Professional Documents

Culture Documents

07 5mcss Wkly Insp Form Rev2

Uploaded by

Cj YamsonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07 5mcss Wkly Insp Form Rev2

Uploaded by

Cj YamsonCopyright:

Available Formats

SAMPLE

Weekly Safety Inspection Report

Plant/Project: ___________________________________ Date: ____________________

Location: ___________________________________

Satisfactory

Item Description Yes No Remarks

1 WELFARE FACILITIES

Clean toilets with exhaust fan

Potable water provided

Eating and resting areas

Canteen facilities

2 FIRST AID STATION

Paramedics

Medical record book

Emergency medical handbook

Telephone numbers displayed

Adequate first aid supplies

Adequate first aid equipment

Clean room with potable water supply

3 HOUSEKEEPING

Segregation of waste and scrap

Waste and scrap regularly collected &

disposed of

No build up of flammable materials

4 SITE SECURITY ACCESS

Security check correctly performed

Guardhouse continuously manned

Round check register updated

Perimeter fence intact

Inspection of materials' gate passes

5 Personal Protective Equipment (PPE)

Eye protection

Head protection

Hand protection

Foot protection

Any other protection

6 EXCAVATIONS

Signs posted

Hard barrier installed

Shoring provided (if applicable)

1m spoil clearance from the excavated pit

Sloping maintained (if applicable)

Appropriate access provided

7 Mechanical and Electrical

Adequate guarding on machines

Insulation, cables, industrial plugs in good

condition

Cables suspended using S hooks and lead

stands

Inspected regularly with color code sticker

ELCB provided to site power boards

Grounding installed to equipment/machine

Unused machines electrically isolated

5MCSS 1 WEEKLY INSPECTION FORM REV2

Satisfactory

Item Description Yes No Remarks

8 SCAFFOLDS/ LADDER

Scaffolds correctly erected

Scaffolds properly secured

Toe boards, guardrails (top & midrail),

handrails & access checked

Fully boarded platforms

Scaffolds correctly tagged

Materials in good condition

9 PLANT & EQUIPMENT

Available license for drivers/operators

Vehicle and equipment condition

Reverse alarm installed

Flashing light installed

Generators and welding machine condition

Compressors and water pumps condition

10 LIFTS & CRANES

Available license or third party certificate

for operators and certificate for banksmen

and riggers

Load capacity displayed

Certification updated

Condition of access, foundation and

supports

Stability

Chains & slings in good condition

11 LIFTING OPERATIONS

Lifting locations properly identified

Loads correctly secured

Lifting gear conditions

Rigging plan

12 COMPRESSED GAS CYLINDERS

Stored upright, valves protected

Gauges working; hoses inspected

Flashback arrestor fitted

Cylinders are securely tied or with trolley

Type of gas clearly marked on cylinders

13 SAFETY SIGNAGE

Clearly displayed

Clean and legible

WORK PERMITS (Confined Space, Hot

14 Work, Excavation and Electrical Work)

Work permit correctly issued and signed

Work permit requirements enforced

15 FIRE PROTECTION

Fire Extinguisher available at hot work

locations

Welding and grinding works locations

properly secured

Fire extinguisher not obstructed

Expiration date of fire extinguisher

checked.

5MCSS 2 WEEKLY INSPECTION FORM REV2

Satisfactory

Item Description Yes No Remarks

16 HAZARDOUS SUBSTANCES

Toxic/ hazardous substance correctly

tagged/ labelled and secured

Adequate storage provided

Appropriate bundwall provided

Safety Data Sheet (SDS) present

17 OTHER RELATED SAFETY ITEMS

SUMMARY

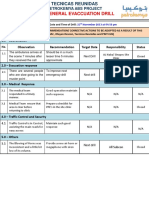

Item Concern (Problem) Action Plan Responsible Target Time Status

Inspected by: ____________________ Approved By: ________________________

5MCSS 3 WEEKLY INSPECTION FORM REV2

You might also like

- Procedure For Packing & Dispatch: Spectraa Technology Solutions LTDDocument4 pagesProcedure For Packing & Dispatch: Spectraa Technology Solutions LTDAshokkumar ThangarajNo ratings yet

- Pre Production ProcedureDocument1 pagePre Production ProcedureNguyen Quoc TriNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- FactoryDocument72 pagesFactorywhitebrosNo ratings yet

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- Resume Suda Mara IDocument5 pagesResume Suda Mara IMd AkhtarNo ratings yet

- Impacto Charpy - Iso - 9016Document12 pagesImpacto Charpy - Iso - 9016Lucas MlbNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- Ed Staff Meeting MinutesDocument3 pagesEd Staff Meeting Minutesapi-236445988No ratings yet

- Samples ITPDocument4 pagesSamples ITPHassan SajidNo ratings yet

- CWRVC-1 2nd Edition 15085Document10 pagesCWRVC-1 2nd Edition 15085Cristi OgaruNo ratings yet

- FOOD SAFETY & GMP (Refresher Course) 2018Document156 pagesFOOD SAFETY & GMP (Refresher Course) 2018QA SpicemixNo ratings yet

- Manufacturing Process AuditDocument1 pageManufacturing Process AuditEdNo ratings yet

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 pagesPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNo ratings yet

- WPS & SmawDocument12 pagesWPS & Smawnuke apriyaniNo ratings yet

- ISO 9001 - 2015 IRCA Lead Auditor TrainingDocument1 pageISO 9001 - 2015 IRCA Lead Auditor TrainingMital DamaniNo ratings yet

- FOF-InP-010 Base Inspection - Operations and Dispatch Check List Rev. 1Document3 pagesFOF-InP-010 Base Inspection - Operations and Dispatch Check List Rev. 1dnana100% (1)

- Outsourced ProcessDocument3 pagesOutsourced ProcessJohn RajeshNo ratings yet

- Shaik Yousufuddin (Welding Inspector)Document3 pagesShaik Yousufuddin (Welding Inspector)Mohamed AdelNo ratings yet

- Qhi Classroom Training List PDFDocument2 pagesQhi Classroom Training List PDFPrakash kumarTripathiNo ratings yet

- Bosch Multi Zone Ductless Air Conditioner / Heat Pump: Installation ManualDocument32 pagesBosch Multi Zone Ductless Air Conditioner / Heat Pump: Installation ManualtedyNo ratings yet

- NS Toolbox Sdftalk 006 Welding Consumable Control and TracebilityDocument1 pageNS Toolbox Sdftalk 006 Welding Consumable Control and TracebilityNeil SoansNo ratings yet

- BS 1724 (Bronze Welding by Gas)Document24 pagesBS 1724 (Bronze Welding by Gas)nandi_scrNo ratings yet

- 2012 IB Self Assessment Checklist V 1Document34 pages2012 IB Self Assessment Checklist V 1Bobby IM SibaraniNo ratings yet

- 01fitting in FabricationDocument11 pages01fitting in Fabricationv.bhamidi100% (1)

- Quality $26 HSE Management Review Example TemplateDocument2 pagesQuality $26 HSE Management Review Example TemplateBoy BangusNo ratings yet

- Attach-15 Work Procedure For Welding Consumables ControlDocument12 pagesAttach-15 Work Procedure For Welding Consumables ControlSukalyan BasuNo ratings yet

- 12 Storage of Parent MaterialsDocument3 pages12 Storage of Parent MaterialselmiraNo ratings yet

- Fabrication ProcessDocument6 pagesFabrication ProcessSounak ChakrabortyNo ratings yet

- LV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientDocument1 pageLV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientsameershahzanNo ratings yet

- Vendor Rejection and Debit PolicyDocument6 pagesVendor Rejection and Debit PolicysharanNo ratings yet

- Hazardous Material Weekly InspectionDocument1 pageHazardous Material Weekly InspectionYexiong YIALENGNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- Supplier Pre-Qualification Document - September 2020Document23 pagesSupplier Pre-Qualification Document - September 2020cephas ventures enterprisesNo ratings yet

- Technical Catalogue: NCL VEKA LimitedDocument52 pagesTechnical Catalogue: NCL VEKA LimitedSachin KothvalNo ratings yet

- Poster Welding P VoxXa PDFDocument1 pagePoster Welding P VoxXa PDFAd Man GeTigNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0010 - A Surface Prepa and Painting Proce - Code BDocument72 pagesHFY 3800 0000 VED 192 QC PD 0010 - A Surface Prepa and Painting Proce - Code BMohamed FarisNo ratings yet

- QUALITY CONTROL PROCEDURE FOR Access Control System InstallationDocument8 pagesQUALITY CONTROL PROCEDURE FOR Access Control System InstallationAbdul JabbarNo ratings yet

- Material Traceability ProcedureDocument12 pagesMaterial Traceability Procedureqamar qateebNo ratings yet

- 8.5.5 Post Delivery ActivitiesDocument2 pages8.5.5 Post Delivery ActivitiesMaricris Napigkit Serrano100% (1)

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- Humade Msds MaDocument5 pagesHumade Msds MadchyNo ratings yet

- Work Instructions - Gas CuttingDocument2 pagesWork Instructions - Gas Cuttingvivek sureshNo ratings yet

- Standard Inspection Procedure A Complete Guide - 2020 EditionFrom EverandStandard Inspection Procedure A Complete Guide - 2020 EditionNo ratings yet

- ATEX Unit VerificationDocument16 pagesATEX Unit VerificationJairo WilchesNo ratings yet

- Test Pack Contents SQ No. Title DescriptionDocument14 pagesTest Pack Contents SQ No. Title DescriptionThắng Trần QuangNo ratings yet

- Audit Evidence Improvement Score Audit QuestionDocument1 pageAudit Evidence Improvement Score Audit QuestionHaleem Ur Rashid BangashNo ratings yet

- Vision FormatDocument2 pagesVision FormatSubramanian VaithilingamNo ratings yet

- Bureau Veritas Certification Application Form (Kindly Enter Information in The Yellow-Coloured Cells)Document15 pagesBureau Veritas Certification Application Form (Kindly Enter Information in The Yellow-Coloured Cells)Gutierrez YuriNo ratings yet

- QT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFDocument3 pagesQT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFGanesh EswaranNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- ISO 9001 2015 Quality Management System RequirementDocument4 pagesISO 9001 2015 Quality Management System RequirementVincent S RyanNo ratings yet

- Flooring Spec No RDSO-2017-CG-05 For Rubberized FlooringDocument15 pagesFlooring Spec No RDSO-2017-CG-05 For Rubberized FlooringIshanNo ratings yet

- SAIC-P-3003 Rev 7 FinalDocument7 pagesSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- ATCS Business Profile 2018Document20 pagesATCS Business Profile 2018Aviects Avie JaroNo ratings yet

- ATCS BOSH Batch 0617: Darell Jake A. Vergara Mar John G. GamuedaDocument1 pageATCS BOSH Batch 0617: Darell Jake A. Vergara Mar John G. GamuedaAviects Avie JaroNo ratings yet

- 9005 Poblacion Bigte Norzagaray Bulacan - 0935 420 1233 - 0999 875 4456 - 0965 324 8264Document3 pages9005 Poblacion Bigte Norzagaray Bulacan - 0935 420 1233 - 0999 875 4456 - 0965 324 8264Aviects Avie JaroNo ratings yet

- Is Given To: Avie Training and Consultancy ServicesDocument3 pagesIs Given To: Avie Training and Consultancy ServicesAviects Avie JaroNo ratings yet

- Occupational Health Hazards: Raymond Gomez BlancoDocument113 pagesOccupational Health Hazards: Raymond Gomez BlancoAviects Avie JaroNo ratings yet

- OHSAS 18001 - Occupational Health and Safety Management SystemDocument31 pagesOHSAS 18001 - Occupational Health and Safety Management SystemAviects Avie JaroNo ratings yet

- 9005 Poblacion Bigte Norzagaray Bulacan - 0935 420 1233 - 0999 875 4456 - 0965 324 8264Document3 pages9005 Poblacion Bigte Norzagaray Bulacan - 0935 420 1233 - 0999 875 4456 - 0965 324 8264Aviects Avie JaroNo ratings yet

- Bosh Cosh Ads Aug 2018Document2 pagesBosh Cosh Ads Aug 2018Aviects Avie JaroNo ratings yet

- Marnie Alfar: HSE International Consultancy OSH PractitionerDocument16 pagesMarnie Alfar: HSE International Consultancy OSH PractitionerAviects Avie JaroNo ratings yet

- Betonbau Philippines Inc. RCBM Bulacan Plant ProjectsDocument1 pageBetonbau Philippines Inc. RCBM Bulacan Plant ProjectsAviects Avie JaroNo ratings yet

- Call Us NOW For A Formal Proposal.: Industrial Safety and Allied Services ProviderDocument4 pagesCall Us NOW For A Formal Proposal.: Industrial Safety and Allied Services ProviderAviects Avie JaroNo ratings yet

- Site Inspection: Marnie AlfarDocument50 pagesSite Inspection: Marnie AlfarAviects Avie JaroNo ratings yet

- PPE: Hand Protection: © BLR® - Business & Legal Resources (1505)Document31 pagesPPE: Hand Protection: © BLR® - Business & Legal Resources (1505)Aviects Avie JaroNo ratings yet

- Bosh Rainy Days PromoDocument1 pageBosh Rainy Days PromoAviects Avie JaroNo ratings yet

- Economic in Loss ControlDocument15 pagesEconomic in Loss ControlAviects Avie Jaro0% (1)

- Occupational Health: Marnie AlfarDocument78 pagesOccupational Health: Marnie AlfarAviects Avie JaroNo ratings yet

- Occupational Safety and Health Standards: Regulatory RequirementsDocument53 pagesOccupational Safety and Health Standards: Regulatory RequirementsAviects Avie JaroNo ratings yet

- Fall Protection: Marnie AlfarDocument42 pagesFall Protection: Marnie AlfarAviects Avie JaroNo ratings yet

- Osh Programming: Marnie AlfarDocument35 pagesOsh Programming: Marnie AlfarAviects Avie JaroNo ratings yet

- 003 MARCH 2018 TRAINING SCHEDULE BataanDocument2 pages003 MARCH 2018 TRAINING SCHEDULE BataanAviects Avie Jaro100% (1)

- Male/Female Marketing Executives 18-31 SingleDocument2 pagesMale/Female Marketing Executives 18-31 SingleAviects Avie JaroNo ratings yet

- Why Choose Avietcs?: Training FocusDocument1 pageWhy Choose Avietcs?: Training FocusAviects Avie JaroNo ratings yet

- Temporary Structure: Raymond G. Blanco DOLE OSH PractitionerDocument42 pagesTemporary Structure: Raymond G. Blanco DOLE OSH PractitionerAviects Avie JaroNo ratings yet

- 00b1. HSE - BOSH Attendance SheetDocument2 pages00b1. HSE - BOSH Attendance SheetAviects Avie JaroNo ratings yet

- Toolbox Meeting: Raymond G. BlancoDocument19 pagesToolbox Meeting: Raymond G. BlancoAviects Avie JaroNo ratings yet

- Safety and Health Training: The History and Philosophy of Loss ControlDocument2 pagesSafety and Health Training: The History and Philosophy of Loss ControlAviects Avie JaroNo ratings yet

- 003-March 2018 Training Schedule BataanDocument2 pages003-March 2018 Training Schedule BataanAviects Avie Jaro100% (1)

- 3NewCOSH ManualDocument136 pages3NewCOSH ManualAviects Avie JaroNo ratings yet

- Site General Evaccuation Drill: Petrokemya Abs ProjectDocument1 pageSite General Evaccuation Drill: Petrokemya Abs ProjectAviects Avie JaroNo ratings yet

- AsdssssDocument1 pageAsdssssAviects Avie JaroNo ratings yet

- Wellbore Departure DPA RioDocument32 pagesWellbore Departure DPA RioAdriana Rezende100% (1)

- Machine Design SpringsDocument4 pagesMachine Design Springscoc boyNo ratings yet

- Ship Bulding Process (SBP)Document168 pagesShip Bulding Process (SBP)Muhammad Tabish100% (1)

- Accident Case Studies Construction Forum PDFDocument62 pagesAccident Case Studies Construction Forum PDFmyo lwinNo ratings yet

- Museum Conceptual Analysis and DevelopmentDocument16 pagesMuseum Conceptual Analysis and DevelopmentDiane ValdrizNo ratings yet

- Fz150 V-Ixion HeadlightDocument1 pageFz150 V-Ixion HeadlightHerman Yoseph WSNo ratings yet

- SB LT32575.compressed 0Document14 pagesSB LT32575.compressed 0Sidali KilardjNo ratings yet

- Deteqstandart PDFDocument4 pagesDeteqstandart PDFMoaed KanbarNo ratings yet

- Performance Evaluation of Water Hyacinth Fiber Reinforced Self-CompactingDocument40 pagesPerformance Evaluation of Water Hyacinth Fiber Reinforced Self-CompactingcarlooooNo ratings yet

- Sample ISO Tank 40ftDocument7 pagesSample ISO Tank 40ftAbu SuraisyNo ratings yet

- SYS Bolt ManualDocument64 pagesSYS Bolt ManualNoppolNorasriNo ratings yet

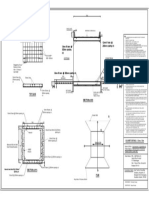

- Culvert 1.5m X 1.5mDocument1 pageCulvert 1.5m X 1.5mNISHIMON0% (1)

- Method StatementDocument13 pagesMethod Statementchandu100% (1)

- Pex InstallDocument37 pagesPex Installtincanandstring987No ratings yet

- Analysis of Rate For Liner+pileDocument6 pagesAnalysis of Rate For Liner+pileFahad Zulfiqar100% (1)

- Catch Basin and Inlet Technical BrochureDocument3 pagesCatch Basin and Inlet Technical BrochuresvsvfafcesNo ratings yet

- Module 4 FULL PDFDocument60 pagesModule 4 FULL PDFsuhan abdullahNo ratings yet

- A Comparative Study of The Use of Concrete Mix Using Jute FibersDocument7 pagesA Comparative Study of The Use of Concrete Mix Using Jute FibersIJRASETPublicationsNo ratings yet

- Bearing Capacity of Closed and Open Ended Piles Installed in Loose Sand PDFDocument22 pagesBearing Capacity of Closed and Open Ended Piles Installed in Loose Sand PDFAnonymous 8KOUFYqNo ratings yet

- Steps For Welding Railroad Tracks - Railroad Thermite WeldingDocument7 pagesSteps For Welding Railroad Tracks - Railroad Thermite WeldingMiroslaw LabudaNo ratings yet

- Procedure For Material PreservationDocument7 pagesProcedure For Material PreservationPugal100% (1)

- Product Catalogue - 03.2021 PDFDocument296 pagesProduct Catalogue - 03.2021 PDFPhú ThànhNo ratings yet

- Catalog Interior Molded Panel FlushDocument11 pagesCatalog Interior Molded Panel FlushSANTI9090No ratings yet

- Saturn Engine CoolingDocument5 pagesSaturn Engine Coolinglamping_apNo ratings yet

- Sustainability ProjectDocument20 pagesSustainability Projectkumar AbhishekNo ratings yet

- Manual of Professional PracticeDocument22 pagesManual of Professional PracticeMarc MathieuNo ratings yet

- Architects, Philosophies and WorksDocument8 pagesArchitects, Philosophies and Worksjames_lodivicoNo ratings yet

- Service - Service Manual Code 950 - 994 - 653 (1) Kubota V2203Document30 pagesService - Service Manual Code 950 - 994 - 653 (1) Kubota V2203ynadeem100% (4)

- Effective Use of Waste Marble Powder As Partial 1Document29 pagesEffective Use of Waste Marble Powder As Partial 1AkashDashNo ratings yet