Professional Documents

Culture Documents

Aluminum Selection Chart

Aluminum Selection Chart

Uploaded by

Takul ThongyooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum Selection Chart

Aluminum Selection Chart

Uploaded by

Takul ThongyooCopyright:

Available Formats

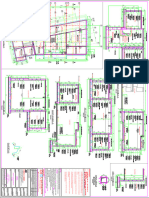

ALUMINUM FILLER

METAL SELECTION CHART METAL GROUPS

Pure

Aluminum Aluminum - Copper

Aluminum -

Manganese Aluminum - Magnesium AL-Mg2 Si AL - Zinc AL - Castings METAL GROUPS

5086, 511.0, 512.0 6061,6005 7005, 7021 413.0, 443.0 319.0, 333.0

BASE FILLER 1100, 1060,

1070, 1080, 2219 3003, 3004, 5005, 5050 513.0, 514.0 6063,6070 7039, 7046 444.0, 356.0 354.0, 355.0 FILLER BASE

2014, 2036 5083, 5454

WELD METAL PROPERTIES METAL METAL 1350 Alclad 3003 Alclad 3004 5052, 5652 5456, 5383

535.0 6151,6201 7146 A356.0, 357.0

C355.0, 380.0 METAL METAL

5154, 5254 6351,6951,6082 710.0, 711.0 359.0

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

CRACK SENSITIVITY The Probability of Hot Cracking - this rating is established through use

CRACKING

of crack sensitivity curves (Developed by Alcoa) and the consideration of filler metal and base

metal chemistry combinations. There are levels of various alloying elements within aluminum WELD METAL WELD METAL

Explanation of Relative Rating A, B, C, & D that have been identified as seriously affecting hot cracking susceptibility during weld solidifi-

cation. This rating is primarily based on the probability of producing a weld outside these crack

PROPERTIES PROPERTIES

Filler metal property ratings A, B, C and D

are relative values for welding base metals sensitive chemistry ranges.

indicated in a specific box. An “A” rating is STRENGTH DUCTILITY STRENGTH Ratings are for fillet weld and groove weld strength in the as welded condition.

the best fit for the weldment property and Groove welds – Any specified filler metal with a rating can provide minimum transverse tensile 319.0, 333.0 2319 B A A A A A A A B A A A A A A A B AA A A A A A 2319 319.0, 333.0

354.0, 355.0 4043/4943** B A A A A A C C C B C A A B C C C B C A A B C B BA A A A C B BA A A A C A A AA A A D B BA A A A C B B A A A A C B B A A A A C 4043/4943** 354.0, 355.0

“D” rating is the least fit. A “blank” rating strength in groove welds that will meet the as-welded strength of the base material. C355.0, 380.0 4145 A A B A A A D A B C B A A A D A B C B A A A D A AB A A A DA AB A A A D A AB A A A D A A B A A A D A AB A A A D A CB B A A A D 4145 C355.0, 380.0

Fillet welds – Ratings provided are for fillet weld shear strength. 413.0, 443.0 4043/4943** A A A A A A C B B A A A A B C B B A A A A B C A AA A A A DA AA A A A DA B AA A A D A BA A A A C A D B A A A C A DA A A A C C 4043/4943** 413.0, 443.0

indicates that the filler metal is not recom- 444.0, 356.0 4145 A A B B A D A A B A A A D A A B A A A D A AB B A D A C B B A D A CB B A B C D 4145

444.0, 356.0

mended for that specific weldment property A356.0, 357.0

A356.0

A357.0

A

A

AA

AA

A

A

A

A

A

A

C

C

A

B

A356.0

A357.0 A356.0, 357.0

DUCTILITY This characteristic of the completed weld may be of consideration if forming

application. All ratings listed are in the as 359.0 5356 B A B B A A A A A A B 5356 359.0

operations are to be used on a completed weldment during fabrication. 4043/4943** A DC A A D B BA A A C B BA A A C A DC A A D A DC B A DB DC B A D ADC B A D B DC BA D 4043/4943**

welded condition. For post weld heat Note: Testing procedure requirements for guided bend tests may need to be adjusted to 7005, 7021 4145 A AB A A D A AB A A D 4145 7005, 7021

treatment (PWHT) ratings, refer to the table accommodate the varying ductility of filler metals (AWS D1.2). 7039, 7046 5183

5356

B AB A A

B BA A A

B

A

B AB A

B BA A

A

A

B B A

A B B

B

A

A

A

A

A

B

A

A

A

A

B

B

A

A

A

A

A

B A AB A

A A BA A

A

A

B AA

A AB

B

A

A

A

A

A

B

A

AA

AB

B

A

A

A

A

A

B

A

AAB

AB A

A

A

A

A

B

A

A

A

A

B

B A A

A A A

C

C

B

A

5183

5356

7039, 7046

7146 7146

on the right. 710.0, 711.0

5554 C C A A A A B B C A A A A B B C A A A B B C A A A A B B CA A A A B B C A AA A C B 5554

710.0, 711.0

5556 B AB A A B B A B A A B B A B A A B A A B A A B A AB A A B AA B A A B AA B A A B AA B A A B A A B A A C B 5556

5654 C C A A B B B C A A A B BC A A A B BC A A A B BC A A A A B C A A A C B 5654

CORROSION

CORROSION RESISTANCE This variable may be a consideration for some environmental 4043** A D C A A C B BA A A C B BA A A C A D C A A C A D C A A C A D C A A D ADB A A B D 4043**

conditions. The rating is based on exposure to fresh and salt water environments and is not 4145 A C D B A DA AB A A D A AB A A D A C DB A DB C D B A D 4145 6061,6005

6061,6005 4943** A C C A A C A C C A A C A C C A A C A C C A A D AC B A A A D 4943** 6063,6070 Filler Metal Selection for Aluminum Welding

associated with a specific chemical exposure. It gives an indication as to the possibility of 6063,6070 5183 B A B A B B A B A B B A B A B B A B C B B A A B A A B B A B C A B B A B C A B BA A C A B 5183

6151,6201

Explanation of Ratings A, B, C, & D - galvanic corrosion due to the difference in the electrode potential between the base metal and 6151,6201 5356

5554

B B A A A B B A A A B B A A A B

C

B

C

A

A

C A

B A B

A

B

A

B

B

C

A

A

A

A

A

A

A

B

B

C

B

C

A

A

C

B

A

A

A

B

B

C

B

C

A

A

C A

A A A

D

B

BB

CC

A

A

C A A

B B A C B

5356

5554 6351,6951, This chart is a tool that is designed to help you select the most

Comparison Between Boxes Ratings have the filler metal. For consideration for other environmental and chemical exposures contact 6351,6951,6082 5556 B AB A B B A B A B B A B A B B A B C B B A A B A A B B A B C A B B A B C A B BA A C A B 5556 6082 appropriate filler metal, taking into consideration base metal, the

5654 C C A B A B C A A B B C C A B A B C C A B B B CC A B B B 5654

comparative meaning within a single box MAXAL. application, and the desired weld metal properties.

TEMPERATURE

5183 B A B A B B A B A A B B A B B A B A A BB A B A A B B A B A A B B A B A A B B A B 5183

only. For example, an “A” rating in one box ELEVATED TEMPERATURE SERVICE This rating is based on the reaction of some filler 5356 B B

B

A B A A B B A B A A B B A B A A A B AB A A A B A B A A A B A B A A A B A B A A 5356 5454 How to use the Chart

does not have any comparative value to an metals when exposed to sustained elevated temperature: 150°F to 350°F (66°C to 180°C). If 5454 5554 C C A A A A B C C A A A A B C C A A A A B C C AA A A B B C A A A B B C A A A B B C A A A A B 5554

5556 B A B B A B B A B B A B B A B B A B A A BB A B A A B B A B A A B B A B A A B B A B 5556 1. Determine which of the weld metal properties are most important for your

“A” rating in another box. 5xxx series base metal or filler metal with more than 3% magnesium content are subjected to 5654 B C AB B B B C A A B B B C A B B B 5654 application. (Table located on far left)

prolonged exposure to these temperatures, precipitate can form within them that is highly 511.0, 512.0 5183 B A B B A B B A B B A B B A B B A B A A BB B B A A B A A B A A B B B B 5183 511.0, 512.0 2. Locate the base metal to be welded in the blue left hand column and in the blue

513.0, 514.0 5356 B B A B A A B B A B A A B B A B A A A B A B A A A B A A A A A B A B A A 5356 513.0, 514.0

anodic to the aluminum-magnesium matrix. It is this continuous grain boundary network of 5554 C C A A A B C C A A A B C C A A A B C C A A B B B C A A A B B C A A B B 5554 row across the top of the chart.

535.0 5556 B A B B A B B A B B A B B A B B A B A A BB B B A A B A A B A A B B A B 5556 535.0 3. Locate the white box where the base metal row and column intersect.

precipitate that produces susceptibility to stress corrosion cracking (SCC) and the potential for 5154, 5254 5654 C C A A B B C C A A B B C C A A B B B C AA A B B C A A B B B C A A A B 5654 5154, 5254 4. Examine the data in the white box and select the row that provides the best match

premature component failure. 5183 A A B A A B A A B A A B A A B A A B A A BA A B A * B A A B 5183

5086, for your application based on the weld metal properties. (There may be more than

**Special Filler Metal Considerations 5086, 5356 A B A A A A A B A A A A A B A A A A A B AA A A A * A A A A 5356

5083, one filler metal that is acceptable.)

COLOR MATCH AFTER ANODIZING Base metal and filler metal color match after post-weld

COLOR

5083, 5554 C C AA A B 5554

Filler Metal 4943 anodizing can be of major concern in cosmetic applications. Some filler metals closely match 5456, 5383

5556

5654

A AB A A B AA B A A BA A BA A B A

B

A

C

BA

AB

A

A

B

B

A * BB A B 5556

5654

5456, 5383 5. Once you identify the row that gives you the properties you need, follow that row to

the left or right until you come to a gray box. The filler metal located in that row in the

4943 will provide substantially higher the base metal color after anodizing and others will react to the anodizing process by changing 4043/4943** A DC A A D A D C A A DA D C A A D A D CB A D 4043/4943** gray box is the most suitable match.

5183 B AB A B B A B A B B A B A B A A BA A B 5183 Example:

strength with comparable weldability and to a color very different to that of the base metal. 5005, 5050 5356 B BA A A B B A A A B B A A A A B AA A A 5356 5005, 5050

Welding 5454 base material that will be used as a

6. Economic Considerations:

5052, 5652 5052, 5652 If there is more than one filler metal that meets the design criteria requirements,

crack sensitivity when compared to 4043. POST WELD HEAT TREATMENT This rating applies to the ability of a weld to respond to

5554

5556 B AB A B B A B A B B A B A B

C

A

C

A

AA A A

BA A

B

B

5554

5556 support bracket for an industrial heater – This choose the most economical product. More than 85% of all aluminum filler metal

This filler metal has an addition of Mg which post-weld heat treatment in the form of solution heat treatment and artificial aging. An “A” 5654 B C AB A B 5654

weldment will be subjected to sustained elevated that is used is 5356 or 4043. These two products are easily acquired and, because of

1100 D D A A A A C C A A AA C 1100

provides it with higher as-welded strength rating indicates that the filler metal is heat treatable and will therefore respond to post weld heat 4043/4943** A C C A A D A C C A A DA D D A A D 4043/4943** temperature of 250 to 300°F (121 to 149°C). their production volume the cost of these products is generally less than others.

4145 B C D B A D B C D B A D 4145

without dependence on dilution from base treatment even without dilution of the base metal. A “B” rating indicates that the filler metal is 3004 3004,

PWHT

5183 C A B B B C A B C A B B A C C A B 5183

Alclad 3004 Alclad 3004

material. It will also provide greater strength not heat treatable. However, it may be used for applications requiring post weld heat treatment 5356

5554

C B B B A C B B C A A B B B C A

C C A B A A

A

B

5356

5554 1. As the welded component is operating at tempera-

in components that are subjected to post but with the understanding that the weld may or may not acquire substantial increase in 5556 C A B B B C B C A B B A C C A B 5556 ture above 150°F (66°C). Elevated TEMPERATURE is

strength dependent on the joint design, welding procedure, and resultant amount of dilution of 3003, 1100 B B A A A A A B A A AA A 1100 3003, the most important weld metal property.

weld heat treatment (solutionizing and/or Alclad 3003 4043/4943** A A B A A D B A AA A D BA A A A D AA B A A D 4043/4943**

Alclad 3003

base metal obtained during welding. A “C” rating requires consultation with MAXAL®. No 4145 A A C B A D A A BA A D AA B A A D AA C B A D 4145 2. Left hand column 5454 (fifth from top), and top row

precipitation hardening). rating indicates that the filler metal is not heat treatable and that it should not be used for 2319 B AAA A A A A AAA A A A A A 2319

4043/4943** B BA A A D B CBC A B D BC B C A B D 4043/4943** 2219 5454 (fifth from right). 5454

Filler Metal 4047 applications requiring post weld heat treatment as it may result in substantial reduction in weld

2219

CRACKING

STRENGTH

DUCTILITY

CORROSION

TEMPERATURE

COLOR

PWHT

TOUGHNESS

4145 A AB A A D A BCB A A D A BC B A A D 4145 3. See insert picture of intersecting row and column

4047 has a lower melting temperature, performance. 2014, 2036

2319

4043/4943** B BA A A

C AAA A A A A

D B CBC A B D

2319

4043/4943** 2014, 2036 *5XXX Series Strength Ratings (On Right).

slightly higher shear strength, higher fluidity TOUGHNESS This rating applies to the ability of an aluminum weldment to deform plastically

4145 A AB A A D A BCB A A D 4145

Base Metal Filler Metal Strength Rating 4. There is only one row that has a rating for elevated 5454

TOUGHNESS

1100, 1060, 1070, 1100 B BA A A B A 1100 1100,1060,1070,

and reduced sensitivity to termination in the presence of stress raisers without low-energy initiation and propagation of cracks. The 1080, 1350 1188 C A A A A A 1188

1080,1350 5356 C temperature.

4043/4943** A AB A A D 4043/4943** 5086

cracking when compared to 4043. It is often most useful test data is from tear resistance testing expressed in unit propagation energy of 5183 B 5. For this particular application we only have one filler

5556 A

selected for leak-tight joints and may also measured crack lengths. In structural design, notch toughness is becoming more emphasized *Hobart Brothers Company disclaims liability for any injury to persons or to property, or 5356

metal that is suitable for this application, and that is

make a good substitute for 4043 when by designers to facilitate the ability to inspect highly stressed structures and find cracks in other damages of any nature whatsoever, whether special, indirect, consequential, or 5083 5183 B filler metal 5554. All the other filler metals within the

welding other types of thin sections. weldments before catastrophic failure occurs. It may also be a design consideration if fatigue compensatory, directly or indirectly resulting from the publication, use of, or reliance on 5556 A box have a blank rating for elevated temperature which

5356 indicates that they are not suitable for this particular

and impact loading are factors directly associated with a weldment. this Guide for Aluminum Welding. Hobart Brothers Company also makes no guarantee or 5456, 5383 5183 5183 A A B B A B

©2017 Hobart Brothers Company 5556 A welding application. 5454 5356 A B A B A A

warranty as to the accuracy or completeness of any information published herein. Note: Any strength rating will meet the minimum transverse tensile

5554 B C A A A A B

5556 A A B B A B

strength requirements of AWS D1.2, a blank rating typically will not. 5654 B C A B B B

You might also like

- Aluminum Filler Metal Selection ChartDocument1 pageAluminum Filler Metal Selection ChartfogdartNo ratings yet

- Aluminum Selection ChartDocument1 pageAluminum Selection ChartFahri Risfa ZulfiNo ratings yet

- Aluminum Selecti TTQVGDocument1 pageAluminum Selecti TTQVGa.kamyabiNo ratings yet

- 1 No. Ver Bracing Required As Drawn MKD' - 1Vb-47: Bolt List For Assembly MKD' 1Vb-47 X 1 Dia. Qty. Bolt GradeDocument1 page1 No. Ver Bracing Required As Drawn MKD' - 1Vb-47: Bolt List For Assembly MKD' 1Vb-47 X 1 Dia. Qty. Bolt Grademo3azNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNo ratings yet

- Detail Section Detail Section: Key PlanDocument1 pageDetail Section Detail Section: Key PlanMJian VergaraNo ratings yet

- 304 To 305 PDFDocument1 page304 To 305 PDFAnonymous GoJpm9WbNo ratings yet

- Bureau of Design: LegendDocument1 pageBureau of Design: LegendKristine ChavezNo ratings yet

- Bureau of Design: LegendDocument1 pageBureau of Design: LegendMNo ratings yet

- Spot Detail: Detail Plan at Second Floor LevelDocument1 pageSpot Detail: Detail Plan at Second Floor LevelMJian VergaraNo ratings yet

- 01Document1 page01ARIFINNo ratings yet

- Petrol Chemical Onshore Structure ModuleDocument18 pagesPetrol Chemical Onshore Structure ModulehavutaNo ratings yet

- 10ENA01BR003 Sheet3-ModelDocument1 page10ENA01BR003 Sheet3-ModelValesh MonisNo ratings yet

- STPDocument1 pageSTPpavankmv2905No ratings yet

- NGUGI GARDEN ESTATE ChangesDocument1 pageNGUGI GARDEN ESTATE ChangesfebousNo ratings yet

- Plan Splice Detail of Rafter I-Beam Wall Footing DetailDocument1 pagePlan Splice Detail of Rafter I-Beam Wall Footing Detailzab04148114No ratings yet

- BBH Boiler Plan-ModelDocument1 pageBBH Boiler Plan-Modeljohn cartagenaNo ratings yet

- 10END30BR001Document1 page10END30BR001Valesh MonisNo ratings yet

- Ground Floor PlanDocument1 pageGround Floor PlanNORTSEN ALBERTNo ratings yet

- Final Project Sub - 150'Document1 pageFinal Project Sub - 150'eng.duaa.aljuNo ratings yet

- Gutter Detail: Eva Mae V. Parrenas Romeo Andig Raul N. Banias M.D.,Mpa Atty. Suzette A. Mamon Arthur R. Defensor JRDocument1 pageGutter Detail: Eva Mae V. Parrenas Romeo Andig Raul N. Banias M.D.,Mpa Atty. Suzette A. Mamon Arthur R. Defensor JRalezandro del rossiNo ratings yet

- Genset RM (Pit)Document1 pageGenset RM (Pit)Julius Dean DumaguingNo ratings yet

- Schedule of Finishes: Unglazed Ceramic Tiles (1800MM HIGH)Document1 pageSchedule of Finishes: Unglazed Ceramic Tiles (1800MM HIGH)markjosephguanzonNo ratings yet

- Key Plan: Typical Detail SectionDocument1 pageKey Plan: Typical Detail SectionMJian VergaraNo ratings yet

- I & D 18.10.17 - Final-Model5Document1 pageI & D 18.10.17 - Final-Model5raghu kiranNo ratings yet

- A-301 - SectionsDocument1 pageA-301 - SectionsMarven SobrevillaNo ratings yet

- Detail Section 2: Reflected Ground Ceiling Plan 1 A4 Reflected Second Ceiling Plan 2 A4Document1 pageDetail Section 2: Reflected Ground Ceiling Plan 1 A4 Reflected Second Ceiling Plan 2 A4JAN WESLEY MORIDONo ratings yet

- PPF Model PDFDocument1 pagePPF Model PDFcesaralfredoquispemoNo ratings yet

- Steel Truss 1 PDFDocument23 pagesSteel Truss 1 PDFMarielle CorpuzNo ratings yet

- Amisa Shoring (Monopost-Terp Fabricated)Document4 pagesAmisa Shoring (Monopost-Terp Fabricated)HeartOfFranceNo ratings yet

- A 15Document1 pageA 15MJian VergaraNo ratings yet

- A B A B: Sewer Line Layout Water Line LayoutDocument1 pageA B A B: Sewer Line Layout Water Line LayoutJudiel Jem G. NarvaezNo ratings yet

- Septic Tank 16.08.19-ModelDocument1 pageSeptic Tank 16.08.19-ModelAnindit MajumderNo ratings yet

- 2016 0928 BGHMC PSY COMPLEX Foundation 4 ModelS4Document1 page2016 0928 BGHMC PSY COMPLEX Foundation 4 ModelS4Justine Pearl SibugNo ratings yet

- Nhokwara 2 Revised-ModelDocument1 pageNhokwara 2 Revised-ModelEdwin ChinhoNo ratings yet

- Scale (1:4) Scale (1:8) : G.L. G.LDocument1 pageScale (1:4) Scale (1:8) : G.L. G.Lses2003_kNo ratings yet

- 18m HIN OCT 101 300 S355JRDocument1 page18m HIN OCT 101 300 S355JRbibinbibinNo ratings yet

- LayoutDocument1 pageLayoutfadhiliNo ratings yet

- Balakan Icra-Model6Document1 pageBalakan Icra-Model6Kazi Arfin HossainNo ratings yet

- Detail Pondasi: KontractorDocument1 pageDetail Pondasi: KontractorElgi Permana PutraNo ratings yet

- 6Document1 page6dipendrakuNo ratings yet

- ELEKTRIKAL DAN PLUMBING 18052021 Pin-11Document1 pageELEKTRIKAL DAN PLUMBING 18052021 Pin-11Wahid AsmaraNo ratings yet

- DWG Add Fiberflow Pma Civil Bagian 1Document17 pagesDWG Add Fiberflow Pma Civil Bagian 1Hermon PakpahanNo ratings yet

- ASHRAE System Selection Competition Lab ElevationDocument1 pageASHRAE System Selection Competition Lab ElevationLawrence CopestickNo ratings yet

- Government Standard Design On Poles PDFDocument7 pagesGovernment Standard Design On Poles PDFSuhas AnilNo ratings yet

- Front Elevation: Bureau of DesignDocument1 pageFront Elevation: Bureau of DesignMNo ratings yet

- S-1.1 Proposed Filling Station (Caltex Station) : Typical Column-Footing (C1-F1) DetailDocument1 pageS-1.1 Proposed Filling Station (Caltex Station) : Typical Column-Footing (C1-F1) DetailCarmela Andrea BuenafeNo ratings yet

- First Floor Framing Plan & Beam - Slab DetailDocument1 pageFirst Floor Framing Plan & Beam - Slab DetailMOHD IMRANNo ratings yet

- Aashto M182Document1 pageAashto M182azeem sarwar0% (1)

- Arc God-ModelDocument1 pageArc God-ModelBASAK ASSOCIATESNo ratings yet

- Right Side Elevation Isometric Viewof Fence: Proposed Perimeter Fencing and Garage Balcony RoofingDocument1 pageRight Side Elevation Isometric Viewof Fence: Proposed Perimeter Fencing and Garage Balcony RoofingRonnie Buico Conejos CENo ratings yet

- Anchor Bolt 8Ø20 450 (GRADE 8.8) Steel Column Pipe: (Ø406 10mm) Steel Column Pipe: (Ø406 10mm) Concreter ConcreterDocument1 pageAnchor Bolt 8Ø20 450 (GRADE 8.8) Steel Column Pipe: (Ø406 10mm) Steel Column Pipe: (Ø406 10mm) Concreter ConcreterLe Cong LyNo ratings yet

- Ply Required For K BlockDocument1 pagePly Required For K BlockumeshNo ratings yet

- Fourth Floor LVL Framing Plan & Beam - Slab DetailDocument1 pageFourth Floor LVL Framing Plan & Beam - Slab DetailMOHD IMRANNo ratings yet

- Air Air KTRDocument1 pageAir Air KTRBayu NirvanaNo ratings yet

- Romeo M. Bathan: Proposed Ventilation Layout ADocument1 pageRomeo M. Bathan: Proposed Ventilation Layout AMark Anthony ValbuenaNo ratings yet

- Erection Anchor: Engr. Rostum Capili Engr. Raffy Jay A. Bacting Precast Panel at Exterior - 10Th FloorDocument1 pageErection Anchor: Engr. Rostum Capili Engr. Raffy Jay A. Bacting Precast Panel at Exterior - 10Th FloorSimeon James Defeo VillacrusisNo ratings yet

- Unless The Question Is D, It Should Be Done Without A CalculatorDocument10 pagesUnless The Question Is D, It Should Be Done Without A CalculatorbrrrrzzzzNo ratings yet

- Poster - Parts of A WeldDocument1 pagePoster - Parts of A WeldbrrrrzzzzNo ratings yet

- Poster Welding P VoxXaDocument1 pagePoster Welding P VoxXabrrrrzzzzNo ratings yet

- Common Welding Troubles: Causes and CuresDocument1 pageCommon Welding Troubles: Causes and CuresbrrrrzzzzNo ratings yet

- Oven Storage & Reconditioning of Stick ElectrodesDocument1 pageOven Storage & Reconditioning of Stick ElectrodesbrrrrzzzzNo ratings yet

- Welding Discontinuities: Porosity Undercut Incomplete FusionDocument1 pageWelding Discontinuities: Porosity Undercut Incomplete Fusionbrrrrzzzz100% (1)

- Ignacio Pavon Garcia PDFDocument533 pagesIgnacio Pavon Garcia PDFhenrynarvaezNo ratings yet

- Mishra Sir PDFDocument14 pagesMishra Sir PDFSumit Kumar100% (1)

- International Journal of Hydrogen Energy 39 (2014) 16983 E17000 PDFDocument18 pagesInternational Journal of Hydrogen Energy 39 (2014) 16983 E17000 PDFSandro Gonzalez AriasNo ratings yet

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroNo ratings yet

- ChloroephedrineDocument4 pagesChloroephedrineConnyNo ratings yet

- Homework Booklet (4, S)Document55 pagesHomework Booklet (4, S)VarshLokNo ratings yet

- Chemistry Home Assignment 01Document11 pagesChemistry Home Assignment 01Nishali Sam100% (1)

- Proposal SteamHeated Web PDFDocument2 pagesProposal SteamHeated Web PDFBenjamin ChipanaNo ratings yet

- Trimet Wire Catalog 2016Document67 pagesTrimet Wire Catalog 2016Akaruii BowoNo ratings yet

- Lightweight Magnesium Aluminum in Lincoln MKT Liftgate Cuts Weight Boosts Fuel EconomyDocument3 pagesLightweight Magnesium Aluminum in Lincoln MKT Liftgate Cuts Weight Boosts Fuel Economyketo517No ratings yet

- Aalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Document2 pagesAalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57SathishbhaskarNo ratings yet

- Dispersion and Surface States of Copper Catalysts by Temperature-Programmed-Reduction of Oxidized Surfaces (S-TPR)Document7 pagesDispersion and Surface States of Copper Catalysts by Temperature-Programmed-Reduction of Oxidized Surfaces (S-TPR)Janete Almeida RassiniNo ratings yet

- Bus Bar Trunking SYstemDocument8 pagesBus Bar Trunking SYstemmmhaq1975No ratings yet

- 10th Chemistry Revision Assignments - All Chapters CombinedDocument11 pages10th Chemistry Revision Assignments - All Chapters CombinedYash KapoorNo ratings yet

- Treatment of Petroleum Wastewater by Conventional and NewDocument14 pagesTreatment of Petroleum Wastewater by Conventional and Newahmedsalemy100% (1)

- Indian Aluminium IndustryDocument34 pagesIndian Aluminium IndustryanoopmangalNo ratings yet

- Grade 9 Homework Booklet - Chemistry Week 1 Unit - Acid/ Bases and SaltsDocument15 pagesGrade 9 Homework Booklet - Chemistry Week 1 Unit - Acid/ Bases and SaltsSyed Shamoun AhmadNo ratings yet

- Nano Powder ProductionDocument6 pagesNano Powder ProductionNarasimha Murthy InampudiNo ratings yet

- RWF Paper 100232Document6 pagesRWF Paper 100232biswajit.baruah1991No ratings yet

- Afsa Corrosion Pocket GuideDocument36 pagesAfsa Corrosion Pocket GuideNuno PachecoNo ratings yet

- Recycling of End of Life Vehicles in Serbia As Resource of Secondary AluminumDocument6 pagesRecycling of End of Life Vehicles in Serbia As Resource of Secondary AluminumManojlovic VasoNo ratings yet

- 6060-T6 Aluminum: Mechanical PropertiesDocument9 pages6060-T6 Aluminum: Mechanical PropertiespenghzNo ratings yet

- Elite Extrusion BrochureDocument13 pagesElite Extrusion BrochureSultana Khanum0% (1)

- Properties of MetalsDocument25 pagesProperties of MetalsRegalado Cereza IIINo ratings yet

- Piston ManufacturingDocument41 pagesPiston ManufacturingDima AlinNo ratings yet

- Alpema Standards Rev1 2000Document8 pagesAlpema Standards Rev1 2000anonimppNo ratings yet

- 4 - Pretreatment of Aluminium For ElectrodepositionDocument4 pages4 - Pretreatment of Aluminium For ElectrodepositionJEDAIAS JANUARIO DA SILVANo ratings yet

- Project Reports ListDocument304 pagesProject Reports ListManish PatelNo ratings yet

- Mark 300 ManualDocument8 pagesMark 300 ManualcjfgksNo ratings yet

- Pinturas para Molde PermenenteDocument122 pagesPinturas para Molde Permenentejose.figueroa@foseco.comNo ratings yet