Professional Documents

Culture Documents

Foot A3

Uploaded by

kheang mengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foot A3

Uploaded by

kheang mengCopyright:

Available Formats

Project

Address

Report

GRAITEC INNOVATION Designed by Date

www.graitec.com Verified by Date

17 Burospace 91572 Bièvres Revision A Drawing S

Reinforced concrete footing

Table of Contents

1 Geometry................................................................................................................................. 2

2 Soil input.................................................................................................................................. 2

3 Loads and combinations......................................................................................................... 3

4 Global assumptions................................................................................................................. 4

4.1 Localisation...................................................................................................................................4

4.2 Units..............................................................................................................................................5

4.3 Materials........................................................................................................................................5

4.4 Concrete covers.............................................................................................................................5

5 Design assumptions................................................................................................................. 6

6 Bearing resistance check......................................................................................................... 7

6.1 Bearing resistance assumptions.....................................................................................................7

6.2 Bearing resistance verification......................................................................................................7

7 Load eccentricity..................................................................................................................... 7

7.1 Compressed surface verification...................................................................................................7

7.2 Simplified eccentricity verification...............................................................................................8

7.2.1 Ellipse interaction verification..........................................................................................8

8 Sliding verification.................................................................................................................. 8

8.1 Sliding verifications at ULS..........................................................................................................8

9 Overturning verification......................................................................................................... 9

10 Settlement verification.......................................................................................................... 10

11 Longitudinal reinforcement................................................................................................. 11

11.1 Footing reinforcement calculation..............................................................................................11

11.2 Supported element reinforcement...............................................................................................14

12 Stresses................................................................................................................................... 15

13 Crack width check................................................................................................................. 16

14 Punching shear check........................................................................................................... 18

15 Bill of materials..................................................................................................................... 19

Advance Design RC Footing 2024 Page 1 of 19

Project: Date: 12-05-2023

1 Geometry

Type of footing : ISOLATED FOOTING

Geometry description Altitude level (mm)

Footing (mm) Supported element (mm) Footing SE

Width Length Height Width Length Height Top Bottom Top

1700.00 1700.00 400.00 600.00 200.00 700.00 -600.00 -1000.00 100.00

Supported element position

Left

Right

Rear

Front

Element under footing

Type of element under footing Blinding concrete

Thickness of element 50.00 mm Not frozen

2 Soil input

No top level for water sheet.

Advance Design RC Footing 2024 Page 2 of 19

Project: Date: 12-05-2023

No bottom level for water sheet.

Soil layers

Min/Max Weight Friction Cohesion

Soil layer Depth Condition angle Type

(mm) (kN/m³) (MPa)

1 - Peat 0.00 / Drained 18.00 25.00 ° 0.01 Cohesive

-300.00 Undrained 18.00 0.00 ° 0.02

2 - Mud, clay(good cohesion) -300.00 / Drained 21.00 30.00 ° 0.06 Cohesive

-800.00 Undrained 21.00 0.00 ° 0.08

3 - Clay (stiff) -800.00 / Drained 19.00 25.00 ° 0.02 Cohesive

- Undrained 19.00 0.00 ° 0.03

Soil layers

Soil layer Poisson's Oedometric Young Menard

ratio modulus modulus modulus

1 - Peat 0.20 0.78 0.70 0.70 1.00

2 - Mud, clay(good cohesion) 0.20 1.67 1.50 0.99 0.66

3 - Clay (stiff) 0.25 6.00 5.00 3.30 0.66

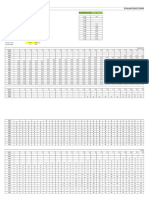

3 Loads and combinations

Load cases description

γEQU γSTR

ID Title Ψ₀ Ψ₁ Ψ₂ γEQU γSTR

Fav Fav

1 G - - - 1.1 1.35 0.9 1

2 Q 0.7 0.5 0.3 1.5 1.5 0 0

3 WX+S 0.5 0.2 0 1.5 1.5 0 0

4 WX+D 0.5 0.2 0 1.5 1.5 0 0

5 WX+S2 0.5 0.2 0 1.5 1.5 0 0

6 WX+D2 0.5 0.2 0 1.5 1.5 0 0

7 WX+S3 0.5 0.2 0 1.5 1.5 0 0

8 WX+D3 0.5 0.2 0 1.5 1.5 0 0

9 WX-S 0.5 0.2 0 1.5 1.5 0 0

10 WX-D 0.5 0.2 0 1.5 1.5 0 0

11 WX-S2 0.5 0.2 0 1.5 1.5 0 0

12 WX-D2 0.5 0.2 0 1.5 1.5 0 0

13 WX-S3 0.5 0.2 0 1.5 1.5 0 0

14 WX-D3 0.5 0.2 0 1.5 1.5 0 0

15 WY+S 0.5 0.2 0 1.5 1.5 0 0

16 WY+D 0.5 0.2 0 1.5 1.5 0 0

17 WY-S 0.5 0.2 0 1.5 1.5 0 0

18 WY-D 0.5 0.2 0 1.5 1.5 0 0

19 Forces Max - - - 1 1 1 1

20 Forces Min - - - 1 1 1 1

Advance Design RC Footing 2024 Page 3 of 19

Project: Date: 12-05-2023

Loads

Load Load case V

name (kN) (kN⋅m) (kN⋅m) (kN) (kN)

1 1-G 43.09 0.00 0.00 -15.31 0.87

2 2-Q 29.46 0.00 0.00 -16.04 0.00

3 3 - WX+S -27.31 0.00 0.00 12.25 0.00

4 4 - WX+D -9.29 0.00 0.00 7.11 0.00

5 5 - WX+S2 -6.22 0.00 0.00 0.69 0.00

6 6 - WX+D2 13.77 0.00 0.00 -5.31 0.00

7 7 - WX+S3 -14.90 0.00 0.00 10.50 0.00

8 8 - WX+D3 7.49 0.00 0.00 2.57 0.00

9 9 - WX-S -45.05 0.00 0.00 25.14 0.01

10 10 - WX-D -20.70 0.00 0.00 16.98 0.00

11 11 - WX-S2 -6.15 0.00 0.00 1.97 0.00

12 12 - WX-D2 30.90 0.00 0.00 -9.78 0.00

13 13 - WX-S3 -37.38 0.00 0.00 11.19 0.00

14 14 - WX-D3 -5.84 0.00 0.00 1.45 0.00

15 15 - WY+S -44.99 0.00 0.00 26.08 0.00

16 16 - WY+D -16.12 0.00 0.00 15.47 0.00

17 17 - WY-S -48.24 0.00 0.00 22.78 0.00

18 18 - WY-D -17.26 0.00 0.00 14.27 0.00

19 19 - Forces Max 125.53 0.00 0.00 -52.07 1.17

20 20 - Forces Min 58.17 0.00 0.00 -20.67 1.16

Load on ground G 1-G 0.00 - - - -

Load on ground Q 2-Q 0.00 - - - -

Position of force components:

dx = 0.00 mm

dy = 0.00 mm

dz = 0.00 mm / top level of

footing

4 Global assumptions

Calculation according to EN1990 / EN 1991 / EN1992-1-1

4.1 Localisation

Localisation United Kingdom

Element type Isolated Footing

Element ID 5

Position Footing 1, Level 1

Drawing S

Level

Advance Design RC Footing 2024 Page 4 of 19

Project: Date: 12-05-2023

Coordinates X = 0.00 mm; Y = 0.00 mm; Z = 0.00 mm

4.2 Units

Lengths mm

Forces kN

Moments kN⋅m

Stresses MPa (N/mm²)

Angles °

Reinforcement areas mm²

Crack width mm

4.3 Materials

Concrete quality (EN1992-1-1 / 3.1)

Concrete class: C25/30

ULS :

ULS-A :

ULS-S :

Steel grade (EN1992-1-1 / Section 3 / Annex C)

Steel grade: B500A

Ductility class: A

Horizontal plastic branch

k = 1.05

ULS:

ULS-A:

ULS-S:

4.4 Concrete covers

Advance Design RC Footing 2024 Page 5 of 19

Project: Date: 12-05-2023

Exposure class XC2 (§4.2)

Structural class S4 (Table 4.3)

Concrete covers (§4.4.1)

Nominal concrete cover (mm) Minimal values (mm)

Top Bottom Lateral

50.00 50.00 50.00 35.00 0.00

Minimal cover value for durability (§4.4.1.2 (5))

Execution tolerance (§4.4.1.1 2(P))

Security tolerance (§4.4.1.2 (6))

Reduction for stainless steel (§4.4.1.2 (7))

Reduction for supplementary protection (§4.4.1.2 (8))

5 Design assumptions

Global design assumptions

Earth loads and overloads on the footing are taken into account for the calculation of the cross sectional

areas of steel in the footing.

Self weight of the footing is considered for reinforcement calculation.

Longitudinal reinforcement design method when no bending moment is defined: Strut-and-tie method

Earthquake codes not taken into account.

Iteration step for calculation of the cross section area of steel is 10.00 mm²

Pedestal self weight taken into account.

Design approach 1

Bearing capacity assumptions

The contact pressure distribution is linear.

The net allowable soil bearing pressure is user-defined.

The inclination factors of the load are taken into account.

Bearing soil behaviour: Cohesive soil (or intermediate).

The soil bearing verification for SLS conditions is not performed.

Sliding assumptions

Type: In-situ member

The friction angle between the soil and the footing: δ = 1 φ’

Load eccentricity assumptions

The footing area in compression must be at least equal to:

7 % of total base area at ULS fundamental/accidental/seismic.

50 % of total base area at SLS characteristic.

67 % of total base area at SLS quasi-permanent/frequent.

Partial factors for soil parameters

Advance Design RC Footing 2024 Page 6 of 19

Project: Date: 12-05-2023

Soil parameter Symbol Set 1 (M1) Set 2 (M2)

Angle of shearing resistance * 1.00 1.25

Effective cohesion 1.00 1.25

Undrained shear strength 1.00 1.40

Unconfined strength 1.00 1.40

Weight density 1.00 1.00

Friction resistance (seismic) 1.25 1.25

* This factor is applied to tan φ'

Partial resistance factors

Resistance Symbol R1

Bearing (ULS) 1.00

Bearing (SLS) 3.00

Sliding (ULS) 1.00

6 Bearing resistance check

6.1 Bearing resistance assumptions

The contact pressure distribution is linear.

The net allowable soil bearing pressure is user-defined.

The inclination factors of the load are taken into account.

Foundation inclination: 0.00 °.

Bearing soil behaviour: Cohesive soil (or intermediate).

Contact pressure distribution: Linear

6.2 Bearing resistance verification

Drained ULS

Combination: 546: 1.35x[1 G]+1x[19 ENV]+1.05x[2 Q]+0.75x[12 V]

Vertical load

Overburden pressure:

Maximum stress

Design value of soil resistance

(D.4) from EN 1997-1

Total footing bearing area A' = 2890000.00 mm²

Soil bearing capacity (impose)

Ground failure resistance

(6.5.2.1) from EN 1997-1 (17.97%) Passed

Undrained ULS

No ULS combination under undrained conditions.

7 Load eccentricity

7.1 Compressed surface verification

Advance Design RC Footing 2024 Page 7 of 19

Project: Date: 12-05-2023

ULS combination 147: 0.9x[1 G]+1.5x[15 V]

Compressed surface verification

8.17 % (Passed)

SLS QP combination 651: 1x[1 G]+0.3x[2 Q]

Compressed surface verification

67.00 % (Passed)

SLS CQ combination 569: 1x[1 G]+1x[2 Q]

Compressed surface verification

50.00 % (Passed)

SLS FQ combination 618: 1x[1 G]+0.5x[2 Q]

Compressed surface verification

67.00 % (Passed)

7.2 Simplified eccentricity verification

7.2.1 Ellipse interaction verification

ULS combination 147: 0.9x[1 G]+1.5x[15 V]

Eccentricity verification

(6.5.4) from EN 1997-1

41.35 % (Passed)

SLS QP combination 651: 1x[1 G]+0.3x[2 Q]

Eccentricity verification

(6.5.4) from EN 1997-1

1.54 % (Passed)

SLS CQ combination 579: 1x[1 G]+1x[2 Q]+0.5x[12 V]

Eccentricity verification

(6.5.4) from EN 1997-1

2.88 % (Passed)

SLS FQ combination 618: 1x[1 G]+0.5x[2 Q]

Eccentricity verification

(6.5.4) from EN 1997-1

1.87 % (Passed)

8 Sliding verification

In-situ member

Friction angle between the soil and the footing: δ = 1 φ'

Bearing soil behavior: Cohesive soil (or intermediate)

8.1 Sliding verifications at ULS

Combi Condition Layer WR

(kN) (kN) (kN)

546 Drained None 135.92 1423.99 0.00 9.54 %

Advance Design RC Footing 2024 Page 8 of 19

Project: Date: 12-05-2023

Drained conditions

Combination: 546: 1.35x[1 G]+1x[19 ENV]+1.05x[2 Q]+0.75x[12 V]

Horizontal load

Vertical load (initial)

Vertical load (including the effect of earth

pressures)

Sliding resistance (initial)

EN 1997-1, (6.5.3)

The resistance will be modified by lateral active and passive earth pressure on footing:

Active earth pressure coefficient

C.1 (2) from EN 1997-1, Annex C

Passive earth pressure coefficient

C.1 (2) from EN 1997-1, Annex C

Horizontal component of the active earth

pressure on X

Vertical component of the active earth pressure

on X

Horizontal component of the passive

resistance on X

Vertical component of the passive resistance

on X

Horizontal component of the active earth

pressure on Y

Vertical component of the active earth pressure

on Y

Horizontal component of the passive

resistance on Y

Vertical component of the passive resistance

on Y

Applied load component on X with load from

earth trust

Applied load component on Y with load from

earth trust

Resultant from passive earth pressure

Resistance load from passive earth pressure

along X

Resistance load from passive earth pressure

along Y

Passive resistance projected along the axis of

resultant between Hdx and Hdy

Sliding resistance (final)

Sliding verification

Work Ratio 9.54 % (Passed)

9 Overturning verification

Advance Design RC Footing 2024 Page 9 of 19

Project: Date: 12-05-2023

X direction:

Load combination 147: 0.9x[1 G]+1.5x[15 V]

Stabilizing moment

Destabilizing moment

Overturning ratio

64.27 % (Passed)

Y direction:

Load combination 149: 0.9x[1 G]+1.5x[17 V]

Stabilizing moment

Destabilizing moment

Overturning ratio

2.41 % (Passed)

10 Settlement verification

The settlement verification is done according the simplified adjusted elasticity method defined in the

appendix F of NF EN1997-1.

Load combination 611: 1x[1 G]+1x[12 V]+0.7x[2 Q]

Allowable settlement

Characteristic vertical load

Bearing pressure

Design value of the elasticity modulus

Poisson coefficient

Shape and rigidity factor

Settlement coefficient

Total settlement

Advance Design RC Footing 2024 Page 10 of 19

Project: Date: 12-05-2023

Settlement verification

30.56 % (Passed )

11 Longitudinal reinforcement

Earth loads and overloads on the footing are taken into account for the calculation of the cross sectional

areas of steel in the footing.

11.1 Footing reinforcement calculation

The bending moments used to calculate the footing longitudinal reinforcement are calculated in a critical

section, at 0,15 · l1 inside the supported element, where “l1” is the supported element width in the current

direction.

The calculation is performed twice, at left and at right of the critical section. In this chapter, the calculation

for which the maximum bending moment resulted will be detailed (at left or at right).

• Design bending moment in critical section, MEd = M - M’= R · k – R’· k’

• R is the resultant of the contact pressures block

• k is the lever arm for R (between R and the critical section where the moment is calculated)

• R' is the resultant of the footing self-weight, earth loads and overloads

• k' is the lever arm for R’ (between R’ and the critical section where the moment is calculated)

Note: When contact pressure distribution is rectangular, soil pressure bending moment (M) is calculated as

pl²/2, where l is the cantilever length (distance between the critical section and the footing edge).

Otherwise, for contact pressure blocks which are not rectangular, the soil pressure bending moment is

calculated as R · k.

• Lc is the foundation length in cantilever

• L1 is the foundation width along the current direction (X/Y)

• L2 is the foundation width perpendicular on the current direction (X/Y)

Along X direction, Bottom side

Advance Design RC Footing 2024 Page 11 of 19

Project: Date: 12-05-2023

ULS load combination 546: 1.35x[1 G]+1x[19 ENV]+1.05x[2 Q]+0.75x[12 V]

Bi-cantilever method.

Critical calculation resulted at Left

Foundation length in cantilever

Footing self weight and earth loads and

overloads resultant force

Footing self weight and earth loads and

overloads bending moment

Soil pressure bending moment

Design bending moment

Reduced moment

Theoretical reinforcement

Minimum reinforcement

Required reinforcement

Provided reinforcement 8 × ø12 (Spacing = 218.29 mm)

Along X direction, Top side

ULS load combination 149: 0.9x[1 G]+1.5x[17 V]

Bi-cantilever method.

Critical calculation resulted at Left

Foundation length in cantilever

Footing self weight and earth loads and

overloads resultant force

Footing self weight and earth loads and

overloads bending moment

Soil pressure bending moment

Design bending moment

Reduced moment

Theoretical reinforcement

Minimum reinforcement

Required reinforcement

Provided reinforcement 8 × ø12 (Spacing = 218.29 mm)

Advance Design RC Footing 2024 Page 12 of 19

Project: Date: 12-05-2023

Along Y direction, Bottom side

ULS load combination 546: 1.35x[1 G]+1x[19 ENV]+1.05x[2 Q]+0.75x[12 V]

Bi-cantilever method.

Critical calculation resulted at Left

Foundation length in cantilever

Footing self weight and earth loads and

overloads resultant force

Footing self weight and earth loads and

overloads bending moment

Soil pressure bending moment

Design bending moment

Reduced moment

Theoretical reinforcement

Minimum reinforcement

Required reinforcement

Provided reinforcement 8 × ø12 (Spacing = 218.29 mm)

Along Y direction, Top side

Advance Design RC Footing 2024 Page 13 of 19

Project: Date: 12-05-2023

ULS load combination 149: 0.9x[1 G]+1.5x[17 V]

Bi-cantilever method.

Critical calculation resulted at Left

Foundation length in cantilever

Footing self weight and earth loads and

overloads resultant force

Footing self weight and earth loads and

overloads bending moment

Soil pressure bending moment

Design bending moment

Reduced moment

Theoretical reinforcement

Minimum reinforcement

Required reinforcement

Provided reinforcement 8 × ø12 (Spacing = 218.29 mm)

11.2 Supported element reinforcement

Earth loads and overloads on the footing are not taken into account for the calculation of the cross sectional

areas of steel in the footing.

Iteration step for calculation of the cross section area of steel is 10.00 mm²

No splitting of the normal force.

Starter bars

Main reinforcement along X 3HA14 (spacing = 46.41 mm)

Scondry reinforcement along X --------

Main reinforcement along Y 3HA14 (spacing = 246.41 mm)

Scondary reinforcement along Y --------

Rectangular Bars 3HA6 (spacing = 299.00 mm) (90°)

Pins

Along X --------

Along Y --------

Advance Design RC Footing 2024 Page 14 of 19

Project: Date: 12-05-2023

12 Stresses

Lower side, X direction

Load combination 611: 1x[1 G]+1x[12 V]+0.7x[2 Q]

Bending moment

Compressed concrete stress

2.79 % (Passed)

Tensioned reinforcement stress

13.79 % (Passed)

Crack opening

17.92 % (Passed)

Lower side, Y direction

Load combination 611: 1x[1 G]+1x[12 V]+0.7x[2 Q]

Bending moment

Compressed concrete stress

3.24 % (Passed)

Tensioned reinforcement stress

15.31 % (Passed)

Crack opening

19.88 % (Passed)

Advance Design RC Footing 2024 Page 15 of 19

Project: Date: 12-05-2023

Upper side, X direction

Load combination 598: 1x[1 G]+1x[15 V]

Bending moment

Compressed concrete stress

0.23 % (Passed)

Tensioned reinforcement stress

0.09 % (Passed)

Crack opening

0.00 % (Passed)

Upper side, Y direction

Load combination 600: 1x[1 G]+1x[17 V]

Bending moment

Compressed concrete stress

0.18 % (Passed)

Tensioned reinforcement stress

0.04 % (Passed)

Crack opening

0.00 % (Passed)

13 Crack width check

Crack width verification

Direction Position Combi WR

(mm) (‰) (mm) (mm)

Along X Bottom 651 583.68 0.09 0.05 0.30 17.92 %

Along Y Bottom 651 583.68 0.10 0.06 0.30 19.88 %

The crack opening calculation is done according to EN 1992-1-1, 7.3.4 (1).

Cracking in X direction (bottom)

Combination 651: 1x[1 G]+0.3x[2 Q]

Neutral axis position

Effective tension area, surrounding the

tension reinforcement

(7.3.4(2), Fig. 7.1)

Maximum crack spacing

(7.3.4(3), 7.11)

Secant Young modulus

Advance Design RC Footing 2024 Page 16 of 19

Project: Date: 12-05-2023

Short term equivalence coefficient

Difference between average strains

(7.3.4 (2))

Crack width

(7.3.4 (1))

Crack width verification

(17.92 %) Passed

Cracking in Y direction (bottom)

Combination 651: 1x[1 G]+0.3x[2 Q]

Neutral axis position

Effective tension area, surrounding the

tension reinforcement

(7.3.4(2), Fig. 7.1)

Maximum crack spacing

(7.3.4(3), 7.11)

Secant Young modulus

Short term equivalence coefficient

Difference between average strains

(7.3.4 (2))

Advance Design RC Footing 2024 Page 17 of 19

Project: Date: 12-05-2023

Crack width

(7.3.4 (1))

Crack width verification

(19.88 %) Passed

14 Punching shear check

Load combination ULS 546: 1.35x[1 G]+1x[19 ENV]+1.05x[2 Q]+0.75x[12 V]

Critical position

Control perimeter

Control area

Net applied stress

(6.49) from EN 1992-1-1

§6.2.2(1) from EN 1992-1-1

§6.4.4(1) from EN 1992-1-1

(6.47) from EN 1992-1-1

Punching shear capacity at control

perimeter

§6.4.4(1) from EN 1992-1-1

(6.50) from EN 1992-1-1

Advance Design RC Footing 2024 Page 18 of 19

Project: Date: 12-05-2023

Punching shear check

(15.90%) Passed

15 Bill of materials

Formwork dimensions summary

A B H

(mm) (mm) (mm)

1700.00 1700.00 400.00

Reinforcement summary

Diameter Length Weight

H6 4362.05 mm 0.97 kg

H14 9990.37 mm 12.07 kg

H12 58156.74 mm 51.63 kg

Footing 5 -

Rigid Point

Concrete Formwork Steel Bedding Muck Backfill Reinf. Ratio

Support Level

1

Quantity 1.16 m³ 2720000.00 64.67 kg 0.00 m³ 3.03 m³ 1.66 m³ 55.94 kg/m³

mm²

Price 0.00 £ 0.00 £ 0.00 £ 0.00 £ - -

Total 0.00 £

Average Diameter: 12.03 mm

Advance Design RC Footing 2024 Page 19 of 19

You might also like

- Footing - F9 - Level 2Document11 pagesFooting - F9 - Level 2Ashok ShresthaNo ratings yet

- Staad OutputDocument73 pagesStaad OutputSaifullahNo ratings yet

- BQ - Bobot RAB KendalDocument4 pagesBQ - Bobot RAB KendalBangun SaranaNo ratings yet

- Test Beam ReportDocument35 pagesTest Beam Reportkheang mengNo ratings yet

- Slender Concrete Columns Sway Frame Moment Magnification ACI318 14 W PDFDocument36 pagesSlender Concrete Columns Sway Frame Moment Magnification ACI318 14 W PDFJorge ChavezNo ratings yet

- Strcutural Analysis and DesignDocument26 pagesStrcutural Analysis and DesignSurendra MaharjanNo ratings yet

- Nh-44a Work Program Upto 31.12.2019 For Rce-IIDocument1 pageNh-44a Work Program Upto 31.12.2019 For Rce-IIMAROTHU MOHAN MANOJNo ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and Momentstham leoNo ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsGelbert SilotNo ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsAtm Tjah Radix LoegoeNo ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsAdi SetiawanNo ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsJohnclaude ChamandiNo ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and Momentssmartz inspectionNo ratings yet

- Pool Deck Design ReportDocument91 pagesPool Deck Design Reportradespino1No ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsShadin Asari ArabaniNo ratings yet

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsChris LuNo ratings yet

- Spreadsheet Of: Job No.: Design By: Date: Page NoDocument3 pagesSpreadsheet Of: Job No.: Design By: Date: Page NoAaditya ChopadeNo ratings yet

- Axis: 1 Storey: 1: Bending (Top Edge) ..Document22 pagesAxis: 1 Storey: 1: Bending (Top Edge) ..Ong George SammyNo ratings yet

- Area of Steel Calculation: (Limit State)Document16 pagesArea of Steel Calculation: (Limit State)RAVI PRAKASH SAININo ratings yet

- Beam design results for different floorsDocument86 pagesBeam design results for different floorsJiya Titus EmmanuelNo ratings yet

- Concrete Beam DesignDocument3 pagesConcrete Beam Designheherson juanNo ratings yet

- Concrete Column DesignDocument2 pagesConcrete Column DesignJohn Aries SarzaNo ratings yet

- calc-SLABS CalculationsDocument3 pagescalc-SLABS CalculationsHussen ShaikNo ratings yet

- Diseño de Un Open Pit Por Corrida: 1.2 11.7 (US$/ton)Document5 pagesDiseño de Un Open Pit Por Corrida: 1.2 11.7 (US$/ton)Anderson Brayan Gaspar RomeroNo ratings yet

- Model Data ProfileDocument18 pagesModel Data ProfileChristian Jeremiah TevesNo ratings yet

- Diseño ColDocument3 pagesDiseño ColHernan Ramiro Suyo LarutaNo ratings yet

- Evaluacion Economica Por Seccion de Un Open PitDocument24 pagesEvaluacion Economica Por Seccion de Un Open PitDarwin Joan AvendañoNo ratings yet

- Cantilever Beam ReportDocument5 pagesCantilever Beam ReportJoseph TuzonNo ratings yet

- Lab Task 02Document6 pagesLab Task 02hammad javedNo ratings yet

- C FIX 117yyyyyyyyDocument10 pagesC FIX 117yyyyyyyychumsak laoNo ratings yet

- CalculatorDocument26 pagesCalculatorJake Ariel Partosa ElmidoNo ratings yet

- Sructural Analysis and Design ReportDocument66 pagesSructural Analysis and Design ReportDessalegn GaminiNo ratings yet

- Garage Ground Floor: Project DateDocument6 pagesGarage Ground Floor: Project DateAmir Shafiq AdhamNo ratings yet

- IUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryDocument6 pagesIUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryTinh T. LeNo ratings yet

- 22floor AnalisysDocument17 pages22floor AnalisysMohamad Ridzuan IsmailNo ratings yet

- Weekly Progress ReportDocument8 pagesWeekly Progress Reportjgawo2022No ratings yet

- Crankshaft DeflectionDocument2 pagesCrankshaft DeflectionrudiNo ratings yet

- SNT512 610 22310 LO310 SNTCylindricalBorePlummerBlockMountedBearingsDocument4 pagesSNT512 610 22310 LO310 SNTCylindricalBorePlummerBlockMountedBearingsSersanassNo ratings yet

- Concrete beam design reportDocument3 pagesConcrete beam design reportheherson juanNo ratings yet

- Duct Weight 28Document16 pagesDuct Weight 28STANDARD EDUCATION ACADEMY M.E.P CENTERNo ratings yet

- ATT - 1.2.0 - Global GC Bid Template MV1 - CGK-063 - CIVIL EXT WORKS REVDocument2 pagesATT - 1.2.0 - Global GC Bid Template MV1 - CGK-063 - CIVIL EXT WORKS REVDeri AnggaraNo ratings yet

- Pipesupport ps28Document5 pagesPipesupport ps28Juragan IwalNo ratings yet

- Kumar SirDocument29 pagesKumar SirRoshan KejariwalNo ratings yet

- Design of Mat Foundation Mat Foundation Design (ACI 318-05) : Job DetailsDocument3 pagesDesign of Mat Foundation Mat Foundation Design (ACI 318-05) : Job DetailsAnonymous ZMLlQvBopNo ratings yet

- SBC 506Document10 pagesSBC 506Amr HassanNo ratings yet

- 02-Ducting SmacnaDocument4 pages02-Ducting SmacnaSonghengNo ratings yet

- Reinforcing Steel & Deformed Bar Diameter ChartDocument69 pagesReinforcing Steel & Deformed Bar Diameter ChartElda Adriani SimarmataNo ratings yet

- Spreadsheet Of: Job No.: Design By: Date: Page NoDocument3 pagesSpreadsheet Of: Job No.: Design By: Date: Page NoAaditya ChopadeNo ratings yet

- Net Allowable Bearing Capacity (KG/CM) : Afra Corporation LTDDocument1 pageNet Allowable Bearing Capacity (KG/CM) : Afra Corporation LTDA.K.M Shafiq MondolNo ratings yet

- Melaka CostingDocument33 pagesMelaka CostingSeng Koon ConstructionNo ratings yet

- 01120003-00 - Vehicle Engineering - Standard For Unspecified TolerancesDocument20 pages01120003-00 - Vehicle Engineering - Standard For Unspecified TolerancesRaj R1No ratings yet

- Structural Analysis and Design Report of Proposed Two Storey CafeDocument55 pagesStructural Analysis and Design Report of Proposed Two Storey CafedasmindpcqboNo ratings yet

- Jadual Waktu Pelaksanaan Rekonstruksi Jalan Sengkol - Kuta T.A 2017Document9 pagesJadual Waktu Pelaksanaan Rekonstruksi Jalan Sengkol - Kuta T.A 2017Ian MancisNo ratings yet

- Yccttaasasr DesingjDocument5 pagesYccttaasasr DesingjAnonymous 7f2mS44JNo ratings yet

- Post TensionDocument8 pagesPost Tensionedc1312No ratings yet

- Job InformationDocument12 pagesJob InformationHitendra KhachaneNo ratings yet

- ANCLAJE PÓRTICO 138 KVDocument6 pagesANCLAJE PÓRTICO 138 KVjavNo ratings yet

- Structural Design and Calculation: Proposed Health Center BuildingDocument58 pagesStructural Design and Calculation: Proposed Health Center BuildingDominic DatuinNo ratings yet

- Excelculvert: TTTTTTTTT TTTTTTTT TTTTT TTTTTTTTDocument34 pagesExcelculvert: TTTTTTTTT TTTTTTTT TTTTT TTTTTTTTmurthy pNo ratings yet

- Rafter ReportDocument2 pagesRafter Reportmengkheang31071999No ratings yet

- Earthquake Resistant Design of Buildings 2020: A Comparative Study of Old and Revised Provisions in Indian Seismic CodesDocument14 pagesEarthquake Resistant Design of Buildings 2020: A Comparative Study of Old and Revised Provisions in Indian Seismic CodesFazilat Mohammad ZaidiNo ratings yet

- Footfall AnalysisDocument32 pagesFootfall Analysiskheang mengNo ratings yet

- Beam-Column Connection 4B ReportDocument15 pagesBeam-Column Connection 4B Reportkheang mengNo ratings yet

- Learn LUSAS SimplyDocument2 pagesLearn LUSAS Simplykheang mengNo ratings yet

- Steel Hauch Connection A4Document15 pagesSteel Hauch Connection A4kheang mengNo ratings yet

- 2-Wind Load Calculation Monoslop RoofDocument4 pages2-Wind Load Calculation Monoslop Roofkheang mengNo ratings yet

- Test1 DrawingDocument1 pageTest1 Drawingkheang mengNo ratings yet

- FTDoc5 ndc03Document2 pagesFTDoc5 ndc03kheang mengNo ratings yet

- The Structural EngineerDocument44 pagesThe Structural Engineerkheang meng100% (2)

- Asphaltic Plug JointDocument8 pagesAsphaltic Plug Jointkheang mengNo ratings yet

- (Thesis) New Materials in Structural DesignDocument57 pages(Thesis) New Materials in Structural DesignShaileshRastogiNo ratings yet

- Physics Form 3 NotesDocument50 pagesPhysics Form 3 NotesCynthia KariukiNo ratings yet

- High Performance Polymer-Bonded Explosive Containing Polynimmo For Metal Accelerating ApplicationsDocument36 pagesHigh Performance Polymer-Bonded Explosive Containing Polynimmo For Metal Accelerating ApplicationsLG GLNo ratings yet

- 9259478Document64 pages9259478Brajesh Kumar100% (1)

- Class XII Physics - Chapt 12 AtomDocument31 pagesClass XII Physics - Chapt 12 AtomTABENDRA MNo ratings yet

- Newton'S Law: Prepared By: Mariane Gioiella Casem Cindy Claire BermudezDocument9 pagesNewton'S Law: Prepared By: Mariane Gioiella Casem Cindy Claire BermudezAngel Jimmyly EstanillaNo ratings yet

- Gas Dynamics-Rayleigh FlowDocument26 pagesGas Dynamics-Rayleigh FlowRahul100% (4)

- G11 Practical 8 (B)Document22 pagesG11 Practical 8 (B)CHAN KOON SEANNo ratings yet

- Industrial Fans Airflow PDFDocument28 pagesIndustrial Fans Airflow PDFSunil Kumar SinghNo ratings yet

- Esrafili2018Document21 pagesEsrafili2018irfanNo ratings yet

- Synthetic PAO Lubricant For Voith Retarders.: VR Fluid BLU S5Document2 pagesSynthetic PAO Lubricant For Voith Retarders.: VR Fluid BLU S5Marco AchinaNo ratings yet

- Leak Check in GCDocument4 pagesLeak Check in GCfahim2806No ratings yet

- PGS2 1997Document184 pagesPGS2 1997Pieter GrendelNo ratings yet

- API MPMS 4.8 - Operation of Proving Systems PDFDocument3 pagesAPI MPMS 4.8 - Operation of Proving Systems PDFIng. Adolfo Garcia50% (2)

- Modelling of Metal Perforated Sheet FacadesDocument30 pagesModelling of Metal Perforated Sheet FacadesMoța FlorinNo ratings yet

- Lecture 27Document36 pagesLecture 27alfredomotaNo ratings yet

- الجزء الثالث-1 PDFDocument26 pagesالجزء الثالث-1 PDFMohammed AlnemeNo ratings yet

- EST120 Basics of Civil and Mechanical Engineering, December 2019Document4 pagesEST120 Basics of Civil and Mechanical Engineering, December 2019KarthikNo ratings yet

- Amico Ci LXSG 15 40e PDFDocument1 pageAmico Ci LXSG 15 40e PDFAgam Alfian NazriNo ratings yet

- Bom 20190524Document1 pageBom 20190524Giang Nguyễn TrườngNo ratings yet

- Structural Analysis of Pipe Rack Structures - FinalDocument205 pagesStructural Analysis of Pipe Rack Structures - FinalJasna Trifković MešićNo ratings yet

- Effect of Porosity On Corrosion Attack of Austenitic Stainless SteelDocument7 pagesEffect of Porosity On Corrosion Attack of Austenitic Stainless SteelIka 1521No ratings yet

- 8 Reinforced Concrete Structure - Park Paulay PDFDocument388 pages8 Reinforced Concrete Structure - Park Paulay PDFPercy Abel Mamani LipaNo ratings yet

- List Asset Wellness H2 Plan A & B: NO KKS Nama PeralatanDocument18 pagesList Asset Wellness H2 Plan A & B: NO KKS Nama Peralatanabdul rokimNo ratings yet

- Assignment 2Document2 pagesAssignment 2Hashir AmeenNo ratings yet

- Third Periodical Grade 5Document10 pagesThird Periodical Grade 5Kaye NodgnalahNo ratings yet

- Introduction To Oil & Gas An ESO PerspectiveDocument97 pagesIntroduction To Oil & Gas An ESO Perspectiveunknown8787No ratings yet

- Unit 9 (DESIGN OF SHEAR REINFORCEMENT)Document29 pagesUnit 9 (DESIGN OF SHEAR REINFORCEMENT)Zara Nabilah76% (25)

- Chapter 7 Semiconductor Detectors: P (T) CT Exp (-E /2kT)Document18 pagesChapter 7 Semiconductor Detectors: P (T) CT Exp (-E /2kT)Phani TejaNo ratings yet

- Co-Cu MOF outperforms Pt/C for oxygen reductionDocument17 pagesCo-Cu MOF outperforms Pt/C for oxygen reductionCB Dong SuwonNo ratings yet