Professional Documents

Culture Documents

Annex A-Scope Matrix - SBT - 14.08.2023 Shop Built Tank PDF

Uploaded by

vasantha kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex A-Scope Matrix - SBT - 14.08.2023 Shop Built Tank PDF

Uploaded by

vasantha kumarCopyright:

Available Formats

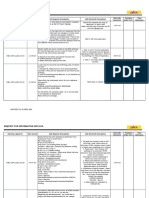

Annexure A - Scope Matrix Client : OQ - TA

STS Ref : Replacement of the existing BWRO Permeate Water Tank ME-5404-T-01 (bolted bottom Rev Rev 1

plate and shell body) with the new welded Tank.

Roof Type : Fixed Cone Roof Tank Details: Date: Date: 14-Aug-23

D 3.751 m x H 7.356 m, Qty-1 No., MOC-A36 / A160 Gr.B / A105N

SCOPE MATRIX

Sr. No. Description STS VENDOR Remarks

1 DESIGN

1.1 Mechanical design of tank Limited to Lifting Design only

1.2 Preparation of GA and detailed Fabrication drawings

1.3 As built drawings

2 SUPPLY OF MATERIALS

2.1 Plates for Shell, Bottom, roof, Platform etc.

2.2 Plates for flanges, plates for nozzle reinforcing pads, plates for necks of nozzles, manholes

MOC as per Datasheet as as per OQ AVME:

All Plates - SA 36.

2.3 Forged flanges, seamless pipes for nozzles, still wells as per data sheet. Nozzles - A 106 GrB / A 105

Fasteners,Gaskets - A 153

Structural Materials- S275 JR

2.4 Fasteners for nozzles, manholes as per data sheet where required.

2.5 Gaskets for manholes, and blind flanges as per data sheet where required.

2.6 Roof access handrails Like to Like as per Design ( Site Verification Required

joint visit with STS TA Team)

2.7 Cage Ladder staircases Like to Like as per Design ( Site Verification Required

joint visit with STS TA Team)

2.8 Supply of name plate, earthing bosses as per data sheet where required. Like to Like as per Design ( Site Verification Required

joint visit with STS TA Team)

As per Design to be installed at Shop

2.9 Anchor chairs ( Site Verification Required joint visit with STS TA

Team)

2.10. Supply of PVRV, PSV as per tank data sheet where required.

2.11 Supply of all other tank instruments Not Considered in BG

2.12 Mechanical works outside tank nozzle/Flanges All BOP works (Not Considered in BG )

2.13 Release Prevention Barrier (RPB) And Leak Detection System All BOP works (Not Considered in BG )

2.14 Insulation No Insulation as per DS

2.15 All welding consumable for fabrication and construction

2.16 Pipe Supports & Instrument and electrical cable supports Like to Like as per Design ( Site Verification Required

joint visit with STS TA Team)

2.17 Safety equipment and signs and signboards Not Considered in BG

2.18 Hydrotest water Supply and Disposal at Shop

2.19 Scaffolding At Shop only

2.20 Tank foundation material Not Considered in BG

3 SCOPE OF WORK - SHOP

3.1 Pre Fabrication of tanks

3.2 PWHT of Shell Manholes & Nozzles as per Code, if required Not Applicable

3.4 Site Erection & Installation of tank Unloading from Trailer at Site excluded

3.5 Hydro testing of tank as per the code Supply and Disposal at Shop

3.6 All NDT (Radiography, MPI, DP etc.) of tank as per the code Related to Tank Only

3.7 Surface preparation & Primer painting of tanks At Shop related to Tank Only ( BG Shop )

3.8 Tank Painting & Lining works As per Datasheet

3.9 All Inspection activities at Shop in compliance to ITP and OQ requirements

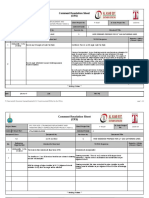

Annexure A - Scope Matrix Client : OQ - TA

STS Ref : Replacement of the existing BWRO Permeate Water Tank ME-5404-T-01 (bolted bottom Rev Rev 1

plate and shell body) with the new welded Tank.

Roof Type : Fixed Cone Roof Tank Details: Date: Date: 14-Aug-23

D 3.751 m x H 7.356 m, Qty-1 No., MOC-A36 / A160 Gr.B / A105N

SCOPE MATRIX

Sr. No. Description STS VENDOR Remarks

4 SCOPE OF WORK - SITE

4.1 Transportation from Shop to Site as per OPAL Compliance Only Loading at Shop by BG Fab Shop only -Tank with

required Supports & Saddles

4.2 Required Lifting Lugs / Calculations on the tank for lifting purpose Only Loading at Shop by BG Fab Shop only -Tank with

required Supports & Saddles

Crew to be deployed by vendor. If not STS Crew shall

4.3 Painting Touchup Works at Site in case of Damage due to Loading at Shop be utilised and Backcharged Price to be mutually

agreed.

5 INSURANCE

5.1 Insurance for crew, vehicles & equipment’s Crew work Insurance available( BG)

5.2 Any other insurance Not Considered in BG

6 DOCUMENTATION

6.1 Quality (QA/QC)

6.2 Progress Report (Weekly/Monthly)

7 PQR & WQT

7.1 PQR & WPS will be followed as per STS procedure BG will follow as per STS approved Procedure

7.2 Welder Deployment ( As per the Mail Confirmation STS will be provided during the Execution time Required Since Welder will be provided by STS WQT not

welders to meet the schedule) considered in BG .

You might also like

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument2 pagesLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- Structural Analysis Report For A 120-ft Monopole Tower, Prepared For Verizon Wireless (Dewberry Engineers Inc., 2020)Document50 pagesStructural Analysis Report For A 120-ft Monopole Tower, Prepared For Verizon Wireless (Dewberry Engineers Inc., 2020)Kirollos ShenoudaNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- TP-WELLS-09073-DAS-A4-D1-L - Valve DSDocument21 pagesTP-WELLS-09073-DAS-A4-D1-L - Valve DSJessica RahmaNo ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument4 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetMr NgocNo ratings yet

- PDS AutoPIPE Vessel Heat Exchanger LTR en LRDocument2 pagesPDS AutoPIPE Vessel Heat Exchanger LTR en LRNicha OuiksNo ratings yet

- Base Plate Design Metric Units PDFDocument8 pagesBase Plate Design Metric Units PDFVinayak PatilNo ratings yet

- 2018.05.29 - 04-05-31et 0017Document81 pages2018.05.29 - 04-05-31et 0017mankari.kamal.18022963No ratings yet

- DDFC Technical Cum Commercial Proposal PV 811Document8 pagesDDFC Technical Cum Commercial Proposal PV 811Siddiqui Muhammad AshfaqueNo ratings yet

- HSA-R Technical DataDocument18 pagesHSA-R Technical DataGuthrieJohn CNo ratings yet

- Jhabua-Sor 20200702 181504Document4 pagesJhabua-Sor 20200702 181504Suaib VCSNo ratings yet

- Hazira-Sor 20200702 181418Document11 pagesHazira-Sor 20200702 181418Suaib VCSNo ratings yet

- Rfi LogDocument64 pagesRfi Logfuadlutfi91No ratings yet

- Cta BMC Brick Making Machine Ceta-Ram For Soil Bricks 1.0Document53 pagesCta BMC Brick Making Machine Ceta-Ram For Soil Bricks 1.0Negrea RobertNo ratings yet

- 0803 - Hkadc - 20191230 (Combine Revised)Document18 pages0803 - Hkadc - 20191230 (Combine Revised)yiuloi997023No ratings yet

- NNGGDocument5 pagesNNGGwill tingNo ratings yet

- Spantech Technical Globe Valve PDFDocument3 pagesSpantech Technical Globe Valve PDFVijay - Spantech EngineersNo ratings yet

- WD CS 01 BFNS22.9 2018Document15 pagesWD CS 01 BFNS22.9 2018Dipanjan chakrabortyNo ratings yet

- Engineering Review Sheet Vyasi Hepp (2 X 60 MW)Document3 pagesEngineering Review Sheet Vyasi Hepp (2 X 60 MW)Sujeet KumarNo ratings yet

- U2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1ADocument14 pagesU2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1ATommy ArjanggiNo ratings yet

- Eg Concrete Jacking PipeDocument8 pagesEg Concrete Jacking PipeSandeep PatelNo ratings yet

- PBR 03Document5 pagesPBR 03iesha canada1No ratings yet

- Double Wall Storage Tank1Document33 pagesDouble Wall Storage Tank1INFO SAGANo ratings yet

- MDX - Specifications Doc - Bridgerail BR20Document4 pagesMDX - Specifications Doc - Bridgerail BR20FernandoNo ratings yet

- Checklist For DG Set Foundation Design & DrawingDocument3 pagesChecklist For DG Set Foundation Design & DrawingRupesh KhandekarNo ratings yet

- MOS of Fabrication and Welding of F27B01 Stainless Steel LateralsDocument8 pagesMOS of Fabrication and Welding of F27B01 Stainless Steel LateralstinzarmoeNo ratings yet

- CRS - Reply To Comment - HDD Profile - 6012 6013 & 6042Document6 pagesCRS - Reply To Comment - HDD Profile - 6012 6013 & 6042Ratnadeep KhobragadeNo ratings yet

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - ADocument3 pagesIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraNo ratings yet

- Retaining Wall Typical Details (7.0M Max. Height) (TYPE 2)Document4 pagesRetaining Wall Typical Details (7.0M Max. Height) (TYPE 2)will tingNo ratings yet

- BT 23 Tec Le HD SH 1006Document5 pagesBT 23 Tec Le HD SH 1006tongtonglian780No ratings yet

- Azspu Major ProjectsDocument9 pagesAzspu Major ProjectsMirzaNo ratings yet

- Required Information For Analysing The Potential Effect of Sheet Pile On Cathodic Protection of Existing Oil PipesDocument23 pagesRequired Information For Analysing The Potential Effect of Sheet Pile On Cathodic Protection of Existing Oil PipesmladenprNo ratings yet

- Inspection of Support Foundation Prior To Structural or Equipment Installation SAIC-M-2006 03-Apr-22 MechDocument2 pagesInspection of Support Foundation Prior To Structural or Equipment Installation SAIC-M-2006 03-Apr-22 MechsankuNo ratings yet

- 1377 CaRs R2 28oct22 MS For Testing of Working Pile (IFA, Rev.B)Document2 pages1377 CaRs R2 28oct22 MS For Testing of Working Pile (IFA, Rev.B)ĐỨC ĐOÀN NGỌCNo ratings yet

- Ac 1143 Wall Cladding S RegisterDocument36 pagesAc 1143 Wall Cladding S Registerreydudes9156No ratings yet

- Bamboo Code Ced13 (7702) PDFDocument21 pagesBamboo Code Ced13 (7702) PDFThilak PrakashNo ratings yet

- SAIC-B-2001 Revw Proprietary Fireproofing MaterialsDocument2 pagesSAIC-B-2001 Revw Proprietary Fireproofing MaterialsAnonymous S9qBDVkyNo ratings yet

- Es-99.00-D2 BeddDocument31 pagesEs-99.00-D2 BeddPaul KIMNo ratings yet

- Saudi Aramco Inspection ChecklistDocument14 pagesSaudi Aramco Inspection Checklistpookkoya thangalNo ratings yet

- Esr 2907Document4 pagesEsr 2907محمد الدعجةNo ratings yet

- $RPC3METDocument3 pages$RPC3METAJEC IndiaNo ratings yet

- Submittal Review Comments Form: Engineer's Review OutcomeDocument3 pagesSubmittal Review Comments Form: Engineer's Review OutcomePradeep GoudaNo ratings yet

- 60 41 Ab SPC 00002Document39 pages60 41 Ab SPC 00002Vineet RungtaNo ratings yet

- BoqDocument8 pagesBoqFoisul Alam100% (1)

- QD-BR-ST-PHI-0001 - B2 - Topside Structures Design PremiseDocument24 pagesQD-BR-ST-PHI-0001 - B2 - Topside Structures Design PremisefedemochileroNo ratings yet

- 200 20 Pi DTS 00003Document111 pages200 20 Pi DTS 00003ritesh142No ratings yet

- Contoh Soal Psikotes Kerja Dan Kunci JawabanDocument74 pagesContoh Soal Psikotes Kerja Dan Kunci JawabanYulia RimadaniNo ratings yet

- Shear Wall Design-ACI-318-14Document30 pagesShear Wall Design-ACI-318-14Christian ReedNo ratings yet

- IAPMO Groutec Report ER - 312 Year 2018 PDFDocument5 pagesIAPMO Groutec Report ER - 312 Year 2018 PDFNaveen NunnaNo ratings yet

- Wa 726 1Document183 pagesWa 726 1Jacob JosephNo ratings yet

- SWD Aci 318 14Document81 pagesSWD Aci 318 14Mukhlish AkhatarNo ratings yet

- TPS 8735Document114 pagesTPS 8735mech1kingNo ratings yet

- Construction of Amenities Building at Nandi Circle Under Smart City Mission in TIRUPATIDocument26 pagesConstruction of Amenities Building at Nandi Circle Under Smart City Mission in TIRUPATIask.kulkarni KulkarniNo ratings yet

- GGG-SPC-PIP-0013 - Rev 02Document25 pagesGGG-SPC-PIP-0013 - Rev 02oleg safaniukNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistMohamad Shafey100% (1)

- SWD Aci 318 11Document75 pagesSWD Aci 318 11AngusNo ratings yet

- SWD Aci 318 14Document74 pagesSWD Aci 318 14Wilson Villalobos100% (1)

- Pour Card 2 - FormatDocument3 pagesPour Card 2 - Formatsyed suleman100% (1)

- ATNM Handrail 2277 DPR 30 03 2023Document1 pageATNM Handrail 2277 DPR 30 03 2023vasantha kumarNo ratings yet

- Expro Production Structural Fabrication and Ga Drawing For Gdu Plant (Mol Seive Adsorber Platform A-B)Document1 pageExpro Production Structural Fabrication and Ga Drawing For Gdu Plant (Mol Seive Adsorber Platform A-B)vasantha kumarNo ratings yet

- Expro ProductionDocument1 pageExpro Productionvasantha kumarNo ratings yet

- ATNM Handrail 2277 DPR 04 04 2023 Report 07Document1 pageATNM Handrail 2277 DPR 04 04 2023 Report 07vasantha kumarNo ratings yet

- ASHOKANDocument2 pagesASHOKANvasantha kumarNo ratings yet

- Expro Production Structural Fabrication and Ga Drawing For Dpcu Plant (Refrigerent Skid)Document1 pageExpro Production Structural Fabrication and Ga Drawing For Dpcu Plant (Refrigerent Skid)vasantha kumarNo ratings yet

- ATNM Handrail 2277 DPR 02 07 2023 Report 35Document1 pageATNM Handrail 2277 DPR 02 07 2023 Report 35vasantha kumarNo ratings yet

- Eps Tank13.10.15 002Document1 pageEps Tank13.10.15 002vasantha kumarNo ratings yet

- Unlocked Equipment CostingDocument39 pagesUnlocked Equipment Costingvasantha kumarNo ratings yet

- C-2101 Sleeve & CollarDocument1 pageC-2101 Sleeve & Collarvasantha kumarNo ratings yet

- Goalsetting 170319080005Document13 pagesGoalsetting 170319080005vasantha kumarNo ratings yet

- Altsnm Chute Misfa Works - DPR - 22.12.2022@12.30AMDocument1 pageAltsnm Chute Misfa Works - DPR - 22.12.2022@12.30AMvasantha kumarNo ratings yet

- IC Resource Histogram 9103Document3 pagesIC Resource Histogram 9103vasantha kumarNo ratings yet

- Manpower HistogramDocument5 pagesManpower Histogramvasantha kumarNo ratings yet

- Itp Tank - 01082023Document4 pagesItp Tank - 01082023vasantha kumarNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- JRC JFE-680 Instruct ManualDocument86 pagesJRC JFE-680 Instruct ManualMark Dominic FedericoNo ratings yet

- Week 1 - NATURE AND SCOPE OF ETHICSDocument12 pagesWeek 1 - NATURE AND SCOPE OF ETHICSRegielyn CapitaniaNo ratings yet

- DOC-20161226-WA0009 DiagramaDocument61 pagesDOC-20161226-WA0009 DiagramaPedroNo ratings yet

- Contemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceDocument25 pagesContemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceGrace06 Labin100% (7)

- LG250CDocument2 pagesLG250CCarlosNo ratings yet

- 08 Activity 1 (10) (LM)Document2 pages08 Activity 1 (10) (LM)Jhanine Mae Oriola FortintoNo ratings yet

- Chapter 7 - Muscular SystemDocument29 pagesChapter 7 - Muscular SystemlNo ratings yet

- Schneider Pressure Switch XMLDocument2 pagesSchneider Pressure Switch XMLhaoNo ratings yet

- CheckList For Checking of Drawings-R1Document4 pagesCheckList For Checking of Drawings-R1jatin kalraNo ratings yet

- 12 Key Principles On Bhava AnalysisDocument28 pages12 Key Principles On Bhava AnalysisDhineshNo ratings yet

- Highway-And-Railroad-Engineering SummaryDocument15 pagesHighway-And-Railroad-Engineering SummaryRodin James GabrilloNo ratings yet

- Port Name: Port of BaltimoreDocument17 pagesPort Name: Port of Baltimoremohd1khairul1anuarNo ratings yet

- Cynosure Starlux 500 Palomar Technical Service ManualDocument47 pagesCynosure Starlux 500 Palomar Technical Service ManualJF SilvaNo ratings yet

- Tugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiDocument4 pagesTugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiFebry SugiantaraNo ratings yet

- Study The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaDocument4 pagesStudy The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaJournal of Nutritional Science and Healthy DietNo ratings yet

- Extract From The Painted Door' by Sinclair RossDocument2 pagesExtract From The Painted Door' by Sinclair RosssajifisaNo ratings yet

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaNo ratings yet

- SambongDocument3 pagesSambongNica Del GallegoNo ratings yet

- Significance of GodboleDocument5 pagesSignificance of GodbolehickeyvNo ratings yet

- FemDocument4 pagesFemAditya SharmaNo ratings yet

- Learning Activity Sheets Introduction To World Religions and Belief SystemDocument56 pagesLearning Activity Sheets Introduction To World Religions and Belief SystemAngelica Caranzo LatosaNo ratings yet

- Piriformis Syndrome: Hardi Adiyatma, Shahdevi Nandar KusumaDocument6 pagesPiriformis Syndrome: Hardi Adiyatma, Shahdevi Nandar Kusumaismael wandikboNo ratings yet

- The Indian Mining Sector: Effects On The Environment & FDI InflowsDocument10 pagesThe Indian Mining Sector: Effects On The Environment & FDI InflowsMehul MandanakaNo ratings yet

- Texto EBAU 1Document2 pagesTexto EBAU 1haridianrm13No ratings yet

- Worksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)Document6 pagesWorksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)AswithNo ratings yet

- Rekomendasi AnimeDocument11 pagesRekomendasi Animeosvaldo manurungNo ratings yet

- Unit 3Document12 pagesUnit 3Erik PurnandoNo ratings yet

- Main Girders: CrossDocument3 pagesMain Girders: Crossmn4webNo ratings yet

- GCSE AstronomyDocument30 pagesGCSE Astronomyharris123mc100% (1)

- H107en 201906 r4 Elcor Elcorplus 20200903 Red1Document228 pagesH107en 201906 r4 Elcor Elcorplus 20200903 Red1mokbelNo ratings yet