Professional Documents

Culture Documents

Carnation Production Flow Chart

Uploaded by

sampriti.roy.589Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carnation Production Flow Chart

Uploaded by

sampriti.roy.589Copyright:

Available Formats

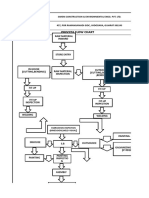

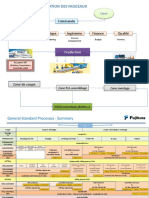

CARNATION CREATIONS PVT. LTD.

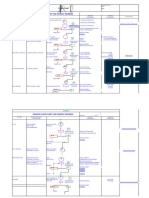

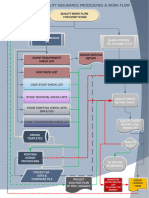

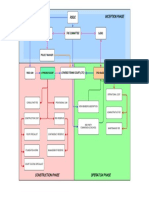

: : Production Process Flow Chart : :

: : Fabric Process Flow : : : : Cutting Process Flow : : : : Garment & Finishing Process Flow : :

FEEDING

FRONT LINE CHECKING REPORT

- a) Counting of cut pieces

- b) arranging

ORDER RECEIVING

RECEIVED FINISHED FABRIC

PLANNING SAMPLING MATERIAL Fabric Received From

- Manpower - FIT Sample SOURCING Inspection Department FUSING

- Material - Size Set Sample

- Machine CUT PLAN & CUT RATIO

RECEIVED FROM PLANNER Thread winding

PP Sample Approval Fabric From Supplier

(By Merchandiser)

Fabric Relaxation STITCHING

FABRIC SPREADING (if needed)

Inspection Fabric Inward Paper Pattern/

Marker Received MARKER MAKING FOR LAY LABELLING

From CAD

Department

Fabric Inspection Shade Check GSM CHECK Fabric Width

- Roll to Roll Shade CUTTING THE LAY

- Within the roll shade variations CHECKING

- Central to Salvage Shade USING CUTTI NG MACHINE END LINE CHECKING REPORT

variation ( different place of the fabric) - Trimming of extra threads Fail

-Assured Repair / Alteration

- Mistake found

- Workers Pass Number Attached

Fabric Relaxation

CHECKING Pass

CUT

COMPONENTS IRONING & FOLDING

TESTING

FINISHING

Washing Test Spirality

SORTING AND NUMBERING

Colour Fastness Soak Test

(For Shrinkage) AND TICKETING

TAGGING

SORTING AND BUNDLING PRINTING /

EMBROIDERY

PACKING

Fabric Inspection Analysis

(Q1, Q2, Q3)

STORE BUNDLES AND

DISPATCH FOR SEWING SECTION

Fail Rechecking

METAL DETECTION TEST

CUTTING

Pass

FINISHED GOODS (CTPAT AREA)

STORAGE AREA

SEGREGATION OF

SIZE & STYLE

CARTOONING

Rechecking Fail

SHIPMENT AUDIT

Pass

SHIPMENT

You might also like

- Moonlight Crochet - Linda DollDocument21 pagesMoonlight Crochet - Linda DollGaAvi Claudia96% (23)

- Fleet Management Guide for Optimal Production, Costs and ProfitsDocument35 pagesFleet Management Guide for Optimal Production, Costs and ProfitsBayu Enasora100% (7)

- Wayne Dobson - Look No Hands PDFDocument18 pagesWayne Dobson - Look No Hands PDFKonoha Magicshop100% (1)

- Technical Textiles - Composites - PDF Test 25 PDocument25 pagesTechnical Textiles - Composites - PDF Test 25 Psayedmorsy100% (1)

- MY SLAM BOOK SampleDocument4 pagesMY SLAM BOOK SampleSamantha Tolentino0% (1)

- Unit 1 Test Upper IntermediateDocument6 pagesUnit 1 Test Upper IntermediateАнастасия ГасинецNo ratings yet

- Recycling and Handicraft: Conserving Resources and Enhancing CreativityDocument2 pagesRecycling and Handicraft: Conserving Resources and Enhancing CreativityCharmaigne Mendrez100% (9)

- Cemetery Index For Bear Grass, Martin County NCDocument17 pagesCemetery Index For Bear Grass, Martin County NCTaneya100% (2)

- Spreading SopDocument3 pagesSpreading SopTANYA TANYANo ratings yet

- Manufacturing Control ProcessDocument9 pagesManufacturing Control ProcessDadang AbdurrazakNo ratings yet

- Appendix - IX Plant LayoutDocument9 pagesAppendix - IX Plant LayoutniftNo ratings yet

- Courtesy by MODEC, Inc. Courtesy by MODEC, Inc.: The Yokohama Rubber Co., LTDDocument2 pagesCourtesy by MODEC, Inc. Courtesy by MODEC, Inc.: The Yokohama Rubber Co., LTDlalitNo ratings yet

- Process flow chart for primary structural steel fabricationDocument3 pagesProcess flow chart for primary structural steel fabricationmadhu krishnaNo ratings yet

- Industry Occupational MappingDocument46 pagesIndustry Occupational MappingRanjit DasNo ratings yet

- CIM DatabaseDocument14 pagesCIM Databasenuha zargarNo ratings yet

- Company Procurement Flow ChartDocument3 pagesCompany Procurement Flow Chart01095902062ahmedNo ratings yet

- Process Flow Chart: Simem Construction & Environmental Engg. Pvt. LTDDocument5 pagesProcess Flow Chart: Simem Construction & Environmental Engg. Pvt. LTDBharat PatilNo ratings yet

- F1 - Process Flow Chart Fabrication - BeamsDocument2 pagesF1 - Process Flow Chart Fabrication - BeamssurwaneNo ratings yet

- DQMS-QA-WRKFLWDocument1 pageDQMS-QA-WRKFLWAli hassanNo ratings yet

- Merchandising Flow ChartDocument1 pageMerchandising Flow ChartshahinrezaNo ratings yet

- SOP CAD Department Production PlanningDocument12 pagesSOP CAD Department Production PlanningAmrita MitraNo ratings yet

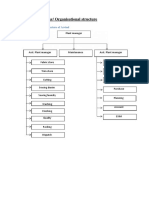

- About The Company/ Organisational Structure: Plant ManagerDocument4 pagesAbout The Company/ Organisational Structure: Plant Managerparash rajNo ratings yet

- Quality Plan CharcoalDocument2 pagesQuality Plan CharcoalPT. Estupedo Agri MakmurNo ratings yet

- BAGGINGDocument1 pageBAGGINGFredrick OtienoNo ratings yet

- Processus de Fabrication Des Faisceaux: CommandeDocument4 pagesProcessus de Fabrication Des Faisceaux: CommandeMOUAD BELKHALIFANo ratings yet

- SOP Flow ChartDocument3 pagesSOP Flow Chartuniformwork draftingNo ratings yet

- Fabric inspection flowchartDocument1 pageFabric inspection flowchartMd.Sadequl IslamNo ratings yet

- Syneverse - Industry AutomationDocument20 pagesSyneverse - Industry AutomationgkdexelNo ratings yet

- Form Inspection JIS RFITDocument7 pagesForm Inspection JIS RFITBadrunNo ratings yet

- HEC WORKFLOW - 20231107 - v0 - AmjadDocument1 pageHEC WORKFLOW - 20231107 - v0 - AmjadUsama RahatNo ratings yet

- Process Flow Diagram (PFD) : Casting Out Source ProcessDocument1 pageProcess Flow Diagram (PFD) : Casting Out Source ProcessPRAMODNo ratings yet

- Total Quality Management: SIPOC Diagram For Irfan TextilesDocument9 pagesTotal Quality Management: SIPOC Diagram For Irfan TextileszainNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- RM Unloading to StoringDocument1 pageRM Unloading to Storingpakaya tamaNo ratings yet

- CBR Laboratory Test AASHTO T 193 - 81: Water ContentDocument2 pagesCBR Laboratory Test AASHTO T 193 - 81: Water Contentivan100% (1)

- Supplier FMEA for ERW tube processDocument1 pageSupplier FMEA for ERW tube processrohitNo ratings yet

- Kunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsDocument2 pagesKunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsSandeep VermaNo ratings yet

- CBR Laboratory Test AASHTO T 193 - 81: Water ContentDocument2 pagesCBR Laboratory Test AASHTO T 193 - 81: Water ContentivanNo ratings yet

- Process Flow PDFDocument2 pagesProcess Flow PDFSakshiNo ratings yet

- Dfma WorkflowDocument1 pageDfma WorkflowAljohn AmbatNo ratings yet

- Client: Aramco Overseas Company B.V. & Sumitomo Chemical Co., LTDDocument1 pageClient: Aramco Overseas Company B.V. & Sumitomo Chemical Co., LTDJaime FlaminianoNo ratings yet

- Incoming Material ChecklistDocument1 pageIncoming Material ChecklistPrathvi Raj SinghNo ratings yet

- MRP V4 PDFDocument32 pagesMRP V4 PDFRx DentviewNo ratings yet

- QC Inspection ProcedureDocument48 pagesQC Inspection ProcedureGIRISH GIRINo ratings yet

- Ache Manufacturing Process - Pembangunan Mini LPG Plant 2.2 MMSCFDDocument1 pageAche Manufacturing Process - Pembangunan Mini LPG Plant 2.2 MMSCFDbayu kusumaNo ratings yet

- Liquid Parenteral SCDocument3 pagesLiquid Parenteral SCKamran AlamNo ratings yet

- SIPOC - EjemploDocument1 pageSIPOC - EjemploHugo JuarezNo ratings yet

- Process Flow Chart: Stocks/ Raw Mats./ArtworksDocument1 pageProcess Flow Chart: Stocks/ Raw Mats./ArtworksJotechPackagingNo ratings yet

- MCR Engineering Room SystemsDocument1 pageMCR Engineering Room SystemsJan Richardo GultomNo ratings yet

- Tailoring Ncii Workshop Lay-Out: Entrance/ ExitDocument1 pageTailoring Ncii Workshop Lay-Out: Entrance/ ExitWendy ArnidoNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Emperor Textiles Private Limited Organizational StructureDocument1 pageEmperor Textiles Private Limited Organizational StructurePace SalemNo ratings yet

- Checkpoint of Final Inspection Check of Tyres After CurringDocument2 pagesCheckpoint of Final Inspection Check of Tyres After CurringDilnesa EjiguNo ratings yet

- Asme Sa-106 Sa 516 Sa193 Sa194 B16.5 B16.9 B16.11-1Document8 pagesAsme Sa-106 Sa 516 Sa193 Sa194 B16.5 B16.9 B16.11-1Farid Ahmed KhwajaNo ratings yet

- DQMS-QC-WRKFLWDocument1 pageDQMS-QC-WRKFLWAli hassanNo ratings yet

- Material Control Flow ChartDocument8 pagesMaterial Control Flow CharthosseinNo ratings yet

- QAP (Honeycomb Fabric)Document4 pagesQAP (Honeycomb Fabric)Ahamed UmarNo ratings yet

- Org Ani GramDocument1 pageOrg Ani GramGerald OdayenNo ratings yet

- Supplier Process FMEA for ERW TubeDocument1 pageSupplier Process FMEA for ERW TuberohitNo ratings yet

- SQP - StructuralDocument3 pagesSQP - Structuralmukherjeemohul25No ratings yet

- Quality inspection plan for dyed and printed finished fabricDocument3 pagesQuality inspection plan for dyed and printed finished fabricITOPS TeamNo ratings yet

- Daily compaction reportDocument2 pagesDaily compaction reportSami AjNo ratings yet

- Risk Management Business ModelDocument1 pageRisk Management Business ModelWan Mohamad Noor Hj IsmailNo ratings yet

- Warehouse Management SystemsDocument5 pagesWarehouse Management SystemsRidho AnjikoNo ratings yet

- SIM KUI HUA CONSTRUCTION PERIODICAL REVIEWDocument10 pagesSIM KUI HUA CONSTRUCTION PERIODICAL REVIEWHaji Mohd DimyatiNo ratings yet

- Baby Pumpkin: Designed by Jo Handmade DesignDocument4 pagesBaby Pumpkin: Designed by Jo Handmade DesignCarls Jr100% (1)

- Among Us CaptainDocument10 pagesAmong Us CaptainVlad Burko100% (3)

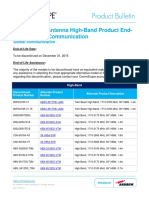

- PB 109438 en High Band EolDocument4 pagesPB 109438 en High Band EolSarsij MishraNo ratings yet

- Dean Whitehead - Creative CV 2020 - Version 2Document1 pageDean Whitehead - Creative CV 2020 - Version 2api-509245608No ratings yet

- Structural Wood Products and Systems PDFDocument105 pagesStructural Wood Products and Systems PDFCharbel Saad SaadNo ratings yet

- Card Rogue Rulebook v1Document30 pagesCard Rogue Rulebook v1Tony LeMesmerNo ratings yet

- Phrasal Verbs ActivityDocument1 pagePhrasal Verbs ActivityDina FernandezNo ratings yet

- Rocket Ship ContainerDocument17 pagesRocket Ship ContainerJanel Lucena100% (1)

- QST Dec 1923Document156 pagesQST Dec 1923Ettel YuangNo ratings yet

- Winter Blanket KAL Knitting Pattern For Christmas in Debbie Bliss Rialto 2NDK 2Document9 pagesWinter Blanket KAL Knitting Pattern For Christmas in Debbie Bliss Rialto 2NDK 2alevegalv2No ratings yet

- Abby ResumeDocument1 pageAbby Resumeapi-276943309No ratings yet

- Berni The ElephantDocument18 pagesBerni The ElephantMariana Sol100% (2)

- 25 Mind Reading SecretsDocument10 pages25 Mind Reading Secretsspippol0No ratings yet

- The Postcard Legacy ChallengeDocument33 pagesThe Postcard Legacy ChallengeElizabeth ONo ratings yet

- T Eal 1646368590 Hobbies Esl Beginner Reading and Writing Ver 1Document5 pagesT Eal 1646368590 Hobbies Esl Beginner Reading and Writing Ver 1YaniraNo ratings yet

- Take It Very Much Further Away From The PhotographDocument11 pagesTake It Very Much Further Away From The PhotographDoğan AkbulutNo ratings yet

- Photography Is The Process of Recording Visual Images by Capturing Light Rays On A LightDocument10 pagesPhotography Is The Process of Recording Visual Images by Capturing Light Rays On A LightTubor AwotuboNo ratings yet

- Sports AchievementsDocument12 pagesSports AchievementsUmesh MauryaNo ratings yet

- Unit 13 Hobbies Reading and SpeakingDocument31 pagesUnit 13 Hobbies Reading and SpeakingHoji ChannelNo ratings yet

- 7 8 Tle Handicraft w6 w7 RevalidatedDocument12 pages7 8 Tle Handicraft w6 w7 RevalidatedPATANI, AIRA MARIE B.100% (1)

- 73 Magazine - August 2002Document68 pages73 Magazine - August 2002radioscribdNo ratings yet

- Woodworking For Beginners Step-By-Step Gu - Tom FosterDocument105 pagesWoodworking For Beginners Step-By-Step Gu - Tom FosterLalu budi SetiawanNo ratings yet

- Giáo Án Tiếng Anh Lớp 7 Thí ĐiểmDocument243 pagesGiáo Án Tiếng Anh Lớp 7 Thí ĐiểmMichiGoGDNo ratings yet