Professional Documents

Culture Documents

CAPA

Uploaded by

DEEPAK MALLIKCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAPA

Uploaded by

DEEPAK MALLIKCopyright:

Available Formats

Own/

Time Contractor / Current

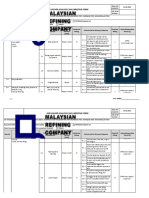

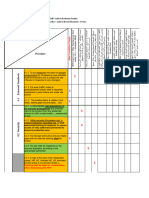

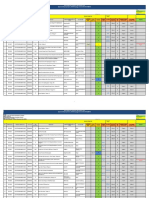

S-N Classification Date Shift Unit Plant SBU Location Name Sex Designation Cause of injury Nature of injury Description Body part Agency Cause Standards CAPA Status Findings on 25-09-2023

(AM/ PM) Visitor/ Truck Status

driver

1-Awareness to all worker for not engaged in the 1- Followed and in presence of

work Supervision-

2-Locking arrangement should be made for the

Forklift operator was doing mixing of dross- During the mixing

mixing tools-

1- Done 1- Done 2- Mixing tools now fitted with JCB at all

process the mixing tool is mounted on Forks of the Forklift- While 2- Done 2- Done DPUS

CH2 Runaya Molten 3-Civil Barrication to be done to place the Dross bin

Molten Material he was mixing the dross, mixing tool came out from the fork of Plam & Vaaman Molten 3- Done 3- Done

2 FAI 3/23/2020 17:30 B Metal Smelter-2 Contractor Cast House Dross Processing NA NA NA

Splash

Burn

Forklift and it fell down in the dross bin- As a result the hot dross Abdomen Eng

Material

material

so that any spillage on floor can be avoided in

4- Done 4- Done 3- Mixing followed with Designated

Unit Splash coming under forklift tyres- Area and by JCB only.

splashed and fell on his palm and upper abdomen- He was 5-Done 5-Done

4-Mixing process should be done by closed process

wearing HR Jacket- A minor bun injury has occurred-

through agitator- 4- Followed

5-Protection for operator cabin with nonflammable 5-Mixing followed by JCB only

material

On 17th July, 2020 at 11:40 am there was a near miss incident 1-Preparing a standard Preoperational

1-Preparing a standard Preoperational checklist

occurred near temporary FG shed- When Forklift operator Anil

(English/Hindi/Odia)and Training of Operator

1- Done 1- Done checklist (English/Hindi/Odia)and

Seth having forklift registration OD 23 J 2356 was shifting hot 2- Done 2- Done Training of Operator followed-

2- Preparing a standard PM and a standard PM

Cast House 2 PROPERTY dross from furnace to DPU suddenly two rotating part bolts Vaaman Vehicle Molten 3- Done 3- Done

3 HIPO 7/17/2020 11:40 A Metal Smelter-2 Contractor Cast House

,Runnaya

NA NA NA Vehicle failure

DAMAGE sheared off with a huge sound ,Due to rain Dross fumes was

NA

Eng failure material

Checklist & Training of Technicians-

4- Done 4- Not Done 2- Followed standard PM and records

3- The rotating fork lift used only for themititing also available-

evacuating , forklift was immediately stopped and necessary steps

process -

were taken and bought the forklift to maintenance area - No

4- No Covering on Dross pan 3-Followed only for thermiting process-

harm to human 4-Not Followed

1-Operators are not allowed to do any maintenance

activities only mechanic authorized to do

maintenance

2-Operator awareness training and competency to

be ensured -

3-Adequate SOP and risk assessment to be made

On dated 28-10-2021 in “Ä” shift IP (Forklift operator) was 1-Without having adequate knowledge operator 1-Done 1-Done

and awareness training should be conducted to all

engaged for shifting of dross bins from DPU-2 to dross shed- At open the Radiator Cap- 2- Done 2- Done

the operators for horizonal deployment -

around 12-40 pm during the operation, forklift engine got over 2-Over confidence about the maintenance of the 3- Done 3- Done

4-Forklift logbook to be maintained and to monitor

CH2 Runaya heated around 120°, IP was parked vehicle in front of the DPU-2 Exposure vehicle 4-Done 4-Done

Exposure to hot Vaaman Vehicle the vehicle healthiness -

4 FAI 10/28/2021 12:40 A Metal Smelter-2 Contractor Cast House Dross Processing NA NA NA Burn road and trying to cool the engine, he was open the bonnet of the Hand to hot 3-There was no SOP forklift operation and no 5- Done 5- Done

Water Eng and Drive 5-Safe indicator of temperature parameter details to

Unit engine for ventilation & tried to open the radiator cap with the Water indicator for safe & dangers operations at 6-Done 6-Done

be displayed in dos and don’ts -

help of a small rod to pour some cold water, some hot water temperature meter 7-Done 7-Done

6-Strict supervision to be ensured, before taking

suddenly splashes in his right-hand wrist of the IP- He was 4-No evidence for running hrs of forklift only verbal 8-Done 8-Done

operational of the vehicles preoperational check

immediately shifted to First-Aid centre for treatment- communications 9-Done 9-Done

must -

7-DD Training to be covered all the operators and

maintenance team -

8-Safe operating awareness stickers of dos & don’ts

to be displayed -

9-Right person and right job to be deployed -

1- HIRADeC to cover hazards related to collision

On dated 27-11-2022 at around 08:50AM, Traveller (OD 23N 9777

while unloading and loading of dross pan from truck

- RUNAYA) drop General shift employees at DPU-2 and ready to

return back- Traveller driver tries to cross in between Truck (MH-

2- Location of loading and unloading of dross pan

1-Done 1-Done Currently, this Operation has been

CH2 Runaya Traveler from truck to be shifted outside road- stopped and all employees have been

PROPERTY 04-JK-1071, Empty Dross Pan loaded) and Forklift (OD 23L 9689) , Vaaman Vehicle & 2- Done 2- Done

5 HIPO 11/27/2022 8:50 A Metal Smelter-2 Contractor Cast House Dross Processing NA NA NA HIT NA hit by 3- Barricading of road during loading and unloading

Unit

DAMAGE at that time right back side of Traveller collides with forks of Eng

forks of

Driving

to be done

3-Done 3-Done picked up and dropped off at the CH@2

Forklift- So back side of Traveller got damaged- During that period 4-Done 4-Done bus stop only.

Forklift 4- All operators to undergo Defensive driving

forks of Forklift was in upward position to lift the empty Dross

training again to strengthen road safety

pan-

1-All walkways connecting Runaya Dross processing

According to the IP statement, on 19-01-2023 at 08:05 AM Mr- units will be inspected immediately by Technical &

Baikunta Kisan forklift operator of M/s- Vaaman Engineers India HSE team-

ltd injured his left leg thigh due to trip and fell on the same level 2-Proper and complete hand railing should be 1-Not Done 1-Done 1. Done

CH2 Runaya 2.Partially Closed

FORKLIFT near the cast house 2 petcock area gate-1 pedestrian walkway- Vaaman SLIP, TRIP SLIP, TRIP provided in the walkway area- 2- Done 2- Done

6 MTI 1/19/2023 8:05 A Metal Smelter-2 Contractor Cast House Dross Processing NA NA Slip & trip BODY PART Leg

Unit

OPERATOR The IP was shifted to VL first-aid center 2 for immediate Eng & FALL & FALL 3-Immediate repair of damaged pedestrian 3-Pending 3-Pending 3.pending under Vedanta Scope

treatment, and later to Vedanta Apollo hospital for further walkways as per horizontal deployment- 4-Done 4-Done 4.Done

treatment- The IP has now been stabilized and is under 4-Housekeeping to be maintained well and walkways

observation at the hospital- to be inspected frequently-

1.Immediate Electrician isolate the energy source &

Disconnected the Cable.

On dated 29.08.2023 at around 03:30 PM, one of electrician (Mr. 2.Awareness and incident communication has been

Prasant Kumar Sahoo) was enter to MMC Panel room for routine done. 1-Done

inspection of MCC Panel and housekeeping work. At the same 3.Refresher Electrical safety & Isolation(LOTOV) 2- Done

CH1 Runaya

time he found that a unknown wire is laying on the floor and he Vaaman Electric Training to be done for all the maintenance crew 3-Going on

6 HIPO 8/29/2023 3:30 B Metal Smelter-1 Contractor Cast House Dross Processing NA NA NA Electrical flash NA NA Isolation

was going to wrap with the Insulation Tape to avoid the safety Eng flash members. 4-Followed

Unit

Non Compliance. At the mean time his leg got touch with the wire 4.Ensure energy restore activities will be validate by 5-Going on

and that wire come in contact with the place and got minor Flash. Isolator and permit Receiver before Permit Sign Off. 6-Going on

The detailed investigation is under process. 5.Review LOTOV instruction and Work procedures.

6.Competent Electrician to be deployed for isolation

and deisolation jobs.

You might also like

- JHA (RO Pump)Document4 pagesJHA (RO Pump)Mohamed Faisal KhanNo ratings yet

- Training MatrixDocument2 pagesTraining MatrixAmeerHamzaWarraichNo ratings yet

- Pre101013 2303Document2 pagesPre101013 2303Ching FanNo ratings yet

- June 4th 2013 Shutdown Workscope PlanningDocument2 pagesJune 4th 2013 Shutdown Workscope PlanningHervé EKOMINo ratings yet

- CFI NonTurnaround - Routine MI Workflow Rev6 - 12-10-19Document1 pageCFI NonTurnaround - Routine MI Workflow Rev6 - 12-10-19TommyNo ratings yet

- Raci Group6Document4 pagesRaci Group6Amandeep SinghNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Jha TentDocument7 pagesJha TentMUHAMAD ROZEE MAT AZMINo ratings yet

- HSP Daily Dashboard 20230812Document1 pageHSP Daily Dashboard 20230812Noli BenongoNo ratings yet

- Risk Assessment For Balustrade Glass InstallationDocument3 pagesRisk Assessment For Balustrade Glass InstallationNicos PapadopoulosNo ratings yet

- Oct 03,2023 Daily Report For Restoration WorksDocument2 pagesOct 03,2023 Daily Report For Restoration WorksKevs MacsNo ratings yet

- Oct 05,2023 Daily Report For Restoration WorksDocument2 pagesOct 05,2023 Daily Report For Restoration WorksKevs MacsNo ratings yet

- Accounting NotesDocument3 pagesAccounting NotesJahanzaib SufyaanNo ratings yet

- Oct 07,2023 Daily Report For Restoration WorksDocument2 pagesOct 07,2023 Daily Report For Restoration WorksKevs MacsNo ratings yet

- Daily Report 6 April 2023 Sent PDFDocument2 pagesDaily Report 6 April 2023 Sent PDFBambang ArdiansyahNo ratings yet

- Workshop 1Document1 pageWorkshop 1KrisantoHH OlindaNo ratings yet

- UpdatedDocument1 pageUpdatedJAWED ALAMNo ratings yet

- GTG Productivity ChartDocument1 pageGTG Productivity ChartburereyNo ratings yet

- Composting TechnologiesDocument11 pagesComposting TechnologiesabdullaNo ratings yet

- EHS Training Matrix - Rev2finalDocument1 pageEHS Training Matrix - Rev2finalMalik Khuram ShazadNo ratings yet

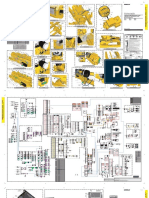

- Main Control Valve: Electrical System 318D2 ExcavatorDocument2 pagesMain Control Valve: Electrical System 318D2 ExcavatorMarco Olivetto100% (1)

- 30 - Turfing WorksDocument1 page30 - Turfing WorksRafee Pie100% (1)

- Daily Report 7 April 2023 Sent PDFDocument2 pagesDaily Report 7 April 2023 Sent PDFBambang ArdiansyahNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Riser TensionersDocument1 pageRiser TensionersDaeng RizalNo ratings yet

- National Trades Matrix - 2021 - V2.1 - CleanDocument4 pagesNational Trades Matrix - 2021 - V2.1 - CleanLeonNo ratings yet

- Appendix B-1 Pre-Entry RequirementsDocument2 pagesAppendix B-1 Pre-Entry Requirementswalter091011No ratings yet

- VESI Skills and Training Matrix-November 2014Document1 pageVESI Skills and Training Matrix-November 2014Satyen ChaturvediNo ratings yet

- Presentation Flowchart Fabricroll - DrawioDocument1 pagePresentation Flowchart Fabricroll - Drawiopakaya tamaNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Cat Wiring Diagram G3608Document4 pagesCat Wiring Diagram G3608Syed Muhammad HashimNo ratings yet

- 2 - Phu Luc 2 - Print - Control - SystemDocument1 page2 - Phu Luc 2 - Print - Control - SystemLý Phương NamNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Report A) Safety Promotion Activity1222Document15 pagesReport A) Safety Promotion Activity1222Eduardo Torrico100% (1)

- Sample Project DASHBOARD REPORT - 03th October 2022 Construction WEEK No. 26Document1 pageSample Project DASHBOARD REPORT - 03th October 2022 Construction WEEK No. 26moes83No ratings yet

- L 02 Floor PlanDocument1 pageL 02 Floor PlanweeragwattaNo ratings yet

- LPMC QTRLY FormDocument1 pageLPMC QTRLY FormDILG Benguet CDS CDSNo ratings yet

- Site Logistics Plan ExampleDocument1 pageSite Logistics Plan ExampleDiego Buitrago67% (3)

- A Holistic Workflow For Evaluating and Developing SRR - CypherDocument23 pagesA Holistic Workflow For Evaluating and Developing SRR - CypherQingming MaNo ratings yet

- BRCGS - Food N Pack - Site StandardsDocument24 pagesBRCGS - Food N Pack - Site StandardsHanan ZayedNo ratings yet

- Diagrama Electrico 740bDocument4 pagesDiagrama Electrico 740bManuel BarronNo ratings yet

- Untitled - UENR58200001Document1 pageUntitled - UENR58200001rado andriamparanyNo ratings yet

- Fuse Block WiringDocument4 pagesFuse Block WiringGilson RodriguesNo ratings yet

- Arquitectura Rev. 7.1 OvationDocument1 pageArquitectura Rev. 7.1 Ovationeduard ramosNo ratings yet

- Flow of MaufacturingDocument1 pageFlow of MaufacturingButhetdohNo ratings yet

- Overall Project - Detail Progress Tracking Sheet - JHP - Updated - 19-Aug-21 - PMDocument59 pagesOverall Project - Detail Progress Tracking Sheet - JHP - Updated - 19-Aug-21 - PMMRadwanNo ratings yet

- Material Delivery Planned Date-MechanicalDocument6 pagesMaterial Delivery Planned Date-MechanicalSohail KhanNo ratings yet

- Irp AcDocument2 pagesIrp Acjpharley603No ratings yet

- D C A B: Installation Electronic Vessel Control D4, D6 EVC - CDocument2 pagesD C A B: Installation Electronic Vessel Control D4, D6 EVC - Csivan_sg1800No ratings yet

- HSP Daily Dashboard 20230809Document1 pageHSP Daily Dashboard 20230809Noli BenongoNo ratings yet

- Procedural Aspects of GST: Ca Raj KumarDocument1 pageProcedural Aspects of GST: Ca Raj KumarDeepak SinghNo ratings yet

- 24 - FormworksDocument2 pages24 - FormworksRafee PieNo ratings yet

- Cahflow (27-02-24)Document1 pageCahflow (27-02-24)eiohatNo ratings yet

- SelectDocument12 pagesSelectAshoka NarayananNo ratings yet

- Manual Ausa c350h EngDocument95 pagesManual Ausa c350h EngwalberNo ratings yet

- Mitsubishi Forklift Edr13n 36v Esr23n 36v Schematic Operation Maintenance Service Manual enDocument23 pagesMitsubishi Forklift Edr13n 36v Esr23n 36v Schematic Operation Maintenance Service Manual enmandyschultz180897bik100% (43)

- Vge ProfileDocument13 pagesVge ProfilexsupermanNo ratings yet

- Cat Forklift Dp35 Service Operation Maintenance ManualDocument27 pagesCat Forklift Dp35 Service Operation Maintenance Manualsamanthamoyer170885csp99% (81)

- Safety Aspects of A ForkliftVENUDocument28 pagesSafety Aspects of A ForkliftVENUjomyNo ratings yet

- 35L/40L/45L/50L-7A: Hyundai LPG Forklift TrucksDocument8 pages35L/40L/45L/50L-7A: Hyundai LPG Forklift TrucksBruno VazNo ratings yet

- Forklift Operations - Risk Assessment & Hazard IdentificationDocument5 pagesForklift Operations - Risk Assessment & Hazard IdentificationSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- OM & Service Manual WS97-12Document42 pagesOM & Service Manual WS97-12Kiều Văn TrungNo ratings yet

- EnerMech TrainingDocument4 pagesEnerMech TrainingZulhilmi ZalizanNo ratings yet

- Dumarent-manUSM Manitou MT1740 - enDocument233 pagesDumarent-manUSM Manitou MT1740 - enstafe100% (5)

- Lift Truck Gear From DTAUTO - CADocument32 pagesLift Truck Gear From DTAUTO - CAGregGGHNo ratings yet

- B&D ManufacuringDocument20 pagesB&D ManufacuringRodolfoMarínNo ratings yet

- Engine Powered Forklift 2 0 3 5 TonDocument8 pagesEngine Powered Forklift 2 0 3 5 TonAndryNo ratings yet

- Genie Operator Training Guide AnswersDocument4 pagesGenie Operator Training Guide Answersmark gonzalez0% (1)

- Orbiter 2010 Product Comparison BestDocument4 pagesOrbiter 2010 Product Comparison BestModern Group, ltdNo ratings yet

- Air Equipment - Compressors - Compressor 100 130CFM E CSE 37 - Operation ManualDocument90 pagesAir Equipment - Compressors - Compressor 100 130CFM E CSE 37 - Operation ManualPrince NeroNo ratings yet

- Lift Truck Gear - QRGDocument46 pagesLift Truck Gear - QRGIng YÔrland R. BlancoNo ratings yet

- Const Safety Exe PlanDocument17 pagesConst Safety Exe PlanbbhattNo ratings yet

- NAHB-OSHA Scaffold-Ladder Safety TrainingDocument132 pagesNAHB-OSHA Scaffold-Ladder Safety TrainingArdamit100% (1)

- Caterpillar Forklift GP35N IC Pneumatic Trucks Electronic Sales Manual PDFDocument139 pagesCaterpillar Forklift GP35N IC Pneumatic Trucks Electronic Sales Manual PDFGiraldo Ramirez100% (4)

- 4 Ton and 5 Ton Electric Lift Truck SpecsDocument4 pages4 Ton and 5 Ton Electric Lift Truck SpecsBiniyam12No ratings yet

- Npp16-20N2 (R) (E), Npv20N2, Npf25N2, Npv20Nd, Npr20N, Nps20N: Power Pallet TrucksDocument16 pagesNpp16-20N2 (R) (E), Npv20N2, Npf25N2, Npv20Nd, Npr20N, Nps20N: Power Pallet TrucksMushfique NowrozNo ratings yet

- Lifting Device Used in ConstructionDocument18 pagesLifting Device Used in ConstructionAr Deyvanai Kannan100% (1)

- Pallet Racking GuideDocument33 pagesPallet Racking GuideAnonymous 1gbsuaafddNo ratings yet

- CAT Delta 30, 90 X-Ray - Service ManualDocument171 pagesCAT Delta 30, 90 X-Ray - Service ManualLuis Fernando Garcia SNo ratings yet

- VGE ProfileDocument13 pagesVGE ProfileRaied AyeshNo ratings yet

- Accident Investigation REVDocument82 pagesAccident Investigation REVAbraham SabarNo ratings yet

- DD BL-S22-0412 Rev 051512 PDFDocument118 pagesDD BL-S22-0412 Rev 051512 PDFDmitryNo ratings yet

- EN SMOKjet-RHDocument22 pagesEN SMOKjet-RHCristiano Rodrigues AlvesNo ratings yet

- Periodic Maintenance: N30ZDRS2, N35-40ZRS2 (B265) N35ZDR2, N45ZR2 (D264) N30ZDR2, N35-40ZR2 (E470)Document52 pagesPeriodic Maintenance: N30ZDRS2, N35-40ZRS2 (B265) N35ZDR2, N45ZR2 (D264) N30ZDR2, N35-40ZR2 (E470)MONTACARGAS AVSNo ratings yet