Professional Documents

Culture Documents

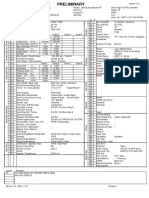

Level 2 FAD1

Level 2 FAD1

Uploaded by

ajkOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Level 2 FAD1

Level 2 FAD1

Uploaded by

ajkCopyright:

Available Formats

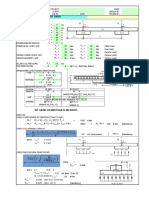

User Inputs

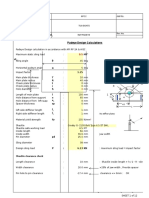

API 579 Level 2 Crack Assessment

Axial Flaws in Pressurized Pipes

Input Parameters Flaw Ta

Outside Diameter (OD) 16 in Total Flaws:

Wall Thickness (t) 0.25 in Flaw #

Yield Strength 52,000 psi 1

Tensile Strength 70,000 psi 2

Charpy Energy 15 ft-lb 3

Fracture Toughness (K_crit) 70,031 psi-sqrt(in) 4

Charpy Test Temperature 55 deg F 5

Pipe Metal Temperature 55 deg F 6

Maximum Operating Pressure 1170 psi 7

Hydrostatic Test Pressure 1500 psi 8

- Do Not Edit Blue Shaded Cells.

- Do Not Add or Delete Rows/Columns.

Click on "User Inputs" button above to edit the values below.

Variable Value Key

ToughnessOption 1 1 - Charpy input

2 - K_crit input

IsExpansion 1 True - cold expanded

SizeFlag 3 1 - full size 2 - 2/3 3 - 1/2

4 - 1/3 5 - Other

CVNSizeVal 0.5 Subsize thickness ratio

FractureMode 4 1 - upper shelf 2 - Lower Shelf

3 - transition 4 - Don't know

ToughnessPercentile 1 1 - median 2 - 5% LB

3 - 95% UB

IsFlawTable 1 Use flaw table

IsFlawCurve 1 Generate critical flaw curves

IsLeakRupture 1 Generate leak/rupture curves

IDorOD 1 1 - ID flaw

2 - OD flaw

Shear 0.5 % Shear/100

Run Analysis

Assessment

ized Pipes

Flaw Table

8 Gaps in Table Not Allowed

Flaw Length (L), in Flaw Depth (d), in Pressure, psi

1 0.08 1170

2 0.08 1170

4 0.08 1170

8 0.08 1170

1 0.12 1170

2 0.12 1170

4 0.12 1170

8 0.12 1170

You might also like

- Ansys Fluent Tutorial Guide 2022 R2Document1,444 pagesAnsys Fluent Tutorial Guide 2022 R2ajkNo ratings yet

- Content: - Measurements of Various PropertiesDocument17 pagesContent: - Measurements of Various PropertiesShubhamGuptaNo ratings yet

- Hydraulic Analysis Report - TORRE ETANOLDocument31 pagesHydraulic Analysis Report - TORRE ETANOLDiana MarcelaNo ratings yet

- Labreport Heat ExchangerDocument27 pagesLabreport Heat ExchangerZainol a-noteNo ratings yet

- Martincek, Gustav - Dynamics of Pavement Structures-Taylor & Francis (1995)Document403 pagesMartincek, Gustav - Dynamics of Pavement Structures-Taylor & Francis (1995)Andrés Juárez SánchezNo ratings yet

- RASNE-3 Superficial Comments 01Document2 pagesRASNE-3 Superficial Comments 01Prashant KumarNo ratings yet

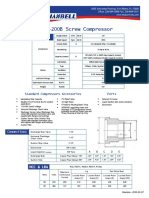

- Hanbell Spec Sheet RC2-200BDocument1 pageHanbell Spec Sheet RC2-200BMuhammadAsim100% (1)

- RQC-RTXR Real Time X-Ray Report Rev 3Document1 pageRQC-RTXR Real Time X-Ray Report Rev 3Makamu Max Las MokgaoganyiNo ratings yet

- PCB Relays H-045: Technical DataDocument3 pagesPCB Relays H-045: Technical DataSamsung KzoomNo ratings yet

- DG25 General Purpose Digital Gauge: Data SheetDocument4 pagesDG25 General Purpose Digital Gauge: Data SheetEcosuministros ColombiaNo ratings yet

- DB WMZ DFS Imf enDocument4 pagesDB WMZ DFS Imf enZakaria Ait MehdiNo ratings yet

- FD2000 - GEN III Rev5 FMDocument5 pagesFD2000 - GEN III Rev5 FMJosé Alberto RodríguezNo ratings yet

- EGCP2 Configuration Sheet: Sales Order Number: 715230432Document8 pagesEGCP2 Configuration Sheet: Sales Order Number: 715230432Santosh TalankarNo ratings yet

- Katalog Baylan Vodomjer 3-4.Document1 pageKatalog Baylan Vodomjer 3-4.Edin DervishiNo ratings yet

- Compact Pressure Switch: Series 8000Document2 pagesCompact Pressure Switch: Series 8000argaNo ratings yet

- AU - iPERL (Intl) Data SheetDocument2 pagesAU - iPERL (Intl) Data SheetHC IngenierosNo ratings yet

- TMSF Kel 1Document14 pagesTMSF Kel 1rozanNo ratings yet

- Master Flo Choke Control Valve Sizing - Version 7.1.0.0046X CV Sizing Calculation - Surface ValvesDocument1 pageMaster Flo Choke Control Valve Sizing - Version 7.1.0.0046X CV Sizing Calculation - Surface ValvesTridi PrintingNo ratings yet

- Semiconductor Technical DataDocument10 pagesSemiconductor Technical DataKbbl FmNo ratings yet

- D Series: Vishay BccomponentsDocument7 pagesD Series: Vishay BccomponentsjairomarcanoNo ratings yet

- S1 PruebaDocument10 pagesS1 PruebaDither Francisco GutierrezNo ratings yet

- Analog To Digital Converters: Nyquist-Rate AdcsDocument42 pagesAnalog To Digital Converters: Nyquist-Rate AdcsPahala SamosirNo ratings yet

- EGCP2 Configuration Sheet: Sales Order Number: 715230433.xls Page 1 of 8Document8 pagesEGCP2 Configuration Sheet: Sales Order Number: 715230433.xls Page 1 of 8Santosh TalankarNo ratings yet

- Relay ParametersDocument16 pagesRelay ParametersmoaazrasoolNo ratings yet

- 02 Datasheet Pressure TransmitterDocument2 pages02 Datasheet Pressure TransmitterFadlila MuhammadNo ratings yet

- LS501 LS501L LS501R Pressure TransmitterDocument16 pagesLS501 LS501L LS501R Pressure TransmitterRamulu VeesamNo ratings yet

- Interactive Catalog Replaces Catalog PagesDocument3 pagesInteractive Catalog Replaces Catalog Pagesmohamad_mozaNo ratings yet

- Discharge Calculations Per Ahri 885-08: Ncplot RcplotDocument16 pagesDischarge Calculations Per Ahri 885-08: Ncplot RcplothanyassawyNo ratings yet

- Pressure Sensor HoneywellDocument6 pagesPressure Sensor Honeywellamol_aradwadNo ratings yet

- Padeye .5MT CHKDocument12 pagesPadeye .5MT CHKDhanraj VasanthNo ratings yet

- Catalogo Medidor Ultrasonico BaylanDocument1 pageCatalogo Medidor Ultrasonico BaylanJeffersonNo ratings yet

- Melegvíz TartályokDocument5 pagesMelegvíz TartályokKovács TamásNo ratings yet

- Amti mc8-10000Document2 pagesAmti mc8-10000Enzo LonghiNo ratings yet

- Sizing Body Valve Torque MN-110873-22 ACTUATOR LEAKAGE VDocument1 pageSizing Body Valve Torque MN-110873-22 ACTUATOR LEAKAGE VPT PUTRA SETIAWAN PRIMANo ratings yet

- Lowering Analysis 10 in Gas PipelineDocument3 pagesLowering Analysis 10 in Gas Pipelinehamid sobirin100% (3)

- Hanbell Spec Sheet RC2-230B PDFDocument1 pageHanbell Spec Sheet RC2-230B PDFDaniel Naoe FestinNo ratings yet

- Neo-Dyn Series 130PDocument2 pagesNeo-Dyn Series 130PDaniel ReyNo ratings yet

- RASNE-3 CommentsDocument2 pagesRASNE-3 CommentsPrashant KumarNo ratings yet

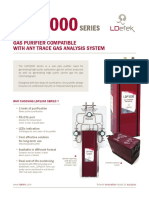

- Series: Gas Purifier Compatible With Any Trace Gas Analysis SystemDocument2 pagesSeries: Gas Purifier Compatible With Any Trace Gas Analysis SystembellaantoNo ratings yet

- WS1512D4 GouldsDocument4 pagesWS1512D4 GouldsJAIME HERNANDEZ HERNANDEZNo ratings yet

- Reem Takrouri PDF - Results PDFDocument5 pagesReem Takrouri PDF - Results PDFريم تكروريNo ratings yet

- Afr Data SheetDocument2 pagesAfr Data Sheetdeepak kumarNo ratings yet

- Fv101x - Specsht2Document1 pageFv101x - Specsht2Claudio Rivadeneira CarrascoNo ratings yet

- Vishay Siliconix: Product SummaryDocument5 pagesVishay Siliconix: Product SummaryytnateNo ratings yet

- Industrial Differential Pressure Transducer: SpecificationsDocument9 pagesIndustrial Differential Pressure Transducer: SpecificationsANo ratings yet

- Sl. No. Items Unit Tender Specification Tenderer ComplianceDocument2 pagesSl. No. Items Unit Tender Specification Tenderer ComplianceRushikiesh JoshNo ratings yet

- Channel OptimizationDocument10 pagesChannel OptimizationMutahir AbbasNo ratings yet

- Exapmle 1Document3 pagesExapmle 1Sazzadul HossainNo ratings yet

- SE20Document5 pagesSE20seyedmajidgNo ratings yet

- NIC Components NMC X8S SeriesDocument2 pagesNIC Components NMC X8S SeriesNICCompNo ratings yet

- Daftar Peralatan Refrigeration-LKS 2017Document1 pageDaftar Peralatan Refrigeration-LKS 2017Fitri YunitaNo ratings yet

- Series: Control ValvesDocument24 pagesSeries: Control ValvesGUSTAVONo ratings yet

- Well Completions QuestionaireDocument27 pagesWell Completions QuestionaireashwaniNo ratings yet

- Time Relays: Output Circuits - Contact DataDocument5 pagesTime Relays: Output Circuits - Contact Datamohammad AshrafNo ratings yet

- NEMA 23 Stats OtherDocument5 pagesNEMA 23 Stats OtherHasnain TariqNo ratings yet

- PCT 267836Document2 pagesPCT 267836Sonu KushwahaNo ratings yet

- F-Sorb X400 User GuideDocument20 pagesF-Sorb X400 User GuideKarla CalderónNo ratings yet

- Product Brief LevelPlus-Series TankSLAYER 551864 enDocument2 pagesProduct Brief LevelPlus-Series TankSLAYER 551864 enMiguel GomezNo ratings yet

- Masoneilan - 21000Document24 pagesMasoneilan - 21000ppsutorNo ratings yet

- NIC Components NRSN SeriesDocument5 pagesNIC Components NRSN SeriesNICCompNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- Fatigue Example 4Document12 pagesFatigue Example 4ajkNo ratings yet

- ANSYS Autodyn Users ManualDocument562 pagesANSYS Autodyn Users ManualajkNo ratings yet

- Ansys ACT API Reference GuideDocument4,876 pagesAnsys ACT API Reference GuideajkNo ratings yet

- 12 Panhard Place 2 - Structural CalculationsDocument39 pages12 Panhard Place 2 - Structural CalculationsmarkomarkomarkomarkoNo ratings yet

- MTech - CE Struc-EnggDocument31 pagesMTech - CE Struc-EnggAlfaiz Ur RehmanNo ratings yet

- Kinematics and Kinetics of Machines: Displacement, Velocity & Accelerationanalysis of A 4-Bar Planar MechanismDocument15 pagesKinematics and Kinetics of Machines: Displacement, Velocity & Accelerationanalysis of A 4-Bar Planar MechanismIsfakul ShihanNo ratings yet

- LAB 3 ENERGY LOSS IN PIPE AND FITTINGS - 23sept2016Document9 pagesLAB 3 ENERGY LOSS IN PIPE AND FITTINGS - 23sept2016Ahmad Raz AkmalNo ratings yet

- UP Diliman Physics 71 Long Exam#2 Sample ExamDocument12 pagesUP Diliman Physics 71 Long Exam#2 Sample Examjerard999No ratings yet

- E106 - AgustinDocument20 pagesE106 - AgustinSeth Jarl G. AgustinNo ratings yet

- Science 1206 Worksheet 12 Graphical Analysis On Non-Uniform MotionDocument7 pagesScience 1206 Worksheet 12 Graphical Analysis On Non-Uniform MotionAlisa RamićNo ratings yet

- Traditional and Innovative Joints in Bamboo ConstructionDocument3 pagesTraditional and Innovative Joints in Bamboo ConstructionAulia Rahman FahmiliNo ratings yet

- 08 Georgiev 45 50 PDFDocument6 pages08 Georgiev 45 50 PDFKuldeep28883No ratings yet

- Potentials of A Numerical Tool For The Simulation of Flow in External Gear MachinesDocument17 pagesPotentials of A Numerical Tool For The Simulation of Flow in External Gear Machines김동하No ratings yet

- Planetary Gear Set Transmission Ratio and ErrosDocument2 pagesPlanetary Gear Set Transmission Ratio and ErrosbarrywarryNo ratings yet

- CE Board Nov 2020 - RCD - Set 6 ColoredDocument3 pagesCE Board Nov 2020 - RCD - Set 6 ColoredDale MalazzabNo ratings yet

- Lira Calculation Report: Ship Name: Builder: JobDocument27 pagesLira Calculation Report: Ship Name: Builder: JobJesus Raul Osco TrujilloNo ratings yet

- DH - Ch2 Fundamentals of Rigid Kinematics - 4x3Document10 pagesDH - Ch2 Fundamentals of Rigid Kinematics - 4x3Hà Giang NguyễnNo ratings yet

- Fluid and Particle Mechanics Lab ExperimentsDocument4 pagesFluid and Particle Mechanics Lab ExperimentsSaiVenkatNo ratings yet

- Ilovepdf MergedDocument23 pagesIlovepdf MergedAhmad AdnanNo ratings yet

- Compendium ClassXII PhyscisDocument11 pagesCompendium ClassXII PhyscisvarunkohliinNo ratings yet

- NBCC 2015 Seismic DataDocument18 pagesNBCC 2015 Seismic DataRick HenbidNo ratings yet

- Momentum Transfer: Jul-Dec 2006 Instructor: Dr. S. Ramanathan Office: CHL 210 Email: Srinivar@iitm - Ac.in Class NotesDocument40 pagesMomentum Transfer: Jul-Dec 2006 Instructor: Dr. S. Ramanathan Office: CHL 210 Email: Srinivar@iitm - Ac.in Class NotesnicoolNo ratings yet

- Test 4 - StressesDocument3 pagesTest 4 - StressesCouline Castillo Roldan - DinoyNo ratings yet

- Water Hammer in Piping System-Part 1Document14 pagesWater Hammer in Piping System-Part 1Việt Đặng XuânNo ratings yet

- STEM General Physics 1: Quarter 1 - Module 6 Graphical Analysis of MotionDocument28 pagesSTEM General Physics 1: Quarter 1 - Module 6 Graphical Analysis of MotionStevenNo ratings yet

- Chapter 5 Force Mass AccelerationDocument12 pagesChapter 5 Force Mass AccelerationAivan SaberonNo ratings yet

- Xi Physics Term 1 SGMSDocument12 pagesXi Physics Term 1 SGMSSankalp JainNo ratings yet

- AEI602Document16 pagesAEI602api-26787131No ratings yet

- Dynamic Mesh OpenFoamDocument27 pagesDynamic Mesh OpenFoamM Ali0% (1)

- 1.2 Continuacion Resumen Principios FundamentalesDocument453 pages1.2 Continuacion Resumen Principios FundamentalesLUIS MATEO BOCANEGRA CANONo ratings yet

- Daniel Tian Li: Grade Beam Design Based On ACI 318-02Document2 pagesDaniel Tian Li: Grade Beam Design Based On ACI 318-02mdalgamouniNo ratings yet