Professional Documents

Culture Documents

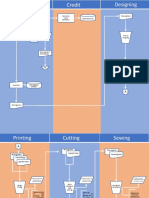

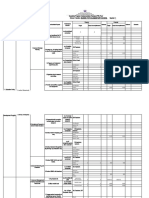

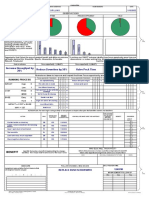

Presentation Flowchart Fabricroll - Drawio

Uploaded by

pakaya tamaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Presentation Flowchart Fabricroll - Drawio

Uploaded by

pakaya tamaCopyright:

Available Formats

RM Unloading bay to Storing

RM fabric issuing to market place

Start: Lorry parked

at B2 Loading bay

Docket

Paste stickers Ratio making,

Receiving the manifest Mark the 10% Send the rolls Segregate the 10% Get an update More material Scan material seaqueniny Picklist

Process GRN on the fabric Process Marker making & Picker allocation

from driver + invoice inspection rolls through conveyoe inspection rolls on location to location & location & table creations

roll & unloading docket creation

allocation

Manual Manual / On the go Manual Manual Manual Manual System Manual System Manual Auto Manual Auto / Manual

Packing list Yellow sticker Freeze plan & Table

Bin management Bin management

Info In Supplier Invoice Material barcode [marked fabric - pasted on the Barcode Info In cutting priority plan 2RFPICK

system system

rolls] fabric roll list 2TBLPLN

Docket creation

Mainfest Material System recording to be 10% - - SAP

Info Out Marked fabric roll - Info Out & marker Table plan Picklist creation

Invoice barcode SAP inspected rolls

making

Unloading

Unloading team Unloading team Storing team Storing team

People team GRN Team Unloading team Unloading team Unloading team

2 leader member member

[GRN point]

People 2 CAD team CAD team RM

2 (done by system) 1

10 set

System 10% Lab

Scanner

label outo

1. 2.

Scanner Elerator

Lorry

print label

Converter Belt Pallet

Part the meveiros on

raw material warehorte

the right position (parrel

Automatic

Manually

(robot arm)

You might also like

- General Motors Supplier Selection WorksheetDocument39 pagesGeneral Motors Supplier Selection WorksheetVarun Singh0% (2)

- PEG Bible Sanitized Version v2Document157 pagesPEG Bible Sanitized Version v2Luke Constable100% (2)

- 4.1) Water Spider Optimization by Eliminating Duplicate ActivitiesDocument9 pages4.1) Water Spider Optimization by Eliminating Duplicate ActivitiessanyamNo ratings yet

- A Research Study On The Effects of CashlDocument93 pagesA Research Study On The Effects of CashlWynona PinlacNo ratings yet

- An Introduction To Digital ForensicsDocument11 pagesAn Introduction To Digital ForensicsSeanNo ratings yet

- Briefing Dealer - Update Socialization Jan 2020Document17 pagesBriefing Dealer - Update Socialization Jan 2020veradanitaNo ratings yet

- Design Architecture: Integration With: AWS Cloud, IBM CloudDocument1 pageDesign Architecture: Integration With: AWS Cloud, IBM Cloudsunshines communityNo ratings yet

- Upgrade Warehouse Searching Navigation System: Plant 1Document1 pageUpgrade Warehouse Searching Navigation System: Plant 1Syahroni Isron RamdanaNo ratings yet

- Oracle Applications User Group Discrete MFG SIG - Cost Group April 27 2010Document50 pagesOracle Applications User Group Discrete MFG SIG - Cost Group April 27 2010Conrad RodricksNo ratings yet

- Major Tables and Relationships For Costing April 2010Document50 pagesMajor Tables and Relationships For Costing April 2010sastrylanka1980No ratings yet

- Major Tables and Relationships For Costing April 2010Document50 pagesMajor Tables and Relationships For Costing April 2010karthik rNo ratings yet

- 08 Mistake Proofing v20130529Document58 pages08 Mistake Proofing v20130529Adrian JoelNo ratings yet

- Check Point For RebberizingDocument1 pageCheck Point For RebberizingDilnesa EjiguNo ratings yet

- Yahotec PFD Stator Line (Min)Document1 pageYahotec PFD Stator Line (Min)akash.research.innovationNo ratings yet

- Work in Progress (WIP) Batch With Quality ManagementDocument4 pagesWork in Progress (WIP) Batch With Quality ManagementsowjanyaNo ratings yet

- EH - PM - Corrective Maintenance - Process FlowDocument1 pageEH - PM - Corrective Maintenance - Process FlowAbdelkader Ben SebgagNo ratings yet

- Book ReferenceLiquidationDocument4 pagesBook ReferenceLiquidationOrlando AlcoberNo ratings yet

- EnglishDocument7 pagesEnglishvijithaNo ratings yet

- Ais - Group 5 - FlowchartDocument2 pagesAis - Group 5 - FlowchartJOHN DAVID WONG MADRONANo ratings yet

- Altsnm Chute Misfa Works - DPR - 22.12.2022@12.30AMDocument1 pageAltsnm Chute Misfa Works - DPR - 22.12.2022@12.30AMvasantha kumarNo ratings yet

- Walker Books, Inc. (Manual System With Minimal PC Support)Document8 pagesWalker Books, Inc. (Manual System With Minimal PC Support)AjunoNo ratings yet

- Carnation Production Flow ChartDocument1 pageCarnation Production Flow Chartsampriti.roy.589No ratings yet

- Process Flow Chart (Pre-Launch / Production)Document1 pageProcess Flow Chart (Pre-Launch / Production)kumar0% (1)

- Module 5 Answer KeyDocument8 pagesModule 5 Answer KeycykablyatNo ratings yet

- Agile Roadmap Excel TemplateDocument1 pageAgile Roadmap Excel TemplateNaif KadrNo ratings yet

- Section 5: Chapter 2: Network Mediation Billing Collections DunningDocument1 pageSection 5: Chapter 2: Network Mediation Billing Collections DunningMorad M SwidNo ratings yet

- G2 Garage Breakdown Report July 2021Document54 pagesG2 Garage Breakdown Report July 2021sanjay ohriNo ratings yet

- 2 - Phu Luc 2 - Print - Control - SystemDocument1 page2 - Phu Luc 2 - Print - Control - SystemLý Phương NamNo ratings yet

- All Section Quality Flow-ChartDocument5 pagesAll Section Quality Flow-ChartRashedul islam ReazNo ratings yet

- Process Steps and Procedures For Print FinishingDocument82 pagesProcess Steps and Procedures For Print FinishingHuynh Thi Thuy VyNo ratings yet

- SIA 4-12 Manual Sales Order Processing SystemsDocument2 pagesSIA 4-12 Manual Sales Order Processing SystemsShela NFNo ratings yet

- Value Stream MappingDocument14 pagesValue Stream MappingGerardo Raamiireez FüğėėnNo ratings yet

- Flow of MaufacturingDocument1 pageFlow of MaufacturingButhetdohNo ratings yet

- Stock Relase Printer Customer: Redesigned Flowchard Sales Computer Operations Warehouse ShippingDocument2 pagesStock Relase Printer Customer: Redesigned Flowchard Sales Computer Operations Warehouse Shippingirene tanNo ratings yet

- Pir-Tool - Quarter 1Document12 pagesPir-Tool - Quarter 1John Angelo T DiangzonNo ratings yet

- Flowchart AccountingDocument4 pagesFlowchart Accountingtomasangel1830No ratings yet

- Yahotec PFD Stator LineDocument1 pageYahotec PFD Stator Lineakash.research.innovationNo ratings yet

- Air LockDocument4 pagesAir LockBansal Engineers Grain Milling Pvt LtdNo ratings yet

- JOBMARKET To-Be Business Flow v1.0Document11 pagesJOBMARKET To-Be Business Flow v1.0Khanh DangNo ratings yet

- Supplier Portal: Task System Code DescriptionDocument1 pageSupplier Portal: Task System Code DescriptionbukangueNo ratings yet

- BPC-2016-TMP-05-2016-V1 Workshop SOW Handout 5 Project Deliverables MatrixDocument6 pagesBPC-2016-TMP-05-2016-V1 Workshop SOW Handout 5 Project Deliverables MatrixSrinivas N Gowda0% (1)

- LP - Process MappingDocument47 pagesLP - Process MappingMugur AchiteiNo ratings yet

- Services DesignDocument20 pagesServices DesignSneha Giji SajiNo ratings yet

- 2 - Paper-OUT - CRTDocument1 page2 - Paper-OUT - CRTrusiru gurugeNo ratings yet

- Flow Process ChartDocument2 pagesFlow Process Chartsanchit gumberNo ratings yet

- Flow Process ChartDocument2 pagesFlow Process Chartsanchit gumberNo ratings yet

- Make-to-Stock - Process Manufacturing Based On Production OrderDocument3 pagesMake-to-Stock - Process Manufacturing Based On Production OrderMohammed HassanNo ratings yet

- SAP Batch ManagementDocument6 pagesSAP Batch ManagementFernando AF100% (2)

- Qad Wi - MPPLDocument22 pagesQad Wi - MPPLKaran Malhi100% (1)

- Welcome To SMDG: Michael Schröder Hapag-Lloyd AG, HamburgDocument15 pagesWelcome To SMDG: Michael Schröder Hapag-Lloyd AG, HamburgDyny MarceeloNo ratings yet

- Reduce Downtime by 50% Halve Peck Time Increase Throughput by 20%Document6 pagesReduce Downtime by 50% Halve Peck Time Increase Throughput by 20%selimNo ratings yet

- 3rdQ ManCon 2023 - Draft For MSD CorrectionsDocument55 pages3rdQ ManCon 2023 - Draft For MSD CorrectionsLeo Artemio PuertosNo ratings yet

- Name of Trainess: Institution: Training ScheduleDocument1 pageName of Trainess: Institution: Training Schedulejohn SagzNo ratings yet

- Progress ChartDocument1 pageProgress Chartjohn SagzNo ratings yet

- LCUSA SAP Implemention Strategy V3.1Document17 pagesLCUSA SAP Implemention Strategy V3.1Madhu MNo ratings yet

- As Is - Inspection and GRN - Wooden Ply, Pallet and Top CoverDocument1 pageAs Is - Inspection and GRN - Wooden Ply, Pallet and Top CoverYousuf KhanNo ratings yet

- Christmas Drive 2020 (SAP Training Module)Document47 pagesChristmas Drive 2020 (SAP Training Module)Gheelynnzzky NaycasiNo ratings yet

- Product Information CSS FenderDocument6 pagesProduct Information CSS FenderUsable ToolsNo ratings yet

- Diagram Alir Paper Machine 3Document3 pagesDiagram Alir Paper Machine 3raiNo ratings yet

- 1 Service - Blueprinting FinalDocument10 pages1 Service - Blueprinting FinalDrSachin SrivastavaNo ratings yet

- KWPG2-EN-FRM-009 REV C FMEA-Bracket KUDocument8 pagesKWPG2-EN-FRM-009 REV C FMEA-Bracket KUMyst ToganNo ratings yet

- DSE 20.2F Computer Architecture and NetworksDocument3 pagesDSE 20.2F Computer Architecture and Networkspakaya tamaNo ratings yet

- DSE 18.1F Computer Architecture and NetworkingDocument3 pagesDSE 18.1F Computer Architecture and Networkingpakaya tamaNo ratings yet

- DSE 20.1F Computer Architecture and NetworksDocument3 pagesDSE 20.1F Computer Architecture and Networkspakaya tamaNo ratings yet

- DSE 19.1F Computer Architecture and NetworksDocument3 pagesDSE 19.1F Computer Architecture and Networkspakaya tamaNo ratings yet

- Descriptive ProgrammingDocument1 pageDescriptive Programmingdevadas26No ratings yet

- English 9 ReviewerDocument5 pagesEnglish 9 Reviewermaridel cristobalNo ratings yet

- Wk-3802w 1ge+1fe+wifi Dual Mode OnuDocument9 pagesWk-3802w 1ge+1fe+wifi Dual Mode OnupilemkuNo ratings yet

- Sap S/4 Hana: Business Material Master List ofDocument12 pagesSap S/4 Hana: Business Material Master List ofOsama Mahmoud100% (1)

- City of Troy Election Inspector TrainingDocument135 pagesCity of Troy Election Inspector TrainingWXYZ-TV Channel 7 DetroitNo ratings yet

- Draw Wire Sensor: Series SX120Document14 pagesDraw Wire Sensor: Series SX120Amilcar MendozaNo ratings yet

- Cube 705/755 HEVC Encoder: Product Specification SheetDocument2 pagesCube 705/755 HEVC Encoder: Product Specification SheetRoberto Rodriguez MirandaaNo ratings yet

- Vearviewepocs2D Operation ENGDocument110 pagesVearviewepocs2D Operation ENGLuis Alberto Díaz OlmedoNo ratings yet

- 1.06 - Security Policy and Logging - Lab - v11Document33 pages1.06 - Security Policy and Logging - Lab - v11Expertise DATANo ratings yet

- Color 1 Color 2 Color 3: HEX RGB HSB Cmyk HEX RGB HSB Cmyk HEX RGB HSB CmykDocument8 pagesColor 1 Color 2 Color 3: HEX RGB HSB Cmyk HEX RGB HSB Cmyk HEX RGB HSB CmykMr. FerreiraNo ratings yet

- ITP Assignment Spring 2024 (5378) - 1Document8 pagesITP Assignment Spring 2024 (5378) - 1kyawkokotunmm475157No ratings yet

- Interim Certificate Amendment: Use This Form IfDocument2 pagesInterim Certificate Amendment: Use This Form Ifdimuthh7441No ratings yet

- Government of Assam: State Level Police Recruitment Board, Assam Rehabari::: GuwahatiDocument1 pageGovernment of Assam: State Level Police Recruitment Board, Assam Rehabari::: GuwahatiAbinash DasNo ratings yet

- Self-Adaptive Single-Event Upset Resilience in Reconfigurable Systems For Space ApplicationsDocument39 pagesSelf-Adaptive Single-Event Upset Resilience in Reconfigurable Systems For Space ApplicationssimbarryNo ratings yet

- Project ReportDocument9 pagesProject Reportapi-307821649No ratings yet

- IT8501 - Web Technology (Ripped From Amazon Kindle Ebooks by Sai Seena)Document532 pagesIT8501 - Web Technology (Ripped From Amazon Kindle Ebooks by Sai Seena)vk des33% (3)

- Abstract FactoryDocument2 pagesAbstract Factoryalejo castaNo ratings yet

- Pass Your OG0-093 Certification Exam With FreedumpspdfDocument12 pagesPass Your OG0-093 Certification Exam With FreedumpspdfbrandonNo ratings yet

- LTE BasicDocument85 pagesLTE BasicRoy Martin100% (3)

- 8 Best Python Cheat Sheets For Beginners and Intermediate LearnersDocument13 pages8 Best Python Cheat Sheets For Beginners and Intermediate LearnersJoseph Jung100% (1)

- Quarter 3 - Module 1: Introduction To Media and Information LiteracyDocument20 pagesQuarter 3 - Module 1: Introduction To Media and Information LiteracyfranNo ratings yet

- As 1038.10.3-1998 Coal and Coke - Analysis and Testing Determination of Trace Elements - Coal and Coke - DeteDocument6 pagesAs 1038.10.3-1998 Coal and Coke - Analysis and Testing Determination of Trace Elements - Coal and Coke - DeteSAI Global - APACNo ratings yet

- Multiprocessor SchedulingDocument22 pagesMultiprocessor Schedulingf2010083No ratings yet

- Xbee ModuleDocument272 pagesXbee ModulePavel TrofimovNo ratings yet

- HU50A6800FUW MX HISENSE User ManualDocument97 pagesHU50A6800FUW MX HISENSE User ManualJose Juan HernandezNo ratings yet

- fm30-5 1973Document262 pagesfm30-5 197320AB14No ratings yet

- NID in Computer Hardware TechnologyDocument78 pagesNID in Computer Hardware Technologytezom techeNo ratings yet

- 19bci0074 VL2021220701828 Da03Document14 pages19bci0074 VL2021220701828 Da03Hemanth Kumaar Reddy NandipatiNo ratings yet