0% found this document useful (0 votes)

268 views62 pagesStructural Footing Design Guide

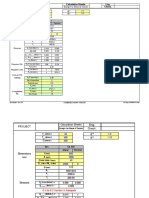

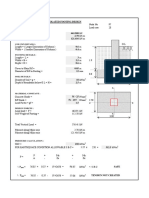

1. The combined footing is designed to support column A with a load of 1200 KN and column B with a load of 1600 KN.

2. The footing dimensions are 4.0 m x 3.9 m with 18 #16mm bars at 150mm c/c for top steel and 21 #12mm bars at 180mm c/c for bottom steel.

3. Punching shear, bearing capacity and transverse reinforcement checks are done to ensure the design is safe based on the given loads and material strengths.

Uploaded by

DVSCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

268 views62 pagesStructural Footing Design Guide

1. The combined footing is designed to support column A with a load of 1200 KN and column B with a load of 1600 KN.

2. The footing dimensions are 4.0 m x 3.9 m with 18 #16mm bars at 150mm c/c for top steel and 21 #12mm bars at 180mm c/c for bottom steel.

3. Punching shear, bearing capacity and transverse reinforcement checks are done to ensure the design is safe based on the given loads and material strengths.

Uploaded by

DVSCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd