Professional Documents

Culture Documents

Altsnm Chute Misfa Works - DPR - 22.12.2022@12.30AM

Uploaded by

vasantha kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Altsnm Chute Misfa Works - DPR - 22.12.2022@12.30AM

Uploaded by

vasantha kumarCopyright:

Available Formats

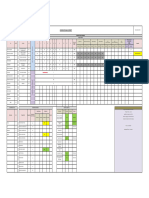

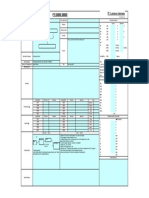

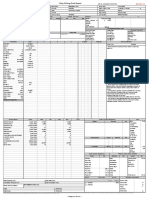

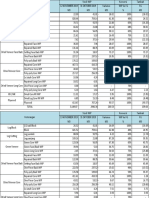

Al Tasnim Misfa - CHUTE FABRICATION PROGRESS ( Mild Steel)

Start Dt: 28 - Nov -2022 Status on : 11-Dec-2022

TON 7.42 MT

Man Hours Consumed 1620 MHRS ( 8+1)

Due To Drg Issue Man hours Loss 140 +95 = 225 Mhrs

Preparation

Scope

Ready for

Raw Material Drg Release / Welding & Activity %

Sr. No. Activity Description Fitup Assy Checking Inspectio Drawing Issue Details Due to Drawing Issue Manhours Loss Remarks

Status Priority Drilling & Cleaning Completion

Marking Cutting n

Weight In Grinding

Each Weight Qty In Each Set UOM

set

Material Chute at Primary Crushing Complex

Single

1A) Drg No: PM0100-2200-DSA-1-P2002-D-02-PCC00-1- Prority -3 7.68 6 7.68 6 5% 10% 25% 25% 15% 20% Tentaive Completion Date : 29.12.22

Piece Only

0002_PCCCHUTEDETAIL_R-1_Sht 1 to 7

Site team need Clarification for make at

1.1 Erection Mark NO : P2002-00-PCC-1 Rec. 6.17 1 6.17 1 Ton / Nos 0 0 0 0 0 0 0%

shop or site

1.2 Erection Mark NO : P2002-00-PCC-2 Rec. 0.44 1 0.44 1 Ton / Nos 1 1 1 0 1 1 75%

1.3 Erection Mark NO : P2002-00-PCC-3 Rec. 0.45 1 0.45 1 Ton / Nos 1 1 1 0 1 1 75%

1.4 Erection Mark NO : P2002-00-PCC-4 Rec. 0.27 1 0.27 1 Ton / Nos 1 1 1 0 1 1 75%

1.5 Erection Mark NO : P2002-00-PCC-SD1 Rec. 0.12 1 0.12 1 Ton / Nos 1 1 1 0 0 0 40%

1.6 Erection Mark NO : P2002-00-PCC-SD2 Rec. 0.23 1 0.23 1 Ton / Nos 1 1 1 1 1 1 100%

1. Holes shifting Rework.

Material Chute at Primary Crushing Complex 2. Plate dimesion as per drg wrong - Assy

3 Sets in Manhours loss : 140 Mhrs

2A) Drg No: PM0100-2300-DSA-1-P2002-D-02-SP001-1- Prority -1 1.51 13 4.54 39 5% 10% 25% 25% 15% 20% Fitment recutting done. Tentaive Completion plan Date : 21.12.22

Each Qty ( Dt: 07 th & 8th)

0004_MKG & GA DWG CHUTEDETAIL_RO-1_Sht 1 to 5 3. Flange connecting area gap found cut

plate added.

2.1 Erection Mark NO : P2002-TT02-CHT-01 Rec. 0.28 1 0.85 3 Ton / Nos 3 3 3 3 3 3 100%

2.2 Erection Mark NO : P2002-TT02-CHT-02 Rec. 0.51 1 1.54 3 Ton / Nos 3 3 3 3 3 1 87%

2.3 Erection Mark NO : P2002-TT02-CHT-03 Rec. 0.21 1 0.62 3 Ton / Nos 3 3 3 3 3 3 100% 140%

2.4 Erection Mark NO : P2002-TT02-CHT-04 Rec. 0.21 1 0.64 3 Ton / Nos 3 3 3 3 3 3 100% 75%

Ready for Inspection on

2.5 Erection Mark NO : P2002-TT02-CHT-05 Rec. 0.16 1 0.49 3 Ton / Nos 3 3 3 3 3 3 100% Saturday 24.12.2022 for 39 nos.

1. Chute : 15 nos.

2.6 Erection Mark NO : P2002-TT02-SD-01 Rec. 0.01 1 0.04 3 Ton / Nos 3 3 3 3 3 3 100%

2. Saddle : 24 nos.

2.7 Erection Mark NO : P2002-TT02-SD-02 Rec. 0.03 2 0.09 6 Ton / Nos 6 6 6 6 6 6 100%

2.8 Erection Mark NO : P2002-TT02-SD-03 Rec. 0.03 3 0.10 9 Ton / Nos 9 9 9 9 9 9 100%

2.9 Erection Mark NO : P2002-TT02-SD-04 Rec. 0.06 2 0.17 6 Ton / Nos 6 6 6 6 6 6 100%

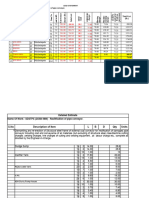

1. Item no: 20 Notch with taper

dimension not provided drawing. Fit

ment time dimension will cross verfied

accordingly will be cut

2. Item no : 46 As per drg :690x304

Material Chute at Primary Crushing Complex As build changed (690x320) new plate

Single Manhours loss : 95 Mhrs

3A) Drg No: PM0100-2300-DSA-1-P2002-D-02-TT02-1-0006- Prority -2 2.88 17.00 2.88 17 5% 10% 25% 25% 15% 20% cut. Tentaive Completion Date : 27.12.22

Piece Only ( Dt: 19 th,20th & 21th)

DET.DWG OF MATERIAL CH. TT-02_R-1_Sht 1 to 5 3. Item no: 61 As per drg (1000x140)

As build changed( 315x140) Re cutting

4. Item no: 19 As per Drg:( 2019 x236)

with taper notch.

As build : ( 1246x226) Re cutting

3.1 Erection Mark NO : P2002-TT02-CHT-01 Rec. 0.27 1 0.27 1 Ton / Nos 1 1 1 1 0 0 65%

3.2 Erection Mark NO : P2002-TT02-CHT-02 Rec. 0.82 1 0.82 1 Ton / Nos 1 1 1 1 0 0 65%

3.3 Erection Mark NO : P2002-TT02-CHT-03 Rec. 0.26 1 0.26 1 Ton / Nos 1 1 1 1 0 0 65%

3.4 Erection Mark NO : P2002-TT02-CHT-04 Rec. 0.07 1 0.07 1 Ton / Nos 1 1 1 1 0 0 65%

3.5 Erection Mark NO : P2002-TT02-CHT-05 Rec. 0.33 1 0.33 1 Ton / Nos 1 1 1 0.75 0 0 59%

3.6 Erection Mark NO : P2002-TT02-CHT-06 Rec. 0.11 1 0.11 1 Ton / Nos 1 1 1 1 0 0 65%

3.7 Erection Mark NO : P2002-TT02-CHT-07 Rec. 0.44 1 0.44 1 Ton / Nos 1 1 1 0.75 0 0 59% In the Chute No: Item # 44,45 &50

Having constrain of the liner plate fixing

3.8 Erection Mark NO : P2002-TT02-SD-01 Rec. 0.01 1 0.01 1 Ton / Nos 1 1 1 0 0 0 40% due to the Access Issue.

Kindly provide the Solution for furher

3.9 Erection Mark NO : P2002-TT02-SD-02 Rec. 0.01 1 0.01 1 Ton / Nos 1 1 1 0 0 0 40%

Option : 1 We required to the Flange

3.10 Erection Mark NO : P2002-TT02-SD-03 Rec. 0.01 1 0.01 1 Ton / Nos 1 1 1 0 0 0 40% plate bolting type to have easy acces .

3.11 Erection Mark NO : P2002-TT02-SD-04 Rec. 0.01 1 0.01 1 Ton / Nos 1 1 1 0 0 0 40%

3.12 Erection Mark NO : P2002-TT02-SD-05 Rec. 0.21 1 0.21 1 Ton / Nos 1 1 1 1 0 0 65%

3.13 Erection Mark NO : P2002-TT02-SD-06 Rec. 0.01 2 0.01 2 Ton / Nos 1 1 1 0 0 0 20%

3.14 Erection Mark NO : P2002-TT02-SD-07 Rec. 0.01 2 0.01 2 Ton / Nos 1 1 1 0 0 0 20%

3.15 Erection Mark NO : P2002-TT02-SD-08 Rec. 0.31 1 0.31 1 Ton / Nos 1 1 1 0 0 0 40%

You might also like

- ROUTE CARD FORMAT FABRICATION RevDocument1 pageROUTE CARD FORMAT FABRICATION RevSridhar SriNo ratings yet

- Project: SR - No: .. .. Dated: .Document2 pagesProject: SR - No: .. .. Dated: .bachir baboriNo ratings yet

- Name of The Project: Avigna Industrial Park, Nagondapalli Village, Hosur, Tamil NaduDocument4 pagesName of The Project: Avigna Industrial Park, Nagondapalli Village, Hosur, Tamil Nadua paul jayakumarNo ratings yet

- Dashboard DPR BBP 07 Desember 2023Document1 pageDashboard DPR BBP 07 Desember 2023vorda buaymadangNo ratings yet

- DTC SS24 T&aDocument4 pagesDTC SS24 T&aemessa.docsNo ratings yet

- Daily Prod Report SGB 05 - 07 - 2022Document2 pagesDaily Prod Report SGB 05 - 07 - 2022Said PrayogiNo ratings yet

- Daily Prod Report SGB 03 - 07 - 2022Document2 pagesDaily Prod Report SGB 03 - 07 - 2022Said PrayogiNo ratings yet

- BH 01Document1 pageBH 01Suvashis PaulNo ratings yet

- RDMP Project Fmar Shop DWG Fabrication Estimated Delivery (On Site)Document12 pagesRDMP Project Fmar Shop DWG Fabrication Estimated Delivery (On Site)Bintang DwiPutraNo ratings yet

- AS-NZS 1554.1-2014 Procedure Qualification Record (PQR)Document1 pageAS-NZS 1554.1-2014 Procedure Qualification Record (PQR)Bobby CurrieNo ratings yet

- Sky Mqap1Document1 pageSky Mqap1Kumara SubramanianNo ratings yet

- DPR-CDU-4 TA23 Dt.-12.10.2023Document13 pagesDPR-CDU-4 TA23 Dt.-12.10.2023hari67No ratings yet

- JG Summit Stage 1 Expansion Project Battery Limit Interface TableDocument2 pagesJG Summit Stage 1 Expansion Project Battery Limit Interface Tablemengelito almonteNo ratings yet

- 10% 15% 15% 50% 10% 100% Dd/mm/yyyy Yes/No 20% 50% 5% 10% 15% 100% Dd/mm/yyyy DaysDocument3 pages10% 15% 15% 50% 10% 100% Dd/mm/yyyy Yes/No 20% 50% 5% 10% 15% 100% Dd/mm/yyyy DaysBassem Ben FrajNo ratings yet

- Design Fmea 1 ST Pipe Teflon HoseDocument11 pagesDesign Fmea 1 ST Pipe Teflon HoseSandeep PandeyNo ratings yet

- Format For BS 2020-22 NH 55& 20Document2 pagesFormat For BS 2020-22 NH 55& 20EE.NH. CuttackNo ratings yet

- Format For BS 2020-22 NH 55Document2 pagesFormat For BS 2020-22 NH 55EE.NH. CuttackNo ratings yet

- Land Rover Freelander 2 Tyre MarkingsDocument2 pagesLand Rover Freelander 2 Tyre MarkingsJimmy TudeskyNo ratings yet

- BS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress ReportDocument1 pageBS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress Reportsusanta100% (1)

- Results: RDC Banner - 2022: Part - 1 PART-2 Part - 3Document1 pageResults: RDC Banner - 2022: Part - 1 PART-2 Part - 3ARYAN JAISWAL IX-B 8No ratings yet

- Project:-Jigjiga-Gelelsh-Deghamedo - Segeg Road ProjectDocument10 pagesProject:-Jigjiga-Gelelsh-Deghamedo - Segeg Road ProjecttsegayNo ratings yet

- Daily Report (The Walk)Document1 pageDaily Report (The Walk)muzaffaralhashmimaazmuzaffarNo ratings yet

- Daily construction progress reportDocument2 pagesDaily construction progress reportSyed Adnan AqibNo ratings yet

- DPRDocument2 pagesDPRSyed Adnan AqibNo ratings yet

- Cube Register LogDocument1 pageCube Register LogNickNo ratings yet

- Welding Process Comparision RevisedDocument2 pagesWelding Process Comparision RevisedFrancis DhanarajNo ratings yet

- Fabrication ChargesDocument5 pagesFabrication Chargessandeep gungiNo ratings yet

- WPS and PQR of GMAWDocument8 pagesWPS and PQR of GMAW魏利强No ratings yet

- Final Enquiry List For ValvesDocument12 pagesFinal Enquiry List For ValvesnikhilNo ratings yet

- Daily Progress Report Diaphragm Wall Pilling BMRCL 28-12-2023Document1 pageDaily Progress Report Diaphragm Wall Pilling BMRCL 28-12-2023Rakshith MarichennaiahNo ratings yet

- Daily Progress Report Jetty South Beach KMT 010423Document1 pageDaily Progress Report Jetty South Beach KMT 010423Haris SutiyonoNo ratings yet

- Bldg. Datas 2018-19 - 121218FCDDocument94 pagesBldg. Datas 2018-19 - 121218FCDDEE QC CHittoorNo ratings yet

- No Part No / Part Name Dies Op Problem Countermeasure PICDocument1 pageNo Part No / Part Name Dies Op Problem Countermeasure PICImam RosyidNo ratings yet

- Daily Prod Report SGB 04 - 07 - 2022Document2 pagesDaily Prod Report SGB 04 - 07 - 2022Said PrayogiNo ratings yet

- L&H - Score - Report 28 - 07 - 2023Document1 pageL&H - Score - Report 28 - 07 - 2023Koné SékouNo ratings yet

- Structural pre-Fabrication Process LegendDocument1 pageStructural pre-Fabrication Process LegendDruid FamilyNo ratings yet

- Home Annexure User Name Settings Audit ReportDocument10 pagesHome Annexure User Name Settings Audit ReportBlack DemonNo ratings yet

- Production OrganogramDocument1 pageProduction Organogrammd habibur rahman shamimNo ratings yet

- SSFD NIMR - EARLY DEVELOPMENT FACILITY UNIT RATE SHEETDocument16 pagesSSFD NIMR - EARLY DEVELOPMENT FACILITY UNIT RATE SHEETSasi MesthiriNo ratings yet

- New Mine - OverviewDocument1 pageNew Mine - Overviewangelo andreeanNo ratings yet

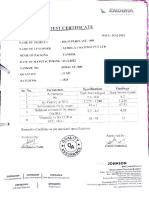

- CoA - MTC - LOT 4525 - 4408Document1 pageCoA - MTC - LOT 4525 - 4408dipen royNo ratings yet

- 12282A - Expansion Joints DatasheetDocument1 page12282A - Expansion Joints DatasheetGaurav TripathiNo ratings yet

- Type - A Manhole BBS FileDocument1 pageType - A Manhole BBS FilefbdfNo ratings yet

- Inward RegisterDocument8 pagesInward RegisterOmkarNo ratings yet

- 25-02-24 DPRDocument3 pages25-02-24 DPRsmn.ussharNo ratings yet

- Manufacturing Part Status Sheet (MPS)Document7 pagesManufacturing Part Status Sheet (MPS)Vighneshwar InjekarNo ratings yet

- Daily Prod Report SGB 01 - 07 - 2022Document2 pagesDaily Prod Report SGB 01 - 07 - 2022Said PrayogiNo ratings yet

- HSS Integrated Sdn Bhd Laboratory Request ScheduleDocument1 pageHSS Integrated Sdn Bhd Laboratory Request ScheduleLee Jia QingNo ratings yet

- Tsr-Sd22e Bd106 TurrbocharrgeDocument2 pagesTsr-Sd22e Bd106 Turrbocharrgedwi supraptoNo ratings yet

- Report Update PT. PIS 20 Desember 2019Document2 pagesReport Update PT. PIS 20 Desember 2019Tika LorenzaNo ratings yet

- Entoto Site Structure and Crew FormationDocument39 pagesEntoto Site Structure and Crew Formationgirmay.filmon5No ratings yet

- Backfilling & Compaction Productive RateDocument4 pagesBackfilling & Compaction Productive RateIshan AththanayakeNo ratings yet

- KWPG2-EN-FRM-009 REV C FMEA-Bracket KUDocument8 pagesKWPG2-EN-FRM-009 REV C FMEA-Bracket KUMyst ToganNo ratings yet

- Book1 R3 Cancel CTODDocument1 pageBook1 R3 Cancel CTODAan SharmaNo ratings yet

- Rebar Weekly Sub Contrat-4Document1 pageRebar Weekly Sub Contrat-4AbdulfetaNo ratings yet

- TSR Sd22e Bd108Document3 pagesTSR Sd22e Bd108dwi supraptoNo ratings yet

- Manzalai-07 Daily Mud Report (10!7!20)Document1 pageManzalai-07 Daily Mud Report (10!7!20)Sharjeel AhmedNo ratings yet

- ATNM Handrail 2277 DPR 30 03 2023Document1 pageATNM Handrail 2277 DPR 30 03 2023vasantha kumarNo ratings yet

- Expro Production Structural Fabrication and Ga Drawing For Gdu Plant (Mol Seive Adsorber Platform A-B)Document1 pageExpro Production Structural Fabrication and Ga Drawing For Gdu Plant (Mol Seive Adsorber Platform A-B)vasantha kumarNo ratings yet

- ATNM Handrail 2277 DPR 30 03 2023Document1 pageATNM Handrail 2277 DPR 30 03 2023vasantha kumarNo ratings yet

- ATNM Handrail 2277 DPR 04 04 2023 Report 07Document1 pageATNM Handrail 2277 DPR 04 04 2023 Report 07vasantha kumarNo ratings yet

- Expro Production Structural Fabrication and Ga Drawing For Dpcu Plant (Refrigerent Skid)Document1 pageExpro Production Structural Fabrication and Ga Drawing For Dpcu Plant (Refrigerent Skid)vasantha kumarNo ratings yet

- Unlocked Equipment CostingDocument39 pagesUnlocked Equipment Costingvasantha kumarNo ratings yet

- ASHOKANDocument2 pagesASHOKANvasantha kumarNo ratings yet

- Expro ProductionDocument1 pageExpro Productionvasantha kumarNo ratings yet

- Eps Tank13.10.15 002Document1 pageEps Tank13.10.15 002vasantha kumarNo ratings yet

- ATNM Handrail 2277 DPR 02 07 2023 Report 35Document1 pageATNM Handrail 2277 DPR 02 07 2023 Report 35vasantha kumarNo ratings yet

- M 503 2705 Demolishing Dismantling Steel Framed Structures in The WorkplaceDocument2 pagesM 503 2705 Demolishing Dismantling Steel Framed Structures in The WorkplaceSatheeshkumar NallusamyNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- Goalsetting 170319080005Document13 pagesGoalsetting 170319080005vasantha kumarNo ratings yet

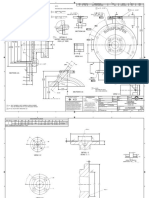

- C-2101 Sleeve & CollarDocument1 pageC-2101 Sleeve & Collarvasantha kumarNo ratings yet

- IC Resource Histogram 9103Document3 pagesIC Resource Histogram 9103vasantha kumarNo ratings yet

- Manpower HistogramDocument5 pagesManpower Histogramvasantha kumarNo ratings yet

- Derricks and CranesDocument34 pagesDerricks and Cranessabeer75% (4)

- Itp Tank - 01082023Document4 pagesItp Tank - 01082023vasantha kumarNo ratings yet

- Details Date Item / Task Description Gathered by Best-Case Worst-Case Weighted Average Most Likely / RealisticDocument5 pagesDetails Date Item / Task Description Gathered by Best-Case Worst-Case Weighted Average Most Likely / RealisticDynamic BuildersNo ratings yet

- Annex A-Scope Matrix - SBT - 14.08.2023 Shop Built Tank PDFDocument2 pagesAnnex A-Scope Matrix - SBT - 14.08.2023 Shop Built Tank PDFvasantha kumarNo ratings yet

- Manohar Complex Terrace Floor PlanDocument1 pageManohar Complex Terrace Floor PlanParvathy ShekharNo ratings yet

- Unit II - Turning Machines PDFDocument137 pagesUnit II - Turning Machines PDFKanda SamyNo ratings yet

- Grizzly Ukulele Kit H3125 ManualDocument24 pagesGrizzly Ukulele Kit H3125 ManualChoo Seng QuahNo ratings yet

- Australian Wood Review December 2018Document100 pagesAustralian Wood Review December 2018Maicon MorandiniNo ratings yet

- G Clamp PDFDocument1 pageG Clamp PDFRendi SastroNo ratings yet

- SE-A KOM Mini Project List-1Document2 pagesSE-A KOM Mini Project List-1AbhiNo ratings yet

- Single Flute Gundrills: BotekDocument40 pagesSingle Flute Gundrills: BotekDANIEL MANRIQUEZ FAVILANo ratings yet

- MT Co234 - MergedDocument49 pagesMT Co234 - MergedPavas ManoharNo ratings yet

- A E B G: CasingDocument2 pagesA E B G: CasingAgnel StanleyNo ratings yet

- Woody Woodworking Sdn. BHD.: Purchase Order No: WWO0577-20Document1 pageWoody Woodworking Sdn. BHD.: Purchase Order No: WWO0577-20MajorNo ratings yet

- Acurate Router Jig-ManualDocument4 pagesAcurate Router Jig-Manualcesar_mosqueda836No ratings yet

- Question Answer On Lathe Milling Drilling Grinding (Join AICTE Telegram Group)Document74 pagesQuestion Answer On Lathe Milling Drilling Grinding (Join AICTE Telegram Group)Vivek SharmaNo ratings yet

- Indian Standard: Specification For Reels and Drums For Bare ConductorsDocument13 pagesIndian Standard: Specification For Reels and Drums For Bare ConductorsUppala Krishna ChaitanyaNo ratings yet

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- WIPDocument3 pagesWIPAris SusantoNo ratings yet

- Tiger Grass Pollen Remover Con Wood Working Machine-IRCHEDocument50 pagesTiger Grass Pollen Remover Con Wood Working Machine-IRCHEchikret_1023000% (1)

- Asme B16.5-2017-02Document2 pagesAsme B16.5-2017-02andhucaos0% (1)

- D28 Series Welding Table Parts ListDocument27 pagesD28 Series Welding Table Parts Listandres buguenoNo ratings yet

- CK210 Micro CNC LatheDocument4 pagesCK210 Micro CNC LatheWilson Sergio Martins DantasNo ratings yet

- Wooden Mallet Plans 2 - WoodArchivistDocument4 pagesWooden Mallet Plans 2 - WoodArchivistEricsNo ratings yet

- First Year Metalwork.: Class Notes and Homework WorkbookDocument117 pagesFirst Year Metalwork.: Class Notes and Homework Workbookbrian DeckerNo ratings yet

- Lintel Installation GuideDocument5 pagesLintel Installation GuideAnneBricklayer100% (1)

- Door FrameDocument1 pageDoor FramegiridharreddyNo ratings yet

- VA42090 Velencia Pergola Costco Instructions NA-UKDocument19 pagesVA42090 Velencia Pergola Costco Instructions NA-UKdawitgggNo ratings yet

- CTU Lathe Machine OperationDocument169 pagesCTU Lathe Machine OperationChristopher VergaraNo ratings yet

- Cordwood Construction PDFDocument8 pagesCordwood Construction PDFamondaca100% (1)

- Pre-Operative Check Up of Farm Tools and EquipmentDocument2 pagesPre-Operative Check Up of Farm Tools and EquipmentRamz Latsiv Yohgat67% (9)

- Milling Drilling Machines 1.2 Milling Machines Industrial 1.5 Milling CNC Industrial 1.16Document16 pagesMilling Drilling Machines 1.2 Milling Machines Industrial 1.5 Milling CNC Industrial 1.16Didier TsheyaNo ratings yet

- MCQs of Jigs and Fixtures (Production Technology-2161909) - GTU MCQ 4Document1 pageMCQs of Jigs and Fixtures (Production Technology-2161909) - GTU MCQ 4Prashant SinghNo ratings yet

- Grinding Equipment: Product CatalogueDocument32 pagesGrinding Equipment: Product CatalogueSebastian Nuñez RiquelmeNo ratings yet