Professional Documents

Culture Documents

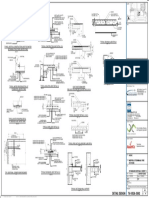

A3 106304 02023 01 A Dimensional Tolerances

Uploaded by

Chandra KanthOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A3 106304 02023 01 A Dimensional Tolerances

Uploaded by

Chandra KanthCopyright:

Available Formats

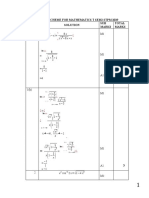

8 7 6 5 4 3 2 1

F F

Elevation of Internal Supports ±1/4" (6mm) (g) For nominal pipe sizes, the following

Bottom of Downcomer Bar Above Tray or Seal Pan Support Ring ±3/16" (5mm)

relationships were used:

Distance Between Adjacent Tray supports ±1/8" (3mm)

MAXIMUM DEVIATION OF SHELL FROM STRAIGHT

Dimensions Between Bolt Holes ±1/16" (1.5mm) 1/8" (3mm) Per 9'-10 1/8" (3m) WITH 1 15/16" (50mm) Max

Maximum Bow in Any 9'-10 1/8" (3m) of Length shall be 1/4" (6mm)

Base Ring or Support Lug to Tangent Line +0 - 1/4" (6mm)

TOP OF WEIR PLATE OUT-OF-LEVEL TOLERANCE

ACROSS LENGTH OF WEIR:±5/16" (8mm)

Bolt Hole to Bottom Tangent Line: ±3/8" (10mm)

Distance Between Insulation Rings: ±1/2" (12mm)

E TRAY SUPPORT OUT-OF-LEVEL TOLERANCE E

±3/8" (10mm) Across the Vessel Diameter

Tray Supports Shall Be Flat to Within ±3/16" (5mm) Insulation Ring to Bottom Tangent Line: ±3/8" (9mm)

on Any 13'-1 1/2" (4m) Chord & ±1/16" (1.5mm) in Width of Ring BASE RING, COMPRESSION RING AND SUPPORT

Height of Weir Above Tray Support Ring ±3/16" (5mm) LUG OUT-OF-LEVEL TOLERANCE ±1/2" (12mm)

BOLT HOLE CIRCLE ±1/4" (6mm)

D D

Tray

Top Plate of Anchor Chair Parallel to Base

Ring to Within ±1/16" (1.5mm)

Orientation of Nozzles ±1/2" (12mm)

C Orientation of Manways ±1/2" (12mm) C

Flange Face of Top Nozzle to Flange Face of Nozzle Parallel to

Top Tangent Line ±1/2" (12mm) Dedicated Plane In Any Direction

to Within ± ½ Degree Flange Face of Nozzle to Tangent Line ±1/2" (12mm)

A 21.11.2023 ISSUED FOR REVIEW DE PM EM

Tangent Line to Tangent Line: ±1' Maximum (25mm) REV DATE ISSUE, SCOPE OF REVISION PREPARED CHECKED APPROVED

PROJECT TITLE:

DESIGN, SUPPLY AND CONSTRUCTION OF NEW LPG STORAGE B

FACILITIES IN FIVE SPHERICAL VESSELS AT

Far Side of Vessel to Weir ±3/8" (10mm) Centerline of Manway to Tangent Line ±1/2" (12mm)

ZARKA REFINERY SITE PROJECT

Dimensions From Internals Related to Manways ±1/8" (3mm)

COMPANY:

Centerline of Nozzle to Tangent Line ±1/4" (6mm)

B

Vessel Diameter Tolerance: ±1.0% of Vessel Diameter JORDAN LIQUEFIED PETROLEUM GAS MANUFACTURING

Maximum Deviation in Actual Circunference: ±1 1/2" (38mm) & FILLING COMPANY

Through an opening or within (1)I.D. of the opening. EPC CONTRACTOR:

Tolerance increased by 2% of the I.D. of the opening. Dimensions From Internals

MID CONTRACTING

Related to Nozzles ±1/8" (3mm)

Flange Face of Manway Parallel to Dedicated Plane TETCO GROUP

In Any Direction to Within ± ½ Degree

CONSULTANT:

ILF CONSULTING ENGINEERS

Center of Manway Flange Face to Vessel Shell ±1/2" (13mm)

A

Center of Nozzle Flange ±1/4" (6mm) From Vessel Shell SUBCONTRACTOR:

DURO FELGUERA ENERGY STORAGE

Energy Storage

A

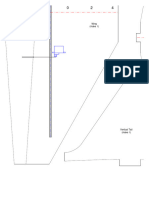

FI-825 8251 S-309 DRAWING TITLE :

FI-825 8252 S-310

FI-825 8253 S-311

DIMENSIONAL TOLERANCES

ORIGINAL SHEET SIZE - A3

(S-309 / S-310 / S311 / S-312 / S-313)

FI-825 8254 S-312

PROJECT No. - 15488

"Copying ofthis documentand giving itto others and the use

FI-825 8255 S-313 or communication of the contents thereof are forbidden SCALE: DRAWING NO: SHEET OF REV.

withoutexpress authority.Offenders are liable to the payment

JOB Nº SERIAL Nº EQUIPMENT ofdamages.Allrights are reserved in the eventofthe grantof

S/E A3-106304-02023-01 1 1 A

a patent or the registration of a utility model of design"

8 7 6 5 4 3 Printing:06.11.2023 1

You might also like

- 2015 Dodge Ram Cab Lights Installation 82211190ABDocument7 pages2015 Dodge Ram Cab Lights Installation 82211190ABmt11280% (1)

- Gates Belt Number and Identification ChartDocument1 pageGates Belt Number and Identification ChartalanbrannNo ratings yet

- Science: Quarter 4 - Module 1: Locating Places Using Coordinate SystemDocument28 pagesScience: Quarter 4 - Module 1: Locating Places Using Coordinate SystemJaken Mack100% (5)

- Designed by Steve Shumate: All Parts Made From 6 MM Depron or Bluecore Foam Unless Otherwise SpecifiedDocument19 pagesDesigned by Steve Shumate: All Parts Made From 6 MM Depron or Bluecore Foam Unless Otherwise SpecifiedDan Stefan DanNo ratings yet

- F-18 Parkflyer (Part Templates Non-Tiled)Document1 pageF-18 Parkflyer (Part Templates Non-Tiled)mohamed sidkyNo ratings yet

- K701 PDFDocument2 pagesK701 PDFJuliermeNo ratings yet

- R A S L I M S-03 Proposed 3-Storey Mix-Used Commercial BuildingDocument1 pageR A S L I M S-03 Proposed 3-Storey Mix-Used Commercial BuildingShariah MelonNo ratings yet

- Concrete Column Schedule: CC1 CC2 CC3 CC4 CC5 CC6 CC7 CC8 CC9 CC10 CC11 CC12 CC13Document1 pageConcrete Column Schedule: CC1 CC2 CC3 CC4 CC5 CC6 CC7 CC8 CC9 CC10 CC11 CC12 CC13Rolly Marc G. SoteloNo ratings yet

- WWMM Toy Planes-1Document2 pagesWWMM Toy Planes-1jhoel andradesNo ratings yet

- LM0013535 Modbar-AvDocument1 pageLM0013535 Modbar-AvUmut GökdenizNo ratings yet

- Gen180 TemplateDocument1 pageGen180 TemplateAlex SmNo ratings yet

- Meta-Nail Tibia ST Low ResDocument44 pagesMeta-Nail Tibia ST Low ResPC0% (1)

- Ball Bearing: Accuride Full Extension, Telescopic, Easy CloseDocument2 pagesBall Bearing: Accuride Full Extension, Telescopic, Easy CloseKissa DolautaNo ratings yet

- SFdetails 1Document1 pageSFdetails 1AlimajNo ratings yet

- Slimtrim Technical Information & Applications : Solutions & Tools For Problems That May AriseDocument15 pagesSlimtrim Technical Information & Applications : Solutions & Tools For Problems That May AriseMarcos JuarezNo ratings yet

- Quick Installation Guide: Read and Save These InstructionsDocument8 pagesQuick Installation Guide: Read and Save These InstructionsWilliam BeadenkopfNo ratings yet

- Construction Details For Nordic Lam™: Product WarrantyDocument2 pagesConstruction Details For Nordic Lam™: Product WarrantyhahaerNo ratings yet

- Exterior Dimensions Uc1A - : JANUARY 2009Document20 pagesExterior Dimensions Uc1A - : JANUARY 2009wayne mcmurrayNo ratings yet

- 020-SpecsDocument1 page020-SpecsjoeNo ratings yet

- F-14 Park Jet (Assembly Drawing Non-Tiled)Document1 pageF-14 Park Jet (Assembly Drawing Non-Tiled)pedrods141No ratings yet

- Silicon Chip Magazine 2009-10 Oct PDFDocument108 pagesSilicon Chip Magazine 2009-10 Oct PDFLucilia Dos Santos100% (1)

- Location Plan: Perimeter Fence DetailsDocument1 pageLocation Plan: Perimeter Fence DetailsLucio AdaNo ratings yet

- Beam Details Pratibha KarnaDocument1 pageBeam Details Pratibha KarnaROSHAN CHAUDHARYNo ratings yet

- Suzuki GSXR 600 2013Document2 pagesSuzuki GSXR 600 2013Adrian De La ConchaNo ratings yet

- 19PG0089 - Plans Page 9-17Document9 pages19PG0089 - Plans Page 9-17asebdcivilengNo ratings yet

- View New Product 2209 2305 230712Document15 pagesView New Product 2209 2305 230712Fauzan AffandiNo ratings yet

- Guardian G1814P Eyewash Station Wall Mounted Plastic Bowl TechdataDocument2 pagesGuardian G1814P Eyewash Station Wall Mounted Plastic Bowl TechdatamwrsbsNo ratings yet

- 757572864003123page206 24Document1 page757572864003123page206 24Jean de MetzNo ratings yet

- Si 6ngfa 004 EngDocument1 pageSi 6ngfa 004 EnglgsmartNo ratings yet

- Truss DEtailDocument1 pageTruss DEtailjerick calingasanNo ratings yet

- S002 76-10526-Detail Design: FOR 400 & 200 THKDocument1 pageS002 76-10526-Detail Design: FOR 400 & 200 THKMazen IsmailNo ratings yet

- T-38 Park Jet Plans (Parts Templates Non-Tiled) BETA2Document1 pageT-38 Park Jet Plans (Parts Templates Non-Tiled) BETA2vscribNo ratings yet

- Belt For TextileDocument6 pagesBelt For TextileArio DigdoyoNo ratings yet

- F-18 Park Jet (Part Templates Non-Tiled) Rev ADocument1 pageF-18 Park Jet (Part Templates Non-Tiled) Rev AvscribNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled)Document15 pagesT-38 Park Jet Plans (Parts Templates Tiled)Iruel Street NewNo ratings yet

- BellDocument2 pagesBellCaryl Ann CompañeroNo ratings yet

- 9 MM (3/8") Belt Sander: Model 9032Document2 pages9 MM (3/8") Belt Sander: Model 9032Wataru Ardhy MizunoNo ratings yet

- Guitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDaniel GarfoNo ratings yet

- Alpine12D2+4 SubwooferDocument1 pageAlpine12D2+4 Subwoofersoundman2No ratings yet

- 2015 Dodge Ram Cab Lights Installation 82211190ABDocument7 pages2015 Dodge Ram Cab Lights Installation 82211190ABhansenfarms.chNo ratings yet

- (Joint Size at Mean T F) (Closes To) (Opens To) : (See "Performance" For Movement Capabilities & Limitations)Document1 page(Joint Size at Mean T F) (Closes To) (Opens To) : (See "Performance" For Movement Capabilities & Limitations)Erickzelaya2014No ratings yet

- Hand Dryer and Waste Receptacle - B-38030 - TD by BobrickDocument6 pagesHand Dryer and Waste Receptacle - B-38030 - TD by Bobrickgabrielmonarchi12No ratings yet

- KnobsDocument3 pagesKnobsAlex SmNo ratings yet

- Ps 800Document2 pagesPs 800Raza SmartNo ratings yet

- Roof PlanDocument1 pageRoof PlanAarti PurohitNo ratings yet

- Mini 3dx Fullsheet A0Document1 pageMini 3dx Fullsheet A0andrequalNo ratings yet

- Mexin Messon Doors Industry Co.: Fire Door RF - 3 Hours Certificate WH (Usa)Document2 pagesMexin Messon Doors Industry Co.: Fire Door RF - 3 Hours Certificate WH (Usa)Pércy RodriguezNo ratings yet

- Cadre Warre Jerome 2011Document1 pageCadre Warre Jerome 2011andonoxNo ratings yet

- Schedule of Beam: Foundation Plan Second Floor Framing Plan Roof Framing PlanDocument1 pageSchedule of Beam: Foundation Plan Second Floor Framing Plan Roof Framing PlanLeonard Delos ReyesNo ratings yet

- TTD 13Document1 pageTTD 13Hector RiveraNo ratings yet

- American March Pump 460 ODSDocument24 pagesAmerican March Pump 460 ODSjuan davidNo ratings yet

- Clips Reference ChartDocument2 pagesClips Reference ChartAni RiveroNo ratings yet

- Gabion Basket Isometric: AB ION CE LLDocument1 pageGabion Basket Isometric: AB ION CE LLruspapiNo ratings yet

- The Printmaster GTO 52 Offers You Ideal Solutions in A3 Format For Discerning CustomersDocument1 pageThe Printmaster GTO 52 Offers You Ideal Solutions in A3 Format For Discerning CustomersLucas ViniciusNo ratings yet

- Style 1101 Rubber Expansion Joint: Shown With Control Unit GR/B Section DetailDocument1 pageStyle 1101 Rubber Expansion Joint: Shown With Control Unit GR/B Section DetailABDERRAZZAKNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)Document6 pagesT-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)vscribNo ratings yet

- Column 1: Edge Slab DetailDocument1 pageColumn 1: Edge Slab Detaildesigncivil144No ratings yet

- Filantro - VRV Schematic - CircuitDocument1 pageFilantro - VRV Schematic - CircuitTanzil HassanNo ratings yet

- DB 000 13302 0301 001 01 Member List For Module Steel StructureDocument1 pageDB 000 13302 0301 001 01 Member List For Module Steel StructurekohilanrkNo ratings yet

- Utball Wappable - 1359780412 PDFDocument1 pageUtball Wappable - 1359780412 PDFNidhiNo ratings yet

- Bird Tracks & Sign: A Guide to North American SpeciesFrom EverandBird Tracks & Sign: A Guide to North American SpeciesRating: 5 out of 5 stars5/5 (1)

- A3-106304-02017-01-A General Arrangement S313Document1 pageA3-106304-02017-01-A General Arrangement S313Chandra KanthNo ratings yet

- Base Plate - Anchor Bolt and Shear Key Design - P1Document3 pagesBase Plate - Anchor Bolt and Shear Key Design - P1Chandra Kanth100% (1)

- 30 June 2022 - Journey of Hajj - 01 Dhul Hijjah 1443Document11 pages30 June 2022 - Journey of Hajj - 01 Dhul Hijjah 1443Chandra KanthNo ratings yet

- Base Plate - Anchor Bolt and Shear Key Design - P1Document3 pagesBase Plate - Anchor Bolt and Shear Key Design - P1Chandra Kanth100% (1)

- 0188PF N DG DG05 ST Dte 1032 001 A01Document2 pages0188PF N DG DG05 ST Dte 1032 001 A01Chandra KanthNo ratings yet

- For Construction: PetrofacDocument1 pageFor Construction: PetrofacChandra Kanth100% (1)

- For Review: PetrofacDocument1 pageFor Review: PetrofacChandra KanthNo ratings yet

- L071ME4182DFADocument81 pagesL071ME4182DFAmegamech23No ratings yet

- Radioddity DMR Programming Tips - (EN+DE)Document35 pagesRadioddity DMR Programming Tips - (EN+DE)David TutNo ratings yet

- Elasticity Measurement of Local Taxes and Charges in Forecast of Own-Source Revenue (PAD) of Provincial Government in IndonesiaDocument27 pagesElasticity Measurement of Local Taxes and Charges in Forecast of Own-Source Revenue (PAD) of Provincial Government in Indonesiaayu desiNo ratings yet

- Alcatel 4029 EngDocument31 pagesAlcatel 4029 Engafsanto2000No ratings yet

- Experiment - 1: Aim: Create Webpage Using HTML Form To Demonstrate Student Information FormDocument29 pagesExperiment - 1: Aim: Create Webpage Using HTML Form To Demonstrate Student Information FormModi rutvikNo ratings yet

- Javascript Date ObjectDocument5 pagesJavascript Date Objectshivi08No ratings yet

- Sesam and Bladed - Efficient Coupled Analyses - Webinar Presentation - tcm8-102589 PDFDocument31 pagesSesam and Bladed - Efficient Coupled Analyses - Webinar Presentation - tcm8-102589 PDFsamiransmitaNo ratings yet

- Asco Series 042 Gas Shutoff CatalogDocument4 pagesAsco Series 042 Gas Shutoff CatalogRoqueNetNo ratings yet

- Service Manual: Fully Automatic Washing MachineDocument41 pagesService Manual: Fully Automatic Washing MachineSơn PhạmNo ratings yet

- ManualDocument31 pagesManualextremtigerNo ratings yet

- C ValueDocument2 pagesC ValuePadmanabh Shetty0% (1)

- Certificate of Analysis: Sulfate IC CRM - 1000 MG/LDocument2 pagesCertificate of Analysis: Sulfate IC CRM - 1000 MG/LasanalyticalNo ratings yet

- Essilor MR - Blue - 20-1Document132 pagesEssilor MR - Blue - 20-1Primoz DolinsekNo ratings yet

- Investment Model QuestionsDocument12 pagesInvestment Model Questionssamuel debebe0% (1)

- Metric Ton Is 1000 KGDocument5 pagesMetric Ton Is 1000 KGmcpayodNo ratings yet

- 001-MBA-SPSS Applications - 10-06-2023Document74 pages001-MBA-SPSS Applications - 10-06-2023seyon sithamparanathanNo ratings yet

- Figure of MeritDocument33 pagesFigure of MeritmuhammadmaihadisiNo ratings yet

- Schiotz TonometerDocument9 pagesSchiotz TonometerDR_LUBYNo ratings yet

- Grade Sheet BlankDocument50 pagesGrade Sheet BlankCarlo Troy AcelottNo ratings yet

- Es3Pt: User ManualDocument53 pagesEs3Pt: User ManualBITGEORGYNo ratings yet

- Kluang (A) S2 STPM 2019Document9 pagesKluang (A) S2 STPM 2019Rex KalNo ratings yet

- TM 9-4110-241-23PDocument41 pagesTM 9-4110-241-23PwwwsurvivalebookscomNo ratings yet

- Tài Liệu CAT Pallet Truck NPP20NDocument9 pagesTài Liệu CAT Pallet Truck NPP20NJONHHY NGUYEN DANGNo ratings yet

- Xii Chemistry MCQ (Haloalanes & Haloarenrs)Document7 pagesXii Chemistry MCQ (Haloalanes & Haloarenrs)SanjanasanjuNo ratings yet

- This Study Resource Was: EvaluateDocument2 pagesThis Study Resource Was: EvaluateMary angel PerjesNo ratings yet

- Zott Business ModelDocument25 pagesZott Business ModelNico LightNo ratings yet

- Color Pencil TheoryDocument2 pagesColor Pencil Theoryapi-246017428No ratings yet

- 3g3JX InverterDocument262 pages3g3JX InverterdatdttvuNo ratings yet

- Effect of Salinity On Proteins in Some Wheat CultivarsDocument9 pagesEffect of Salinity On Proteins in Some Wheat Cultivarsray m deraniaNo ratings yet