— Printed copy. For the latest revisions, check UniSea QA.

—

Stödig Ship Management

MAN/SOM/WPCHE-1850

Approved: Revision 02 / 31.05.2019

Manuals • Ship Operation Manual • Work Permits common for all vessels

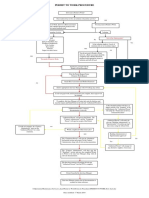

Cold work permit - all vessels (CSR)

1. PURPOSE

The purpose of this procedure is to define instructions for specific cold work operations that are critical with respect to safety.

2. SCOPE

This procedure applies to the chemical tankers.

3. RESPONSIBILITY

The Master, Chief Officer or the Chief Engineer has the authority to issue a Cold Work PTW.

For work on electrical circuits, only the CE has this authority.

The nominated "responsible person" is responsible for the safety of the operation.

The Master is responsible to verify that the PTW is completed.

4. DEFINITIONS

The following work operations require a Cold work permit:

All vessels:

Work on pressure vessels

Work on pumps, pipelines, valves, spades and blind which are under pressure

All work on electrical circuits. Work on low voltage electronics (typically from 12 to 48 V) does not require a PTW. Exchange of light bulbs is

not considered "work on electrical circuits", and does not require a PTW, with one exception for chemical tankers, ref below.

Chemical tankers:

All work on electrical circuits in EX area, including exchange of light bulbs.

Pressure testing of hoses, pipes and other pressure vessels.

Dry Cargo vessels:

Maintenance on the side door system

5. DESCRIPTION

5.1 General

When performing any of the work listed above a Cold work permit shall be obtained.

Cold work shall always be carried out by a person considered to be competent for the job. The issuing authority shall consider the competence

before nominating a responsible person.

Chemical tankers: Cold work on deck/cargo area in port shall be approved by Port Authorities/Terminals, if required.

Dry cargo: Cold work on deck / cargo area in port shall be reported to the relevant authorities, if required.

Working instructions from manufacturer must be understood before the work is started.

For work on electrical circuits, the procedure "Work on high voltage and low voltage" systems also applies, ref link below.

5.2 Lock-out / tag-out

Lock-out is the process of blocking the flow of energy (electrical, pneumatic, hydraulic etc.) to a piece of equipment and keeping it blocked out.

A lock-out device is a barrier (e.g. lock, block or chain) that keep the switch, valve or lever in the off position.

Tags shall be used to support the lock-out. The tag-out and lock-out shall be verified in the work permit.

The tags used shall clearly state: "DO NOT OPERATE".

Special precautions:

The person in charge shall identify all parts that are to be shut down and which switches, equipment and people that will be involved in the

maintenance, repairs or installation work. The restart procedure shall also be planned (when and how to carry it out).

All involved crew shall be advised about the lock-out/tag-out.

The responsible person shall remove locks and test the system before the tag is removed.

� References

Type Title Number

QADocument Work on electrical circuits (CSR) MAN/SOM/ENG-0767

QADocument Cold work permit - All vessels (CSR) BFT/WPS/WPS-1712

Exported by: Helge Hals/SSM @ 2023-01-20T11:26:31.919+01:00