Professional Documents

Culture Documents

Fabric inspection flowchart

Uploaded by

Md.Sadequl IslamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabric inspection flowchart

Uploaded by

Md.Sadequl IslamCopyright:

Available Formats

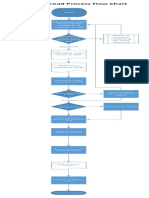

SKYLINE GROUP

Fabric Inspection Flow - Chart

Fabric in House from supplier

Fabric Inventory Make Report &send to

Merchandiser.

Pass

Roll Head Cutting Fabric

Inspection 10%

Shade Blanket & Shrinkage Test Fabric Twisting Check & Fail

Cut Make Report

Pass

Again 15%

Inform to

Inspection

G Merchandiser

Pass

Fail

Make Shade Blanket, Shrinkage

Test Panels and Send to Wash

Pass

Inspection fails

Fail

Again 100%Roll report send to

Make After Wash

Inspection& Merchandiser.

& Before Wash

Fail Keep Separate

Blanket After Wash Blanket Check

Rejected Roll

with Approved Lab Dip or

Counter Sample in the

Light Box.

Send the Rejected

Pass Fabrics to Rejection

Make Color Continuity Fail Re Shrinkage & Re- Goods Keeping Area

After Wash check with Washing

Control Card by Using All

Shrinkage Check Plant

Shade Swatches (8” x 6”).

Make Clear Which Shade Pass

is Using for Which Make Shrinkage

Country. Report

Report Issue to Cad Submit to GPQ., Cutting, Sewing,

Department for making Make Shade Band Chart Finishing & Packing Section

Shrinkage Wise Pattern

Shade & Shrinkage wise Fabric

issue to Cutting

You might also like

- 4 Point SystemDocument5 pages4 Point SystemAdnan QayumNo ratings yet

- Drugs To Avoid in Myasthenia GravisDocument3 pagesDrugs To Avoid in Myasthenia GravispapitomalosoNo ratings yet

- Internal Audit Checklist For Garments Manufacturing IndustryDocument7 pagesInternal Audit Checklist For Garments Manufacturing Industrysunny saroarNo ratings yet

- Fabric Inspector ProcedureDocument7 pagesFabric Inspector ProcedureSayed Aasim JawaidNo ratings yet

- Manage Business Operations with ACCNUDocument2 pagesManage Business Operations with ACCNUEmphorasoft gmailNo ratings yet

- APPAREL INTERNSHIP at SSAL 1Document25 pagesAPPAREL INTERNSHIP at SSAL 1aarushi100% (1)

- Merchandising Process Report for Triburg Spring 12Document37 pagesMerchandising Process Report for Triburg Spring 12Divya SrivastavaNo ratings yet

- Costing Techiniques in Apparel IndustryDocument16 pagesCosting Techiniques in Apparel Industrymahe_ftNo ratings yet

- Social Media Audit TemplateDocument43 pagesSocial Media Audit Templatesocial.blincNo ratings yet

- Manage pre-production with critical pathDocument6 pagesManage pre-production with critical pathSiddharth JhaNo ratings yet

- Apparel Merchandising - Types of BuyersDocument24 pagesApparel Merchandising - Types of BuyersNithyaprakashNo ratings yet

- Garment Industry DepartmentsDocument61 pagesGarment Industry DepartmentsDeepthi SonuNo ratings yet

- Course Guide Book of Garment CostingDocument5 pagesCourse Guide Book of Garment Costingwendosen seifeNo ratings yet

- Textile Printing: Sri Lanka Institute of Texte & ApparelDocument40 pagesTextile Printing: Sri Lanka Institute of Texte & ApparelAjith SatyapalaNo ratings yet

- Industry Visit Report of Sai Baba Garments: BY - Ashish Bhuwania BFT/17/381Document8 pagesIndustry Visit Report of Sai Baba Garments: BY - Ashish Bhuwania BFT/17/381ravikantNo ratings yet

- 2 Manufacturing and Production Information SystemsDocument3 pages2 Manufacturing and Production Information SystemsJai GaizinNo ratings yet

- Avanced Apparel Manufacturing ManagementDocument6 pagesAvanced Apparel Manufacturing ManagementRAVIKANT DEONo ratings yet

- Pre-production process overviewDocument7 pagesPre-production process overviewsanyaNo ratings yet

- Dry Cleaning Fastness TestDocument5 pagesDry Cleaning Fastness TestAkriti Dixit0% (1)

- Corporate Finance Case NPV AnalysisDocument5 pagesCorporate Finance Case NPV AnalysisRohit RahangdaleNo ratings yet

- Social Media Posting ScheduleDocument1 pageSocial Media Posting ScheduleRoHit ShaRmaNo ratings yet

- Sewing Thread Process Flow ChartDocument1 pageSewing Thread Process Flow ChartMunem Shahriar100% (1)

- Internal Audit Checklist of Garments Manufacturing Industry - Garments AcademyDocument6 pagesInternal Audit Checklist of Garments Manufacturing Industry - Garments AcademyAriful HasanNo ratings yet

- Training ScheduleDocument3 pagesTraining ScheduleJonathan TanNo ratings yet

- Tailoring UnitDocument8 pagesTailoring UnitSuresh sureshNo ratings yet

- 1-Day Awareness Course On Co$T of Quality: Presented by Neville-Clarke InternationalDocument85 pages1-Day Awareness Course On Co$T of Quality: Presented by Neville-Clarke Internationaldyogasara2No ratings yet

- Cutting Section SOPDocument4 pagesCutting Section SOPsok daraNo ratings yet

- Sewing Quality Control SOPDocument3 pagesSewing Quality Control SOPsok daraNo ratings yet

- Uaq Jury 1 PDFDocument17 pagesUaq Jury 1 PDFBhagya MNo ratings yet

- Process Flow and Activities of Garment Sample MakingDocument5 pagesProcess Flow and Activities of Garment Sample MakingRana Muhammad Arif KhanNo ratings yet

- Machinery, Manpower Planning in Garment IndustryDocument12 pagesMachinery, Manpower Planning in Garment IndustryPRIYANKA GADENo ratings yet

- ZCC+Features ListDocument7 pagesZCC+Features ListMirjana EricNo ratings yet

- Skirt Garment Breakdown 1Document1 pageSkirt Garment Breakdown 1MriNo ratings yet

- Policy for Sewing Floor ManagementDocument3 pagesPolicy for Sewing Floor ManagementAmit hasanNo ratings yet

- SDL ATLAS TextileDocument1 pageSDL ATLAS TextilesamsinternationalNo ratings yet

- Resume AfreenDocument3 pagesResume AfreenAfreen YunusNo ratings yet

- Dyeing and Printing DefectsDocument35 pagesDyeing and Printing DefectsGemeda GebinoNo ratings yet

- H&M AQL Table RequirementDocument4 pagesH&M AQL Table RequirementMoklesur RahmanNo ratings yet

- ZSK Machines BrochureDocument44 pagesZSK Machines BrochureThiagarajan LakhsmananNo ratings yet

- MEN'S CASUAL HALF SLEEVE SHIRT TECH PACKDocument23 pagesMEN'S CASUAL HALF SLEEVE SHIRT TECH PACKAbhinav AshishNo ratings yet

- Section - I Company Overview: Aquarelle India Pvt. LTDDocument79 pagesSection - I Company Overview: Aquarelle India Pvt. LTDShivasrri SethuramanNo ratings yet

- Aquarelle Kanban Production System: Material FlowDocument2 pagesAquarelle Kanban Production System: Material FlowSharvari ShankarNo ratings yet

- Standard Operating Procedure IN Cutting Section: Pranshu Gupta Arvind Lifestyle Apparels - Shirting DivisionDocument8 pagesStandard Operating Procedure IN Cutting Section: Pranshu Gupta Arvind Lifestyle Apparels - Shirting DivisionpranshuNo ratings yet

- Babylon GroupDocument24 pagesBabylon GroupFarzana IshratNo ratings yet

- Kohl's - Packing Requirment'sDocument8 pagesKohl's - Packing Requirment'sDebashishDolonNo ratings yet

- Industrial Engineering PresentationDocument13 pagesIndustrial Engineering PresentationKent RodriguezNo ratings yet

- Time LogDocument4 pagesTime LogFelicia GhicaNo ratings yet

- Balancing Simulation-2008 PDFDocument12 pagesBalancing Simulation-2008 PDFAnonymous wA6NGuyklDNo ratings yet

- Apparel Internship Report 2021 Sai Creations NoidaDocument55 pagesApparel Internship Report 2021 Sai Creations NoidaPreeti Baheti0% (1)

- Apparel Quality Management and Control TechniquesDocument9 pagesApparel Quality Management and Control TechniquesMekuria Melkamu100% (1)

- Brother Sewing Machine S7250aDocument88 pagesBrother Sewing Machine S7250aDavid Andres Ducuara MayorgaNo ratings yet

- Technology Cutting Room PDFDocument3 pagesTechnology Cutting Room PDFShubham TilaraNo ratings yet

- Pre-Production Process Production Process Post-Production ProcessDocument2 pagesPre-Production Process Production Process Post-Production ProcessDevjyoti ShawNo ratings yet

- JOB Analysis Report (Naveena Denim Mills)Document4 pagesJOB Analysis Report (Naveena Denim Mills)NomanNo ratings yet

- Productvity and Quality ManagementDocument38 pagesProductvity and Quality ManagementNikunj AgrawalNo ratings yet

- Apparel Internship Document PDFDocument117 pagesApparel Internship Document PDFAnkitaKumar100% (1)

- Stree MGMT of T.C Terrytex Ltd.Document55 pagesStree MGMT of T.C Terrytex Ltd.Mahfooz IlahiNo ratings yet

- Tls ReportDocument19 pagesTls Reportsharanabasava malipatilNo ratings yet

- Skyline Group: Flow Chart For FinishingDocument1 pageSkyline Group: Flow Chart For FinishingMd.Sadequl IslamNo ratings yet

- STANDARD OPERATING PROCEDURE FOR FABRIC STOREDocument8 pagesSTANDARD OPERATING PROCEDURE FOR FABRIC STOREAnkita SinghNo ratings yet

- Skyline Group: Flow Chart For Packing DepartmentDocument1 pageSkyline Group: Flow Chart For Packing DepartmentMd.Sadequl IslamNo ratings yet

- Skyline Group: Flow Chart Cutting DepartmentDocument1 pageSkyline Group: Flow Chart Cutting DepartmentMd.Sadequl IslamNo ratings yet

- Skyline Group: Flow Chart For FinishingDocument1 pageSkyline Group: Flow Chart For FinishingMd.Sadequl IslamNo ratings yet

- 1.shrinkage ProcedureDocument1 page1.shrinkage ProcedureMd.Sadequl IslamNo ratings yet

- Importance: HighDocument2 pagesImportance: HighMd.Sadequl IslamNo ratings yet

- Nur Group Company ProfileDocument22 pagesNur Group Company Profilesamin3shohelNo ratings yet

- Mollie Makes ChristmasDocument102 pagesMollie Makes ChristmasPaul Draper100% (4)

- 03-ASTM - Technical - Training-081518-R1 Random Tumble Pilling TestDocument51 pages03-ASTM - Technical - Training-081518-R1 Random Tumble Pilling TestTahir NizamNo ratings yet

- Bloodborne Hunter - Cosplay GuideDocument51 pagesBloodborne Hunter - Cosplay Guidemegalo28No ratings yet

- HISTORY OF SILkDocument3 pagesHISTORY OF SILkAzmirul Morsalin TanzilNo ratings yet

- Tulip Garden: Designed by Wendy Sheppard Featuring Abigail Blue by Mary KovalDocument18 pagesTulip Garden: Designed by Wendy Sheppard Featuring Abigail Blue by Mary KovalPetya Kirilova ManevaNo ratings yet

- some thinks design hanging decorspringDocument23 pagessome thinks design hanging decorspringTiduj RácsibNo ratings yet

- Tle 3rd Quarter ExamDocument5 pagesTle 3rd Quarter ExamJudilyn Llamas LabendiaNo ratings yet

- Polushka Bunny Mouse Outfit MIMI 1Document7 pagesPolushka Bunny Mouse Outfit MIMI 1hanıfe ak100% (6)

- Ariel The MermaidDocument26 pagesAriel The MermaidPopescu DianaNo ratings yet

- Abstract:: Name Muhammad Hamza and Abdul Rehman Registration Number 18-NTU-0106 and 007 Techonolgy GM 4Document5 pagesAbstract:: Name Muhammad Hamza and Abdul Rehman Registration Number 18-NTU-0106 and 007 Techonolgy GM 4Muhammad Hamza 18-NTU-0106No ratings yet

- Crochet - Pattern No 1716 Sunflower by KrawkaDocument9 pagesCrochet - Pattern No 1716 Sunflower by KrawkaNana Realuyo100% (4)

- Analyzing The Cost Structure of Garments From Fiber To FashionDocument3 pagesAnalyzing The Cost Structure of Garments From Fiber To FashionProf Dr Kathirrvelu SubramanianNo ratings yet

- Restoration and Conservation of TextilesDocument78 pagesRestoration and Conservation of TextilesCrisencio M. PanerNo ratings yet

- Basic Warp Knitting PrincipleDocument8 pagesBasic Warp Knitting PrincipleTamanna Ahmed100% (1)

- Tibetan Hand Knotted Carpet: History, Process & DefectsDocument13 pagesTibetan Hand Knotted Carpet: History, Process & DefectsSumit SagarNo ratings yet

- New Home:New National Hand Crank Machine Sewing Machine Instruction ManualDocument10 pagesNew Home:New National Hand Crank Machine Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Fox - Little Owlet-EngDocument13 pagesFox - Little Owlet-EngJorge Omar Diaz Martinez100% (5)

- Marie Pencil Skirt InstructionsDocument3 pagesMarie Pencil Skirt InstructionsMonika SalNo ratings yet

- Cirrus: Expression Fiber ArtsDocument9 pagesCirrus: Expression Fiber ArtsRogan100% (1)

- Crochet Crazy Dragon PDF Amigurumi Free PatternDocument7 pagesCrochet Crazy Dragon PDF Amigurumi Free PatternAmber Clé100% (1)

- Buttonhole MachinesDocument12 pagesButtonhole Machinesskknitman100% (1)

- 108 Kinnauri ShawlDocument40 pages108 Kinnauri ShawlArchana0% (1)

- Modified Activity Sheets in Tle 7 DressmakingDocument6 pagesModified Activity Sheets in Tle 7 DressmakingKeith Pujante100% (5)

- Lion Brand Yarns: Jump To Navigationjump To SearchDocument4 pagesLion Brand Yarns: Jump To Navigationjump To SearchLittle SpidermanNo ratings yet

- Flytech Aviation Academy English Grammar Work BookDocument21 pagesFlytech Aviation Academy English Grammar Work BooktanmayNo ratings yet

- Dimensional Stability To Washing (ISO 3759)Document5 pagesDimensional Stability To Washing (ISO 3759)Md MasumNo ratings yet

- Inside Crochet 87Document100 pagesInside Crochet 87Екатерина Матушинец100% (2)

- Mach2xs enDocument2 pagesMach2xs enAslepNo ratings yet

- Tle8 - Week-1-DressmakingDocument5 pagesTle8 - Week-1-DressmakingDonna Joy Garcia CanoNo ratings yet