Professional Documents

Culture Documents

Ezt-Fc 60-06

Uploaded by

ashenafiiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ezt-Fc 60-06

Uploaded by

ashenafiiCopyright:

Available Formats

DIVISION 09 00 00 Finish EZT/FC 60-06

09 29 00 – Gypsum Board Page 1 of 3

09 29 10 – Gypsum Board Accessories

EZT/FC 60-06

Joint Tape

All Products, LLC., d.b.a. E-Z Taping Systems®

Fire Tape®

ASTM E119, UL 263, NFPA 251, CAN/ULC S101

Fire Resistance Rating – 1 hour

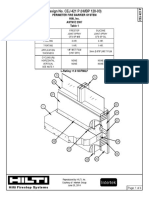

Figure 1 – Floor/Ceiling Assembly & Details

1. GYPSUM BOARD – Select any 1 hour, fire- 500-599 under Designation L; or under the

resistance rated, loadbearing, floor-ceiling Gypsum Association’s GA-600, Fire

assembly comprised of wood framing with a Resistance Design Manual under GA File

gypsum board ceiling supported by resilient Numbers 5000-5999 under Designation FC,

steel framing (Item 2). under Intertek’s Wood Framed Floor-Ceilings. Gypsum

Design Category FC-60, Floor-Ceiling board panel’s nominal thickness shall be as

Assembly, or under UL’s Category BXUV specified in the specific Intertek or UL

and ULC’s Category BXUVC, Floor-Ceilings: Design Number selected. Gypsum board

Wood Joists and Trusses, Design Numbers panels shall comply with ASTM

Date Revised: June 13, 2016 ©Intertek

Project No: G102560982

DIVISION 09 00 00 Finish EZT/FC 60-06

09 29 00 – Gypsum Board Page 2 of 3

09 29 10 – Gypsum Board Accessories

C1396/C1396M, Standard Specification for Treatment Materials for Gypsum Board

Gypsum Board, and be Listed and Labeled Construction, complying with requirements

under a recognized third-party Listing and for joint tape under ASTM C475, Standard

Follow-up Program. Gypsum board panels Specification for Joint Compound and Joint

shall be installed in accordance with ASTM Tape for Finishing Gypsum Board.

C840, Standard Specification for Application A. Fire Tape® is typically used as a Level 1

and Finishing of Gypsum Board, and GA- Finish as described in GA-216,

216 Application and Finishing of Gypsum Recommended Specifications for the

Panel Products. All gypsum board panels Application and Finishing of Gypsum

shall be kept dry. All gypsum board panels Panel Products, (ASTM C840, Standard

shall be installed without flexing or sagging Specification for Application and

and shall have clean sharp edges, ends, Finishing of Gypsum Board) because is

and surfaces. The room temperature shall not required to be set in or covered by

be maintained at a min. temperature of 40°F joint compound. Level 1 Finish

(4.4°C) for the mechanical application of applications are typically used in

gypsum board panels. All joints of gypsum unfinished parts of the building where

board panels shall be tightly abutted and aesthetics are not an issue, such as in

centered over steel ceiling framing (Item 2). plenum areas above ceilings, in attics, in

2. RESILIENT STEEL FRAMING – Use areas where the assembly would

resilient steel framing as specified in the generally be concealed or in building

specific Design Number compliant with Item service corridors; and other areas not

1 for size and gauge as well as attachments normally open to public view or such as

and length in relationship to distance in corridors, storage rooms, garages,

between perimeter wall steel ceiling framing parking structures, and other similar

(not shown). Ceiling cavity can be either areas.

empty or filled with insulation as specified in B. The temperature of Fire Tape® shall be

the specific Design Number compliant with at least 55°F prior to application. Do not

Item 1. install Fire Tape® below 50°F (10°C).

3. FASTENERS – Spacing pattern, length, and Low Temperature Conditions – In cold

diameter of fasteners shall be as specified in weather, heat shall be provided to

the specific Design Number compliant with maintain a temperature not below 50°F

Item 1. Use Type S screws for attaching (10°C) for 48 hours prior to taping and

gypsum board panels (Item 1) to light gauge finishing and maintained for not less

steel ceiling framing (Item 2) and screws than 48 hours thereafter.

shall comply with ASTM C 1002, Standard C. Center and apply Fire Tape® over the

Specification for Steel Self-Piercing Tapping vertical and horizontal gypsum board

Screws for Application of Gypsum Panel panel (Item 1) butt joints covering the

Products or Metal Plaster Bases to Wood butt joint and fasteners (Item 4). The

Studs or Steel Studs. butt joints and angles of the gypsum

4. CERTIFIED MANUFACTURER: E-Z Taping board panels (Item 1) shall be clean,

Systems® e.g. free of dust or powder, and

CERTIFIED PRODUCT: Joint Tape completely dry prior to the application of

CERTIFIED MODEL: Fire Tape® Fire Tape®. The pressure sensitive

JOINT TAPE – Use patented, multi-layer, adhesive shall be in complete contact

fiberglass reinforced, Fire Tape® with with the adjacent gypsum board panel

pressure sensitive adhesive tested to

requirements for joint tape under ASTM

C474, Standard Test Methods for Joint

Date Revised: June 13, 2016 ©Intertek

Project No: G102560982

DIVISION 09 00 00 Finish EZT/FC 60-06

09 29 00 – Gypsum Board Page 3 of 3

09 29 10 – Gypsum Board Accessories

Figure 2 – Installation Methods

with the adjacent gypsum board panel coat over Fire Tape® to promote

(Item 1) surfaces. Apply sufficient adhesion to Fire Tape®. After the primer

pressure to the Fire Tape® using the E- is applied in accordance with the

Z Tape 3 in. plastic knife to aggressively manufacturer’s instructions and

adhere the pressure sensitive adhesive completely dry, joint compound or a

to the gypsum board panels’ (Item 1) latex paint can be applied over Fire

surfaces. Do not use your hand or any Tape®.

other tool because sufficient adhesion of F. Use only rolls of Fire Tape® bearing the

the Fire Tape® to the gypsum board Intertek Mark for the United States (US)

panels (Item 1) will not be achieved. and Canada (C).

Use a corner roller to adhere Fire

Tape® to inside and outside gypsum

board panel (Item 1) corners, e.g.

angles.

D. The exposed outer surface of the Fire

Tape® is treated with silicone. Do not

overlap Fire Tape® onto itself because it

will not adhere to itself. At intersections

of Fire Tape®, e.g. “L”, “Ő” and “T”, abut

the leading edge of the Fire Tape® to

the longitudinal edge of the Fire Tape®

being intersected.

E. Joint compound and paint will not

adhere to Fire Tape® without the

application of an oil based primer. When

paint or a Level 2 or a Level 3 Finish

using joint compound is desired, a

compatible primer is required to promote

adhesion to Fire Tape®. A Rustoleum®

primer called Zinsser® Bulls Eye®

1

Odorless has been found suitable to

1 http://www.rustoleum.com/product-catalog/consumer-

brands/zinsser/primer-sealers/odorless-oil-base-stain-

blocker/

Date Revised: June 13, 2016 ©Intertek

Project No: G102560982

You might also like

- Gypsumation 2006 JuneDocument4 pagesGypsumation 2006 JunecarineNo ratings yet

- 092116Document7 pages092116kupaloidNo ratings yet

- CEJ114PDocument2 pagesCEJ114PGauri Calderon TrujilloNo ratings yet

- 09 28 13 Cement Board CeilingsDocument6 pages09 28 13 Cement Board CeilingsWagih NabihNo ratings yet

- Tuff Span FRP Roofing Siding Panel SpecificationDocument1 pageTuff Span FRP Roofing Siding Panel Specificationjupiter1208No ratings yet

- SECTION 09 29 00 Gypsum BoardDocument10 pagesSECTION 09 29 00 Gypsum BoardRima Baz FadousNo ratings yet

- Us G Shaft and Stair Wall SystemsDocument11 pagesUs G Shaft and Stair Wall SystemsanhnguyenhaiNo ratings yet

- FS - Muro Cortina - ASSET-DOC-LOC-7765712Document3 pagesFS - Muro Cortina - ASSET-DOC-LOC-7765712S. Priscila Castillo V.No ratings yet

- GFRG SpecsDocument4 pagesGFRG SpecsA.Subin DasNo ratings yet

- C840 373465-1 PDFDocument18 pagesC840 373465-1 PDFEsteban Mora100% (1)

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimNo ratings yet

- 09250.517.gypsum DrywallDocument7 pages09250.517.gypsum DrywallNguyen BachNo ratings yet

- 12 StoStucco RoughcastDocument6 pages12 StoStucco RoughcastmmojicNo ratings yet

- PDS Gyproc SoundBloc FDocument2 pagesPDS Gyproc SoundBloc FhartzcarzNo ratings yet

- Site Book Timber JoistDocument16 pagesSite Book Timber JoistarkiNo ratings yet

- Flame StopDocument31 pagesFlame StopaNo ratings yet

- AD Fire AD-IMF 120-01Document2 pagesAD Fire AD-IMF 120-01Jorge perezNo ratings yet

- GYPSUM Separating WallsDocument28 pagesGYPSUM Separating WallsoinkedNo ratings yet

- SECTION 07 51 00 Built-Up Bituminous RoofingDocument23 pagesSECTION 07 51 00 Built-Up Bituminous RoofingJuanPaoloYbañezNo ratings yet

- Pierced fix roofing spec languageDocument1 pagePierced fix roofing spec languageDushan Lalithya Gamaethige100% (1)

- PDS Gyproc FireLineDocument2 pagesPDS Gyproc FireLineSugumarNo ratings yet

- Fireline Ceilings DetailsDocument14 pagesFireline Ceilings DetailsconorNo ratings yet

- PDS Gyproc WallBoardDocument3 pagesPDS Gyproc WallBoardBülent KabadayiNo ratings yet

- Pyrolite 15 PDS PDFDocument5 pagesPyrolite 15 PDS PDFbhavesh solankiNo ratings yet

- Gyproc HabitoDocument3 pagesGyproc HabitoumaNo ratings yet

- Firestop CEJ 421 PDocument4 pagesFirestop CEJ 421 PErlanggaRizkiFauziNo ratings yet

- Knauf SafeboardDocument4 pagesKnauf SafeboardAmin ChhipaNo ratings yet

- PDS Gyproc WallBoard DUPLEX PDFDocument3 pagesPDS Gyproc WallBoard DUPLEX PDFRATHEESH P.KNo ratings yet

- SECTION 09 23 00 Gypsum PlasteringDocument12 pagesSECTION 09 23 00 Gypsum PlasteringRima Baz FadousNo ratings yet

- Section 08630 Metal-Framed SkylightDocument4 pagesSection 08630 Metal-Framed SkylightMØhãmmed ØwięsNo ratings yet

- FT AislantesFV Ducwrap CTDocument2 pagesFT AislantesFV Ducwrap CTRODOLFONo ratings yet

- P.O. Number: 7200018725Document6 pagesP.O. Number: 7200018725sethu1091No ratings yet

- Finishes Section Provides Details on Plaster, Tiles, Stones and MoreDocument54 pagesFinishes Section Provides Details on Plaster, Tiles, Stones and MoresothilingamnNo ratings yet

- SECTION 03 55 11 Gypsum Concrete Floor DecksDocument5 pagesSECTION 03 55 11 Gypsum Concrete Floor DecksJuanPaoloYbañezNo ratings yet

- Spec Sheet - MetecnoPanelDocument2 pagesSpec Sheet - MetecnoPanelriskiriskNo ratings yet

- Shaftwall PD and UL DesignsDocument57 pagesShaftwall PD and UL DesignsBlake FicklingNo ratings yet

- Shingle Architectural Specification-1Document8 pagesShingle Architectural Specification-1Murillo ZagonelNo ratings yet

- Approval Document ASSET DOC LOC 299Document3 pagesApproval Document ASSET DOC LOC 299Anonymous a3K3WgNo ratings yet

- PDS Gyproc SoundBlocDocument2 pagesPDS Gyproc SoundBlocneeelNo ratings yet

- Fendolite Thickness IndustrialDocument4 pagesFendolite Thickness IndustrialMohamed Zain100% (1)

- 092900Document5 pages092900Manuela AvendañoNo ratings yet

- PDS Glasroc-F-FIRECASE ENGL 1 PDFDocument3 pagesPDS Glasroc-F-FIRECASE ENGL 1 PDFVlad TirzianNo ratings yet

- Architectursl SpecsDocument10 pagesArchitectursl Specshadjie ansayNo ratings yet

- Metecnopanel Information Guide NZDocument8 pagesMetecnopanel Information Guide NZbassouadNo ratings yet

- Argeton Technical InformationDocument41 pagesArgeton Technical InformationSandu CiprianNo ratings yet

- Plastic Skylight SpecificationsDocument5 pagesPlastic Skylight Specificationsmohamed fathiNo ratings yet

- p911 de 2021-06 0 Eng ScreenDocument4 pagesp911 de 2021-06 0 Eng ScreenanhnguyenhaiNo ratings yet

- Polyiso InsulationDocument2 pagesPolyiso Insulationarbor02No ratings yet

- HOT INSULATION JOBS IN FREDocument9 pagesHOT INSULATION JOBS IN FREraghbirNo ratings yet

- FRP Ceiling Panel Roof Deck - Data Sheet - FINAL - 03 01 18Document2 pagesFRP Ceiling Panel Roof Deck - Data Sheet - FINAL - 03 01 18Research DevelopmentNo ratings yet

- Fire Rated Aluminum Panel CertificateDocument5 pagesFire Rated Aluminum Panel CertificateSanjeev SinghNo ratings yet

- Astm C1396 C1396M 17Document6 pagesAstm C1396 C1396M 17carineNo ratings yet

- Drywall Wood Framed Systems SA924Document24 pagesDrywall Wood Framed Systems SA924bo cephusNo ratings yet

- ThermPanManufactureInst 05Document1 pageThermPanManufactureInst 05imeqingenieriaNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Modelling a Sturmgeschütz III Sturmgeschütz IIIG early version (December 1942 production): In 1/35 scaleFrom EverandModelling a Sturmgeschütz III Sturmgeschütz IIIG early version (December 1942 production): In 1/35 scaleNo ratings yet

- Inspection Report - GBT Raft FoundationDocument6 pagesInspection Report - GBT Raft FoundationvidyaNo ratings yet

- Audi Case StudyDocument8 pagesAudi Case Studydhanaraj100% (1)

- Compound wall structural detailsDocument1 pageCompound wall structural detailssandip wankhadeNo ratings yet

- Ewc - Company ProfileDocument92 pagesEwc - Company ProfileJason Bodie Dela CruzNo ratings yet

- Noma Thermostat ManualDocument44 pagesNoma Thermostat ManualLuca MiscelliNo ratings yet

- Corrugated iron roofing bill of quantitiesDocument3 pagesCorrugated iron roofing bill of quantitiesguchiNo ratings yet

- Biomaterials For Dental Implants: PART II Basic SciencesDocument29 pagesBiomaterials For Dental Implants: PART II Basic SciencesAna-Maria RoșuNo ratings yet

- SATIP-B-069-01 Rev 8 Emergency EyewashShower System FinalDocument2 pagesSATIP-B-069-01 Rev 8 Emergency EyewashShower System FinalmominNo ratings yet

- Mobile Home Recycling: A Feasibility Study ofDocument46 pagesMobile Home Recycling: A Feasibility Study ofTracy PattersonNo ratings yet

- Builders' Technical Quality Assurance Checklist: Notes For Using The ChecklistsDocument12 pagesBuilders' Technical Quality Assurance Checklist: Notes For Using The ChecklistsAndrew LeeNo ratings yet

- Roof Deck SpecificationsDocument2 pagesRoof Deck SpecificationsVictor IkeNo ratings yet

- 5.7.5 Span/effective Depth Ratios 5.7.6 Section Design: 5.7.4.3 Stairs With Open WellsDocument2 pages5.7.5 Span/effective Depth Ratios 5.7.6 Section Design: 5.7.4.3 Stairs With Open WellsBertin BakariNo ratings yet

- Neutral Refractories 2021Document36 pagesNeutral Refractories 2021Daniel AppuingNo ratings yet

- 920 & 926 Stangard Water Seal SystemDocument5 pages920 & 926 Stangard Water Seal SystemAbishek Senthil NathanNo ratings yet

- Office at Biratnagar Mep Works Summary of Costs Section B: Electrical and Allied Works Sl. Description Total AmountDocument36 pagesOffice at Biratnagar Mep Works Summary of Costs Section B: Electrical and Allied Works Sl. Description Total AmountyogenNo ratings yet

- Submittal Data Sheet: Ftk18Nmvju / Rk18NmvjuDocument4 pagesSubmittal Data Sheet: Ftk18Nmvju / Rk18NmvjubenNo ratings yet

- C55Document4 pagesC55Rufo CascoNo ratings yet

- GRINNELL Figure 780 Grooved Snap Couplings 1-1/4 Thru 8 Inch (DN32 Thru DN200) General DescriptionDocument2 pagesGRINNELL Figure 780 Grooved Snap Couplings 1-1/4 Thru 8 Inch (DN32 Thru DN200) General DescriptionСергей КолесниковNo ratings yet

- Type GF Grate-Fast by Lindapter 1242Document1 pageType GF Grate-Fast by Lindapter 1242FourHorsemenNo ratings yet

- Chap 5 Development of Beam Equations: Review Simple Beam Theory Two Methods To Develop Beam EquationsDocument35 pagesChap 5 Development of Beam Equations: Review Simple Beam Theory Two Methods To Develop Beam Equationsparin advaniNo ratings yet

- Analysis of Bond Stress Distribution For Prestressing Strand by StandardDocument8 pagesAnalysis of Bond Stress Distribution For Prestressing Strand by StandardSameerKareeeemNo ratings yet

- LASTO®HDRB International EN (Eversion)Document4 pagesLASTO®HDRB International EN (Eversion)SanjaNo ratings yet

- ArteviaTM IM Mixes Concrete Data SheetDocument2 pagesArteviaTM IM Mixes Concrete Data SheetPete 'Pip' CoppenhallNo ratings yet

- Abaqus Standard Built-In User Subroutines For LaRC05 Composite Failure CriteriaDocument5 pagesAbaqus Standard Built-In User Subroutines For LaRC05 Composite Failure Criteriajunjie yi100% (1)

- I262 2003 eDocument7 pagesI262 2003 enancy100% (1)

- Sikacryl®-150: Product Data SheetDocument3 pagesSikacryl®-150: Product Data SheetMoatz HamedNo ratings yet

- Case Hardening Steel 16MnCr5 AUSADocument3 pagesCase Hardening Steel 16MnCr5 AUSAShubhangi ShindeNo ratings yet

- Acristar #300Document1 pageAcristar #300ChristinaNo ratings yet

- Transportation Engineering II: Flexible Pavement DesignDocument80 pagesTransportation Engineering II: Flexible Pavement DesignMugahed Abdo Al-gahdari100% (1)

- 1 Strengthofmaterials Interview QuestionsDocument21 pages1 Strengthofmaterials Interview QuestionsChanduReddyNo ratings yet