Joseph MalitNo ratings yet

- Mitigating The Effect of Voltage Sags On Contactors in Industrial Plant and SubstationsDocument4 pagesMitigating The Effect of Voltage Sags On Contactors in Industrial Plant and SubstationsarisNo ratings yet

- Trip Coil Signature Measurement and Analysis Techniques For Circuit BreakerDocument7 pagesTrip Coil Signature Measurement and Analysis Techniques For Circuit Breakerhizbi7No ratings yet

- 132kV Network ReconfigurationDocument35 pages132kV Network ReconfigurationAkinwumi OluwatosinNo ratings yet

- LV Shore Connection Power SystemsDocument7 pagesLV Shore Connection Power SystemsJavier EverestNo ratings yet

- Design and Application of Optical Voltage and Current Sensors For RelayingDocument6 pagesDesign and Application of Optical Voltage and Current Sensors For Relayingsanjiv0909No ratings yet

- 2012 Substation Reference BookDocument18 pages2012 Substation Reference BookMarcelo SalvadorNo ratings yet

- A Three-Phase State Estimation in Active Distribution Networks PDFDocument9 pagesA Three-Phase State Estimation in Active Distribution Networks PDFJesus Ortiz LopezNo ratings yet

- Typical Bill For A 2x15MVA Transformer Substation ConstructionDocument6 pagesTypical Bill For A 2x15MVA Transformer Substation ConstructionKAREEM OLAWALE100% (1)

- 001 RP en - 6Document97 pages001 RP en - 6BADRI VENKATESHNo ratings yet

- p3f30 en M f006 Iec WebDocument392 pagesp3f30 en M f006 Iec WebCarlos Rafael Acosta MolinaNo ratings yet

- Operation and Mantance of Substation 220/132/33kv SubstationDocument109 pagesOperation and Mantance of Substation 220/132/33kv SubstationUmla Naik Nenavath100% (1)

- Voltage Sag Assessment of Distribution System Using Monte Carlo SimulationDocument6 pagesVoltage Sag Assessment of Distribution System Using Monte Carlo SimulationJAGANNATH PATRANo ratings yet

- (PDF) Eee-Viii-Power System Operation and Control (10ee82) - NotesDocument130 pages(PDF) Eee-Viii-Power System Operation and Control (10ee82) - NotesAbhinavNo ratings yet

- Fundamental Concepts in Substation Design PDFDocument26 pagesFundamental Concepts in Substation Design PDFvishalkumarNo ratings yet

- CV of Mr. S.Sajiv: Skill SetDocument4 pagesCV of Mr. S.Sajiv: Skill SetmadhavanNo ratings yet