Professional Documents

Culture Documents

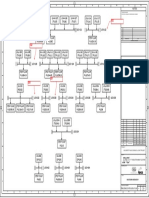

62 D1 Model

Uploaded by

usman0280038Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

62 D1 Model

Uploaded by

usman0280038Copyright:

Available Formats

GENERAL NOTES LINE SYMBOLS EQUIPMENT LIST DRAWING INDEX (20)

EQUIP. TYPE ITEM NO. DWG. NO. EQUIP. TYPE ITEM NO. DWG. NO. EQUIP. TYPE ITEM NO. DWG. NO. DWG. NO. DESCRIPTION

101-B 62-D3 1101-F 64-D1 62-D1 GENERAL NOTES, LIST OF EQUIPMENT, DRAWIND INDEX & SYMBOLS

B 1101-BJ 62-D3 101-F 64-D1 102-L 62-D3 62-D2 FEED HYDROTREATER & DESULFURIZER

FURNACES

102-B 62-D7 102-F 62-D4 171-L 64-D3 62-D3 AIR COMPRESSOR & PRIMARY REFORMING

1. ALL PIPING VENTS ARE 3 4" , EXCEPT AS NOTED. GATE VALVE "Y" TYPE STRAINER 103-B 62-D2 172-L 64-D1 62-D4 SECONDARY REFORMING & SHIFT CONVERSION

2. ALL PIPING DARAINS ARE 3 4" , EXCEPT AS NOTED.

3. ALL EQUIPMENT VENTS & DRAINS ARE TAP SIZE, EXCEPT AS NOTED. GLOBE VALVE "T" TYPE STRAINER 104-F 62-D6 1172-L 64-D1 62-D5 CO2 REMOVAL

4. ALL SINGLE BLOCKED VENTS & DRAINS IN PROCESS SERVICE SHALL 1101-C 62-D4 105-F 62-D6 174-L 64-D3 62-D6 SYNTHESIS GAS COMPRESSOR

BE PLUGGED EXCEPT AS NOTED. LUBRICATED PLUG VALVE

101-CJ 64-D5 106-F 62-D6

L 175-L 62-D5 62-D7 AMMONIA SYNTHESIS

5. HIGH POINT VENTS & LOW POINT DRAINS ARE PROVIDE, BUT ARE DUPLEX TYPE STRAINER SPECIAL

NOT SHOWN ON FLOW SHEETS, NON-OPPRATNIG VENTS & DRAINS NON LUBRICATED PLUG VALVE 102-C 62-D4 107-F 62-D8 EQUIPMENT 62-D8 REFRIGERATION

AT EXCHANGERS &ROTARY EQUIPMENT ARE PROVIDED, BUT ARE 103-C 62-D4 108-F 62-D6 460-L 62-D9 LINES CROSSING BATTERY LIMITS

BUTTERFLY VALVE PURITAN HAT STRAINER

NOT SHOWN ON FLOW SHEETS.

6. WHEN BLINDS ARE INDICATED ON FLOW SHEETS, THE TYPE OF 104-C DELETED 109-F 62-D8 62-D101 FEED GAS SATURATOR SYSTEM

BLINDS SHALL BE DETERMIND BY KELLOGG SPECS. BUTTERFLY CONTROL VALVE CONE TYPE STRAINER 105-CA & CB DELETED 110-F 62-D8 62-D102 SYNTHESIS GAS PRIER & MOL. SIEVE FILTERS

7. FLOWMETER ORFICE FLANGES SHALL BE SUPPLIED IN ACCORDANCE CONTROL VALVE F 111-F 62-D8 63-D1 FUEL GAS, INSTRUMENT AIR, SYN. GAS, PLANT AIR & NITROGEN

WITH THE PIPING SPECIFIED BUT WITH A MINIMUM RATING, REDUCER WELD CAP TANKS

(AIR DIAPHRAGM) 62-D5

FACING OF 300# R.F. 107-C1 & C2 64-D3 DRUMS 112-F 62-D8 1109-LA & LB 62-D102

8. CONTROL VALVE ACTION ON AIR FAILURE "O" OPENS, "C" CLOSES. CONTROL VA. WITH HANDWHEEL LINE SIZE ORIFICE RUN SEPARATORS 113-F 62-D5 63-D3 VENT & RELIEF VALVE SYSTEMS

9. LOCATION & ORIENTAION OF SMALL VALVES AT PROCESS BLOCK SELF DRAINING VALVE

VALVES: (KELLY HYDRANT)

109-C 62-D5 114-F 62-D5 63-D4 DIAGRAMMATIC DETAILS

INCREASED ORIFICE RUN

M 110-C1A & B 62-D5 115-F 64-D2

BALL MOTOR OPER.

IF VALVE CAN BE TAPPED (DIA) RO

110-C2A & B 62-D5 116-F 62-D5

VALVE BALL VA. RESTRICTION ORIFICE & DIAMETER

111-C DELETED 117-F 62-D5 63-D101 FUEL GAS PREHEAT AND BURNER SYSTEM

CHECK STOP CHECK

VALVE BLINDABLE FLANGES 112-C DELETED 118-F 62-D5 64-D1 STEAM GENERATION

VALVE (SPACER OR FIG '8' SEE NOTE 6)

114-C 62-D6 64-D2 STEAM DISTRIBUTION SYSTEM

DUAL-TANDEM BLOWOFF VA. PLASRIC WEATHER CAP 115-C 62-D6 156-F 64-D1 64-D3 DEMINERALIZER STORAGE & DEAERATOR

DRAIN OR H.C. ETC RUPTURE DISC 116-C 62-D6 157-F 64-D3 101-U 64-D3 64-D4 SURFACE CONDENSER

ANGLE VALVE

SP SPOOL SIGHT FLOW 117-C 62-D6 & 8 64-D5 COOLING WATER SYSTEM, DRINKING WATER, SERVICE WATER

PIECE INDICATOR 118-C 62-D6 & 8 64-D6 FEED WATER DEMINERALIZER (OFFSITE)

ANGLE CONTROL VALVE

MINIMUM DISTANCE 119-C 62-D6 & 8 1134-F 62-D6 175-U1 & U2 64-D7 NITROGEN GENERATOR (OFFSITE) NOT USED

EXPANSION JOINT

120-C 62-D6 1139-F 62-D101 64-D8 CONDENSATE POLISHER

NEEDLE VALVE KV RELIEF VALVE 121-C 62-D6 1160-F 62-D5 177-U 64-D9 DIAGRAMMATIC DETAILS

IF VALVE IS NOT TAPPED

122-CA & CB 62-D7

HAND CONTROL VALVE VB VACUUM BREAKER 123-C DELETED 450-U

124-C DELETED

VEE BALL CONTROL VALVE 125-C 62-D6 & 8 451-U1,2,3

ATWOOD & MORRILL STRAIGHT

126-C 62-D8

U 451-UJ

GEAR OPERATED GATE VA. THRU RELIEF VALVE WATER

PITOT

C 127-CA-CB-CC 62-D8 101-J * 62-D3 TREATING

PITOT TUBE EXCHANGERS EQUIPMENT

SOLENOID VALVE VENTURES 128-C 62-D8 102-J * 62-D2 452-U

FLOW TUBE 129-C 62-D6 & 8 103-J * 62-D6

10. THERMOWELLS & THERMOMETER WELLS SHALL BE 1 2" FLANGED MOTOR OPERATED VALVE 133-C 62-D2 104-J & JA 64-D3 453-U1,2,3

EXCEPT THAT WELLS OF SPECIAL MWK DESIGN SHALL BE USED FOR EJECTOR, EDUCATOR, BOOSTER

134-C 62-D2 105-J 62-D8 453-UJ

THE SPECIAL REQUIREMENTS. FOOT VALVE

11. INTRUMENT PRESSURE CONNS. TO PIPNIG VESSELS & EQUIPMENT 136-C DELETED 106-J & JA 62-D4

SHALL BE 1" FLANGED EXCEPT ON MANUFATURER'S STANDARD

SNUBBER

SEPARATOR 129-JC 62-D3 107-J & JA 62-D5 454-U LINE DESIGNATION

EQUIPMENT. (LONG WELD NECK FLANGES SHALL NOT BE USED.)

130-JC 62-D3 108-J & JA 62-D5 454-UC PREFIX SERVICE PREFIX SERVICE

12. THE SYMBOL 1 DENOTES HIGH PRESSURE DROP VALVE REQUIRING

SPECIAL ANCHOR. ROTAMETER 131-JC 62-D3 109-J & JA 62-D8 454-UJ1 A PROCESS AIR PA PLANT AIR

LINE ABOVE GROUND

13. THE SYMBOL 2 DENOTES HIGH PRESSURE DROP VALVE REQUIRING 1111-C 62-D5 110-J & JA 62-D5 454-UJ2 BD BLOWDOWN PG PROCESS GAS

STREAM LINE PIPING. LINE BELOW GROUND

14. THE SYMBOL 3 DENOTES THAT LINE TO BE BLAST, CLEANED, OR, 1104-C 62-D4 111-J 62-D5 BF FEED WATER PO PUMP OUT

FLOW QUANTITY OR

PICKLED IN ACCORDANCE WITH MWK ENGINEERING STANDARD STEAM TRACED 1105-CA &CB 62-D4 & 5 112-J & JA 64-D4 BFH FEED WATER CODE PW PROCESS WATER

M7-1S69 THE LIMIT OF CLEANING IN BRANCH LINES IS TO THE

DISPLACEMENT METER J

JACKETED PIPE 1109-C 62-D102 COMPRS BO BLOW OFF RV RELIEF VALVE

FIRST BLOCK VALVE. FLAME ARRESTOR

15. THE SYMBOL 4 REFERS TO FIELD CHEMICAL CLEANING OF LINES 1110-CA/CB DELETED PUMPS 114-J 62-D5 BOH BLOW OFF CODE S 180# STEAM

BATTERY LIMIT

AND EQUIPMENT FIELD CHEMICALLY IN ACCORDANCE WITH T TRAP 1112-C 62-D4 BWH FEED WATER CODE SC STEAM CONDENSATE

PURCHASING SPECIFICATION 7-4F. LINE CROSSING BATTERY LIMIT 1123-C 62-D6 CAT CATACARB SG SYNTHESIS GAS

16. THE SYMBOL 5 DENOTES THAT LINE TO BE MECHANICALLY

CLEANED IN ACCORDANCE WITH MWK ENGINEERING STANDARDS DIAG. DIAGRAM DESIGNATION 1124-C 62-D6 CF CHEMICAL FEED SO SEAL OIL

SAMPLE CONNECTION

M7-2S69 THE LIMIT OF CLEANING BRANCH LINES IS THE FIRST 1131-C DELETED 120-J 62-D8 CFH CHEMICAL FEED CODE SW SERVICE WATER

BLOCK VALVE. S

17. NEW PIPING DENOTED BY THICK LINES. 1136-C 62-D6 121-J 62-D2 CW COOLING WATER V VENT

OPEN DRAIN TO OILY WATER SEWER

SC SAMPLE COOLER 1139-C 62-D3 122-J & JA 64-D3 450-K DM DEMINERALIZED WATER VE VACUUM EXHAUST

1140-C 62-D6 451-K DR DRAINS WA 93° COOLING WATER

SPECIAL MATERIAL

CLOSED CHEMICAL SEWER (REFER TO SPECIAL MATERIAL SHEETS) 1141-C 62-D5 DW DRINK WATER WB 111° COOLING WATER

FG FUEL GAS NP CRUDE NAPHTHA

PERFORATED PIPE (SPARGER) INSTUMENT LOCALLY MOUNTED

101-D 62-D2 451-J &JA HS 1500 # STEAM

BLINDED CONN. INSTRUMENT BOARD MOUNTED 102-DA & DB 62-D2 HSH 1500 # STEAM CODE

K

INSTRUMENT COMPRESSOR 103-D 62-D4 BLDGS HW COOLING WATER RETURN

PLUGGED CONN.

BOARD MOUNTED 104-D 62-D4 1101-J DELETED IA INSTRUMENT

BUTT WELD VALVE 105-DA & DB DELETED 1104-JB 64-D3 LO LUBE OIL

INSTRUMENT LINE

FLEXIBLE HOSE 106-D 62-D6 1108-J DELETED LS 50# STEAM

D 107-D DELETED 1130-J DELETED MS 590# STEAM

DEMISTING PAD AUTO DRAINER REACTORS

108-D 62-D4 1139-J/JA 62-D101 N NITROGEN

172-J/JA 64-D1 NG NATURAL GAS

1172-J/JA 64-D1 NH AMMONIA

1105-D 62-D7 171-J 64-D3 OCO CARBONE DIOXIDE

1107-D 62-D3 & 4 174-J 64-D3 OW OILY WATER

1109-DA/DB 62-D102 175-J (EAST) 64-D3

101-E 62-D5

102-E 62-D5

E

TOWERS 1103-E 62-D5

1104-E DELETED

3 P&IDs UPDATION, AS BUILT 10-11-2020 MAJID WK,MTB

CO BASELINE PHA 2017 MAJID

2

CO REVISED AS PER DOCUMENT NO.

1 MA-103 TO 104 BY MKW

17 JUNE 90

· THESE MACHINES HAVE BEEN INTERNALLY MODIFIED AND ARE

REFERED TO ON DATA SHEETS AS 1101-J, 1102-J AND 1103-J CO FOR CONTRUCTION 22 NOV 88

RESPECTIVLY.

2 ISSUED FOR PRODUCTION 25 MAR 88

1A CLIENT APPROVED 18 DEC 87

1 FOR CLIENT REVIEW 7 OCT 87

R FOR INTERNAL REVIEW 6 AUG 87

REV DESCRIPTION DATE BY CHK APP

REVISION

SCALE: NTS DRAWN: MAJID BASHIR FATIMAFERT LIMITED

TITLE:

CHECKED CHECKED MTPD AMMONIA UNIT

(UM. Proj): (U.M Process): NOTES, EQUIPMENT,

DRAWING INDEX & SYMBOLS

CHECKED APPROVED

JOB #: 5382 (U.M Prod): (TSM/PM): PROCESS PIPING & INSTRUMENTATION

REV #: 3 DWG # 62 - D1 FLOW SHEET

You might also like

- Harness KenworthDocument17 pagesHarness KenworthNembot AmedeNo ratings yet

- SZ RR V2.0Document55 pagesSZ RR V2.0Amit Dutta43% (7)

- 2023-05-16 Package 21 OC Rev.4Document123 pages2023-05-16 Package 21 OC Rev.4pham locNo ratings yet

- Hydro-Test Manifold 1Document1 pageHydro-Test Manifold 1ryan gumanitNo ratings yet

- 835-ASMESectionIIID1NC 3658Document2 pages835-ASMESectionIIID1NC 3658nurilmuNo ratings yet

- MSS SP-70 (1998)Document13 pagesMSS SP-70 (1998)Allan SousaNo ratings yet

- DSHG 06 3C4 YukenDocument16 pagesDSHG 06 3C4 YukenJindal HydraulicsNo ratings yet

- Piping TableDocument59 pagesPiping TableExsan Othman100% (1)

- Systematic Lessons Learned Analysis ForDocument100 pagesSystematic Lessons Learned Analysis ForPranpath NarupantawartNo ratings yet

- UXO in Kuwait EOD Operators Pocket BookDocument150 pagesUXO in Kuwait EOD Operators Pocket Bookkako083No ratings yet

- Digital No Flow TimerDocument4 pagesDigital No Flow Timerzhangjie100% (1)

- Piping HandbookDocument3 pagesPiping Handbookbarlang12350% (4)

- Service Parts List: Transmission 6422-131 4266465Document52 pagesService Parts List: Transmission 6422-131 4266465Bryan RibeiroNo ratings yet

- WeldBend Catalog PDFDocument186 pagesWeldBend Catalog PDFDavid MahoneyNo ratings yet

- Ads 2200 2700 PDFDocument17 pagesAds 2200 2700 PDFPaul Albu100% (1)

- Cam Follower BearingDocument21 pagesCam Follower Bearingmohammed barghothiNo ratings yet

- SPEC Tuberías de AireDocument3 pagesSPEC Tuberías de AireAbel Enríquez RomeroNo ratings yet

- Specification: 2.speed Advance 3 DDocument2 pagesSpecification: 2.speed Advance 3 Djohnny sabinNo ratings yet

- Alto A200.2 Power Amp Service ManualDocument25 pagesAlto A200.2 Power Amp Service ManualmundomusicalmeriaNo ratings yet

- Directional Controls: Manually Operated Directional ValvesDocument7 pagesDirectional Controls: Manually Operated Directional ValvesRiyaz SiddiqueNo ratings yet

- CS11 Compactor Training CourseDocument60 pagesCS11 Compactor Training CourseJamper MutuNo ratings yet

- Hydraulic Intank DiffusersDocument1 pageHydraulic Intank DiffusersMaxNo ratings yet

- All Dimensions Metric: FAA24270APDocument6 pagesAll Dimensions Metric: FAA24270APЕкатерина АндрееваNo ratings yet

- Kenwood Kdc-203s 209sDocument19 pagesKenwood Kdc-203s 209skriegsterNo ratings yet

- Revised STD DWG 07 Nov 2016Document50 pagesRevised STD DWG 07 Nov 2016sathishNo ratings yet

- Commercial Split System Installation Chart: Typical Piping and Wiring 3) Install Refrigerant PipingDocument2 pagesCommercial Split System Installation Chart: Typical Piping and Wiring 3) Install Refrigerant PipingcarlosorizabaNo ratings yet

- Shutdown HierarchyDocument1 pageShutdown HierarchyAditya Pranoto100% (1)

- 25-31-50 SCH 50 P 0046 Sheet 1 - High Speed Oven DF1000Document1 page25-31-50 SCH 50 P 0046 Sheet 1 - High Speed Oven DF1000atony357No ratings yet

- Product Specifications: VickersDocument1 pageProduct Specifications: VickersPapaNo ratings yet

- DWG 00001Document4 pagesDWG 00001ariyaNo ratings yet

- Uh1000a12 1Document1 pageUh1000a12 1MARTIN GONZALEZNo ratings yet

- BOQ Air Terminal UnitsDocument9 pagesBOQ Air Terminal UnitsBahaa AbdulhadiNo ratings yet

- Specification Att - 3-23 - 7-68-0501 Rev 7 - Standard For Handrails, Stairs N LaddersDocument8 pagesSpecification Att - 3-23 - 7-68-0501 Rev 7 - Standard For Handrails, Stairs N LaddersAvinash ShuklaNo ratings yet

- Memoria de Calculo Alumbrado ExteriorDocument11 pagesMemoria de Calculo Alumbrado ExteriorHernan PachecoNo ratings yet

- Hotel Santika - Tmii 4LTDocument24 pagesHotel Santika - Tmii 4LTGogik AntoNo ratings yet

- Motor AcuáticoDocument43 pagesMotor AcuáticoSergio SagastumeNo ratings yet

- Kenwood CD-203-204 DPF-R3010-4010-5010 Service ManualDocument17 pagesKenwood CD-203-204 DPF-R3010-4010-5010 Service ManualBigg Dady100% (1)

- Miscellaneous Products Used On Helicopters: 305. Use of Hydraulic FluidsDocument4 pagesMiscellaneous Products Used On Helicopters: 305. Use of Hydraulic FluidsJurin Kuprodjana-aungkunNo ratings yet

- Prince Hydraulics - SPD3 Series Hydraulic Double Gear Pumps Offered by PRC Industrial SupplyDocument2 pagesPrince Hydraulics - SPD3 Series Hydraulic Double Gear Pumps Offered by PRC Industrial SupplyPRC Industrial SupplyNo ratings yet

- Saudi Arabian Oil Company: Pipe Support Schedule (Foundation) NotesDocument1 pageSaudi Arabian Oil Company: Pipe Support Schedule (Foundation) Notesbarış aydınNo ratings yet

- Gearbox: GENERAL: 8209 D4Document30 pagesGearbox: GENERAL: 8209 D4Hamid edris100% (1)

- Sectional ValvesDocument107 pagesSectional Valveswalk111No ratings yet

- Inq. 4502Document27 pagesInq. 4502srave_k07No ratings yet

- Airband English VersionDocument4 pagesAirband English VersionGilles FexNo ratings yet

- H BurndyDocument1 pageH BurndyJuan Carlos ParedesNo ratings yet

- 5600 CFMDocument1 page5600 CFMmohammed rameesNo ratings yet

- Tema Flanges Class R" Hub FlangesDocument3 pagesTema Flanges Class R" Hub FlangesChano HanokNo ratings yet

- Single Wire Braid Hydraulic Hose On Easy-To-Handle Reels - TR1SNDocument1 pageSingle Wire Braid Hydraulic Hose On Easy-To-Handle Reels - TR1SNT TODOROVNo ratings yet

- Service Manual: Telephone Answering MachineDocument12 pagesService Manual: Telephone Answering MachineRuben MoralesNo ratings yet

- DETAIL OF FOUNDATION 132 KV CIRCUIT BREAKERDocument1 pageDETAIL OF FOUNDATION 132 KV CIRCUIT BREAKERManas MondalNo ratings yet

- 033 PDFDocument1 page033 PDFjugaad bazi rahul kumarNo ratings yet

- E3160 PDFDocument2 pagesE3160 PDFmxckcxzlm.c,No ratings yet

- Final de Carrera D4enDocument14 pagesFinal de Carrera D4enJonatan Ferney Valenzuela ForeroNo ratings yet

- Diagramas Electricos 5500i 5600i 5900i 9200i 9400i and 9900i Chassis Built December 1 2005Document1 pageDiagramas Electricos 5500i 5600i 5900i 9200i 9400i and 9900i Chassis Built December 1 2005Wilfredo Ferman MejiaNo ratings yet

- Connection Chart Ods Sizes 1.125" 1.625" 2.125" 2.625" 3.125" GPM 1-10 11-35 36-75 76-120 121 &Document1 pageConnection Chart Ods Sizes 1.125" 1.625" 2.125" 2.625" 3.125" GPM 1-10 11-35 36-75 76-120 121 &JOHNNo ratings yet

- Dsme Piping - Practice PDFDocument117 pagesDsme Piping - Practice PDFJesus PlacedesNo ratings yet

- D4E - N Small Sealed SwitchDocument13 pagesD4E - N Small Sealed SwitchMuhamad PriyatnaNo ratings yet

- Lubrication Order L05 4320-258-12 20 JULY 1977 (Supersedes L05-4320-258-12, 30 July 1971)Document5 pagesLubrication Order L05 4320-258-12 20 JULY 1977 (Supersedes L05-4320-258-12, 30 July 1971)SteveNo ratings yet

- 2300JKVDocument44 pages2300JKVapi-3756260100% (1)

- 12-00009WD - F - Audio Interface (Garmin GMA 1347D)Document11 pages12-00009WD - F - Audio Interface (Garmin GMA 1347D)Deleh GonzalezNo ratings yet

- Data Sheet: HSMP-389x Series, HSMP-489x SeriesDocument13 pagesData Sheet: HSMP-389x Series, HSMP-489x SeriesDimitris DimitriadisNo ratings yet

- 86SA9000-10 Customer Information Terminal Block Layout 9000 Series SystemsDocument1 page86SA9000-10 Customer Information Terminal Block Layout 9000 Series SystemsRonaldNo ratings yet

- Injection Pump JDB431MD2800 Specification: ModelDocument3 pagesInjection Pump JDB431MD2800 Specification: ModelRobert Alexander FrankNo ratings yet

- 5 05 e Adcamat-Pops-K-Simplex 5d63dd49c6aaaDocument2 pages5 05 e Adcamat-Pops-K-Simplex 5d63dd49c6aaaAnonymous fSbJSZNo ratings yet

- Schematic 1 - TransmitterDocument1 pageSchematic 1 - TransmittermeghsnrynnNo ratings yet

- Model: Catalog Page No: 50 0 - DBGFC63741AJ Customer Part NoDocument2 pagesModel: Catalog Page No: 50 0 - DBGFC63741AJ Customer Part NodieselmotorsbogotasasNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesFrom EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNo ratings yet

- Signs x2Document1 pageSigns x2usman0280038No ratings yet

- CR Interview QuestionsDocument1 pageCR Interview Questionsusman0280038No ratings yet

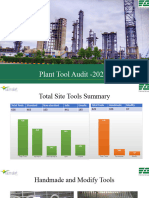

- Summary of Plant Site ToolsDocument9 pagesSummary of Plant Site Toolsusman0280038No ratings yet

- Portable ToolsDocument5 pagesPortable Toolsusman0280038No ratings yet

- Work Instruction For Repair of Steam TrapsDocument3 pagesWork Instruction For Repair of Steam Trapsusman0280038No ratings yet

- Minimum Pressure-Thermostatic ValveDocument2 pagesMinimum Pressure-Thermostatic ValveНариман ТусупбековNo ratings yet

- Purchase Spec. For Flanges (Sa182 F304&F304L)Document4 pagesPurchase Spec. For Flanges (Sa182 F304&F304L)Daison PaulNo ratings yet

- Vol 2 - 2 BOQs Kaliro-NamungalweDocument133 pagesVol 2 - 2 BOQs Kaliro-Namungalweshopspark597No ratings yet

- Knife Gate Valves PDFDocument2 pagesKnife Gate Valves PDFashish_pradhan75No ratings yet

- Gore Sealants/gaskets DimensionsDocument4 pagesGore Sealants/gaskets DimensionsHiroaki HamadaNo ratings yet

- SV 22 P H 30 Parts ManualDocument462 pagesSV 22 P H 30 Parts ManualEnrique RojoNo ratings yet

- Rosemount 2120 Vibrating Fork Liquid Level SwitchDocument16 pagesRosemount 2120 Vibrating Fork Liquid Level SwitchTariqMalikNo ratings yet

- Rightpdf - Siemens Quotation SIQRMI231003001 REV03 Gradiant Pty LTD - WatermarkDocument14 pagesRightpdf - Siemens Quotation SIQRMI231003001 REV03 Gradiant Pty LTD - WatermarkNirmal KumarNo ratings yet

- Virgo Trunnion Ball ValveDocument16 pagesVirgo Trunnion Ball ValveKamalNo ratings yet

- B 50N Centrifugal Pumps PDFDocument8 pagesB 50N Centrifugal Pumps PDFdadhouNo ratings yet

- Vodovodne ArmantureDocument30 pagesVodovodne ArmantureJastreb SxeNo ratings yet

- PLUG VALVE - Full Bore - Technical BulletinDocument28 pagesPLUG VALVE - Full Bore - Technical BulletinRenzo Conde Montenegro100% (1)

- Vickers V10Document6 pagesVickers V10AdrianaNo ratings yet

- Consolidated: Consolidated Safety Valve Type 1700-2-S and 1700-3-SDocument69 pagesConsolidated: Consolidated Safety Valve Type 1700-2-S and 1700-3-SSravan DasariNo ratings yet

- Dungs Frs Gas Pressure RegulatorsDocument8 pagesDungs Frs Gas Pressure RegulatorsSandeep JajawaraNo ratings yet

- Unib Ody Floating B All Valves: KVC Fire-Safe and Anti-Static ASME 150/300 One Piece, End EntryDocument4 pagesUnib Ody Floating B All Valves: KVC Fire-Safe and Anti-Static ASME 150/300 One Piece, End EntryDoris AbadiNo ratings yet

- TC Fls Sihi Zti en SihiDocument12 pagesTC Fls Sihi Zti en SihiArdi 4791No ratings yet

- KAT B 1913 - Spring Loaded Air Valve - Edition1 - en - 01 10Document11 pagesKAT B 1913 - Spring Loaded Air Valve - Edition1 - en - 01 10Sathishkumar DhamodaranNo ratings yet

- CEE 241 Notes IIIDocument58 pagesCEE 241 Notes IIINguyen DuyNo ratings yet

- A1ADocument8 pagesA1ASumantrra ChattopadhyayNo ratings yet

- Peikko Katalog 2011Document64 pagesPeikko Katalog 2011Vilandas CeNo ratings yet

- Api Tools PresentationDocument18 pagesApi Tools Presentationpashamr1No ratings yet