Professional Documents

Culture Documents

Itp Bop

Uploaded by

Agung NugrohoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itp Bop

Uploaded by

Agung NugrohoCopyright:

Available Formats

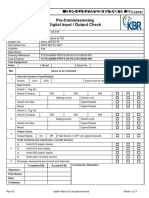

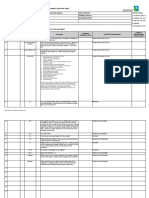

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-01

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) AOGAA12AA002

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Forwarding Pump B Discharge Valve

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

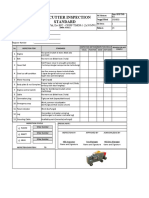

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-02

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) AOGAA11AA002

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Forwarding Pump A Discharge Valve

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-03

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) AOGAA11AA002

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Check Valve Forwarding Pump A

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-04

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) AOGAA12AA002

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Check Valve Forwarding Pump B

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-05

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAB11AA003

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Port Venting Discharge Header CWP

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-06

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA11AA007

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Inlet MOV Travveling Screen A

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-07

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA12AA007

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Inlet MOV Travveling Screen B

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-08

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA13AA007

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Inlet MOV Travveling Screen C

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-09

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA11AA002

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Traveeling Screen Wash Pump Inlet Vlv A

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-10

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA12AA002

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Traveeling Screen Wash Pump Inlet Vlv B

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-11

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA13AA002

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Traveeling Screen Wash Pump Inlet Vlv C

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-12

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA11AA004

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Traveeling Screen Wash Pump Outlet Vlv A

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-13

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA12AA004

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Traveeling Screen Wash Pump Outlet Vlv B

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-14

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA13AA004

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Traveeling Screen Wash Pump Outlet Vlv C

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-15

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA11AA005

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Screen Wash Pump A Discharge Isolation Vlv

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-16

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA12AA005

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Screen Wash Pump B Discharge Isolation Vlv

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-17

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAA13AA005

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Screen Wash Pump C Discharge Isolation Vlv

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-18

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAB11AA001

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Discharge Isolation Venting Port Valve CWP A

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-19

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAB12AA001

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Discharge Isolation Venting Port Valve CWP B

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-20

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) 10PAB13AA001

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Discharge Isolation Venting Port Valve CWP C

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-21

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) A0GCF21AP001

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION BWRO HPP A

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-22

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) A0GCF22AP001

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION BWRO HPP B

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-23

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) A0GCL11AP001

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION New pit pump A

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-24

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) A0GCL12AP001

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION New pit pump B

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer

Approved By

LBE Manager

PT Lestari Banten Energi

INSPECTION TEST PLAN

Responsible Person Issue Date Revision No : File No : PAGE

TS/Planning 01/11/2022 1 R01WTS08020 1 OF 1

A ITP REFERENCE NO MTB-ITP-2023-115-25

WORK ORDER NUMBER 4100015259

EQUIPMENT NUMBER (KKS NO) A0GTA62AP001

EQUIPMENT DESCRIPTION INSPECT & REPAIR TURBINE AUX VALVES

ACTIVITY DESCRIPTION Intermediate pump B

WORK DURATION/ DATE December 2023 - February 2024

B Inspection by Section Name of Inspectors Control Activity

1. Maintenance Engineer 1. Rudi KT W: Witness M : Modification

2. Maintenance Supervisor 2. Sugeng/Warisman C : Calibration I : Inspect

3. Contractor 3. Agung Nugroho S : Setting V : Verification

4. Operation 4 R : Repair/ Replace N : NDT

5. Condition Monitoring 5 T : Testing (Function) X : Performed

6. Others (Scaffolding/Insulation/Cladding) 6

C Pre Shutdown Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

1 Pre-inspection I I X

Receive and mark control number (KKS/Stamp)

2 I I X

at local site.

3 Strip, clean, and inspect. I I X

4

5

D Shutdown/ Outage Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Disassembly valve actuator (motorized /

1 pneumatic), *During this process the vendors will be I I X

accompany with LBE personnel.

2 Valve Inspection and Repair (Cleaning process) I I X,R

3 Valve Inspection and Repair (NDT inspection) I I X,N

4 Inspect and check all trims parts condition. I,W I,W X

Lapping for seat, disc, and other parts as

5 I,W I,W X,R

appropriated.

6 Polish and run out spindle. I,W I,W X

Recondition all broken parts to the dimension as

7 I,W I,W X

standards

Conduct blue contact check for finalize the

8 I,W I,W X

contact/sealing point

Replace and Install new soft kits parts (gasket,

9 I,W I,W X,R

packing, bonnet seal, etc.)

Re - Assembly the Valve assemble and Re-install

10 I,W I,W,C X,S

Valve actuator

Re-setting and adjust valve position (Close or

11 open) to its actuator stroke appropriatly and I,W I,W,C X,S

tighly.

It should be able operated smootly and

12 I I,C

appropriatly during stroking test.

13 Painting as existing color I I X

E Recommissioning Work Control Activities Signatures

Task

Task Description 1 2 3 4 5 6 LBE Sign Contr Sign Date

No

Inspect and check condition valve during tsrt-up

1 I,T I,T I,T

(check lekakage / passing)

2

3

4

5

FINAL CONDITION

F Final Result

Measurement (Standard) Value (as found)

CLOSE OUT SIGNATURES

Department/

G Name Name Designation Signature Date

Company

Performed By

LBE/ Contractor

Checked By

LBE Supervisor

Verified By

LBE Engineer