Professional Documents

Culture Documents

06 - Fatigure Assessment Report Rev.01 2023.10.18-Final

Uploaded by

Hoang HoangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 - Fatigure Assessment Report Rev.01 2023.10.18-Final

Uploaded by

Hoang HoangCopyright:

Available Formats

TẬP ĐOÀN ĐIỆN LỰC VIỆT NAM

CÔNG TY CỔ PHẦN TƯ VẤN XÂY DỰNG ĐIỆN 1

PROJECT: 26.2023

VIEN AN WIND POWER PLANT

WORKING DRAWING STAGE

FATIGUE CALCULATION REPORT OF ANCHORED BOLT

TURBINE NO.5

REVIEW REPORT REV.01

Reviewer : Hoang Anh Minh

Head of Technical and International

Cooperation Department : Le Quang Huy

Hanoi, June 2023

GENERAL DIRECTOR

Nguyen Huu Chinh

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

TABLE OF CONTENTS

Part 1: OVERVIEW ...………………………………………………………………. 1

1.1. General introduction .............................................................................................. 1

1.2. Scope of work .......................................................................................................... 1

1.3. Applicable standards and documents ................................................................... 2

1.3.1. Standards ....................................................................................................... 2

1.3.2. Used documents ............................................................................................. 2

1.4. Geometric dimensions ............................................................................................ 2

1.5. Data .......................................................................................................................... 4

1.5.1. Concrete material ........................................................................................... 4

1.5.2. Reinforcement materials ................................................................................ 4

1.5.3. Anchor bolt parameters ................................................................................. 4

1.5.4. Requirements on steel strength ...................................................................... 5

1.6. Phenomenon description ........................................................................................ 5

Part 2: LOADS ………………………………………………………………………..8

2.1. Turbine load ............................................................................................................ 8

2.1.1. Overview ....................................................................................................... 8

2.1.2. Direction and orientation of loads ................................................................. 8

2.2. ULS loads................................................................................................................. 9

2.3. SLS loads ............................................................................................................... 10

2.4. Fatigue loads ......................................................................................................... 11

2.5. Calculation cases ................................................................................................... 11

2.6. Boundary conditions applied in calculation ....................................................... 12

Part 3: ANALYSIS CALCULATION RESULTS …………………………………13

3.1. Finite element calculation model ......................................................................... 13

3.2. Case 1 – SLS-QP- Normal anchor bolts ............................................................. 13

3.3. Case 2 – Fatigue, m = 5, anchor bolts with stress loss ....................................... 16

3.4. Assessment and analysis of calculation results .................................................. 20

3.4.1. Results of anchor bolt stress ........................................................................ 20

3.4.2. Results of fatigue state................................................................................. 20

Part 4: CONCLUSIONS …………………………………………………………….23

4.1. Stress state in anchor bolts: ................................................................................. 23

4.2. Fatigue state in anchor bolts: .............................................................................. 23

Công ty TNHH MTV Năng lượng Viên An Cà Mau

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

LIST OF TABLES

Table 1.1 - General parameters of the project................................................................. 1

Table 1.2 – Parameters of concrete material ................................................................... 4

Table 1.3 – Parameters of steel material ......................................................................... 4

Table 1.4 – Parameters on anchoring moment ................................................................ 5

Table 2.1 – ULS combination ......................................................................................... 9

Table 2.2 – SLS combination ........................................................................................ 10

Table 2.3 – Fatigue load combination ........................................................................... 11

Table 2.4 – Summary of calculation cases .................................................................... 12

Table 2.5 – Factor of load combination ........................................................................ 12

Table 2.7 – Tensile stress range of anchor bolts ........................................................... 12

Table 3.1 – Summary results of stresses inside anchor bolts ........................................ 20

Table 3.2 – Fatigue state assessment results of anchor bolt ......................................... 22

Công ty TNHH MTV Năng lượng Viên An Cà Mau

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

LIST OF FIGURES

Figure 1.1 – Section ........................................................................................................ 3

Figure 1.2 – Layout plan ................................................................................................. 3

Figure 1.3 – Details of anchor bolts and steel plates of the cover at the top and at the

bottom .............................................................................................................................. 6

Figure 1.4 – Details of status of bolt No. 62 after installation – WT05 ......................... 6

Figure 1.5 – Details of status of bolt no. 61,62 and 63 after installation – WT05 ......... 7

Figure 2.1 – Direction and orientation of loads .............................................................. 8

Figure 3.1 – FE calculation model is built from actual design model, including details

of reinforcement and anchor bolts ................................................................................. 13

Figure 3.2 – Case 1 – Displacement Ux (mm) ............................................................. 13

Figure 3.3 – Case 1 – Displacement Uy (mm).............................................................. 14

Figure 3.4 – Case 1 – Displacement Uz (mm) .............................................................. 14

Figure 3.5 – Case 1 – Tension of anchor bolts (kN) ..................................................... 15

Figure 3.6 – Case 1 - Stress of anchor bolts (MN/m2) ................................................. 15

Figure 3.7 – Case 2 – Displacement Ux (mm) ............................................................. 16

Figure 3.8 – Case 2 – Displacement Uy (mm).............................................................. 16

Figure 3.9 – Case 2 – Displacement Uz (mm) .............................................................. 17

Figure 3.10 – Case 2 – Tension of normal anchor bolts (kN) ...................................... 17

Figure 3.11 – Case 2 – Stress of normal anchor bolts (MN/m2) .................................. 18

Figure 3.12 – Case 2 – Tension of anchor bolts with stress loss (kN) ......................... 18

Figure 3.13 – Case 2 – Stress of anchor bolts with stress loss (MN/m2) ..................... 19

Công ty TNHH MTV Năng lượng Viên An Cà Mau

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Part 1: OVERVIEW

1.1. General introduction

The Vien An Wind Power Plant (WPP) has an initial design installed

capacity of 50MW and is the near-shore WPP in Ca Mau Province, Vietnam.

Project parameters are listed below:

Table 1.1 - General parameters of the project

No. Contents Information

01 Project Vien An Wind Power Plant

02 Location Ca Mau

03 Stage Technical Design and Review

04 Capacity of the plant 50 MW

05 Number of turbines 16

1.2. Scope of work

This calculation report is made to check and calculate performance of

anchor bolts in the WT5 foundation, the built offshore wind turbine foundation

has some pre-stressed anchor bolts found with stress loss phenomenon. The

foundation concrete strength and serviceability states are not considered.

Equipment installed in foundation WT05:

+ Brand: MingYang;

+ Turbine type: MySE3.2-156;

The modeled and applied calculations are of the non-linear finite element

problem type – Structural non-linear.

Within the scope of this report, the project's anchor bolts are said to have

load bearing problems without accurate measurement results of the current

bearing capacity. Therefore, during the anchor bolts calculation, they are

considered to be pre-stress loss.

Công ty TNHH MTV Năng lượng Viên An Cà Mau 1

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

1.3. Applicable standards and documents

1.3.1. Standards

- EN 61400-1: Design requirements of wind turbines.

- IEC 61400-1: Design requirements;

- IEC 61400-3: Design requirements of offshore wind turbine;

- Eurocode 1: IMPacts on structure;

- Eurocode 2: Concrete work design;

- DNV-OS-J101: Structural design of offshore wind turbine;

- DNV-OS-C205: Offshore concrete structure;

- TCVN 7888:2014: Pre-stressed centrifugal concrete piles;

- TCVN 5574:2018: Design of concrete and reinforced concrete structures;

- TCVN 9346:2012: Concrete and reinforced concrete structures -

Requirements of protection against corrosion in marine environment;

- TCVN 4116:1985: Concrete and reinforced concrete structures - Design

standards;

- GB 50017-2003 - Code for Design of Steel Structures;

- And several other relevant standards.

1.3.2. Used documents

- Design drawings for foundation of wind tower turbine WT05;

- Tensile parameters of anchor bolts provided by the manufacturer;

- Technical design document of the previous stage: (No): 220001N-

NC00691S-T0206 Vien An 50MWW Offshore Wind Farm Project in Ca Mau,

Vietnam - WTG Pile Foundation Design Report in 2020;

- Parameters from the turbine supplier MingYang;

+ The anchor steel tie is based on documents provided by MingYang;

+ Loads at the base of the tower provided by MingYang.

1.4. Geometric dimensions

Công ty TNHH MTV Năng lượng Viên An Cà Mau 2

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Figure 1.1 – Section

Figure 1.2 – Layout plan

Công ty TNHH MTV Năng lượng Viên An Cà Mau 3

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

1.5. Data

1.5.1. Concrete material

Table 1.2 – Parameters of concrete material

TT Subject Value Unit

01 Concrete grade C45/55 -

02 Compressive strength of cylinder specimen at 28 days 45 MPa

03 Elastic modulus 36000 MPa

04 Coefficient of thermal expansion 1.08e-05 1/oC

05 Concrete unit weight 24.5 kN/m3

06 Unconfined compression factor 0.2 -

Note: The concrete must comply with standards: EN206-1 and TCVN

9346:2012 Concrete and reinforced concrete structures – Requirements of

protection against corrosion.

1.5.2. Reinforcement materials

Table 1.3 – Parameters of steel material

No. Subject Value Unit

01 Reinforcement grade CB400V -

02 Elastic modulus Es 200000 MPa

03 Liquid limit fy 500 MPa

04 Specific factor of safety for reinforcement fs 1.15 -

Note: The reinforcement must comply with EN10080 or TCVN 1651-

2008.

1.5.3. Anchor bolt parameters

Parameters of anchor bolts are taken according to technical guide of

suppliers as in the table below:

Công ty TNHH MTV Năng lượng Viên An Cà Mau 4

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Table 1.4 – Parameters on anchoring moment

1.5.4. Requirements on steel strength

Steel strength is designed in compliance with GB50017-2003 - Code for

Design of Steel Structures.

1.6. Phenomenon description

The upper and lower steel plates are connected to each other using 256

anchor bolts of the M48 type. Bolts are embedded in concrete, and then stressed

with a post-tensioning force of 640 kN;

Công ty TNHH MTV Năng lượng Viên An Cà Mau 5

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Figure 1.3 – Details of anchor bolts and steel plates of the cover at the top and

at the bottom

Figure 1.4 – Details of status of bolt No. 62 after installation – WT05

Công ty TNHH MTV Năng lượng Viên An Cà Mau 6

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Figure 1.5 – Details of status of bolt no. 61,62 and 63 after installation – WT05

According to the images and phenomenon description, anchor bolts No. 61,

62 and 63 have the phenomenon of losing stress after being tensioned. The

phenomenon of stress loss is caused by various reasons. But the main cause is

due to the effects of friction and elastic contraction.

The main assessments in this report include:

1. Checking the stress conditions of tension anchor bolts in case of

calculated tension force. The load applied to the concrete structure corresponds

to the SLS combination. Anchor bolts operate normally;

2. Checking the tension force in the case post-tension anchor bolts have

stress loss. Anchor bolts are subjected to stress loss according to the calculation

diagram.

3. Assessing the fatigue conditions of anchor bolts in the case post-tension

anchor bolts have stress loss.

Công ty TNHH MTV Năng lượng Viên An Cà Mau 7

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Part 2: LOADS

2.1. Turbine load

2.1.1. Overview

- Loads upon foundation are provided by the turbine supplier: MingYang;

- According to document No.: MySE3.2-156 (V2G2)/ HH111m /TCS

WTG16 Elevated Pile Caps Load Calculation Report.

2.1.2. Direction and orientation of loads

Direction and orientation of loads are displayed as below figure:

Figure 2.1 – Direction and orientation of loads

Công ty TNHH MTV Năng lượng Viên An Cà Mau 8

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

2.2. ULS loads

Table 2.1 – ULS combination

Công ty TNHH MTV Năng lượng Viên An Cà Mau 9

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

2.3. SLS loads

Table 2.2 – SLS combination

Công ty TNHH MTV Năng lượng Viên An Cà Mau 10

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

2.4. Fatigue loads

Table 2.3 – Fatigue load combination

2.5. Calculation cases

In order to evaluate and comprehensively analyze working state of the

anchor bolts in the wind tower foundation in normal cases (correct installation

procedure, correct tensile force) and in abnormal cases (some anchor bolts do

not achieve required tension as shown in the figure above), the following

calculation cases are conducted:

- Case 1:

+ Load corresponding to SLS-QP (Service Limit State – Quasi –

Permanent), long term service limit state;

+ Anchor bolts are installed and operate normally with post-tensioning

force of bolts of 640 kN;

+ Assessment results: stress status of anchor bolts.

- Case 2:

The value m 5 is normally associated with steel casing and anchors. This

value is recommended by the Turbine supplier and used in the design 1.

+ Load corresponding to Fatigue, m = 5;

1

https://mp.weixin.qq.com/s/7EGqpxNbXk8I05EHp9N91w (accessible in June 2023)

Công ty TNHH MTV Năng lượng Viên An Cà Mau 11

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

+ Some installed anchor bolts are recorded with stress loss.

+ Assessment results: stress status of anchor bolts; fatigue state.

Table 2.4 – Summary of calculation cases

Parameters Case 1 Case 2

Loads SLS -QP Fatigue, m = 5

State of anchor bolts Good Stress loss

Stress state of anchor bolts X X

Fatigue state of anchor bolts - X

Load combination factors are referred to the table given below.

Table 2.5 – Factor of load combination

2.6. Boundary conditions applied in calculation

- Tensile stress range of anchor bolts according to fatigue analysis:

+ Tensile stress of anchor bolts: 150 MPa at 10e6 oscillation periods;

Refer to the following table for details of limits:

Table 2.6 – Tensile stress range of anchor bolts

Công ty TNHH MTV Năng lượng Viên An Cà Mau 12

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Part 3: ANALYSIS CALCULATION RESULTS

3.1. Finite element calculation model

The calculation models of finite element analysis problem and non-linear

problem take into account the simultaneously working of reinforcement and

concrete;

Figure 3.1 – FE calculation model is built from actual design model, including

details of reinforcement and anchor bolts

3.2. Case 1 – SLS-QP- Normal anchor bolts

Figure 3.2 – Case 1 – Displacement Ux (mm)

Công ty TNHH MTV Năng lượng Viên An Cà Mau 13

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Figure 3.3 – Case 1 – Displacement Uy (mm)

Figure 3.4 – Case 1 – Displacement Uz (mm)

Công ty TNHH MTV Năng lượng Viên An Cà Mau 14

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Figure 3.5 – Case 1 – Tension of anchor bolts (kN)

Figure 3.6 – Case 1 - Stress of anchor bolts (MN/m2)

Công ty TNHH MTV Năng lượng Viên An Cà Mau 15

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

3.3. Case 2 – Fatigue, m = 5, anchor bolts with stress loss

Figure 3.7 – Case 2 – Displacement Ux (mm)

Figure 3.8 – Case 2 – Displacement Uy (mm)

Công ty TNHH MTV Năng lượng Viên An Cà Mau 16

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Figure 3.9 – Case 2 – Displacement Uz (mm)

Figure 3.10 – Case 2 – Tension of normal anchor bolts (kN)

Công ty TNHH MTV Năng lượng Viên An Cà Mau 17

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Figure 3.11 – Case 2 – Stress of normal anchor bolts (MN/m2)

Figure 3.12 – Case 2 – Tension of anchor bolts with stress loss (kN)

Công ty TNHH MTV Năng lượng Viên An Cà Mau 18

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Figure 3.13 – Case 2 – Stress of anchor bolts with stress loss (MN/m2)

Công ty TNHH MTV Năng lượng Viên An Cà Mau 19

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

3.4. Assessment and analysis of calculation results

3.4.1. Results of anchor bolt stress

Table 3.1 – Summary results of stresses inside anchor bolts

Stresses inside Limitation

No Cases Load Bolt state Conclusion

anchor bolt (MN) scope (MN)

Good [400 MN]

01 Case 1 SLS-QP 353.68 Accepted

operation

02 Case 2 FLS, m = 5 stress lost 294.3 to 295.5 [400 MN] Accepted

The stress state inside anchor bolts, both in SLS-QP and FLS cases, is less

than the allowable stress limit value.

3.4.2. Results of fatigue state

At the same time, the relevant fatigue curve of DNV RP C203-2020 is

supplemented for further supplementary fatigue checking.

The bolts are wrapped in concrete and can be considered to be fatigued in the

air. The parameters of various types of fatigue curves are shown in the table

below. The bolts that are mainly subjected to tensile force belong to category F1

or category G (category G can be conservatively used in calculation).

Công ty TNHH MTV Năng lượng Viên An Cà Mau 20

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

F1 or G curves can be used for bolts mainly subject to tension and pressure

(G type can be conservatively used for calculation).

The fatigue life can be calculated by following equation:

Công ty TNHH MTV Năng lượng Viên An Cà Mau 21

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

According to above table, when the number of equivalent fatigue load

cycles of the wind turbine is 1×10 8, using the second segment of the S-N curve,

the calculation parameters are shown in the table below.

The stress calculated by the finite element can be considered as the nominal

stress Δσnormal, according to the above tables, considering that the stress

concentration factor SCF of the G curve is 1.8, the Δσ in the actual calculation

should be brought into SCF×Δσnormal, and the specific calculation process is as

follows:

Table 3.2 – Fatigue state assessment results of anchor bolt

m2 5

loga2 14.33

Δσnormal 1.2

SCF (Stress concentration factor) 1.8

logN 12.65773124

N 4547065856282.5

nload 1×108

Damge= nload/N 0.1

After calculation, the maximum damage of the anchor bolts is only about

0.1, indicating that the fatigue performance of the anchor bolts meets the

requirement by the standard.

Công ty TNHH MTV Năng lượng Viên An Cà Mau 22

Vien An Wind Power Plant Fatigue Calculation Report on Anchor Bolts - Turbine No.05

Part 4: CONCLUSIONS

4.1. Stress state in anchor bolts:

The stress value of anchor bolts operates normally and in case anchor bolts

is subjected to stress loss, the stress value is always less than the allowable limit

stress of high-strength steel material.

4.2. Fatigue state in anchor bolts:

Assessment of the fatigue state of anchor bolts shall be in accordance with

DNV RP C203-2020. For the case of two bolt malfunctioned, the maximum

fatigue damage value is less than 1, i.e. within the allowable range in the

standard.

Công ty TNHH MTV Năng lượng Viên An Cà Mau 23

You might also like

- Belarus 1822.3Document358 pagesBelarus 1822.3paky1111No ratings yet

- Manual VCB PDFDocument142 pagesManual VCB PDFGold Flake100% (2)

- LMV36 Dual FuelDocument242 pagesLMV36 Dual FuelhenddikNo ratings yet

- BasicDocument24 pagesBasicAhmad Iman SetyonoNo ratings yet

- HLC - TLC - FO - 08 - G28 - APPENDIX M - Roof Parapet Design Report-RevCDocument56 pagesHLC - TLC - FO - 08 - G28 - APPENDIX M - Roof Parapet Design Report-RevCPhú NguyễnNo ratings yet

- Seat Leon 3 Electrical System EngDocument290 pagesSeat Leon 3 Electrical System EngIlko VelichkovNo ratings yet

- Fracture Analysis GN Feb22Document64 pagesFracture Analysis GN Feb22samiran.sahaNo ratings yet

- gp860110 ComDocument30 pagesgp860110 Comfahimidrus1No ratings yet

- Jud408310 b8000 Oper Man Eng-Rev DDocument79 pagesJud408310 b8000 Oper Man Eng-Rev DJorge Armando LaiNo ratings yet

- JICA Report Design of SHPDocument60 pagesJICA Report Design of SHPArnold GarciaNo ratings yet

- ABB Photo Voltaic PlantsDocument116 pagesABB Photo Voltaic PlantsfiestastefNo ratings yet

- Cost Assessment of Hydrogen Production From PV and ElectrolysisDocument44 pagesCost Assessment of Hydrogen Production From PV and ElectrolysisZakiah Darajat Nurfajrin100% (1)

- 5 9835Document29 pages5 9835Lesley HoodNo ratings yet

- PDFDocument139 pagesPDFAnonymous ItzBhUGoi100% (2)

- Manual Chiller YCME 162 HEDocument102 pagesManual Chiller YCME 162 HECarlos Bruno MatosNo ratings yet

- ABB Installation and MaintenanceDocument85 pagesABB Installation and MaintenanceHéctor D. BuelvasNo ratings yet

- Modular Expansion Joints For Road Bridges: August 2019Document65 pagesModular Expansion Joints For Road Bridges: August 2019Marko ZgbNo ratings yet

- Central Inverter: Planning of A PV GeneratorDocument37 pagesCentral Inverter: Planning of A PV Generatorraj sekhar100% (1)

- 141A Service PDFDocument101 pages141A Service PDFAndrás SzabóNo ratings yet

- Comentários MODU ABSDocument3 pagesComentários MODU ABSLucas TarcioNo ratings yet

- FANUC DC SERVO MaintManDocument105 pagesFANUC DC SERVO MaintManRudolf Oppermann100% (1)

- Electrical PanelDocument152 pagesElectrical Panelvijayabhaskar83100% (3)

- Guideline For Technical Regulation Vol.2 - Design of Thermal Power Facilities Book 4.12 Coal Fuel Handling FacilityDocument114 pagesGuideline For Technical Regulation Vol.2 - Design of Thermal Power Facilities Book 4.12 Coal Fuel Handling FacilityQuang Minh Trần100% (1)

- ead-120109-00-0107-NOSING JOINTS - ETAG 032-4 - UnlockedDocument80 pagesead-120109-00-0107-NOSING JOINTS - ETAG 032-4 - UnlockedMarko ZgbNo ratings yet

- Mi 20 D K st5 s1Document98 pagesMi 20 D K st5 s1Fernando GuardaNo ratings yet

- VW Up 2017 Electrical System EngDocument165 pagesVW Up 2017 Electrical System Engjohoba5344No ratings yet

- Mtu - Technical Documentation: ServiceDocument224 pagesMtu - Technical Documentation: ServiceAGugerNo ratings yet

- SL1000 Hardware Manual 1.1 GEDocument144 pagesSL1000 Hardware Manual 1.1 GEJohn Paje0% (1)

- AC Service Unit: Repair InstructionsDocument29 pagesAC Service Unit: Repair InstructionsPavel Spáčil100% (1)

- VSC Report Version1Document51 pagesVSC Report Version1ankur rathiNo ratings yet

- Technical CalculationDocument272 pagesTechnical CalculationmcbluedNo ratings yet

- Division 2 Project SpecificationsDocument474 pagesDivision 2 Project Specificationsdowen sorianoNo ratings yet

- Comparison Between Underground and Over Head Power Line in The Distribution of Electricity in Middle and Low VoltageDocument78 pagesComparison Between Underground and Over Head Power Line in The Distribution of Electricity in Middle and Low VoltageChana WannapookNo ratings yet

- Volume II O and M and MaintenanceDocument81 pagesVolume II O and M and Maintenanceabdalla magzoubNo ratings yet

- TRACTABEL-Distribution System Study PDFDocument229 pagesTRACTABEL-Distribution System Study PDFAshfaaq OchatoyaNo ratings yet

- Info Iec61400-21 (Ed2.0) BDocument15 pagesInfo Iec61400-21 (Ed2.0) BmarinflorentinaoanaNo ratings yet

- Modu - Commentary Combined - 01 Dec 04Document64 pagesModu - Commentary Combined - 01 Dec 04djodje1No ratings yet

- Ministry of Water - SewerDocument250 pagesMinistry of Water - Sewerfaisal100% (1)

- General Requirement ............................................ 1Document10 pagesGeneral Requirement ............................................ 1Hamza AldaeefNo ratings yet

- 170kV Siemens 8DN9 2016Document365 pages170kV Siemens 8DN9 2016Oktafian PrabandaruNo ratings yet

- 14 - Metro Rail Design Criteria Fire Life Safety Criteria Revision 1, 072612 FINAL PDFDocument78 pages14 - Metro Rail Design Criteria Fire Life Safety Criteria Revision 1, 072612 FINAL PDFJothimanikkam SomasundaramNo ratings yet

- Saes P 103Document32 pagesSaes P 103Hussein ZeyadaNo ratings yet

- Hospital WiringDocument126 pagesHospital WiringMarikaniNo ratings yet

- DC-DC Step-Down FelixDocument31 pagesDC-DC Step-Down FelixGFGHJHKNo ratings yet

- ABB Electrical Installation Handbook 2 - Electrical DevicesDocument134 pagesABB Electrical Installation Handbook 2 - Electrical Devicesanon_266748100% (2)

- Final ReportDocument518 pagesFinal Report李奕孜No ratings yet

- Robotics, Mechatronics, and Artificial Intelligence: Experimental Circuit Blocks for DesignersFrom EverandRobotics, Mechatronics, and Artificial Intelligence: Experimental Circuit Blocks for DesignersRating: 5 out of 5 stars5/5 (8)

- GP-16!02!01 Power System DesignDocument38 pagesGP-16!02!01 Power System DesignabenitechNo ratings yet

- Miller TM-2206 INVISION 304PDocument106 pagesMiller TM-2206 INVISION 304PLila WeldingNo ratings yet

- EGruposDMime - Ground Mat Resistance TestDocument39 pagesEGruposDMime - Ground Mat Resistance Testtransient matterNo ratings yet

- VW Id4 Electrical System EngDocument200 pagesVW Id4 Electrical System Engadylhanshermatov11No ratings yet

- WEEK 1: Cathode Ray Oscilloscope: List of ContentsDocument52 pagesWEEK 1: Cathode Ray Oscilloscope: List of ContentsTosin OgunrindeNo ratings yet

- M007-OnW-ARC-SPE-11303-V1.0 - (Msheireb Station, Finishes Materials and Structural Works Specifications, P1.2 Secondary Shelters De)Document318 pagesM007-OnW-ARC-SPE-11303-V1.0 - (Msheireb Station, Finishes Materials and Structural Works Specifications, P1.2 Secondary Shelters De)Mikku KattaNo ratings yet

- Guidelines For Fatigue Strength AssessmentDocument110 pagesGuidelines For Fatigue Strength Assessmentjoejo_s_hotmailNo ratings yet

- DescriptionDocument111 pagesDescriptionKaaliNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- Strengthening of T Section RC Beams in Shear Using CFRP: January 2012Document13 pagesStrengthening of T Section RC Beams in Shear Using CFRP: January 2012Hoang HoangNo ratings yet

- Evaluation Report On HMT FinalDocument113 pagesEvaluation Report On HMT FinalHoang HoangNo ratings yet

- Offshore Foundations - PSADocument145 pagesOffshore Foundations - PSABehrang BaghernejadNo ratings yet

- 3D 1 Tutorial UnlockedDocument138 pages3D 1 Tutorial Unlockedmarvin santiNo ratings yet

- Uplift PressureDocument10 pagesUplift PressureBurhan AhmadNo ratings yet

- Reading: January 25, 2013 9:21 WSPC/S1793-4311/238-JET 1250026Document42 pagesReading: January 25, 2013 9:21 WSPC/S1793-4311/238-JET 1250026Hoang HoangNo ratings yet

- Chap3 Dam DesignDocument67 pagesChap3 Dam DesignAshraf BestawyNo ratings yet

- Features of LNG Tank Civil Engineering: AbstractDocument6 pagesFeatures of LNG Tank Civil Engineering: AbstractHoang HoangNo ratings yet

- NREL - Torres Acero-Hormigón PDFDocument698 pagesNREL - Torres Acero-Hormigón PDFLeandro MarzonettoNo ratings yet

- 03 Fema P-1016Document149 pages03 Fema P-1016Hoang HoangNo ratings yet

- 05-Seismic PerformanceDocument281 pages05-Seismic PerformanceHoang HoangNo ratings yet

- Uplift PressureDocument10 pagesUplift PressureBurhan AhmadNo ratings yet

- 02 - 2019 - 623 - Structural Safety of Cracked Concrete DamsDocument295 pages02 - 2019 - 623 - Structural Safety of Cracked Concrete DamsHoang HoangNo ratings yet

- Tanahu Hydropower PDFDocument23 pagesTanahu Hydropower PDFpitamberNo ratings yet

- 07-New Approach Design DamDocument26 pages07-New Approach Design DamHoang HoangNo ratings yet

- 01 FinalReport MainTextDocument57 pages01 FinalReport MainTextHoang HoangNo ratings yet

- 03 Fema P-1016Document149 pages03 Fema P-1016Hoang HoangNo ratings yet

- 04-Bridge Design Manual PDFDocument1,310 pages04-Bridge Design Manual PDFHoang HoangNo ratings yet

- Features of LNG Tank Civil Engineering: AbstractDocument6 pagesFeatures of LNG Tank Civil Engineering: AbstractHoang HoangNo ratings yet

- Design Load Basis For Onshore Turbines - Revision 00Document21 pagesDesign Load Basis For Onshore Turbines - Revision 00Hoang HoangNo ratings yet

- Working Group On "Wind Turbine Foundations" Recommendations For The Design, Calculation, Installation and Inspection of Wind-Turbine FoundationsDocument109 pagesWorking Group On "Wind Turbine Foundations" Recommendations For The Design, Calculation, Installation and Inspection of Wind-Turbine FoundationsGonçalo SonaglioNo ratings yet

- 01-Bowles-Foundation Analysis and Design PDFDocument6 pages01-Bowles-Foundation Analysis and Design PDFHoang HoangNo ratings yet

- 01 DTU Offshore Design Load Basis Rev 0 PDFDocument33 pages01 DTU Offshore Design Load Basis Rev 0 PDFHoang HoangNo ratings yet

- MOJAVE Single Wide Proof 2014Document16 pagesMOJAVE Single Wide Proof 2014Donnarose DiBenedettoNo ratings yet

- Coppus Steam Turbine BrochureDocument6 pagesCoppus Steam Turbine Brochuredevdown100% (2)

- Cat Aquaedge-19xr e 1506-05-cnDocument29 pagesCat Aquaedge-19xr e 1506-05-cnThắng Nguyễn TrọngNo ratings yet

- BMC 4TH Sem Infil WallsDocument32 pagesBMC 4TH Sem Infil WallsArsh ChaudharyNo ratings yet

- Waterproofing, Construction Chemicals Manufacturers & Suppliers IndiaDocument8 pagesWaterproofing, Construction Chemicals Manufacturers & Suppliers IndiaNagesh ShuklaNo ratings yet

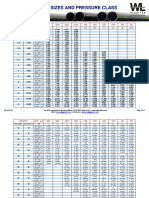

- WL102-0118 Ips Size Chart Pe4710Document2 pagesWL102-0118 Ips Size Chart Pe4710MarcoiNo ratings yet

- Leonhardt Cable StayDocument29 pagesLeonhardt Cable StayTarun Kant GoyalNo ratings yet

- ISO 3010 - OverallDocument13 pagesISO 3010 - OverallFilippoNo ratings yet

- SmartJoist Design Guide 2011Document40 pagesSmartJoist Design Guide 2011Suciul E ViuNo ratings yet

- Lab 2 - Tensile Testing of MetalsDocument8 pagesLab 2 - Tensile Testing of MetalsMoey RenNo ratings yet

- Design of Slabs For ResidentialDocument12 pagesDesign of Slabs For ResidentialWilbert ReuyanNo ratings yet

- The Road Pavement Condition Index (PCI) Evaluation and MaintenanceDocument10 pagesThe Road Pavement Condition Index (PCI) Evaluation and MaintenancelauNo ratings yet

- Etabs WindDocument86 pagesEtabs WindV.m. Rajan100% (1)

- D10TDocument2 pagesD10TjoseluisyalicoNo ratings yet

- IEEE Guide To The Assembly and Erection of Metal Transmission StructuresDocument44 pagesIEEE Guide To The Assembly and Erection of Metal Transmission StructuresGenesis ToledoNo ratings yet

- Standard Bill of MaterialsDocument5 pagesStandard Bill of MaterialsManjunath HrmNo ratings yet

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNo ratings yet

- Acetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Document1 pageAcetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Anonymous UcmNTu6rNo ratings yet

- Illlffl FDocument26 pagesIlllffl FosamaNo ratings yet

- Inspection Manual 2009: Luxfer Carbon Composite CylindersDocument44 pagesInspection Manual 2009: Luxfer Carbon Composite CylindersGOLDEN CNG TESTING CENTRENo ratings yet

- Tugas Mam EkaDocument14 pagesTugas Mam EkaDanny SNo ratings yet

- Catalogo de Peças Scania - 2015Document433 pagesCatalogo de Peças Scania - 2015João Paulo Gonçalves100% (2)

- Construction Method Statement and Structural Report London W10 5BZDocument29 pagesConstruction Method Statement and Structural Report London W10 5BZAtilla AkdoganNo ratings yet

- Design of Bolted Connections in Steel StructuresDocument4 pagesDesign of Bolted Connections in Steel StructuresHarish T S Gowda0% (1)

- p-16-68 - Copper Wire For Earthing - PDFDocument6 pagesp-16-68 - Copper Wire For Earthing - PDFsohaibNo ratings yet

- FHWA Design and Construction of Stone Columns Vol.1 ExtraDocument46 pagesFHWA Design and Construction of Stone Columns Vol.1 ExtranoordenNo ratings yet

- BIM E-Submission - General GuidelinesDocument13 pagesBIM E-Submission - General GuidelinesTamouh ZakrtNo ratings yet

- Em (1) GTRDocument151 pagesEm (1) GTRlee sampsonNo ratings yet

- Chemical Quality of TMT Bars: View Previous Topic View Next TopicDocument6 pagesChemical Quality of TMT Bars: View Previous Topic View Next Topicpatrik710No ratings yet